AnsixTech has four production bases in China and Vietnam. We have a total of 260 injection molding machines. The tonnage of injection molding machines ranges from the smallest 30 tons to 2800 tons. The main injection molding machines include Japan's Fanuc, Sumitomo, Toshiba, Nissei, Engel, and Germany's Arburg (mainly liquid silicone injection molding, mainly two component). China has Haitian and Victor Taichung Machinery, etc.

AnsixTech is mainly engaged in the fields of medical equipment, automotive interior molds, automotive interior decoration (INS/TOM/DOD), household appliances, daily necessities, kitchenware series, 3C, consumer electronics, industrial control appliances, maternal and infant products, etc.

Advanced equipment: AnsixTech factory has advanced injection molding equipment, mold manufacturing equipment and processing equipment. our use the latest technology and equipment to ensure efficiency and quality of the production process.

Production capacity: AnsixTech factory has strong production capacity and can meet customers’ mass production needs. our have efficient production lines and processes that enable them to quickly respond to customer orders and deliver on time.

Quality Control: AnsixTech factory attaches great importance to quality control.our have a strict quality management system, including quality control and inspection from raw material procurement to production process. our use advanced testing equipment and methods to ensure that the quality of their products meets customer requirements and standards.

Technical team: AnsixTech factory has a professional technical team, including engineers, technicians and quality control personnel. our have rich experience and professional knowledge and can provide technical support and solutions to ensure the smooth progress of the production process and the quality of the products.

Environmental management: AnsixTech factory focuses on environmental protection and sustainable development. our comply with environmental regulations and standards and take steps to reduce their impact on the environment, such as waste disposal and energy management.

Supply chain management: AnsixTech factory has good supply chain management capabilities. our have established long-term cooperative relationships with reliable suppliers to ensure the quality of raw materials and the stability of supply. our also work with logistics companies to ensure timely delivery of products and efficient logistics.

Innovation capability: AnsixTech factory focuses on innovation and technological progress. our continuously research and develop new materials, processes and technologies to provide better products and solutions. our actively participate in industry seminars and exhibitions, communicate and share experiences with experts in the same industry, and continuously improve their innovation capabilities and competitiveness.

AnsixTech factory relies on its advanced equipment, strong production capacity, strict quality control, professional technical team, environmental management, supply chain management and innovation capabilities to provide customers with high-quality, efficient and reliable products and services. Serve. They are committed to working with customers to jointly promote the development and progress of the industry.

Professional experience: AnsixTech has many years of experience in precision plastic injection services and is very familiar with the needs and standards of the control industry. our are able to provide high-quality injection services and ensure product safety and reliability.

Advanced equipment: AnsixTech has advanced injection equipment and technology, which can meet various complex injection needs. our constantly update their equipment and technology to ensure they can provide the latest solutions.

Quality control: We have the international medical certification ISO9001/ISO13485/IATF16949 system, and have obtained an ISO 8 Cleanroom and GMP, which complies with the US medical grade FDA510K standard, and strictly implements it in accordance with the standards.AnsixTech focuses on quality control, and they adopt a strict quality management system to ensure that each product meets relevant standards and requirements. our conduct rigorous inspection and testing to ensure product quality and performance.

Midwest-Based with a Global Presence

Our flagship facility is located in Shenzhen and Dongguan China,and Vietnam, but we’ve expanded multiple times to meet the growing needs of our customers and expectations within manufacturing. Our 4 facilities are strategically located to ensure parts are efficiently manufactured and shipped. Each facility offers expertise in plastic injection molding, tooling, production, quality and logistics, and is fully supported and connected with our centralized design and engineering team.

