Out Mold decoration technology

FEATURES

- Out Mold decoration technology

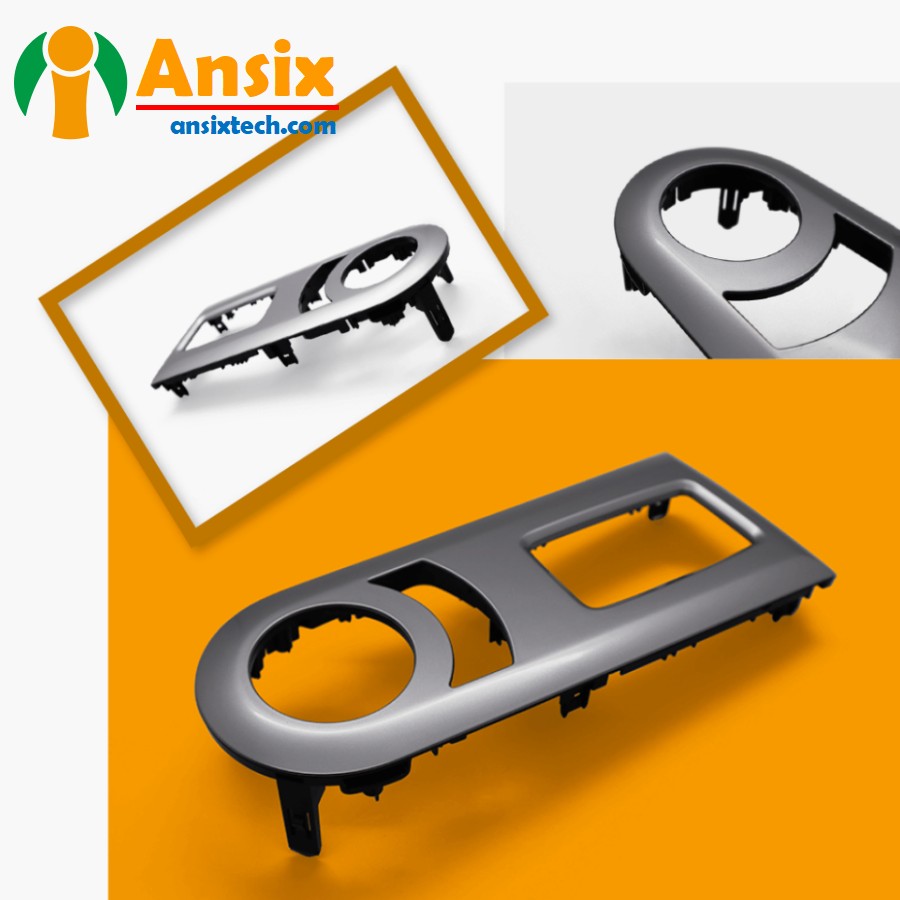

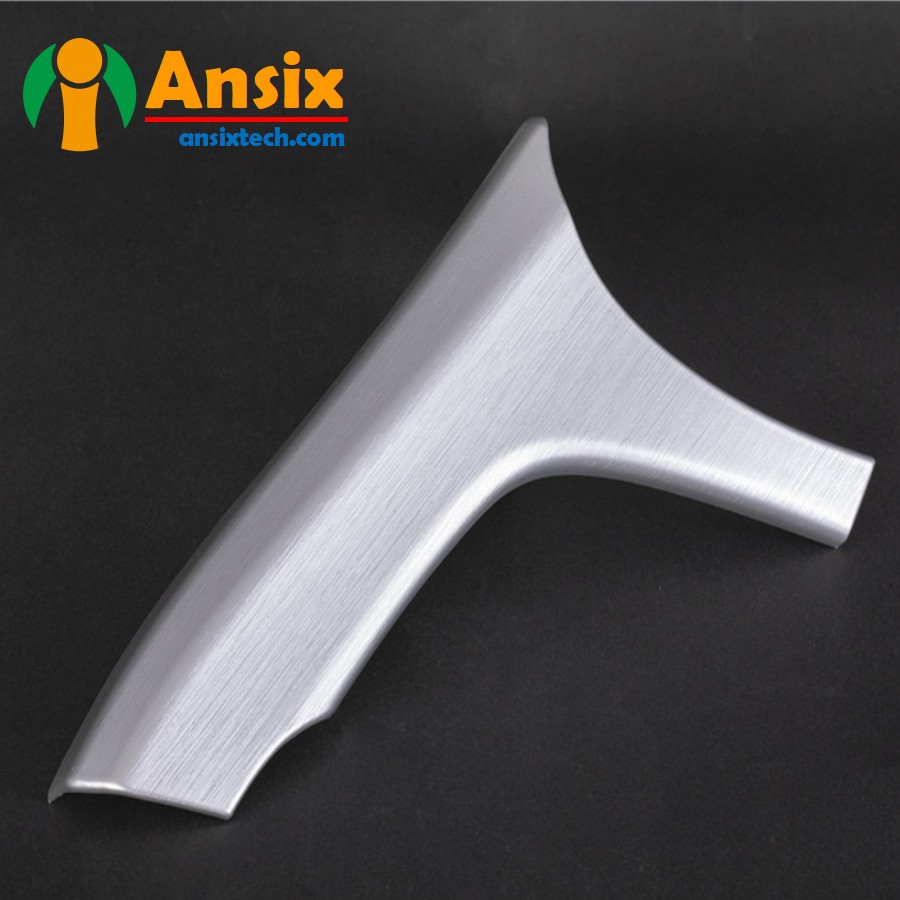

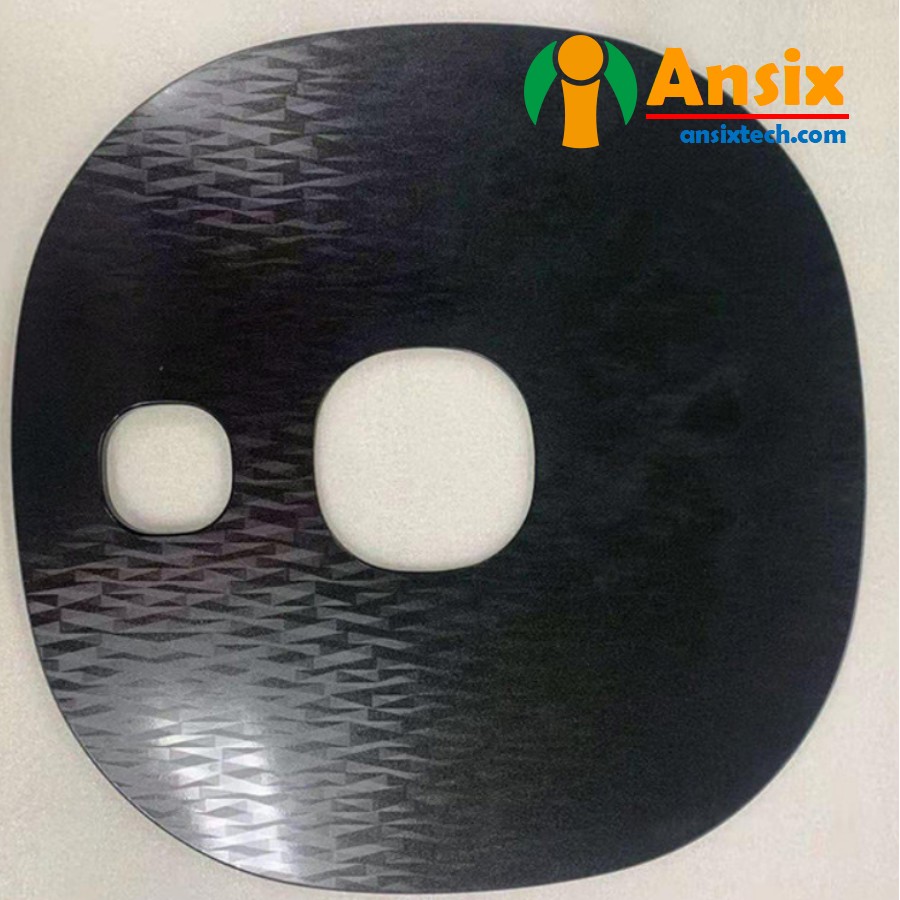

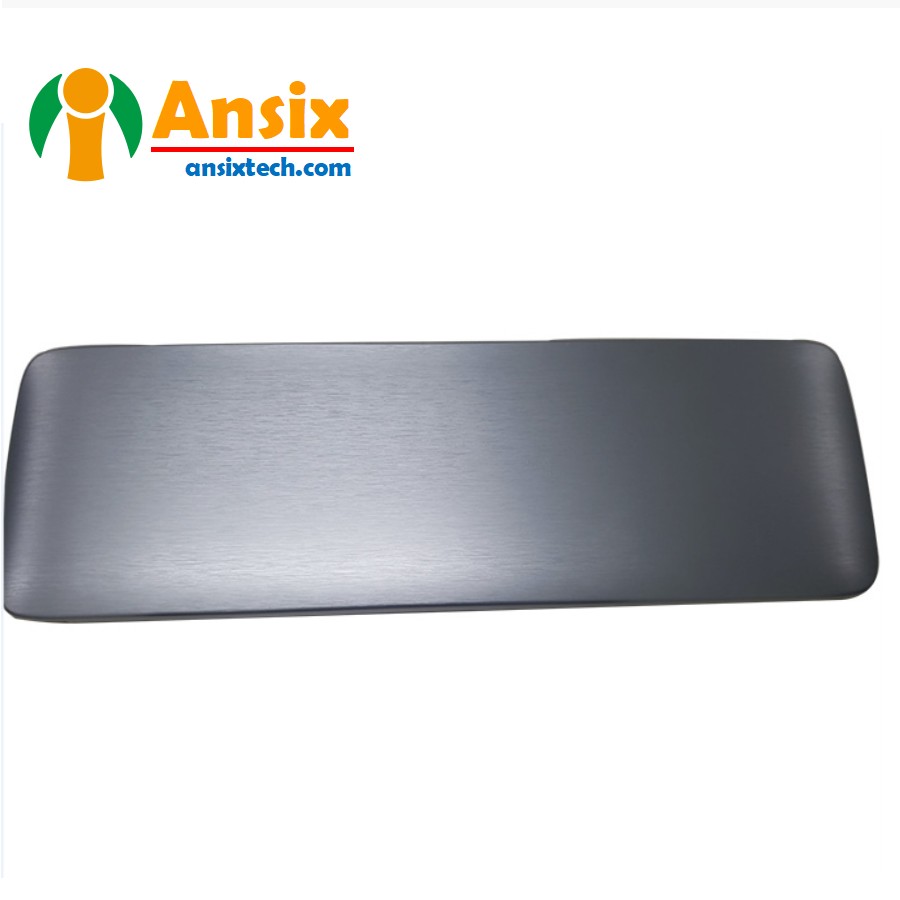

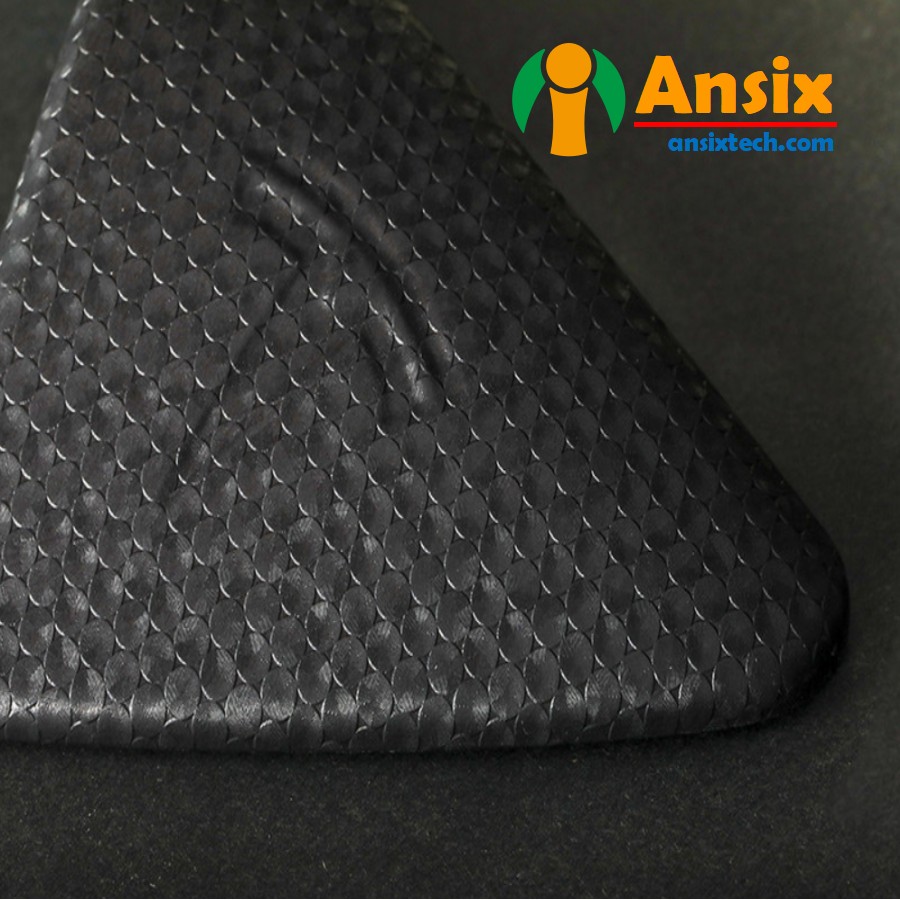

The following are some common applications of out-of-mold decoration OMD processes:Mobile phone cases and electronic products: The out-of-mold decoration OMD process can provide personalized decorative effects for mobile phone cases, tablets, laptops and other electronic products. Products can be made more attractive and unique by applying different decorative materials and patterns.Household items: The out-of-mold decoration OMD process can be applied to household items, such as furniture, lamps, decorations, etc. You can add beauty and personalization to your home products by adding decorative materials and patterns.Automotive interiors: The out-of-mold decoration OMD process can be used for automotive interior parts, such as instrument panels, central control panels, door trims, etc. By applying different decorative materials and patterns, the luxury and decorative effect of the car’s interior can be enhanced.Packaging boxes and gift boxes: The out-of-mold decoration OMD process can provide unique decorative effects for packaging boxes and gift boxes. By applying decorative materials and patterns, you can make the packaging box more attractive and increase the value and appeal of the gift.Personal accessories: The out-of-mold decoration OMD process can be applied to personal accessories, such as watches, glasses, jewelry, etc. It is possible to add style and personalization to personal accessories by applying different decorative materials and patterns.The out-of-mold decoration OMD process has a wide range of applications and can be customized and innovated according to the needs of different products. It can provide rich and diverse decorative effects, making products more attractive and unique. When performing the out-of-mold decoration OMD process, attention needs to be paid to selecting appropriate decorative materials and adhesives, and controlling process parameters to ensure the decorative effect and product quality.

