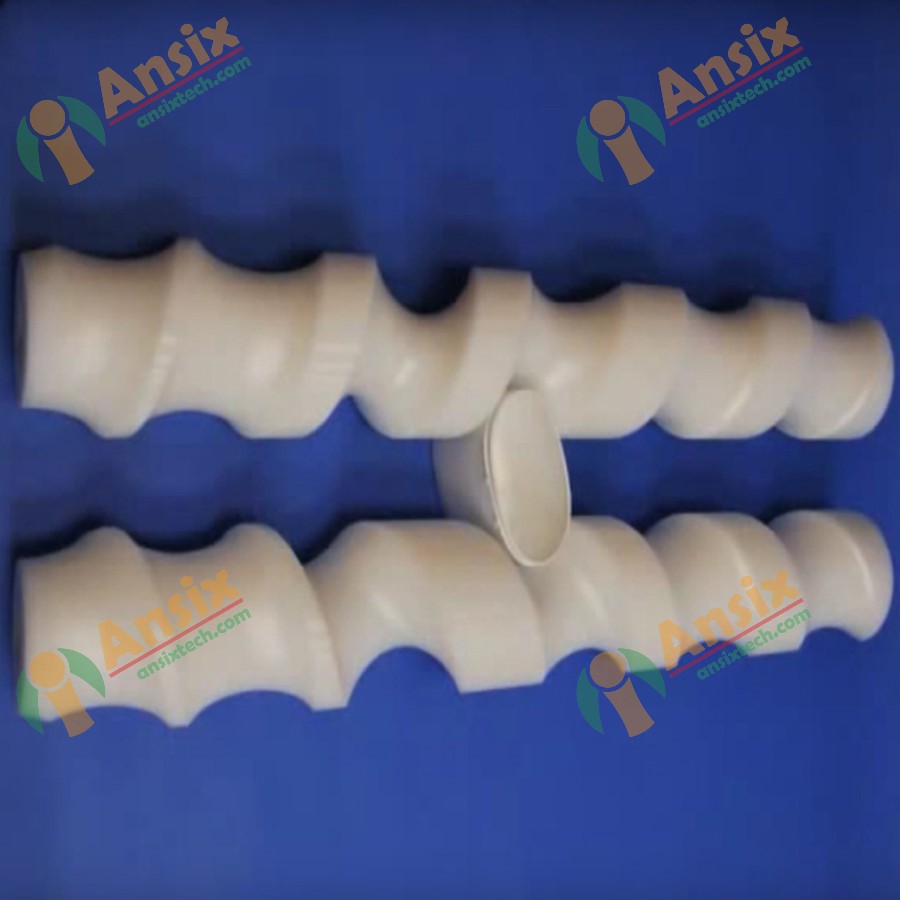

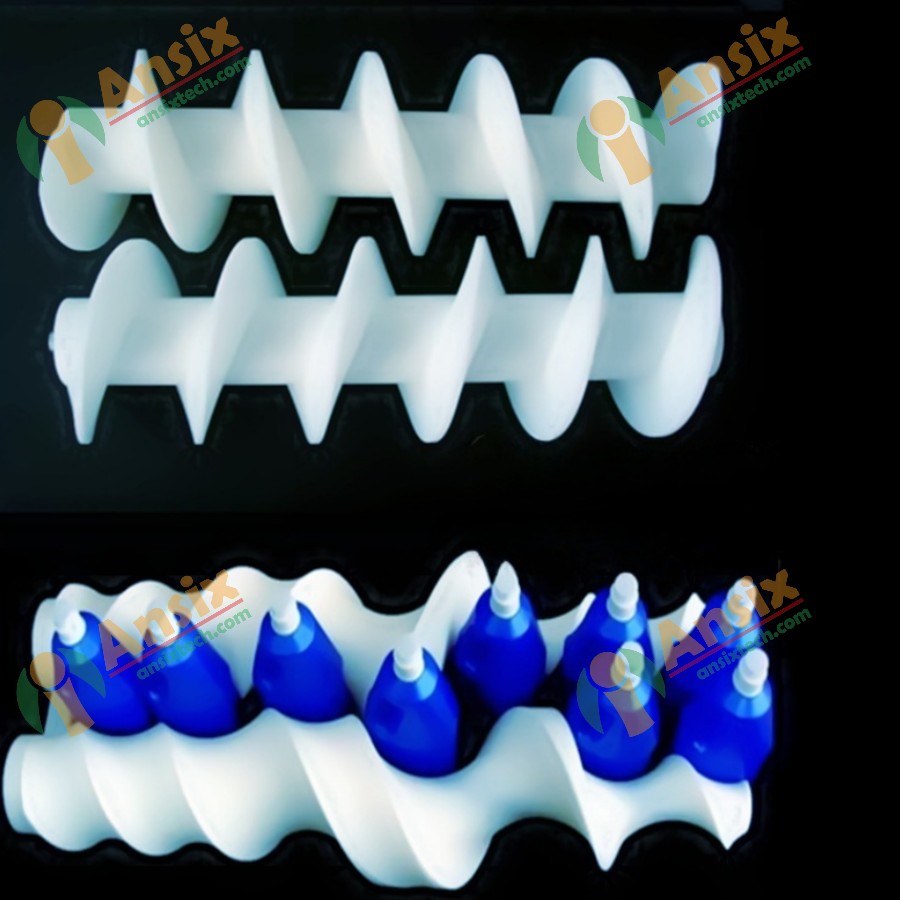

Mechanical automation equipment custom screw POM screw industrial equipment screw Plastic POM Screw

FEATURES

- Mechanical automation equipment custom screw POM screw industrial equipment screw Plastic POM Screw

The machining process of customized POM screws with automated equipment includes steps such as material preparation, manufacturing process and surface treatment. POM screws are mainly used in fields such as automated conveying systems, automated assembly equipment, and automated packaging equipment to realize the automated process of material transportation, parts assembly, and product packaging.., please send us a message (Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