-

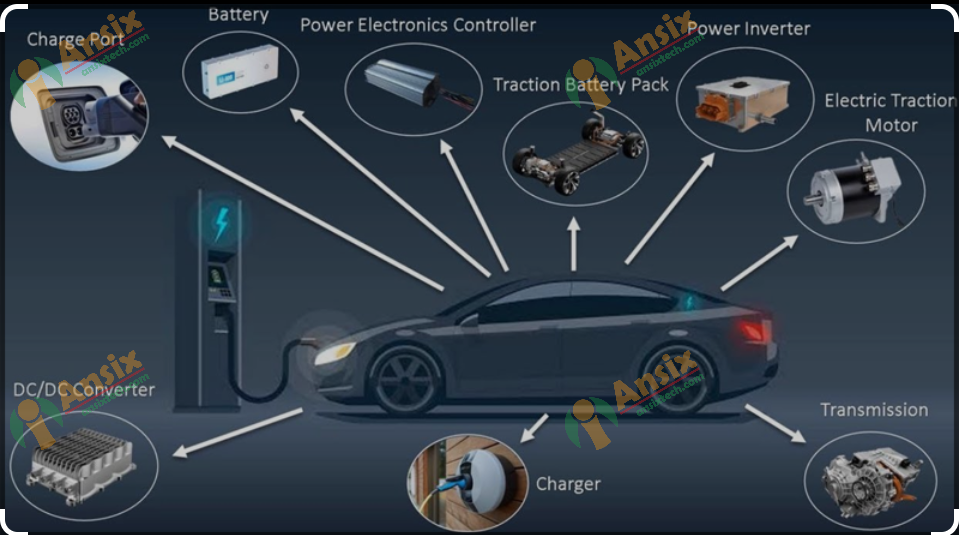

Automotive industry:The automotive industry is one of the important areas of mold injection molding services. With the development of the automobile industry and the rise of electric vehicles, the demand for mold injection parts continues to increase. AnsixTech tooling provide mold design and injection molding production services for automotive parts to meet the needs of automobile manufacturers.