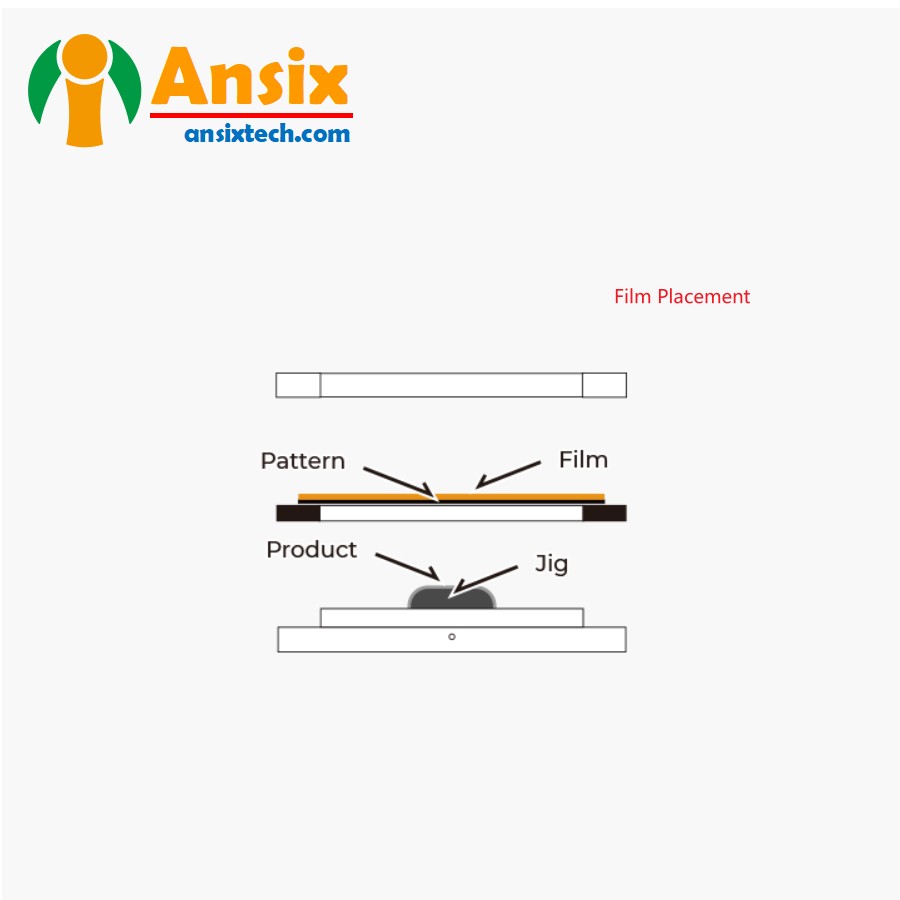

- Out Mold decoration technology process

OMD out-of-mold decorative diaphragm implantation refers to an out-of-mold decoration process that embeds decorative diaphragms into the surface of the product. This process can provide a unique decorative effect to the product, making it more attractive.The following are the general steps for OMD out-of-mold decorative diaphragm implantation:Prepare the decorative diaphragm: Choose a suitable decorative diaphragm, which can be a film material with patterns, textures or special effects.Prepare the product substrate: Make sure the surface of the product substrate is clean and flat, and perform necessary pretreatment, such as cleaning, sanding or applying primer.Make a diaphragm notch: Make a notch or groove suitable for decorative diaphragm on the product surface. This can be achieved by cutting, engraving or other processing methods.Place the decorative diaphragm in the notch: Carefully place the decorative diaphragm in the notch, ensuring that the diaphragm is tightly attached to the product base material.Apply adhesive or hot melt technology: Apply adhesive or hot melt glue around the notch to secure the decorative diaphragm. Adhesives or hot melt glue can make the film firmly bonded to the product surface.Pressing and curing: Use appropriate pressure and temperature to press the decorative film and the product base material to make them firmly adhered. Depending on the adhesive or hot melt glue requirements, some curing time may be required.Inspection and trimming: Check the decorative effect to ensure the fit and appearance quality of the decorative film and the product base material. use an edge tool or sandpaper to trim the edges to make them smoother and neater.The OMD out-of-mold decorative diaphragm implantation process can be applied to various products, such as mobile phone cases, electronic products, household items, etc. It can provide a unique decorative effect to the product, increasing its visual appeal and personalization. When implanting the OMD out-of-mold decorative film, you need to pay attention to selecting the appropriate decorative film and adhesive, as well as controlling the pressure, temperature and curing time to ensure the decorative effect and product quality.

