The manufacturing content of connector precision molds

2024-04-29 16:27:22

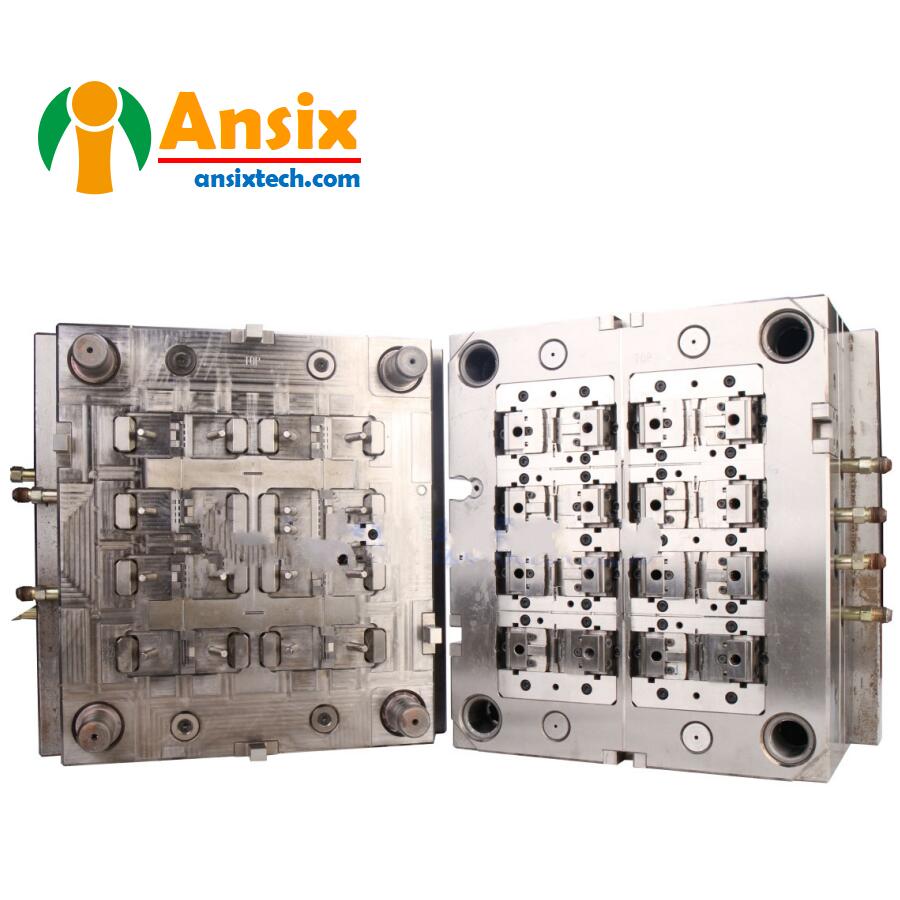

Mold design: Design the mold according to the shape, size and functional requirements of the connector. This includes determining the structure, size and material of the mold, etc. Designers use computer-aided design (CAD) software to create 3D models to ensure the mold accurately replicates the connector’s shape and size.

Material preparation: According to the mold design requirements, select suitable materials for the manufacturing of connector precision molds. The material should have sufficient strength, hardness and wear resistance to meet the usage requirements of the mold.

Mold processing: According to the mold design drawings, use high-precision CNC machine tools or other processing equipment to process the mold. This includes precise cutting and forming to produce connector precision molds that meet the requirements. The quality of each step during the processing needs to be strictly controlled, and necessary inspections and adjustments are made to ensure that the mold can accurately replicate the shape and size of the connector.

Surface treatment: Connector precision molds usually require surface treatment to improve the wear resistance and corrosion resistance of the mold. This includes surface coatings, heat treatments and other treatments to enhance the surface hardness and durability of the mold.

Mold trial and debugging: After completing the mold manufacturing, carry out mold trial and debugging. This is to ensure that the mold accurately replicates the shape and size of the connector. During the mold trial and debugging process, necessary adjustments and corrections need to be made to ensure that the mold can meet the requirements of the connector.

Mold testing and verification: After completing the mold trial and debugging, conduct mold testing and verification. This includes using molds for connector production and checking whether the quality and performance of the connector meet requirements.

The above are the general contents of connector precision mold manufacturing. The specific manufacturing methods and steps may vary due to different connector design requirements. Manufacturing connector precision molds requires highly precise processing equipment and technology to ensure the accuracy and quality of the molds. The manufacturing quality of connector precision molds directly affects the quality and performance of the connector. Therefore, the quality of each step needs to be strictly controlled during the mold manufacturing process, and necessary inspections and adjustments are made to ensure that the mold can meet the requirements of the connector.