Interior decoration(INS) for Automotive Parts

2024-01-24 16:12:25

Automotive interior technology includes the design, material selection and decoration methods of various internal components of the vehicle. These processes can involve the selection and production of seat materials, the design and decoration of dashboards and door panels, the processing of interior trim strips, the design and laying of ceilings and carpets, etc. The decoration process of automobile interiors is designed to enhance the comfort, aesthetics and practicality of vehicle interiors, while taking into account factors such as service life, ease of cleaning and safety. These processes typically include material selection, molding, assembly and testing to ensure compliance with vehicle manufacturer requirements and user expectations.

INS injection molding process The full name of INS is INSert-Mould-Decoration (embedded injection molding decoration process). It refers to placing a blister-molded diaphragm into an injection mold for injection molding.

INS injection molding process

The full name of INS is Insert-Mould-Decoration (embedded injection molding decoration process), which refers to placing a blister-formed diaphragm into an injection mold for injection molding. The INS process is a new process derived from the IML process. As countries have increasingly higher requirements for ecological and environmental protection, INS technology has been increasingly used in modern advanced manufacturing industries, such as automotive interiors, home appliance decoration, and smart digital casings, and has gradually replaced spraying, electroplating and other environmentally polluting processes. Surface treatment process.

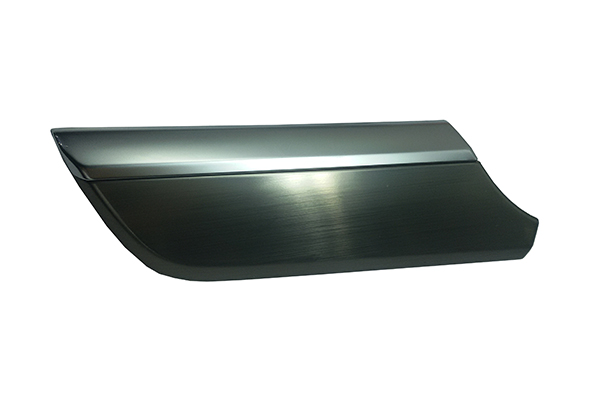

Plastic parts made by the INS process have rich surface expressions and can be high-gloss, matt, metallic, wood grain, leather grain, flat or three-dimensional. Currently, there are thousands of types of INS films. For new product development, there is a large space for choice of appearance expression methods. Because the surface of the INS process can achieve a metallic texture without blocking signals, and because 5G has much greater signal requirements than 4G, in order to make 5G smart digital products have a metallic texture and have good signal transmission functions, INS has become a new generation of smart phones. Hardware is an indispensable craft.One-stop supply service for INS parts.

If you want to know more about INS injection molding process, We have the most advanced manufacturing equipment in the world, and the mold accuracy can reach 0.002mm. We can provide you with the most effective quality assurance and the most competitive price.please call the official consultation hotline: 0086 13530645990 or enter the official website: https://www.ansixtech.com to learn more.