OMD&TOM Decoration Introduction

FEATURES

- OMD&TOM Decoration Introduction

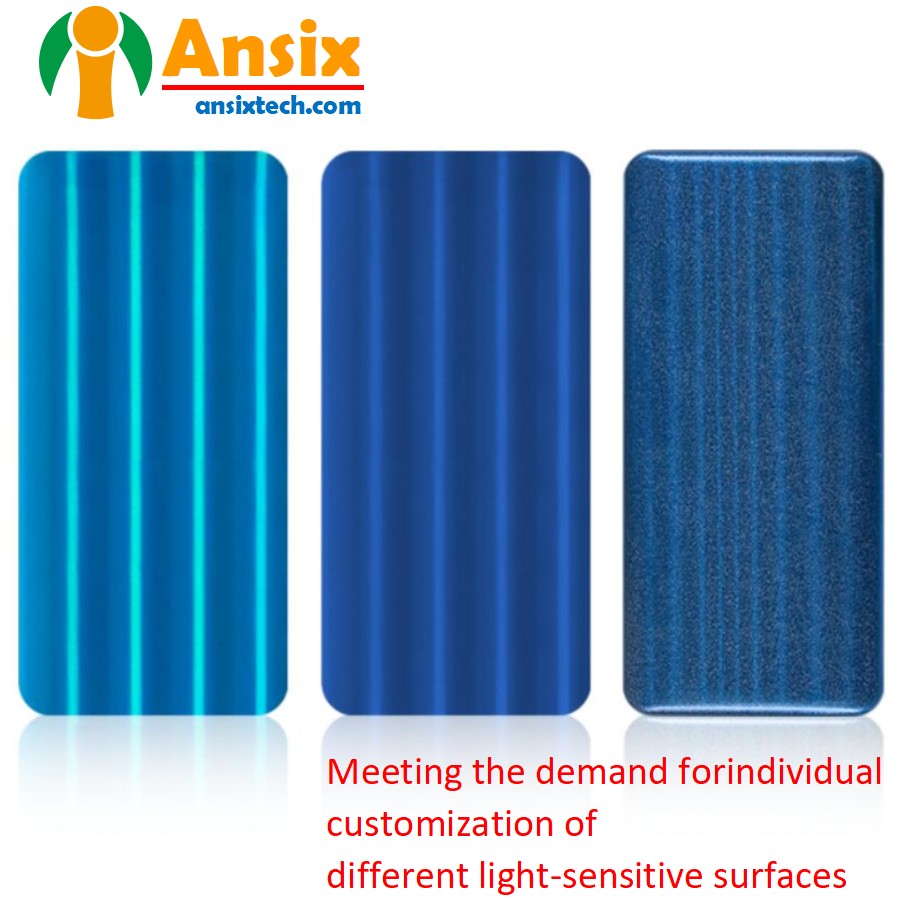

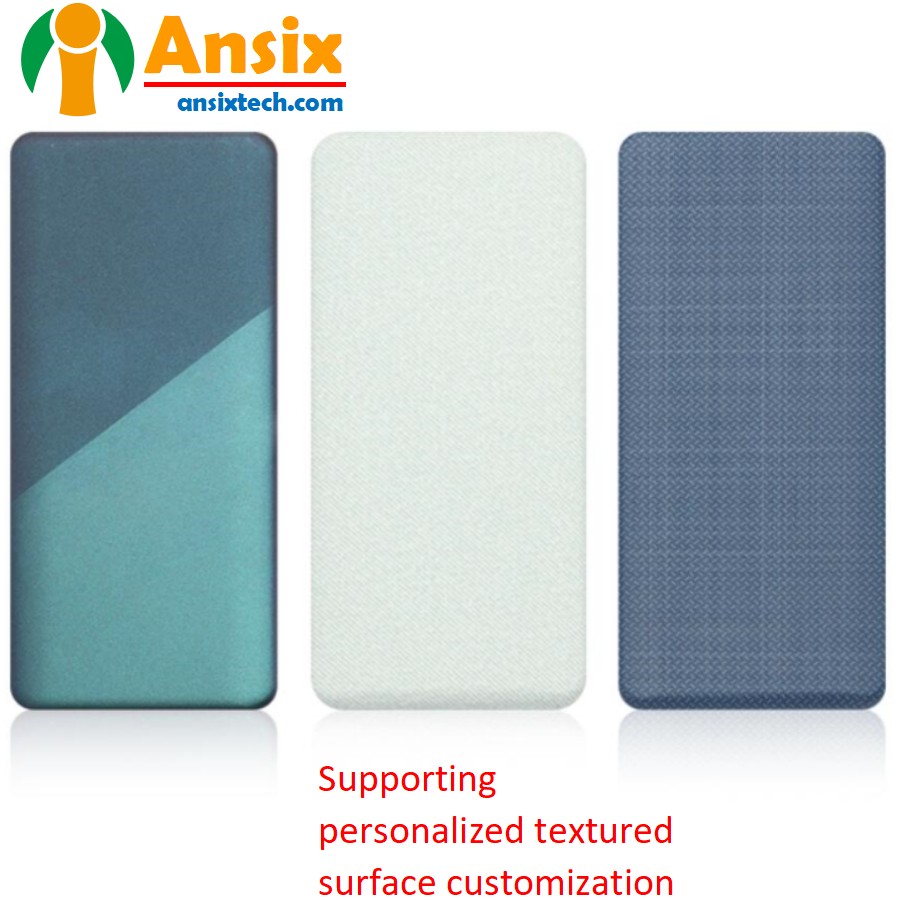

OMD decoration technology has the following advantages:Improve the appearance quality of the product: Through spraying, printing, engraving and other technologies, the surface of the product can be given better color, gloss and texture, improving the appearance quality of the product and making it more beautiful and attractive.Increase the added value of the product: Exterior decoration technology can add personalized patterns, text or logos to the product, making it unique and branding, thus increasing the added value and market competitiveness of the product.Improve product quality: Through technologies such as hot stamping and laser engraving, high-precision patterns and text can be realized on the surface of the mold, increasing the fineness and quality of the product, making it more high-end and textured.Enhance product recognition: Exterior decoration technology can add unique logos or logos to products, making them easier to identify and recognize in the market, increasing the product’s visibility and market share.Improve product durability: By spraying paint or coating, the wear resistance, corrosion resistance and high temperature resistance of the mold surface can be increased, and the service life and durability of the product can be improved.OMD product exterior decoration technology can give products better appearance quality, personalized features and sense of quality, improve the added value and market competitiveness of products, and meet consumers’ needs for beauty, quality and personalization.

