Kwi-Mold Decoration IMD-IMF-INS

IIMBONAKALO

- Kwi-Mold Decoration IMD-IMF-INS

Le teknoloji yahlulwe kwi-IMR (kwi-mold roller okanye kwi-mold transfer), i-IML (ileyibhile ekwi-mold), kunye ne-lMF (kwi-mold eyenza ifilimu ye-orin-mold), eyaziwa ngokuba yi-INS.I-IMR (kwi-mold roller okanye kwi-mold transfer) kukuprinta ipateni eyilwe kwifilimu yokudlulisa ukukhutshwa. Ngexesha lenkqubo yokuvelisa, ifilimu yokudlulisa kufuneka ifudunyezwe, yenziwe, kwaye ifakwe kwisitofu sokubumba. Emva kokugqitywa, i-IMRfilm iya kususwa, ishiya i-inki kunye nokhuseleko kwindawo yemveliso.I-IML(In-Mold Label) yifilim elayitiweyo eprintwe ngemizobo okanye iilogo. Ngexesha lokubumba inaliti, ifilimu ye-lML incanyathiselwa kumphezulu wemveliso.Xa kuthelekiswa nophawu lwemveli, iimveliso ezigqityiweyo ezinefilim ye-lIML zidibanisa iilebhile kunye nezinto zokusebenza zeplastiki kanye ezinokulingana ngokugqibeleleyo.I-IMF ikwabizwa ngokuba yi-LINS efanelekileyo kakhulu kwiimveliso ze-3D ezigobileyo kune-lIMP kunye nobuchwepheshe be-IML. I-Sage igxile kwi-IMF (INS) yokwenziwa kwefilimu kwishishini le-lMD. Ukulungiswa kukwenza kwangaphambili ifilimu ye-IMF (INS) eprintiweyo kumatshini wokwenza uxinzelelo oluphezulu, kwaye emva koko usike ifilimu eyenziweyo. Icala le-inki kufuneka libekwe kumngundo ongundoqo kunye nenaliti yeplastiki. Ifilimu ye-IMF (INS) yenziwe ngefilim ecace gca phezulu (ezona zinto zixhaphakileyo yiPC, PET,PMMA, njalo njalo.), umaleko oprintiweyo wepatheni embindini, kunye nomaleko weplastiki (uninzi lusetyenziswa ABS) emazantsi. Isikhundla se-inki kwifilimu ye-IMF (INS) yahlukile kwifilimu yeteknoloji emibini yangaphambili, i-IMR, kunye ne-lML ikhuselwe kakuhle phakathi kwefilimu ye-IMF (INS) .Ngoko ke, inokuqinisekisa umbala obalaseleyo kunye nokumelana okuphezulu kokukrala. yemveliso. Ukongeza, ifilimu ye-IMF (INS) inokudityaniswa namacandelo e-elektroniki. Shicilela ipateni yokuhambisa ukukhanya ezantsi kwe-IMF (INS) bhanyabhanya nge-silkscreen, kwaye usebenzise umbala kunye nokuqina kokukhanya okubonakalayo okutyebileyo.

- Izinto eziluncedo kwinkqubo ye-IMD ziquka:Isiphumo esihle sokuhombisa: Itekhnoloji ye-IMD inokufikelela kwisiphumo somgangatho ophezulu wokuhlobisa, kunye neepateni ezicacileyo, imibala eqaqambileyo, ingqiqo ye-three-dimensional and texture.Ukuqina okuqinileyo: Ifilimu yokuhlobisa idityaniswe ngokusondeleyo kunye neemveliso zeplastiki, akulula ukuyixobula okanye ukunxiba, kwaye inokuqina okuhle kunye nokuchasana nokukrwempa.Ukubumba okudibeneyo: Inkqubo ye-IMD ifaka ifilimu yokuhlobisa kunye neplastiki kunye, ukuphepha ifilimu elandelayo okanye inkqubo yokutshiza, ukugcina ixesha kunye neendleko.Ububanzi besicelo: Inkqubo ye-IMD ifanelekile kwiimveliso zeplastiki ezahlukeneyo, ezifana neemeko zefowuni ephathwayo, iimeko zemveliso ye-elektroniki, iinxalenye zangaphakathi zemoto, njl.Itekhnoloji ye-IMD isetyenziswa ngokubanzi kwiimveliso ze-elektroniki, iimoto, iimpahla zasekhaya kunye nezinye iindawo, ukubonelela ngeemveliso ezineempembelelo ezizodwa zokuhombisa kunye nemisebenzi eyongeziweyo.

