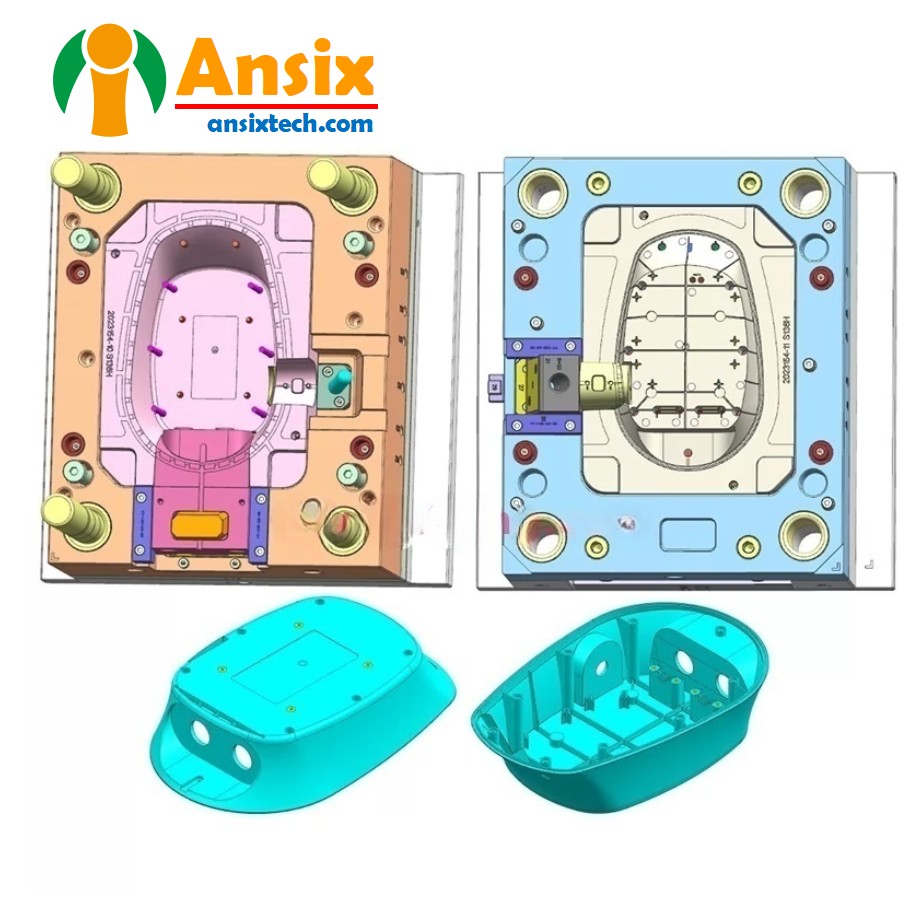

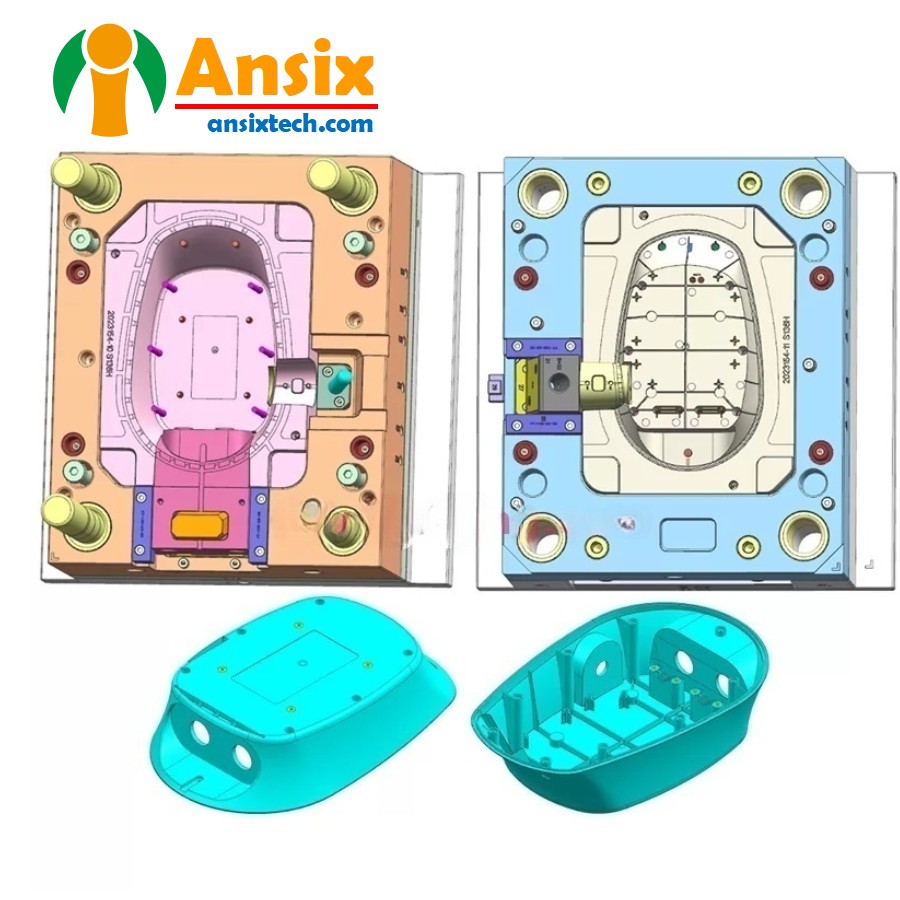

New Energy Vehicle Charging Wall-Mounted Pile Back Cover Injection Mold Forma Wtryskowa

FEATURES

- The process flow of the injection mold for the back cover of the new energy vehicle charging wall-mounted pile is as follows

Design mold: Design the mold according to the design requirements and specifications of the back cover of the charging wall mount. The design includes mold structure, mold cavity, cooling system, exhaust system, etc.

Material preparation: Select plastic materials suitable for injection molding and prepare the required mold materials, such as steel.

Processing of molds: Processing and manufacturing of molds according to design drawings. This includes CNC machining, EDM, wire cutting and other processes.

Assemble the mold: Assemble the processed mold parts, including the mold cavity, cooling system, exhaust system, etc.

Debugging and testing: Debugging and testing the assembled mold to ensure the normal operation of the mold and the quality of injection molding.

Prepare the injection molding material: According to the requirements of the back cover of the charging wall mount, select a suitable plastic material and heat it to melt it into a liquid state.

Injection molding: Inject molten plastic into the mold cavity. Through the pressure and temperature control of the injection molding machine, the plastic fully fills the mold cavity and solidifies during the cooling process.

Open the mold and take out the injection molded parts: After the injection molded parts have cooled and solidified, open the mold and take out the injection molded parts.

Inspection and trimming: Inspect injection molded parts to check size, appearance and quality, etc. Trim and post-process if necessary.

Maintenance and maintenance: Regular maintenance and upkeep of injection molds, including cleaning, lubrication, replacement of worn parts, etc., to ensure long-term use of the mold.

In the manufacturing process of the injection mold for the back cover of the new energy vehicle charging wall-mounted pile, attention needs to be paid to the accuracy and stability of the mold to ensure the quality and efficiency of injection molding. At the same time, it is also necessary to rationally design the mold structure and cooling system according to the requirements of the injection molding process to improve the quality and production efficiency of injection molded parts.Please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

-

Mold Description

Product Materials:

PC

Mold Material:

738H

Number of Cavities:

1*1

Glue Feeding Method:

Hot runner

Cooling Method:

Water cooling

Molding Cycle

46.5s

- Mold flow analysis and mold designAnsix's New energy vehicle home charging pile product introductionWith the popularity of new energy vehicles, home charging piles have become the choice of more and more car owners. Home charging piles can not only provide car owners with convenient charging services, but also save energy costs for families and reduce their reliance on traditional fuel vehicles. This article will introduce the functions and characteristics of home charging piles as well as common products on the market.Functions of home charging pilesHome charging pile is a kind of charging equipment specially designed for new energy vehicles. Its main function is to provide charging services for vehicles. Compared with ordinary household sockets, household charging piles have higher charging efficiency and safer charging protection functions. Through home charging piles, car owners can conveniently charge their vehicles at home, eliminating the need to frequently go to charging stations, saving time and costs.In addition to basic charging functions, some home charging piles also have intelligent management functions that can be remotely controlled and monitored through mobile apps. In this way, car owners can know the charging status of the vehicle anytime and anywhere, and can schedule charging according to needs, improving charging flexibility and convenience.Characteristics of household charging pilesSafe and reliable: Home charging piles adopt professional charging technology and safety protection measures to ensure the safety and reliability of the charging process. For example, it has multiple protection functions such as overcurrent, overvoltage, and overtemperature, which can effectively avoid safety hazards during the charging process.High efficiency and energy saving: Home charging piles adopt efficient charging technology, which can improve charging efficiency and reduce energy waste. At the same time, some home charging piles also have intelligent energy-saving functions, which can adjust the charging power according to the load of the grid to maximize the use of electrical energy resources.Intelligent management: Some home charging piles have intelligent management functions and can be remotely controlled and monitored through mobile apps. Car owners can understand the charging status at any time and schedule charging to improve charging flexibility and convenience.Appearance design: The household charging pile has a stylish and beautiful appearance design, suitable for use in home environments. Some products are also waterproof and dustproof, making them suitable for various outdoor environments.Compatibility: Home charging piles usually have good compatibility and can be adapted to new energy vehicles of different brands and models to meet the needs of different car owners.Common household charging pile products on the marketTesla home charging pile: Tesla is a world-renowned new energy vehicle manufacturer, and its home charging pile products are efficient, safe, and intelligent. Tesla home charging piles can perfectly cooperate with Tesla vehicles to provide fast and convenient charging services.CATL home charging piles: CATL is a well-known domestic manufacturer of new energy vehicle charging equipment. Its home charging pile products have high performance, high safety and intelligent management functions. CATL’s home charging piles are highly adaptable and can meet the charging needs of new energy vehicles of different brands.Huawei home charging piles: Huawei is a world-renowned technology company. Its home charging pile products combine intelligent management and efficient charging technology, and are highly intelligent and convenient. Huawei’s home charging pile has a stylish and beautiful appearance and is suitable for home use.Guodian Nari home charging piles: Guodian Nari is a leading domestic manufacturer of new energy vehicle charging equipment. Its home charging pile products are of high quality, high safety and high compatibility. Guodian NARI has a rich product line of home charging piles that can meet the needs of different car owners.The above are common household charging pile products on the market. They have different features and advantages. Car owners can choose the appropriate product according to their own needs and vehicle brand.Ansix New energy vehicles: As an important supporting equipment for new energy vehicles, household charging piles have the characteristics of safety, reliability, high efficiency, energy saving, and intelligent management, providing car owners with convenient charging services. With the continuous development of the new energy vehicle market, home charging pile products are also constantly innovating and improving to provide car owners with a better charging experience. We hope that the introduction in this article can help car owners better understand household charging pile products, choose products that suit them, and contribute to the popularization and development of new energy vehicles.