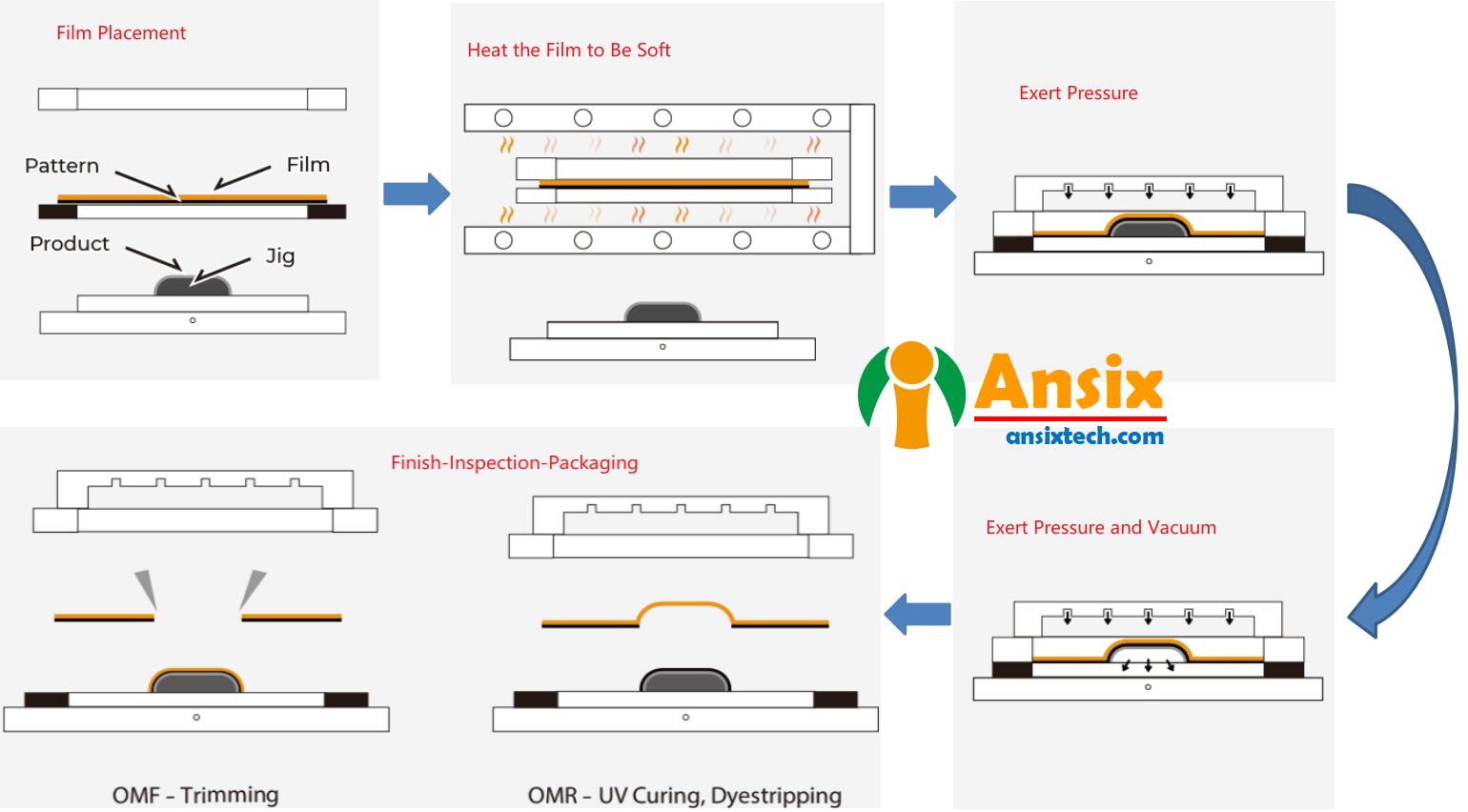

- OMD&TOM Process

OMD product surface decoration technology manufacturing processes can vary based on specific decoration technology and product requirements. Here is a general process example:Design and preparation stage: At this stage, product design and decoration plans need to be determined. Determine the decoration technology and materials used based on product requirements and market demand.Material preparation: According to the decoration plan, prepare the required decoration materials, such as paint, ink, metal foil, etc. Ensure the quality and suitability of materials.Surface treatment: Before decoration, the surface of the product needs to be properly treated, such as cleaning, polishing, priming, etc. This ensures the quality and durability of the decorative effect.Application of decoration technology: According to the decoration plan, use corresponding technology methods for decoration. For example, spray paint, print, engrave or foil stamping, etc. Carry out corresponding operations and controls according to specific process requirements.Drying and curing: After the decoration is completed, drying and curing processing is required to ensure the stability and durability of the decorative layer. This may require the use of drying equipment, UV curing equipment, etc.Inspection and quality control: Conduct inspection and quality control on the decorated products to ensure that the decorative effect meets the requirements. This may include visual inspection, color consistency, adhesion testing, etc.Packaging and shipping: After finishing decoration and quality control, the products are packaged and ready for shipping.It should be noted that different decoration technologies and product types may have different processes and details. Therefore, in practical applications, it needs to be adjusted and optimized according to specific conditions. At the same time, we strictly abide by relevant safety operating procedures and environmental protection requirements to ensure the safety and environmental protection of the production process.