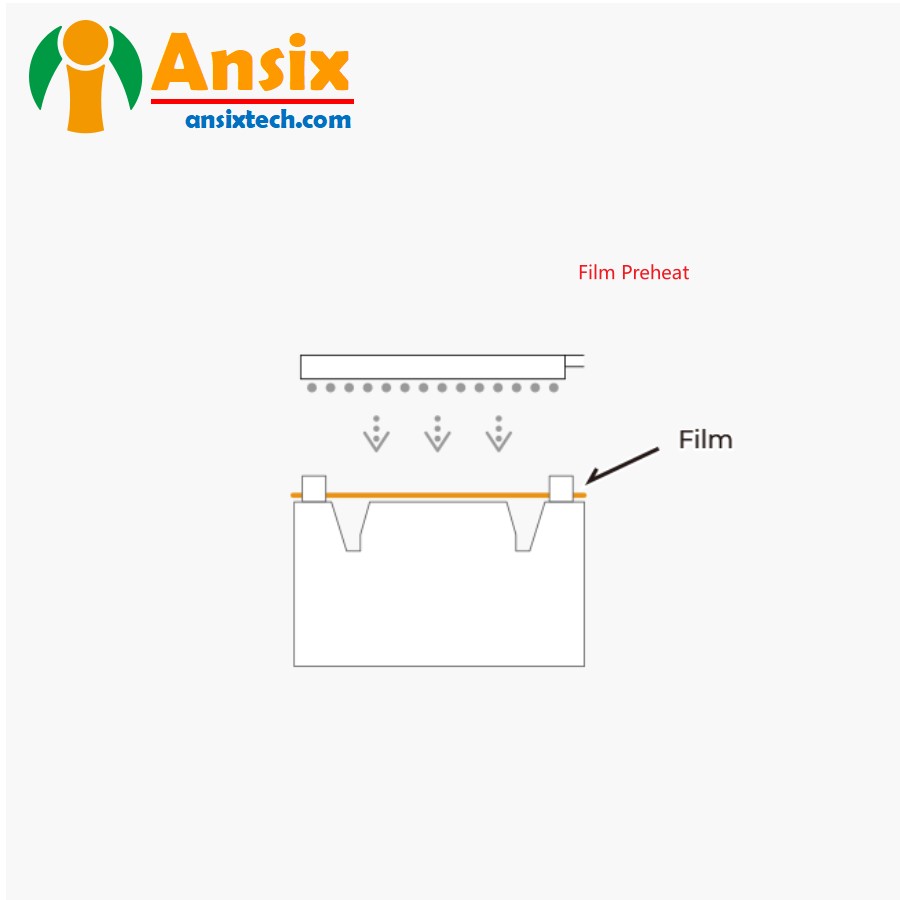

- KwiNkqubo yeTekhnoloji yoMhlobiso womngundoIfilimu Preheat

I-IMD in-mold yokuhombisa ifilimu yokufudumeza kuthetha ukuba ngaphambi kokusebenzisa ifilimu yokuhlobisa i-IMD kwi-mold kwimveliso yemveliso, ifilimu kufuneka ifudunyezwe. Injongo yokushisa kwangaphambili kukwenza ifilimu ibe yincinci kwaye ilula ukulungelelanisa ukuqinisekisa ukuhlobisa okungcono kwi-mold.Beka ifilimu yokuhlobisa i-IMD kwi-mold kwindawo eyomileyo ukuze ugweme umswakama.Sebenzisa izixhobo ezikhethekileyo zokufudumeza ukutshisa ifilimu kwiqondo lokushisa elifanelekileyo. Ukukhethwa kweqondo lokushisa kufuneka kumiselwe ngokwezinto ezithile zefilimu kunye nobukhulu, ngokubanzi phakathi kwama-50-80 degrees Celsius.Beka ifilimu eshushu ngaphambili kwi-mold, uqinisekise ukuba ifilimu idibene ngokusondeleyo kunye nobuso bobumba.Sebenzisa uxinzelelo olufanelekileyo kunye nobushushu ukutshisa-cinezela ifilimu kunye nezinto ezisisiseko semveliso ukuzilungisa kumphezulu wemveliso.Emva kokulinda ifilimu ukuba ipholile, thabatha imveliso kwi-mold ukugqiba inkqubo yokuhlobisa.Ukushisa kwangaphambili kuyinyathelo elibalulekileyo kwinkqubo yokuvelisa i-IMD kwi-mold ifilimu yokuhlobisa, enokuphucula umphumo wokuhlobisa kunye nomgangatho wemveliso. Xa ufudumeza, kufuneka ubeke ingqalelo ekulawuleni ubushushu kunye nexesha lokuphepha ukufudumala okanye ukufudumeza ixesha elide ukuze ugweme umonakalo kwifilimu.