-

The mold manufacturing process and product material selection

Product material selection:Ansix’s new energy vehicle home charging pile shell mold manufacturing and material selection are very important links, directly affecting product quality and production efficiency. The following will introduce the relevant content of Ansix Company in the mold manufacturing and material selection of new energy vehicle home charging pile shells.Mold manufacturingMold manufacturing processAnsix uses advanced processing techniques in mold manufacturing, including CNC machining, EDM, wire cutting, etc., to ensure the accuracy and stability of the mold. At the same time, Ansix also pays attention to the heat treatment and surface treatment of the mold to improve the hardness and wear resistance of the mold and extend the service life of the mold.Mold manufacturing equipmentAnsix Company has advanced mold processing equipment, including CNC lathes, CNC milling machines, EDM machines, wire cutting machines, etc., which can meet the processing needs of different types of molds. At the same time, Ansix also has a complete mold design and manufacturing team that can customize mold manufacturing according to customer needs.Quality control of mold manufacturingAnsix strictly implements quality control standards during the mold manufacturing process and strictly controls the processing accuracy, surface quality and assembly accuracy of the mold to ensure the quality and stability of the mold.Material selectionSelection of shell mold materialsAnsix usually chooses high-strength and high-hardness engineering plastic materials, such as fiberglass-reinforced polymer (FRP), polystyrene (PS), polypropylene (PP), etc., in the manufacturing of housing molds for new energy vehicle home charging piles. These materials have good mechanical properties, wear resistance and corrosion resistance, and are suitable for the manufacture of shell molds.Consideration of material propertiesWhen selecting shell mold materials, Ansix will also consider factors such as material cost, processing performance, surface quality and environmental protection to comprehensively consider customer needs and the actual application of the product.Material sustainabilityAnsix also pays attention to sustainable development in material selection, preferring to choose recyclable materials or biodegradable materials that meet environmental protection requirements to reduce the impact on the environment.Ansix Company has rich experience and advanced technology in new energy vehicle home charging pile shell mold manufacturing and material selection, and can provide customers with high-quality, high-performance mold products to meet customer needs and market requirements.a. Injection molding material: Select the appropriate injection molding material according to the requirements of the plastic product and the application environment. Common plastic materials include ABS,PP,PC,ABS/PC,PBT,PMMA,SAN,PA,PA66,PA6,POM,PET,PE,PVT,TPE,TPR,SILICONE,PEEK,PEI,PS,PES,PI,PPSU,PETG,PCTG,PFA,NBR,PTFE,PAEK,PAA,PEAA etc. According to the characteristics and requirements of the product, select materials with appropriate hardness, wear resistance, chemical resistance and other properties.

Mold material selection:

The selection of mold materials should take into account the shape, size and requirements of the plastic product, as well as the service life and production volume of the mold. Common mold materials include tool steel, stainless steel,738、2738H 、718、718H、NAK80、2083、2316、2344、2083H、2316H、S136、S136H、S136-D、HPM38、M300、S-STAR、M333、S196 etc., which have high hardness and wear resistance.

- Ansix’s new energy vehicle Mass production and Quality controlAnsix Company has rich experience and advanced production management system in the mass production and quality assurance of new energy vehicle home charging piles. The following will introduce the relevant content of Ansix Company in this regard.Mass productionProduction equipment and processesAnsix Company has advanced production equipment and processes, including injection molding equipment, automated assembly lines, quality inspection equipment, etc. These equipment and processes can meet the needs of large-scale production and improve production efficiency and product quality.Production management systemAnsix Company has established a complete production management system, including production plan management, material supply chain management, production process control, quality management, etc. Through information management and automated production, Ansix can achieve efficient, precise and controllable production processes.Supply chain managementAnsix has established long-term and stable cooperative relationships with high-quality suppliers to ensure stable supply of raw materials and controllable quality. At the same time, Ansix also focuses on the transparency and collaborative management of the supply chain to reduce costs and improve efficiency.Quality assuranceQuality management systemAnsix has established a strict quality management system, including the establishment of quality control points, the formulation of quality inspection standards, and the traceability of quality records. Through full-process quality control, Ansix can ensure stable and reliable product quality.Detection means and methodsAnsix company has advanced quality testing equipment and a professional quality testing team, which can conduct comprehensive and accurate testing of various indicators of products. At the same time, Ansix also focuses on the innovation of quality testing means and methods to continuously improve the quality level of its products.Quality culture constructionAnsix pays attention to the construction of quality culture and advocates the participation of all employees and the cultivation of quality awareness of all employees to ensure that every employee can put quality first and continuously improve the quality of products.Ansix Company has rich experience and advanced management system in mass production and quality assurance of new energy vehicle home charging piles. It can provide customers with high-quality, high-performance products and ensure a stable supply of products. At the same time, Ansix also focuses on continuous improvement and innovation, constantly improving production efficiency and product quality to meet customer needs and market requirements.