OMD&TOM Application

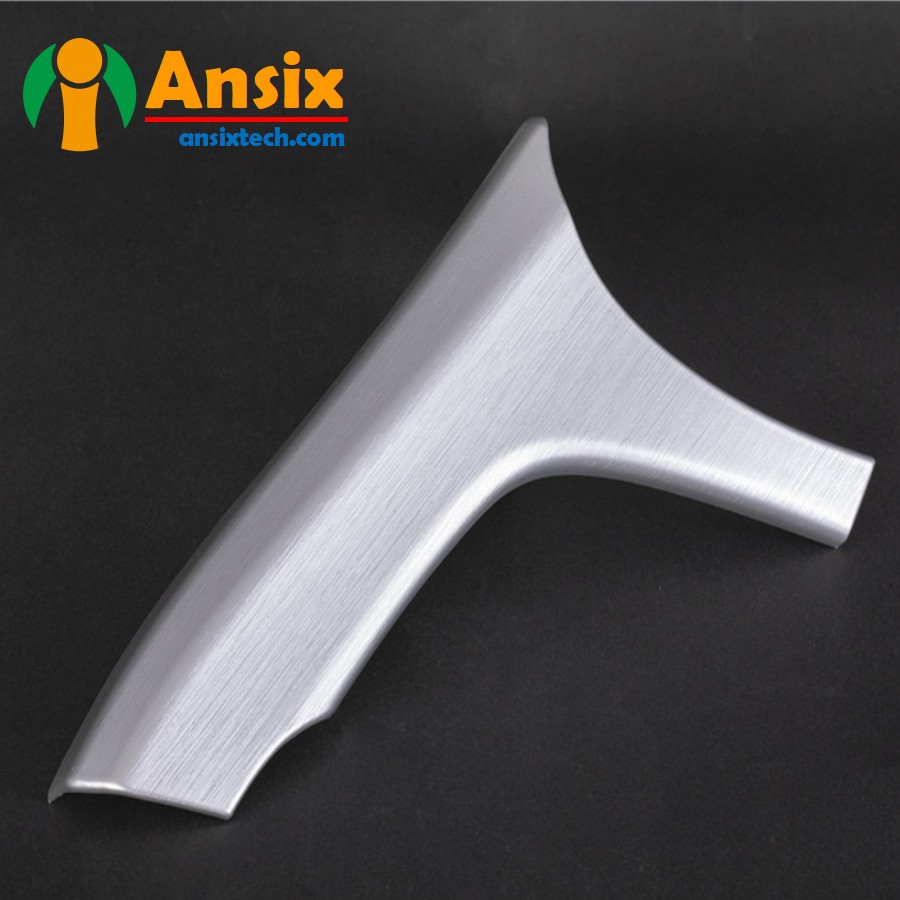

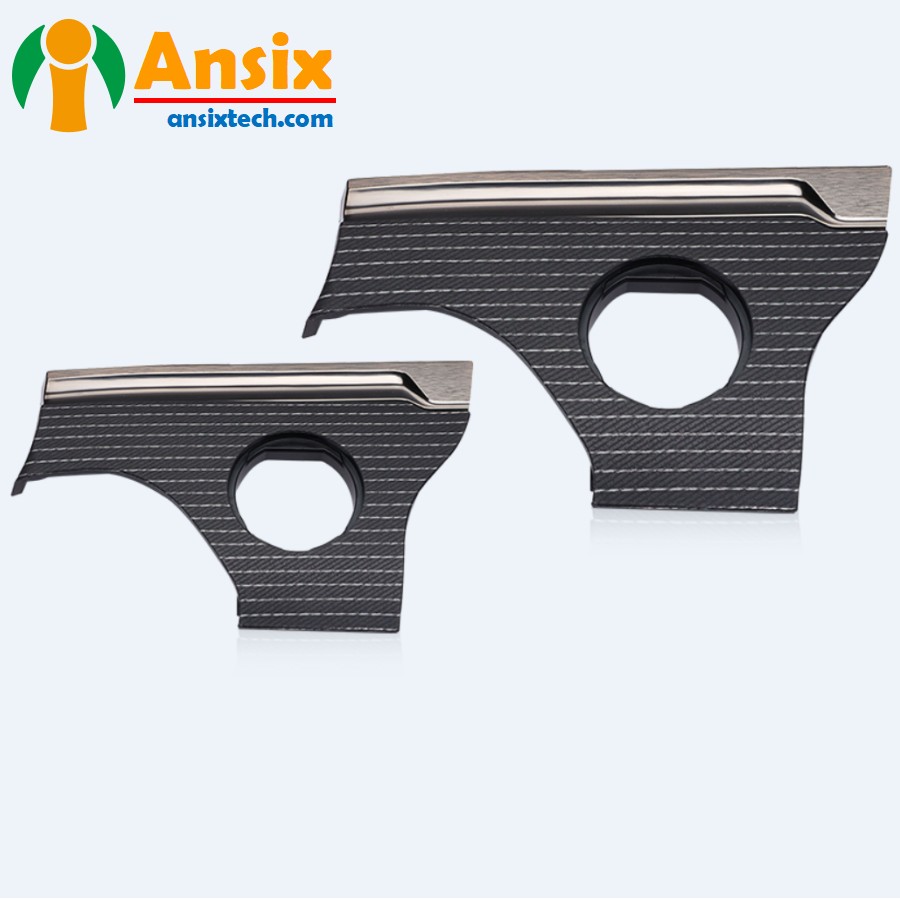

- Automotive parts

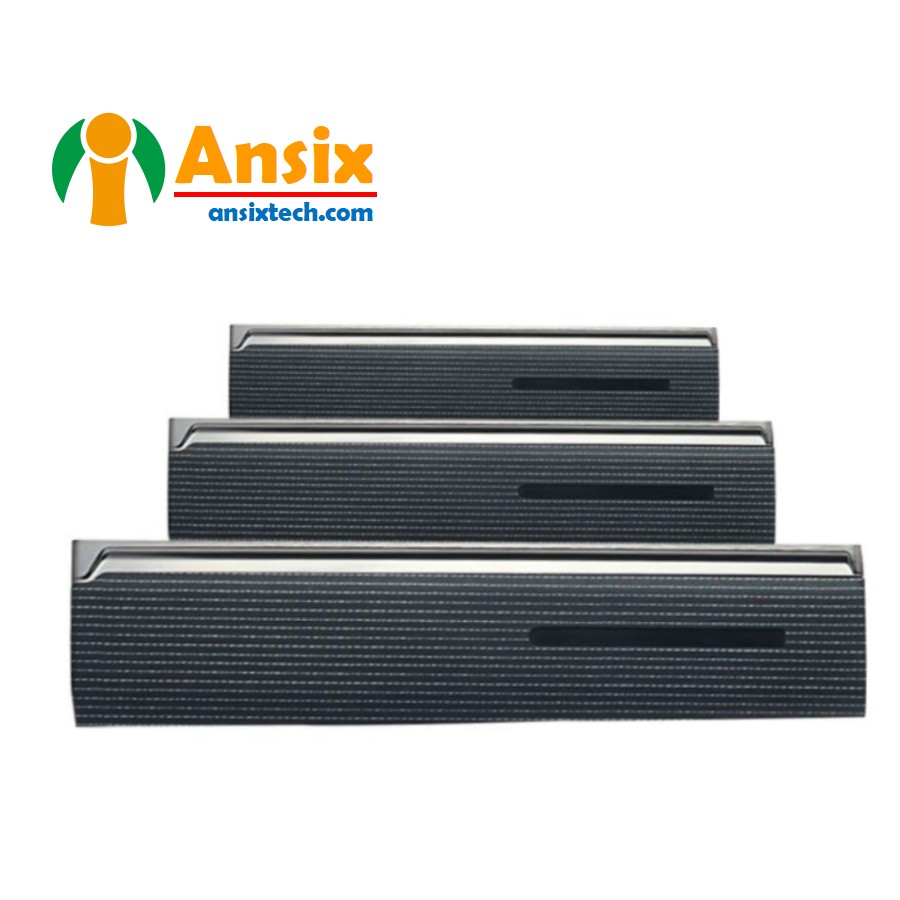

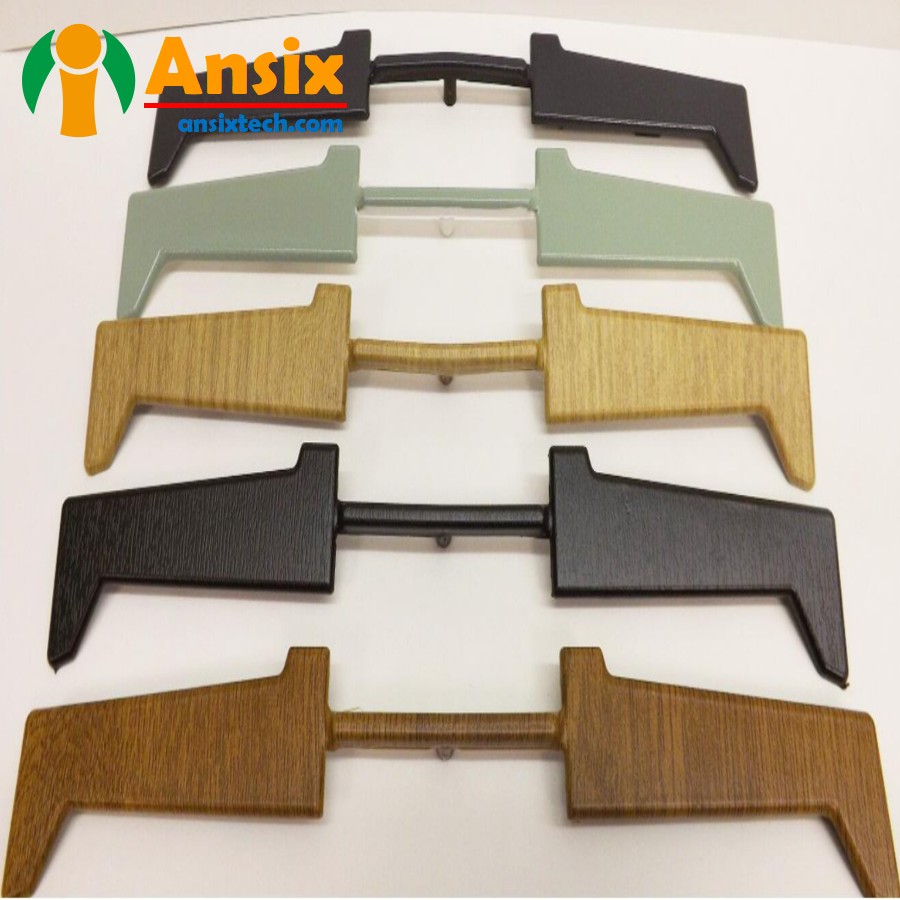

OMD&TOM surface decoration technology can be applied to various parts of the car to enhance its appearance quality, personalized features and sense of quality. The following are some common automotive parts that can be applied with OMD&TOM surface decoration technology:Body appearance: The car body appearance is the most intuitive part and can be decorated through spraying, printing, engraving and other technologies. For example, spray paint can change the color and gloss of the car body, printing can print brand logos and patterns on the car body, and engraving can engrave textures and patterns on the car body.Interior panels: The interior panels of automobiles include instrument panels, central control panels, door panels and other parts, which can be decorated through spraying, printing, engraving and other technologies. For example, spray painting can provide personalized colors and effects for interior panels, printing can print patterns and text on panels, and engraving can engrave textures and patterns on panels.Wheel hub: The wheel hub of a car is an important decorative component and can be decorated through spraying, hot stamping and other techniques. For example, spray coating can change the color and gloss of the wheel hub, and hot stamping can hot stamp metal foil on the wheel hub.Logos and emblems: Car logos and logos are important representatives of the brand and can be decorated through printing, hot stamping and other techniques. For example, printing can print the brand name and pattern on the logo, and hot stamping can hot stamp metal foil on the logo.Lamps: Car lamps include headlights, taillights and other parts, which can be decorated through spraying, printing and other technologies. For example, spraying can change the color and gloss of lamps, and printing can print patterns and text on lamps.In addition to the above components, there are many other automotive components that can be applied with OMD&TOM surface decoration technology, such as door handles, window frames, exhaust pipes, etc. Through the application of OMD&TOM surface decoration technology, more personalized choices and decorative effects can be provided for cars to meet consumers’ needs for car appearance. If you have any questions about products in the plastic molding and mold field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