-

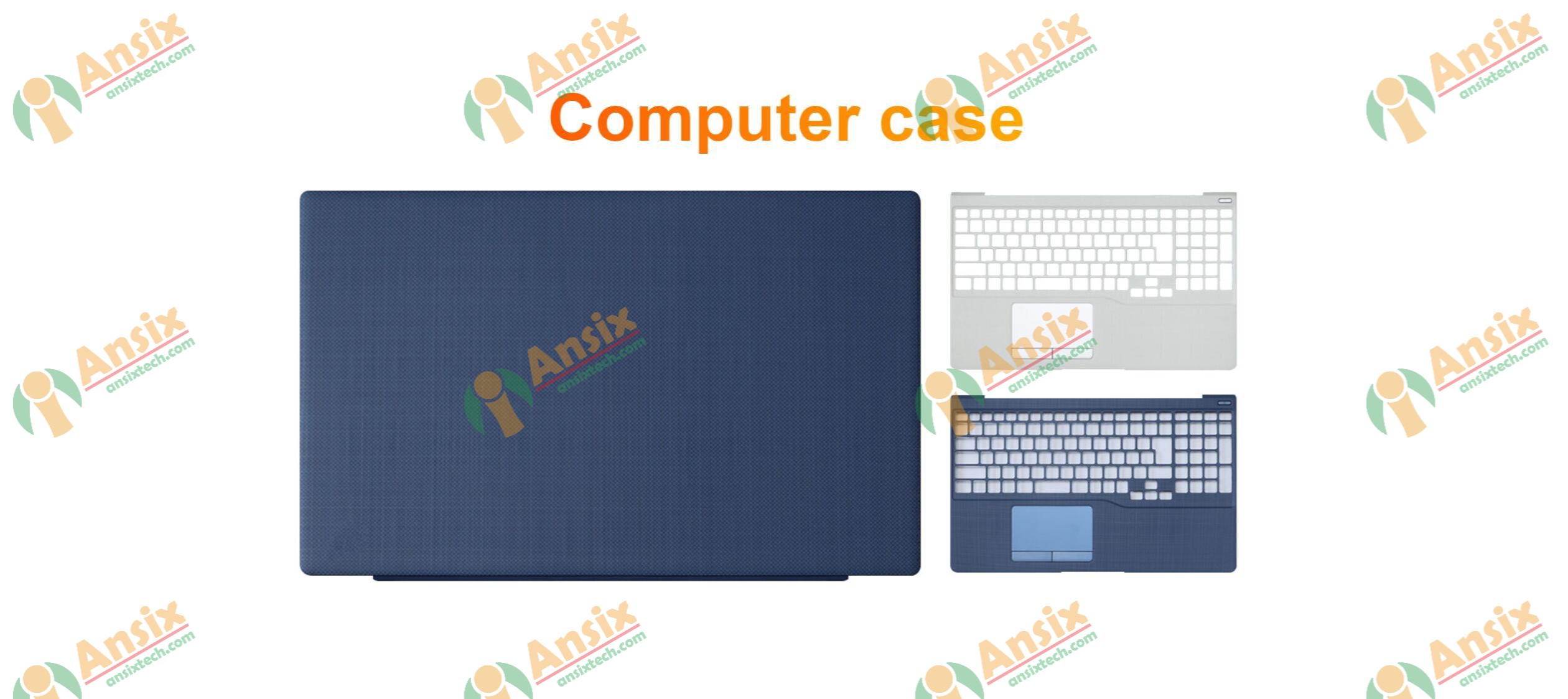

Electronics industry:The electronics industry also has a huge demand for mold injection parts. With the continuous updating and intelligent development of electronic products, the demand for high-precision and high-reliability injection molded parts is also increasing. AnsixTech tooling provide design and production services for injection molded parts such as electronic product casings and connectors.

-

Medical industry: The demand for mold injection molding services in the medical industry is mainly concentrated in medical devices and medical equipment. AnsixTech tooling provide design and production services for injection molded parts such as medical device casings, syringes, and infusion sets to meet the needs of the medical industry.

-

Home appliance industry: The demand for mold injection services in the home appliance industry is mainly concentrated in home appliance shells and accessories. AnsixTech tooling provide design and production services for injection molded parts such as home appliance casings, switches, and sockets to meet the needs of home appliance manufacturers.

- Industrial equipment industry:The demand for mold injection services in the industrial equipment industry is mainly concentrated in industrial equipment casings and accessories. AnsixTech tooling provide design and production services for industrial equipment casings, control panels, connectors and other injection molded parts to meet the needs of industrial equipment manufacturers

-

SemiconductorSemiconductor users push the limits of trace metals determination more than any other industry. AnsixTech’s know-how in fluoropolymer molding, in-house tooling, design and manufacturing enables it to produce the cleanest available PFA products – helping semiconductor labs to meet ever lower measurement targets. For the past 15 years, AnsixTech has focused on designing the highest performing PFA sample introduction products for ICP-MS. AnsixTech inert ICP-MS sample introduction systems are used in more semiconductor labs worldwide than any other manufacturer.

- Aerospace & DefenseOur in-house engineering expertise and automated technologies allow us to deliver mission-critical solutions fast and error-free with a certified commitment to quality, AnsixTech can provide high-quality mold injection molding services to meet the needs of the aerospace industry through cooperation with spacecraft manufacturers, aerospace research institutions and related enterprises. At the same time, AnsixTech can also pay attention to the development trends of aerospace technology and continuously improve its technical capabilities and innovation capabilities to adapt to industry changes and needs.

- In the global large-scale business field, AnsixTech can provide high-quality mold design and injection molding production services to meet the needs of different industries by establishing cooperative relationships with global customers, participating in international exhibitions and industry events. At the same time, AnsixTech also needs to pay attention to global market trends and competition, and continuously improve its technical capabilities and innovation capabilities to maintain its competitive advantage.

-

In the new energy industry, AnsixTech tooling provide solutions related to mold injection services to meet the needs of the new energy industrySolar energy: Solar energy is a renewable energy source. AnsixTech tooling provide mold design and injection molding production services for solar modules. This includes injection molded parts such as solar panel housings, connectors and brackets.Wind energy: Wind energy is another renewable energy source, and AnsixTech tooling provide mold design and injection molding production services for wind energy equipment. This includes injection-molded parts such as casings, blades and towers for wind turbines.Electric vehicles: Electric vehicles are an important field of new energy transportation. AnsixTech tooling provide mold design and injection molding production services for electric vehicles. This includes injection molded parts such as electric vehicle casings, battery boxes, and charging interfaces.Energy storage equipment: Energy storage equipment plays an important role in the new energy field. AnsixTech tooling provide mold design and injection molding production services for energy storage equipment. This includes injection molded components such as energy storage device housings, connectors and battery holders.Smart grid: Smart grid is a key component of new energy systems. AnsixTech tooling provide mold design and injection molding production services for smart grid equipment. This includes injection molded components such as smart meter housings, communication modules and distribution boxes.In the new energy industry, AnsixTech tooling provide high-quality mold injection molding services to meet the needs of the new energy industry through cooperation with new energy equipment manufacturers, energy companies and related enterprises. At the same time, AnsixTech can also pay attention to the development trends of new energy technologies and continuously improve its technical capabilities and innovation capabilities to adapt to industry changes and needs.