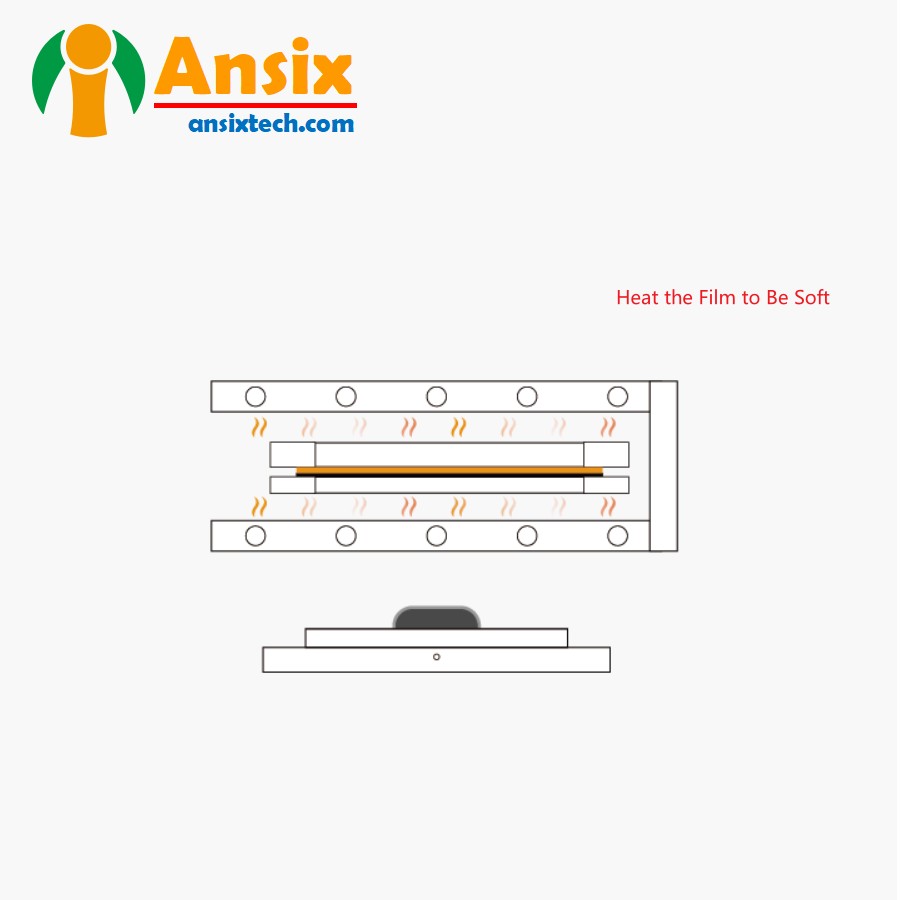

- Heat the Film to Be Soft

In OMD out-of-mold decoration, it is sometimes necessary to heat the film to a softened state in order to better adhere to the product surface. Here are the general steps for heating a film to a softened state:Prepare decorative film: Choose a suitable decorative film, usually made of PET or PC material. Make sure the quality and dimensions of the film meet requirements.Prepare heating equipment: Use special heating equipment, such as a heat gun, hot plate or hot melt equipment. Select the appropriate heating temperature and time according to the film material and thickness.Heating the film: Place the film on the heating device to heat it. According to the characteristics of the film material, the heating temperature and time are controlled to make the film reach a softened state.Monitor the heating process: During the heating process, the condition of the film must be closely monitored to avoid overheating or burning. If needed, tools such as infrared thermometers can be used to monitor the temperature of the film.Attach the film: When the film reaches a softened state, carefully attach it to the product surface. Ensure that the film adheres closely to the product substrate and eliminates air bubbles or wrinkles.Cooling and solidification: After the film is attached to the product surface, wait for the film to cool and solidify. Depending on the film material and process requirements, a certain cooling time may be required.Heating the film to a softened state is an important step in OMD out-of-mold decoration, which allows the film to better fit the product surface and achieve better decorative effects. When performing the heating process, attention needs to be paid to controlling the heating temperature and time to avoid overheating or burning of the film. At the same time, be careful to avoid damage to the film and yourself.