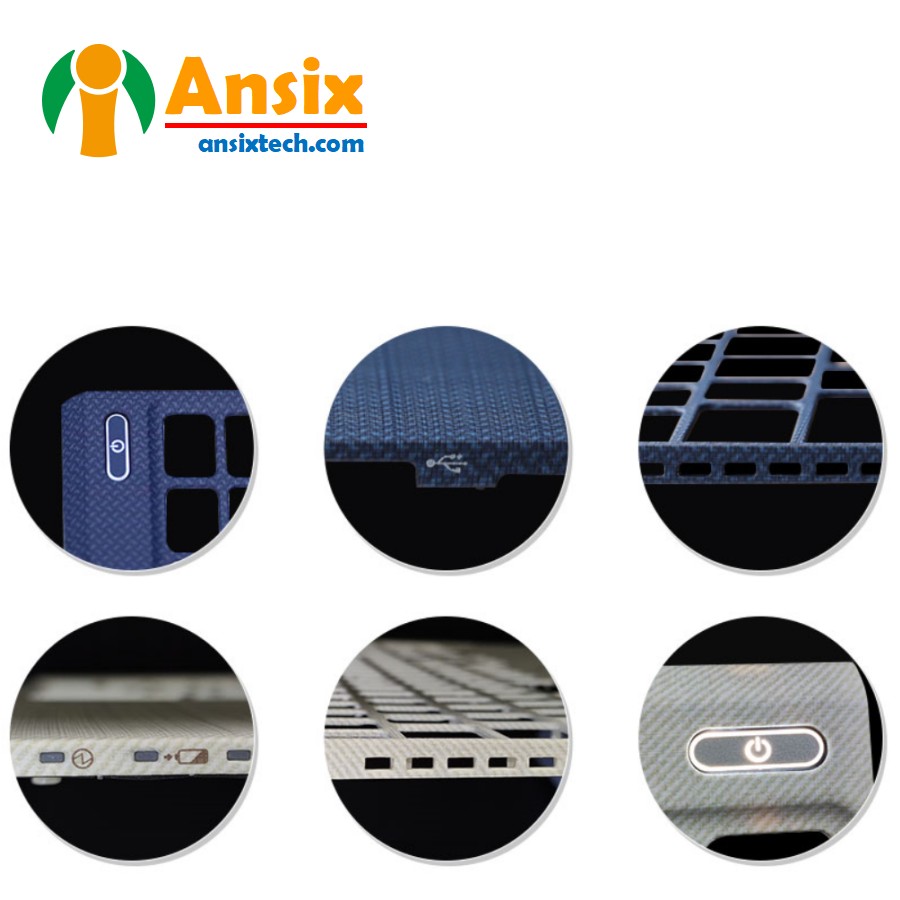

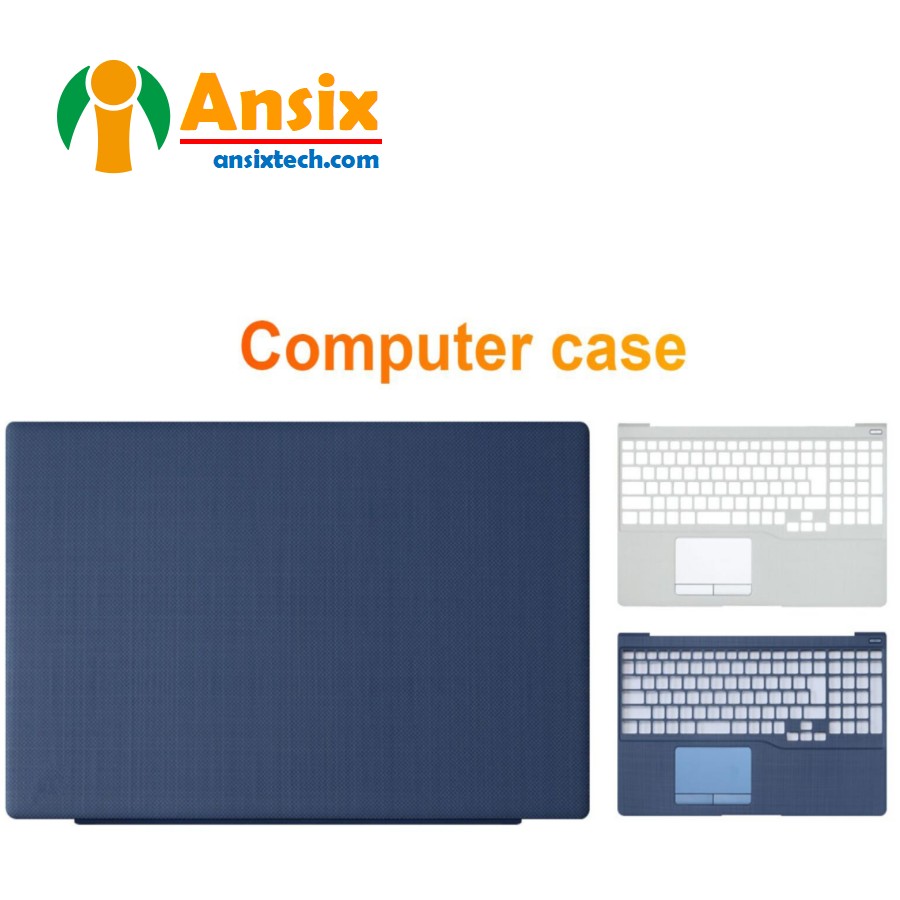

- Computer case

OMD&TOM surface decoration technology can be applied to various components of notebook computers to improve their appearance quality, personalized features and sense of quality.Shell: The shell of a laptop is the most intuitive part and can be decorated through spraying, printing, engraving and other techniques. For example, spray paint can change the color and gloss of the shell, printing can print patterns and text on the shell, and engraving can engrave textures and patterns on the shell.Keyboard: The keyboard of a laptop computer is a part that users often touch, and it can be decorated through printing, hot stamping and other technologies. For example, printing can print special patterns and text on the keyboard, and hot stamping can stamp metal foil on the keyboard.Touchpad: The touchpad of a laptop is an important part of user operation and can be decorated through printing, engraving and other technologies. For example, printing can print special patterns and text on the touch panel, and engraving can engrave textures and patterns on the touch panel.Frames and edges: The frames and edges of laptops can be decorated through spraying, printing and other techniques. For example, spray paint can change the color and gloss of the borders and edges, and printing can print special patterns and text on the borders and edges.Logos and logos: Laptop logos and logos are important representatives of the brand and can be decorated through printing, hot stamping and other techniques. For example, printing can print the brand name and pattern on the logo, and hot stamping can hot stamp metal foil on the logo.In addition to the above components, there are many other notebook components that can apply OMD&TOM surface decoration technology, such as screen borders, interface sockets, heat dissipation holes, etc. Through the application of OMD&TOM surface decoration technology, notebook computers can be provided with more personalized choices and decorative effects to meet consumers’ needs for appearance. If you have any questions about products in the plastic molding and mold field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