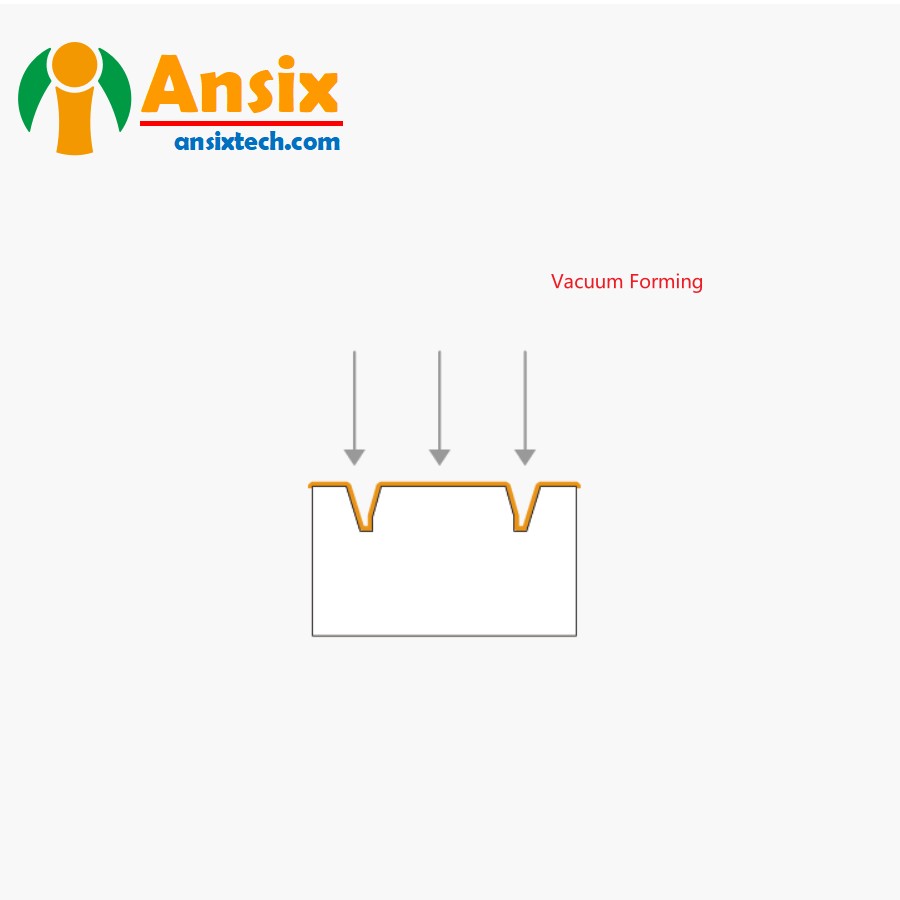

- Ukwenziwa kweVacuum

I-IMD in-mold yokubumba i-vacuum vacuum yitekhnoloji eyenza i-vacuum-adsorbs kwaye yenze ifilimu yokuhombisa ye-IMD kwi-mold kunye nesiseko semathiriyeli kunye. Idibanisa izibonelelo ze-IMD kwi-mold yokuhombisa kunye nokwenza i-vacuum, kwaye inokuqonda ukuhlobisa imveliso kunye nokubumba kwinkqubo enye yokubumba.Amanyathelo okwenziwa kwevacuum yokuhombisa ye-IMD ekumngundo ngala alandelayo:Lungiselela ifilimu yokuhombisa ye-IMD ekwimold kunye nesiseko semathiriyeli yemveliso. Ifilimu idla ngokwenziwa ngePET okanye ngePC izinto ezineepateni zokuhombisa kunye neengubo ezisebenzayo.Beka ifilimu kwi-mold, uqinisekise ukuba ifilimu idibene ngokusondeleyo kunye nomphezulu we-mold.Beka i-substrate yemveliso ngaphezu kwefilimu kwindawo ehambelana nefilimu.Beka i-mold kumatshini wokwenza i-vacuum, qalisa impompo yokucoca, kwaye ukhuphe umoya ngaphakathi kwi-mold ukwenza indawo ye-vacuum.Kwindawo yokucoca, fudumeza isikhunta ukuze uthambise ifilimu kwaye udibanise ngokuqinileyo kunye nesiseko semveliso.Emva kwexesha elithile kunye nobushushu, ifilimu kunye nesiseko sezinto zenziwe ukuba zenze umphumo wokuhlobisa.Cima impompo yokufunxa kwaye ukhuphe imveliso eyenziweyo.Itekhnoloji yokwenza itekhnoloji ye-IMD yokuhlobisa i-vacuum inokufezekisa iziphumo zokuhombisa ezichanekileyo ngelixa igcina amandla emveliso kunye nokuqina. Isetyenziswa ngokubanzi kwiifowuni eziphathwayo, iimveliso ze-elektroniki, izinto zangaphakathi zeemoto kunye nezinye iindawo, zongeza ubuhle kunye nokusebenza kweemveliso. Xa usenza i-vacuum yokubumba i-IMD kwi-mold yokuhlobisa, kufuneka kuhlawulwe ingqalelo ekulawuleni ubushushu, isidanga se-vacuum kunye nexesha lokubumba ukuze kuqinisekiswe umphumo wokubumba kunye nomgangatho wemveliso.