-

In the new energy industry, AnsixTech tooling provide solutions related to mold injection services to meet the needs of the new energy industryOur customers enjoy the advantages of extensive experience and a range of services encompassing design, engineering, supply chain management, process development, and production solutions.We diligently apply our wealth of experience and finely-tuned processes to every product line, guaranteeing that you can trust us wholeheartedly.Our operational approach in tooling and injection manufacturing stands out, with dedicated teams tailored to each partner customer This approach ensures a deep understanding of our customers business drivers and critical success factors, fosters close collaboration, and prioritizes projects effectively. AnsixTech tooling and injection solutions is seamlessly incorporating cutting-edge technologies into medical,automotive interior molds, automotive interior decoration (INS/TOM/DOD), household appliances, daily necessities, kitchenware series, 3C, consumer electronics, industrial control appliances, maternal and infant products and consumer health devices to empower our customers in navigating the ever-evolving healthcare landscape successfully.Global Scale UpAnsixTech Medical Solutions… a Global Technology led Contract Manufacturing business with ISO 13485, FDA 21CFR820 and MDR accredited facilities offering:ISO 14644 accredited Clean Room ProductionAccelerated time to market mobilising our digital technovation centers with Carbon® M3 printers utilizing Digital Light Synthesis printing technologyPost processing of complex products and components ensuring regulatory complianceAccess to leverage the entire AnsixTech manufacturing footprint throughout North America, Europe, and AsiaMedical Solutions CertificationsTo ensure that we meet and exceed the industry standards for safety and performance, we have obtained several key certifications, including:Our commitment to these certifications ensures that we deliver precision, quality, and performance in every medical manufacturing project we undertake.ITAF16949ITAF 16949 is a quality management system standard for the automotive industry, designed to ensure that products and services meet quality requirements, providing a guarantee of continuous improvement and customer satisfaction.ISO 13485Our medical manufacturing facilities meet the rigorous requirements of ISO 13485, an international standard for quality management systems in the medical device industry.ISO 14644-1We maintain certified cleanroom facilities in accordance with ISO 14644-1, which establishes standards for air cleanliness in cleanrooms and controlled environments.Class 8 CleanroomOur production environment ranges from 'white room' to certified cleanroom class 8, ensuring that we can meet the specific requirements of your products.New Product Introduction (NPI) ProcedureOur NPI procedure covers both new product development and existing product transfers, with defined gates, start conditions, scope, and goals overseen by a steering group.AnsixTech Standard Validation RoutineAll of our tools, equipment, and production processes are validated through AnsixTech's standard validation routine with IQ, OQ, PQ, or according to specific customer requirements.