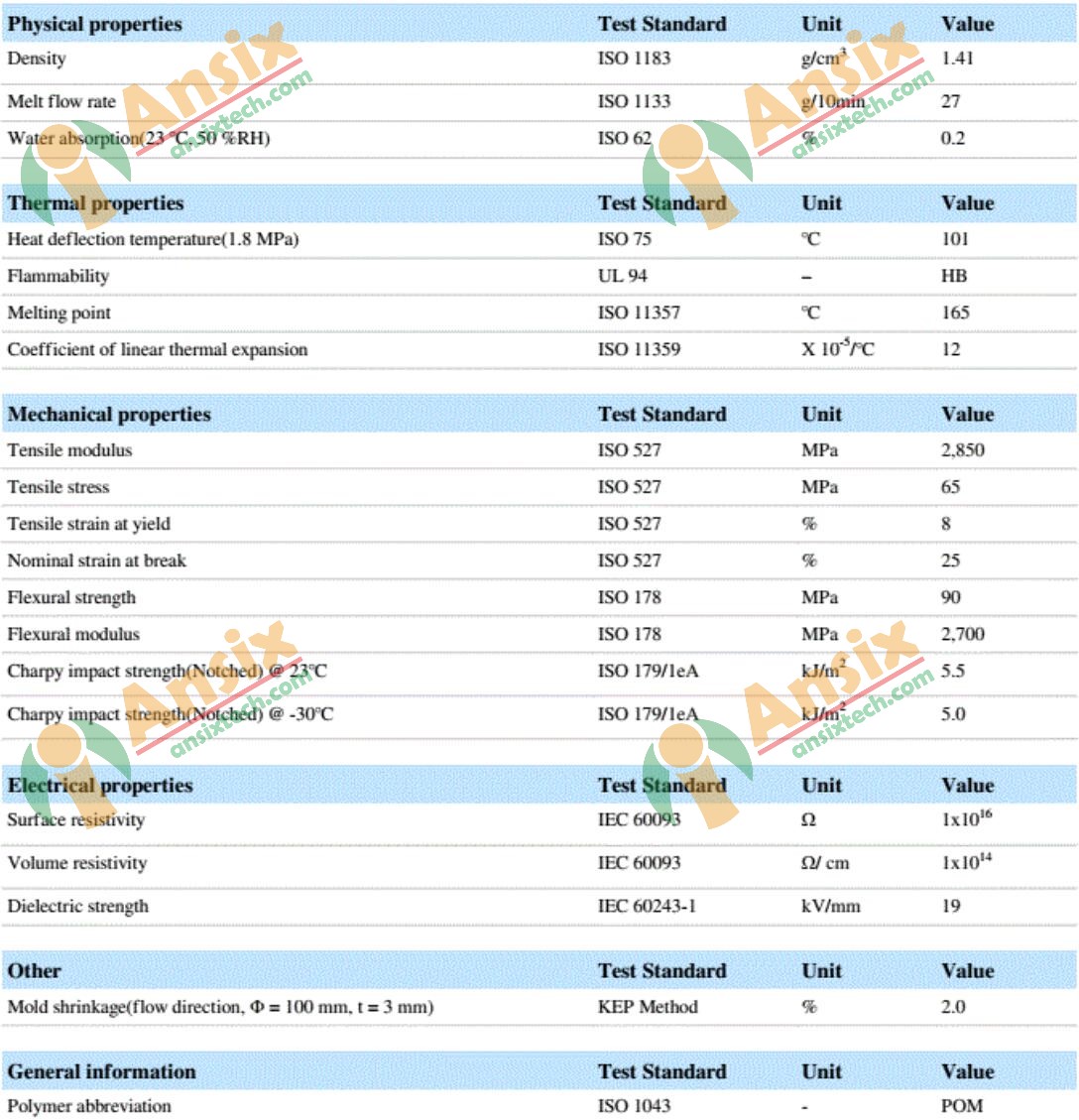

- POM Material Parameter Sheet

POM, polyoxymethylene, is an engineering plastic whose main component is polyoxymethylene resin. It is usually produced from formaldehyde through a polymerization reaction. The chemical composition of POM materials includes carbon, oxygen, and hydrogen elements, and its molecular structure contains a large number of formaldehyde units. In addition, POM materials may also contain some additives, such as plasticizers, antioxidants, etc., to adjust the properties of the material. These chemical components make POM have excellent mechanical properties, wear resistance and chemical corrosion resistance, making it suitable for manufacturing various parts and engineering components.