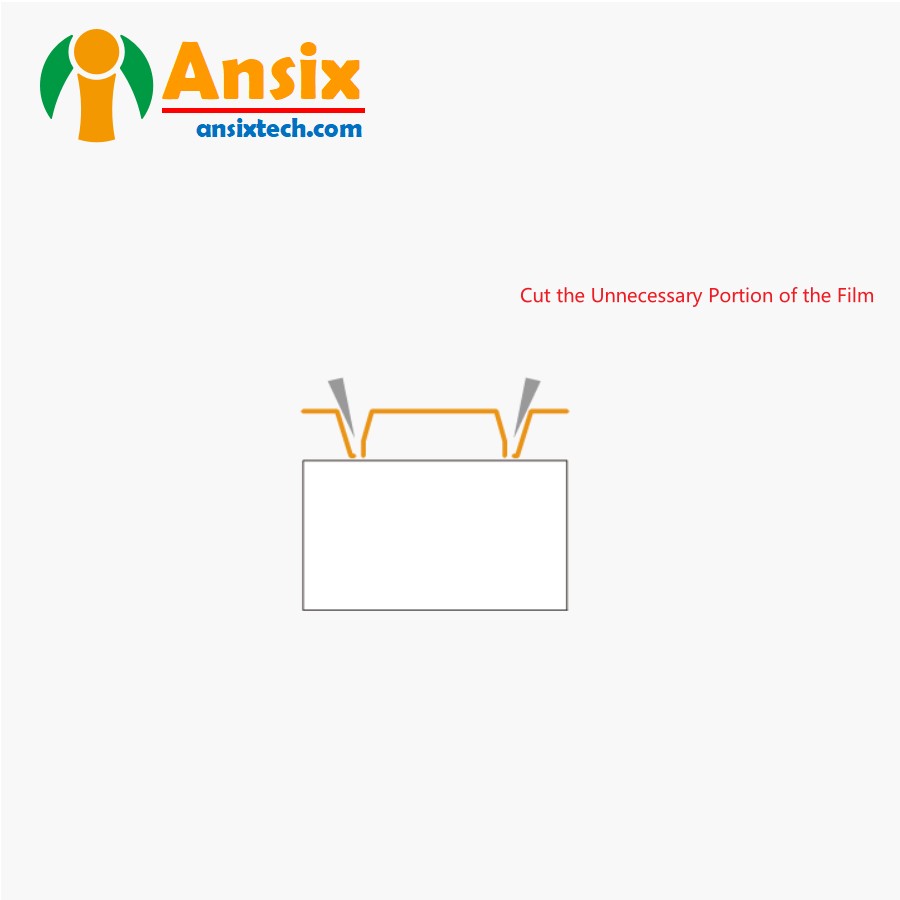

- Sika iSahlulo esingeyomfuneko seFilimu

Ngexesha lenkqubo yokuhlobisa i-IMD kwi-mold, ngamanye amaxesha kuyimfuneko ukunqumla iindawo ezingafunekiyo zefilimu ukufumana umphumo ofunekayo wokuhombisa. Nanga amanyathelo okusika iindawo ezingafunekiyo zefilimu yakho:Lungiselela ifilimu yokuhlobisa i-IMD kwi-mold kunye nezixhobo ezihambelanayo. Isixhobo sinokuba sikere, imela okanye i-laser cutter, kuxhomekeke kwizinto zefilimu kunye nokuma.Beka ifilimu yokuhlobisa i-IMD kwi-mold kwi-workbench flat, uqiniseke ukuba akukho mibimbi ecacileyo okanye umonakalo ebusweni befilimu.Phawula umgca wokusika okanye indawo yokusika kwifilimu ngokwecandelo elifuna ukunqunyulwa. Ungasebenzisa irula okanye imigca ephawulweyo kumngundo ukunceda.Ukusebenzisa isixhobo esifanelekileyo, usike ngomgca ophawulweyo okanye indawo eqingqiweyo. Ukuba usebenzisa i-scissors, qiniseka ukuba iingcebiso ze-scissors zidibene ngokusondeleyo nefilimu yomgca ochanekileyo wokusika.Nika ingqalelo ekulawuleni amandla kunye ne-engile yokucheba ukunqanda ukonakalisa ifilim okanye ukuvelisa imiphetho engalinganiyo.Emva kokugqiba ukusika, khangela ukuba imiphetho yefilimu ilula kwaye icocekile. Sebenzisa i-sandpaper okanye isixhobo se-edging ukusika ukuba kuyimfuneko.Ukunqumla iindawo ezingadingekile zefilimu yinyathelo elibalulekileyo kwinkqubo yokuhlobisa i-IMD kwi-mold, enokuqinisekisa umphumo wokuhlobisa kunye nomgangatho wemveliso yokugqibela. Xa usika, kufuneka ubeke ingqalelo kwimisebenzi ekhuselekileyo ukuze ugweme umonakalo kwifilimu kunye nawe.

