Connector mold injection molding mass production delivery

2024-05-03 16:27:22

Connector mold injection molding mass production delivery refers to the realization of large-scale connector production and delivery through efficient production processes and management control during the connector mold injection molding production process.

Production plan and schedule: Develop production plan and schedule based on order demand and production capacity. Determine key information such as production quantities, delivery times and production batches.

Raw material procurement and preparation: According to the production plan, purchase and prepare injection molding raw materials. Ensure adequate supply of raw materials and conduct necessary raw material inspection and quality control.

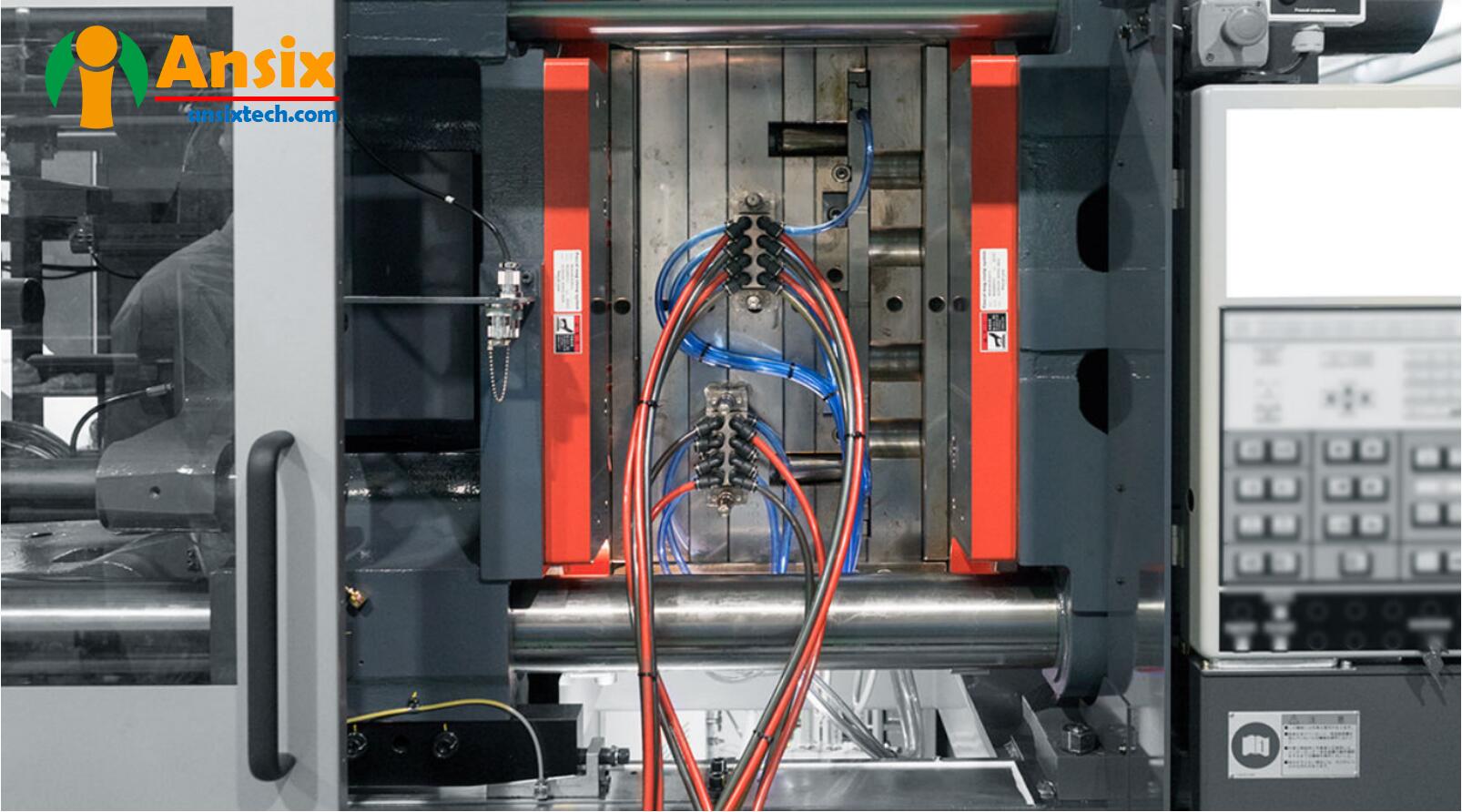

Mold preparation and debugging: Ensure that the preparation and debugging of the connector mold is completed. Including mold installation, adjustment and testing to ensure the normal operation and stability of the mold.

Injection molding production: Carry out injection molding production of connectors according to the production plan. Molten plastic is injected into the mold through an injection molding machine for shaping and solidification. Injection molding parameters and quality need to be strictly controlled during the injection molding production process to ensure the consistency and quality of the connector.

Inspection and testing: Inspection and testing of connectors produced by injection molding, including appearance inspection, dimensional measurement, electrical performance testing, etc. Ensure connector quality and performance meet requirements.

Packaging and shipment: Pack the qualified connectors and prepare them for shipment. Packaging should comply with transportation and storage requirements to ensure the safety and integrity of the connector.

Quality control and records: Quality control and records are carried out throughout the entire production process. Including raw material quality control, production process monitoring, product inspection records, etc. Ensure the stability and traceability of the production process.

Delivery and after-sales service: timely delivery of connector products according to order requirements. Provide necessary after-sales service and support to ensure customer satisfaction.

Connector mold injection molding mass production delivery requires efficient production management and quality control to ensure connector quality and delivery time. Through reasonable production planning and process optimization, production efficiency and capacity can be improved, and large-scale connector production and delivery can be achieved. At the same time, the implementation of quality control and records can ensure connector consistency and traceability, improving customer satisfaction and trust.