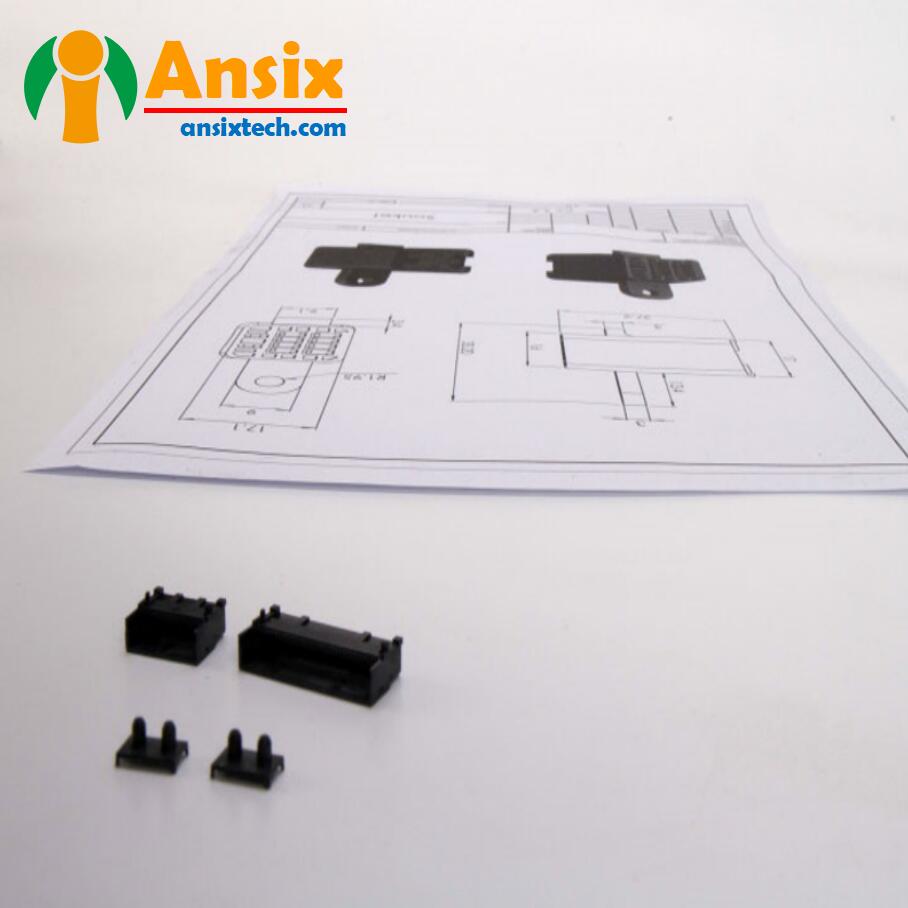

Connector mold injection molding verification

2024-05-01 16:27:22

Connector mold injection molding verification is an important step to ensure that the quality and performance of the connector during the connector mold injection molding production process meet the requirements.

Appearance inspection: Conduct an appearance inspection on the connector, including checking the surface finish, color, pattern, etc. of the connector. Make sure the connector has no obvious defects, scratches or deformations.

Dimensional measurement: Use appropriate measuring tools to measure the dimensions of the connector. Compare the measurement results with the specifications of the connector design drawing to ensure that the connector dimensions meet the requirements.

Electrical performance testing: Conduct electrical performance testing on the connector, including resistance, insulation resistance, current capacity, etc. Ensure that the electrical performance of the connector meets the design requirements of the connector.

Functional testing: Carry out corresponding functional testing according to the functional requirements of the connector. For example, for plug-in and pull-out connectors, perform plug-in and pull-out force tests; for waterproof connectors, perform waterproof performance tests, etc. Make sure the connector is functioning properly and reliably.

Durability test: Conduct a durability test on the connector to simulate the long-term use of the connector. For example, conduct plug-and-unplug times test, heat resistance test, cold resistance test, etc. Ensure that the connector maintains stable performance over long periods of use.

Reliability test: Conduct reliability test of the connector to simulate the use of the connector under various environmental conditions. For example, conduct vibration testing, impact testing, heat and humidity cycle testing, etc. Ensure connectors maintain stable performance in various environments.

The purpose of connector mold injection molding verification is to ensure that the quality and performance of the connector meet the requirements, and to verify the stability and reliability of the connector mold injection molding production process. Through verification, problems in the connector production process can be discovered and solved in time, and the consistency and reliability of the connector can be improved. The verification results can be used to adjust and improve the connector mold injection molding production process to further improve connector quality and performance.