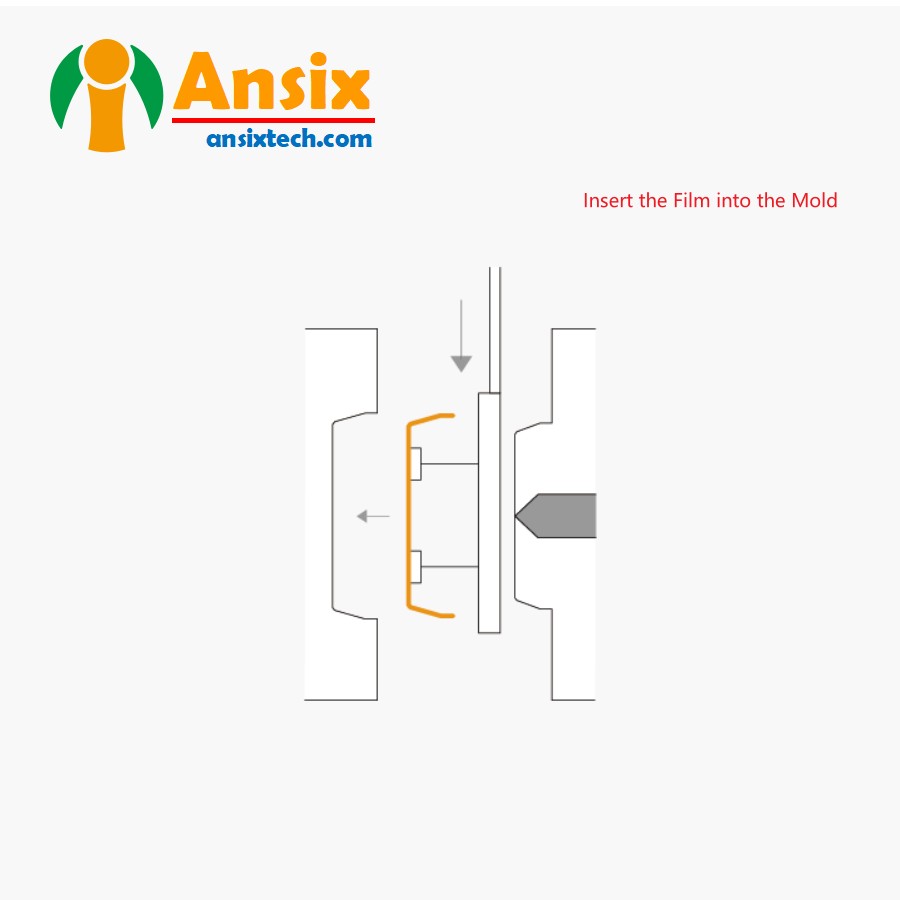

- Faka ifilimu kwiMold

Kwinkqubo yokuhlobisa i-IMD kwi-mold, ukubeka ifilimu kwi-mold yinyathelo elibalulekileyo. Nanga amanyathelo aqhelekileyo okubeka ifilim kwisibumba:Lungiselela ifilimu yokuhlobisa i-IMD kwi-mold kunye ne-mold ehambelanayo. Ifilimu ngokuqhelekileyo yenziwe nge-PET okanye i-PC impahla kunye neepatheni zokuhlobisa kunye neengubo ezisebenzayo. Isikhunta singenziwa ngesinyithi okanye iplastiki kunye nemveliso efunwayo kunye nesakhiwo.Beka ifilimu yokuhlobisa i-IMD kwi-mold kwi-bottom ye-mold, uqinisekise ukuba ifilimu ifakwe ngokuqinileyo kwindawo yokubumba. Izibonda ezikhethekileyo okanye izixhobo zingasetyenziselwa ukuncedisa ekubambeni i-membrane kwindawo.Ukuba kuyimfuneko, ukulungelelaniswa kunye nokulungelelaniswa kunokwenziwa kwifilimu ukuze kuqinisekiswe imbalelwano echanekileyo phakathi kwepateni yokuhlobisa kunye nesakhiwo semveliso.Beka isiqingatha esiphezulu se-mold ngaphezu kwefilimu, ehambelana ne-mold ezantsi.Ukusebenzisa uxinzelelo olufanelekileyo kunye nobushushu, dibanisa iindawo eziphezulu kunye nezisezantsi zokubumba ukuze ukhusele ifilimu kwi-mold.Qinisekisa ukutywinwa kunye nokuzinza kwesikhunta ukukhusela ifilimu ekutshintsheni okanye ukuguqulwa.Ngokweemfuno zenkqubo ethile, yenza imisebenzi efana nokucofa okushushu okanye i-vacuum adsorption ukudibanisa ngokuqinileyo ifilimu kunye nesiseko semveliso.Emva kwexesha elithile kunye nobushushu, ifilimu kunye nezinto ezisisiseko zihlotshiswe kwaye zenziwe.Ukubeka ifilimu ekubumbeni linyathelo eliphambili kwinkqubo yokuhlobisa i-IMD kwi-mold. Kuyimfuneko ukuba ubeke ingqalelo ekulawuleni uxinzelelo, ubushushu kunye nexesha lokuqinisekisa umphumo wokuhlobisa kunye nomgangatho wemveliso. Ngethuba lokusebenza, phatha ifilimu ngokucophelela ukuze ugweme imikrwelo okanye umonakalo.