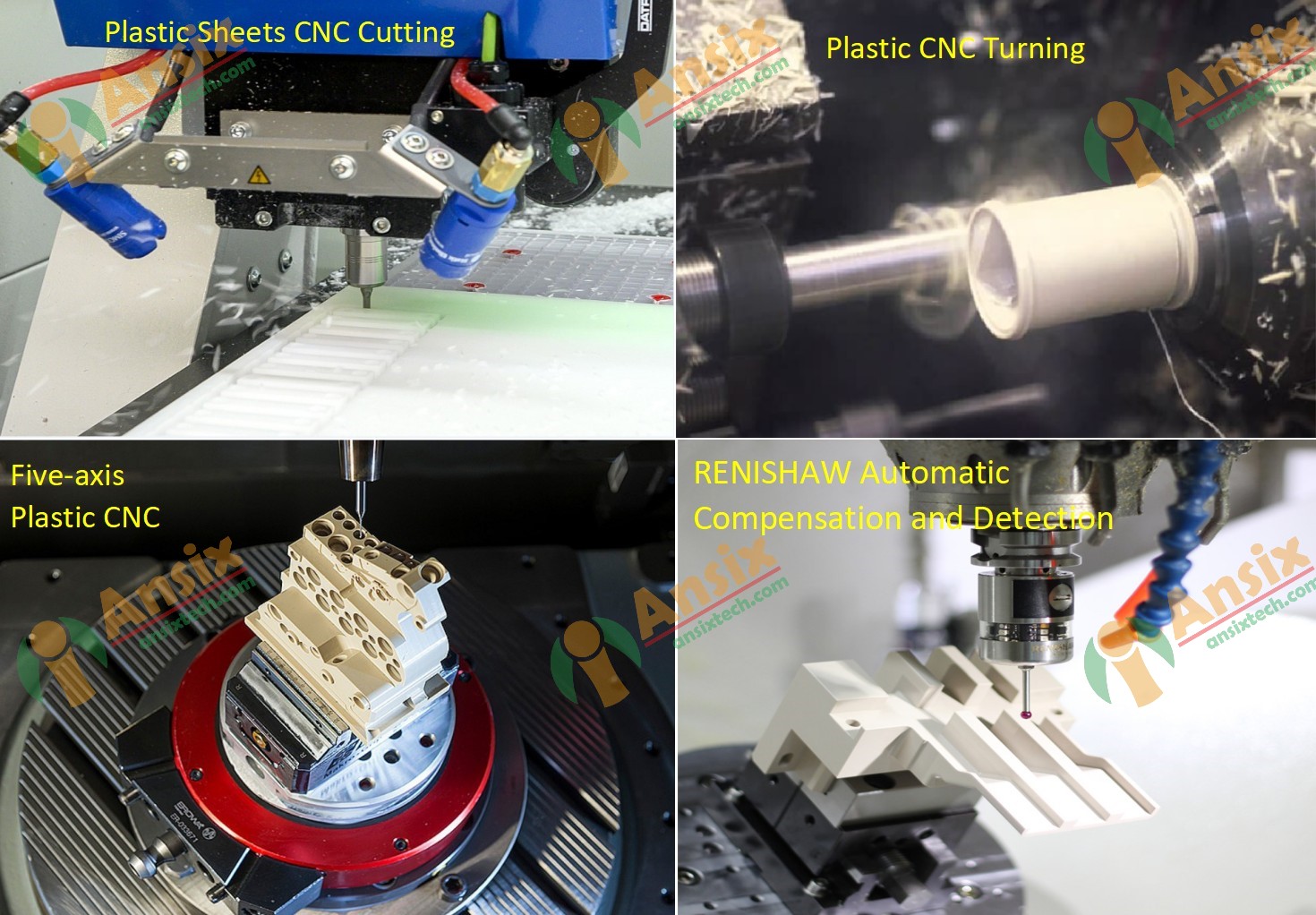

- The process of customizing plastic POM screws at Ansix Tech is as follows:Demand confirmation: Communicate with customers to understand their specific needs for POM screws, including size, materials, uses, etc.Design and engineering: According to customer needs, design a POM screw that meets the requirements, and conduct engineering analysis to ensure its performance and feasibility.Material selection: Select appropriate POM materials, such as polyoxymethylene (POM), according to customer requirements and application scenarios.Manufacturing and processing: According to the design drawings, use equipment such as CNC machine tools or injection molding machines to manufacture and process the POM screw. This process may include steps such as cutting, drilling, milling, heat treatment, etc.Inspection and quality control: Strict inspection and quality control are carried out on the manufactured POM screws to ensure that their dimensional accuracy, surface smoothness and strength meet the requirements.Packaging and Delivery: POM screws are properly packed to prevent damage and delivered as per customer requirements.Throughout the entire customization process, Ansix Tech will maintain close communication and cooperation with customers to ensure that the final POM screw meets customer needs and expectations. At the same time, Ansix Tech Company will also provide professional technical support and after-sales service to ensure customer satisfaction.

- Customized Plastic CNC Machining POM screwAt Ansix Tech, processing a POM screw may involve the following steps:Design Planning: Make sure the designer understands the function and needs of the screw, as well as the characteristics of the POM material that will be used. This includes determining the screw diameter, pitch, and screw head design.Material procurement: Select appropriate POM materials and ensure that they meet relevant standards and quality requirements. Mechanical processing: Use appropriate equipment (such as injection molding machine or CNC machine tool) to blow blow or injection mold the POM material into the initial shape of the screw.Precision processing: Precision processing of the initially formed screw, including thread processing, surface smoothing, etc., to ensure the quality and accuracy of the screw.Quality inspection: Carry out quality inspection of screws, including dimensional measurement, appearance inspection, etc.Packaging and shipment: After passing the quality inspection, the screw will be packaged and shipped. During this process, it is necessary to ensure strict compliance with relevant processing techniques, quality standards and safety regulations to ensure the production of high-quality POM screw products.

-

- Quality Assurance of Plastic CNC Machined POM Screw