Tooling and Injection Solutions Project ManagementA robust quality management system ensures we meet all regulatory and compliance requirementsOur commitment to quality and service enables us to maintain exceptional levels of efficiency and effectiveness across all phases of our work, spanning from design and development to manufacturing and post-launch support.This commitment is upheld through:Standardized global quality system processes, tools, and a unified software platform.Stringent processes and commitment to quality cultureIntegration of top-tier quality controls into product designs right from the outset.Regulatory compliance across all our facilities to adhere to relevant legal, industry, and country-specific standards.AnsixTech is a company with large-scale business distribution around the world. We are committed to providing customers with high-quality products and solutions and providing comprehensive after-sales technical services. Our global business covers multiple countries and regions, including Asia, Europe, North America and South America.In terms of global large-scale business, AnsixTech has established extensive cooperative relationships with partners and customers all over the world. We work with leading companies in various industries to provide them with innovative products and solutions. Our products cover many fields, including aerospace, automotive, electronics, medical, etc., meeting the needs of different industries.We have multiple offices and branches around the world to better serve our customers. These offices and branches are equipped with professional sales teams and technical support teams that can respond to customer needs in a timely manner. We have established close cooperative relationships with our customers, and through regular communication and communication, we understand their needs and challenges and provide them with customized solutions.In terms of after-sales technical services, AnsixTech attaches great importance to customer satisfaction and experience. We have a dedicated after-sales technical service team, composed of experienced engineers, who are responsible for handling customers’ technical problems and needs. We provide services such as remote technical support, on-site maintenance, spare parts supply and training to ensure that customers get the best experience and value when using our products and solutions.Our after-sales technical service teams are located all over the world and can respond to customer needs in a timely manner. No matter where our customers are, we will provide fast, professional and reliable technical support. We keep in touch with our customers through multiple methods such as phone, email, and online chat to ensure that they can receive timely help and support when they encounter technical problems.We also conduct regular customer satisfaction surveys to understand customer evaluations and feedback on our products and services. We value our customers’ opinions and suggestions and constantly improve and optimize our after-sales technical services to provide better support and maintenance.AnsixTech is committed to building long-term relationships and growing and developing with its customers. We not only provide high-quality products and solutions, but also strive to be a trusted technology partner for our customers. We will continue to expand the scale of our global business and continuously improve the quality and efficiency of our after-sales technical services to meet the needs of our customers around the world.Through large-scale global operations and comprehensive after-sales technical services, AnsixTech will continue to provide customers with excellent products and solutions to help them succeed in the highly competitive market. We will continue to innovate and improve to meet the changing needs of our customers and provide them with continuous technical support and value.If you have any questions about products in the plastic molding and mold field, please send us a message (Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

Tooling and Injection Solutions Project ManagementA robust quality management system ensures we meet all regulatory and compliance requirementsOur commitment to quality and service enables us to maintain exceptional levels of efficiency and effectiveness across all phases of our work, spanning from design and development to manufacturing and post-launch support.This commitment is upheld through:Standardized global quality system processes, tools, and a unified software platform.Stringent processes and commitment to quality cultureIntegration of top-tier quality controls into product designs right from the outset.Regulatory compliance across all our facilities to adhere to relevant legal, industry, and country-specific standards.AnsixTech is a company with large-scale business distribution around the world. We are committed to providing customers with high-quality products and solutions and providing comprehensive after-sales technical services. Our global business covers multiple countries and regions, including Asia, Europe, North America and South America.In terms of global large-scale business, AnsixTech has established extensive cooperative relationships with partners and customers all over the world. We work with leading companies in various industries to provide them with innovative products and solutions. Our products cover many fields, including aerospace, automotive, electronics, medical, etc., meeting the needs of different industries.We have multiple offices and branches around the world to better serve our customers. These offices and branches are equipped with professional sales teams and technical support teams that can respond to customer needs in a timely manner. We have established close cooperative relationships with our customers, and through regular communication and communication, we understand their needs and challenges and provide them with customized solutions.In terms of after-sales technical services, AnsixTech attaches great importance to customer satisfaction and experience. We have a dedicated after-sales technical service team, composed of experienced engineers, who are responsible for handling customers’ technical problems and needs. We provide services such as remote technical support, on-site maintenance, spare parts supply and training to ensure that customers get the best experience and value when using our products and solutions.Our after-sales technical service teams are located all over the world and can respond to customer needs in a timely manner. No matter where our customers are, we will provide fast, professional and reliable technical support. We keep in touch with our customers through multiple methods such as phone, email, and online chat to ensure that they can receive timely help and support when they encounter technical problems.We also conduct regular customer satisfaction surveys to understand customer evaluations and feedback on our products and services. We value our customers’ opinions and suggestions and constantly improve and optimize our after-sales technical services to provide better support and maintenance.AnsixTech is committed to building long-term relationships and growing and developing with its customers. We not only provide high-quality products and solutions, but also strive to be a trusted technology partner for our customers. We will continue to expand the scale of our global business and continuously improve the quality and efficiency of our after-sales technical services to meet the needs of our customers around the world.Through large-scale global operations and comprehensive after-sales technical services, AnsixTech will continue to provide customers with excellent products and solutions to help them succeed in the highly competitive market. We will continue to innovate and improve to meet the changing needs of our customers and provide them with continuous technical support and value.If you have any questions about products in the plastic molding and mold field, please send us a message (Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.