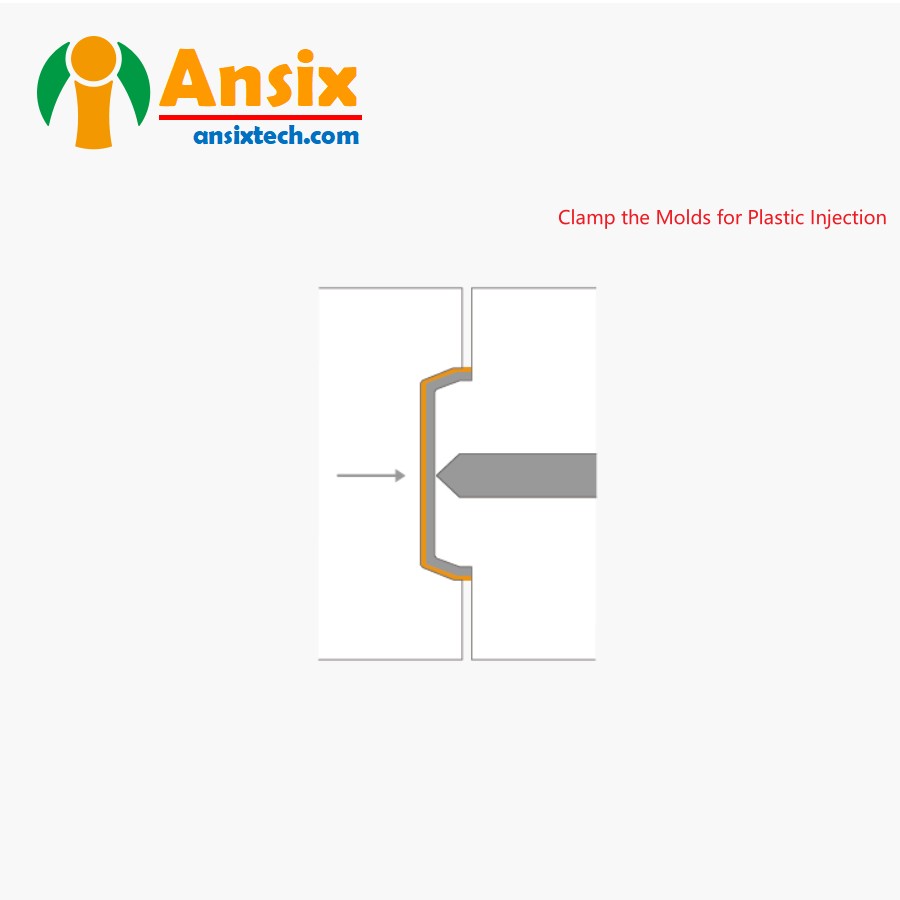

- Gxotha iiMold ukuze utofelwe ngePlastiki

I-IMD in-mold umhombiso wokubumba inaliti yokubumba yitekhnoloji edibanisa ifilimu yokuhombisa ye-IMD ekwimold kunye nesitofu sokubumba. Idibanisa amanyathelo amabini okuhombisa kunye nokubumba ibe nye, kwaye inokuqonda imveliso yokuhlobisa kunye nokubumba kwinkqubo enye yokubumba.Oku kulandelayo ngamanyathelo aqhelekileyo e-IMD ekubumbeni kokubumba inaliti yokuhombisa yokuhombisa:Lungiselela ifilimu yokuhlobisa i-IMD kwi-mold, umatshini wokubumba inaliti kunye nokubumba okuhambelanayo. Ifilimu idla ngokwenziwa ngePET okanye ngePC izinto ezineepateni zokuhombisa kunye neengubo ezisebenzayo. Isikhunta singenziwa ngesinyithi okanye iplastiki kunye nemveliso efunwayo kunye nesakhiwo.Beka ifilimu yokuhlobisa i-IMD kwi-mold kwelinye icala le-mold, uqinisekise ukuba ifilimu ifakwe ngokuqinileyo kwindawo yokubumba. Izikhonkwane ezikhethekileyo okanye izixhobo zingasetyenziselwa ukuncedisa ekubambeni ifilimu kwindawo.Beka isikhunta kumatshini wokubumba umjovo, uqinisekise indawo kunye nokuzinza kwesikhunta.Qala umatshini wokubumba inaliti kwaye ugalele imathiriyeli yeplastiki etyhidiweyo kumngundo. Umatshini wokubumba inaliti utshisa iplastiki etyhidiweyo kwaye uyifake kwi-mold, apho idibaniswe ngokuqinileyo kunye nefilimu.Ngexesha lenkqubo yokubumba inaliti, ifilimu ifakwe inaliti kunye nezinto zeplastiki ukwenza umhombiso kunye nesakhiwo semveliso.Emva kokuba isitofu sokubumba sigqityiwe, linda imathiriyeli yeplastiki ukuba iphole kwaye yomelele. Ngokuxhomekeke kwisixhobo esithile sokubumba isitofu kunye neemfuno zenkqubo, ixesha elithile lokupholisa linokufuneka.Vula i-mold kwaye ukhuphe imveliso eyenziwe ngenaliti. Ngeli xesha, umphumo wokuhlobisa we-IMD kwi-mold umhlobiso ugqityiwe kwimveliso.Itekhnoloji yokubumba itekhnoloji ye-IMD yokubumba i-IMD in-mold clamping inaliti yokubumba inokuqonda umhombiso osebenzayo nodibeneyo kunye nenkqubo yokubumba, ukuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Xa usenza i-IMD in-mold umhombiso wokubumba inaliti yokubumba, ingqalelo kufuneka ihlawulwe ekulawuleni ubushushu benaliti, uxinzelelo kunye nexesha lokuqinisekisa ukuzinza kwenkqubo yokubumba inaliti kunye nomgangatho wemveliso.