To ensure the quality of machined POM screws, the following measures can be taken:Choose high-quality POM materials: Make sure to use high-quality POM raw materials that meet relevant standards for processing to ensure the wear resistance, chemical resistance, and mechanical properties of the product.Strictly control the processing technology: Develop strict processing technology procedures, including processing parameters, tool selection, processing sequence, etc., to ensure the processing accuracy and surface finish of the POM screw.Precision equipment and technology: Use high-precision CNC machine tools and advanced processing technology, such as grinding, turning, etc., to ensure the dimensional accuracy and surface quality of the POM screw.Quality control inspection: Establish a complete quality control system and conduct strict quality inspection and control on each processing link to ensure that the product meets the design requirements. Continuously improve the technical level: Continuously improve and enhance the technical level, and master the latest processing technology and technology to ensure that the quality and performance of POM screw products are at the leading level in the industry. Through the above measures, the quality of machined POM screws can be effectively guaranteed to meet customer needs and requirements.

- AnsixTech’s Commitment to Cooperative Customers

Ansix Tech's service mission is to provide customers with high-quality customized processing services to meet their specific needs and requirements. We are committed to providing customers with high-quality POM screws and related customized processing products, while ensuring product quality and on-time delivery. We continuously optimize production processes and technologies to improve production efficiency and product quality, and establish long-term cooperative relationships with customers to ensure that customers are satisfied with our services and products. Our aim is to provide customers with reliable customized processing solutions with professionalism, integrity and responsibility.Product or service quality commitment: Commitment to provide high-quality, reliable products or services to meet customer needs and expectations.

Delivery and service commitment: Commitment to deliver products or provide services on time and provide timely after-sales support and customer service.Price and cost commitment: Promise to provide reasonable prices and cost-effectiveness to ensure that customers receive value-for-money products or services.Commitment to innovation and technology: Commitment to continuous innovation and introduction of new technologies to provide more advanced and competitive solutions.Commitment to sustainable development: Commitment to consider environmental, social and economic sustainability in business operations and promote sustainable development.