- Consumer/Phone

OMD&TOM surface decoration technology can be applied to various 3C consumer product components to improve their appearance quality, personalized features and sense of quality. The following are some common 3C consumer product components that can be applied with OMD&TOM surface decoration technology:

Mouse: The mouse is an important part of user operation and can be decorated through printing, engraving and other technologies. For example, printing can print special patterns and text on the mouse, and engraving can engrave textures and patterns on the mouse.

Headphones: Headphones are an important part of audio equipment and can be decorated through printing, spraying and other technologies. For example, printing can print special patterns and text on the earphones, and spray paint can change the color and gloss of the earphones.

Speakers: Speakers are an important part of audio equipment and can be decorated through spraying, printing and other technologies. For example, spray paint can change the color and gloss of the speaker, and printing can print special patterns and text on the speaker.

Shell and panel: The shell and panel of 3C consumer products are the most intuitive parts and can be decorated through spraying, printing, engraving and other technologies. For example, spray paint can change the color and gloss of the shell and panels, printing can print patterns and text on the shells and panels, and engraving can engrave textures and patterns on the shells and panels.

Mobile phone case: The mobile phone case is the most intuitive part and can be decorated through spraying, printing, engraving and other techniques. For example, spray coating can change the color and gloss of the mobile phone case, printing can print patterns and text on the mobile phone case, and engraving can engrave textures and patterns on the mobile phone case.

Screen: The screen of a mobile phone is a part that users often come into contact with and can be decorated through printing, laser engraving and other technologies. For example, printing can print special patterns and text on the screen, and laser engraving can achieve high-precision patterns and text on the screen.

Keys and buttons: The keys and buttons of 3C consumer products can be decorated through printing, hot stamping and other technologies. For example, printing can print special patterns and text on keys and buttons, and hot stamping can hot stamp metal foil on keys and buttons.

Frames and edges: The frames and edges of 3C consumer products can be decorated through spraying, printing and other technologies. For example, spray paint can change the color and gloss of the borders and edges, and printing can print special patterns and text on the borders and edges.

Logos and logos: The logos and logos of 3C consumer products are important representatives of the brand and can be decorated through printing, hot stamping and other techniques. For example, printing can print the brand name and pattern on the logo, and hot stamping can hot stamp metal foil on the logo.The mold manufacturing process and product material selection of plastic products are key factors to ensure product quality and production efficiency.

- There are several reasons to choose AnsixTech for water transfer printing, IMD, INS, TOM, OMD and DOD processes

Rich experience: AnsixTech has extensive experience and expertise in water transfer printing and related processes. They understand the characteristics of different materials and products and can provide professional technical support and solutions.High-quality products: AnsixTech is committed to providing high-quality water transfer printing and related process products. They use advanced equipment and technology to ensure that the pattern transfer is clear and stable, with good durability and decorative effects.Customized services: AnsixTech can provide customized water transfer printing and related process services according to customer needs and requirements. Whether it is pattern design, material selection or process flow, all can be adjusted and optimized according to customer requirements.Diversified application fields: AnsixTech’s water transfer printing and related processes can be used in many fields, such as automobiles, furniture, electronic products, toys, etc. Whether it is mass production or small batch customization, we can meet customer needs.Excellent customer service: AnsixTech focuses on communication and cooperation with customers and provides excellent customer service. They are able to respond promptly to customer needs and questions and provide professional advice and solutions.If you choose AnsixTech for water transfer printing, IMD, INS, TOM, OMD and DOD processes, you can get professional technical support, and we have more than 10 years of work experience and technology accumulation in automotive interior decoration technology.high-quality products and customized services to meet the needs of different fields. If you have any questions about products in the plastic molding and mold field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.