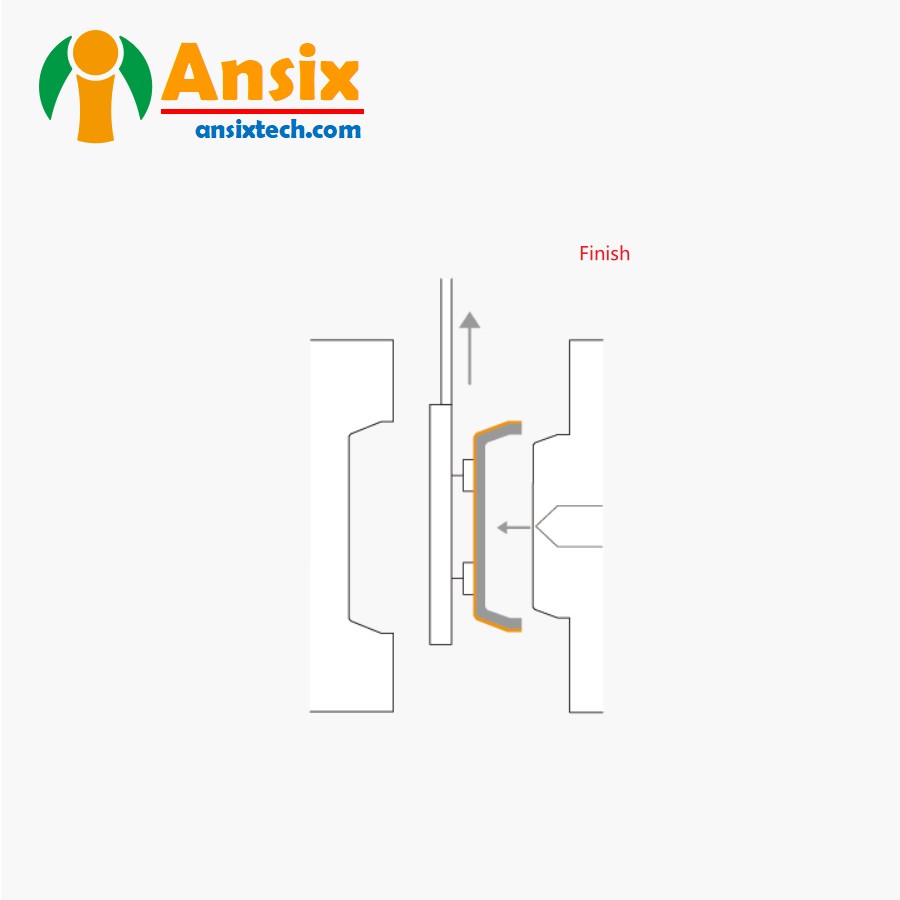

- Gqiba

Xa i-IMD in-mold umhombiso igqityiwe, la manyathelo alandelayo okusebenza kunye nokuhlola imveliso yokugqibela:Khupha ukubumba: Vula i-mold kwaye ukhuphe imveliso ehonjisiweyo kwi-mold. Qaphela ukuba uyisuse ngobumnene ukuphepha ukulimaza imveliso okanye ifilimu yokuhlobisa.Hlola umphumo wokuhlobisa: Hlola ngokucophelela umphumo wokuhlobisa imveliso ukuqinisekisa ukuba ifilimu yokuhlobisa idibaniswe ngokuqinileyo kunye nesiseko semveliso kwaye akukho bhubhu, ukuwa okanye umonakalo.Ukucoca kunye nokugqiba: Ukuba kukho imfuneko, sebenzisa ilaphu elithambileyo okanye isepha ukosula ngobunono umphezulu wemveliso ukususa uthuli okanye amabala. Kwangaxeshanye, ungasebenzisa izixhobo zokucheba okanye i-sandpaper ukucheba imiphetho yemveliso ukuze iphucuke kwaye icoceke.Uvavanyo olusebenzayo: Yenza uvavanyo olusebenzayo lwemveliso ukuqinisekisa ukuba inkqubo yokuhlobisa ayichaphazeli ukusetyenziswa okuqhelekileyo kwemveliso. Umzekelo, kwimeko yefowuni ephathwayo, unokuvavanya uvakalelo kunye nokuziva kwe-tactile yezitshixo.Ukupakishwa kunye nokuhlolwa komgangatho: Ukupakishwa kunye nokuhlolwa komgangatho kwenziwa ngokweemfuno zemveliso. Qinisekisa ukuba ukupakishwa kwemveliso kugqibelele kwaye uhlole umgangatho ukuqinisekisa ukuba imveliso iyahlangabezana nemigangatho kunye neemfuno ezifanelekileyo.

- Kukho izizathu ezininzi zokukhetha i-AnsixTech ye-IMD, iinkqubo ze-INS

Ukuba unayo nayiphi na imibuzo malunga neemveliso kwi-plastiki yokubumba kunye nentsimi yokubumba, nceda usithumelele umyalezo (i-imeyile: info@ansixtech.com) nangaliphi na ixesha kwaye iqela lethu liya kukuphendula kwiiyure ze-12.Ukukhetha i-AnsixTech ye-IMD (i-In-Mold Decoration) kunye ne-INS (i-In-Mold Electronics) iinkqubo lukhetho oluhle. I-AnsixTech yinkampani egxile kwitekhnoloji ye-IMD kunye ne-INS enamava atyebileyo kunye nobuchule.Inkqubo ye-IMD yitekhnoloji ehloma ngokuthe ngqo iipateni zokuhombisa okanye imifanekiso kumphezulu weendawo ezibunjiweyo zesitofu. Ngokudibanisa ifilimu yokuhlobisa kunye nezinto zeplastiki ngexesha lenkqubo yokubumba i-injection, umphumo ophezulu wokuhlobisa ufezekiswa. Le nkqubo inika ukugqiba ixesha elide elithintela i-decorative layer ukuba ingagubuki okanye igubungele, kwaye ivumela iintlobo ezahlukeneyo zemibala kunye neepatheni.Inkqubo ye-INS iphuhliswa ngakumbi ngesiseko se-IMD. Ifakela amacandelo e-elektroniki (njengama-touch sensors, izibane ze-LED, njl.) ngokuthe ngqo kwiindawo ezibunjiweyo ze-injection, ukuphumeza ukuhlanganiswa komhlobiso kunye nomsebenzi. I-teknoloji ye-INS inokufezekisa imisebenzi enzima ngakumbi kunye nokusebenzisana, ukubonelela ngenqanaba eliphezulu lamava omsebenzisi.Xa ukhetha i-AnsixTech ye-IMD kunye neenkqubo ze-INS, ungonwabela ezi zibonelelo zilandelayo:Ubuchwephesha bobuchwephesha: I-AnsixTech inamava atyebileyo kwi-IMD kunye ne-INS iteknoloji kwaye inokubonelela ngezisombululo zobungcali kunye nenkxaso yobugcisa.Iziphumo zokuhlobisa ezikumgangatho ophezulu: Ngenkqubo ye-IMD, iziphumo zokuhlobisa ezikumgangatho ophezulu zinokufezekiswa, kubandakanywa iintlobo ezahlukeneyo zemibala kunye nokukhetha kwepateni.Umsebenzi odityanisiweyo: Ngenkqubo ye-INS, amacandelo e-elektroniki anokuthi afakwe ngokuthe ngqo kwiindawo ezibunjiweyo zenaliti ukuze kufezekiswe ukuhlanganiswa kokuhlobisa kunye nomsebenzi.Ukuphuculwa kwamava omsebenzisi: Itekhnoloji ye-INS inokufezekisa imisebenzi enzima ngakumbi kunye nokusebenzisana, ukubonelela ngenqanaba eliphezulu lamava omsebenzisi.Izisombululo ezenziwe ngokwezifiso: I-AnsixTech inokubonelela ngezisombululo ezilungiselelwe ngokweemfuno zabathengi ukuhlangabezana neemfuno zeemveliso ezahlukeneyo.Ukukhetha i-AnsixTech ye-IMD kunye neenkqubo ze-INS zinokubonelela ngenkxaso yobuchwephesha obuchwephesha kunye neziphumo zokuhlobisa ezikumgangatho ophezulu, kwaye kwangaxeshanye ufezekise ukudityaniswa komhlobiso kunye nemisebenzi yokuphucula amava omsebenzisi.