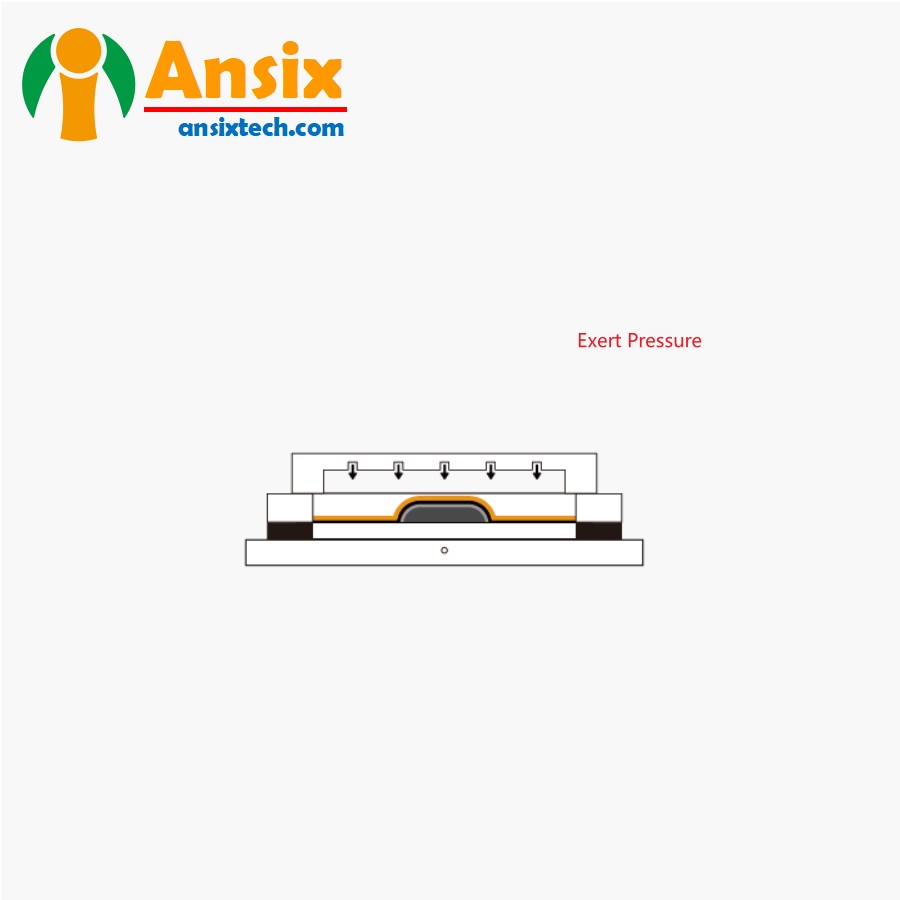

- Exert Pressure

In OMD out-of-mold decoration, applying appropriate pressure is an important step to ensure that the decoration material adheres closely to the product base material. By applying pressure, problems such as bubbles, wrinkles, and poor fit can be eliminated for better decorative results.Here are the general methods for applying pressure in OMD out-of-mold decoration:Prepare decorative materials: Choose suitable decorative materials, such as film, stickers or printed patterns. Make sure that the quality and size of the decorative materials are as required.Prepare pressure equipment: Use special pressure equipment, such as a laminator, press or heat press. Choose the appropriate pressure method and pressure according to the requirements of the decorative materials and products.Place the decorative material on the product surface: Carefully place the decorative material on the product surface to ensure a tight fit with the product base material.Apply pressure: Use pressure equipment to apply appropriate pressure between the decorative material and the product base material. The amount of pressure depends on the characteristics of the decorative material and the requirements of the product, and can be adjusted according to the actual situation.Control the pressure time: Control the pressure time according to the requirements of the decorative materials and products. Generally, a longer pressure time can better ensure that the decorative material adheres to the product substrate.Release pressure: After the pressure application time is over, gradually release the pressure from the pressure application device. Ensure that the decorative material and product base material maintain a tight fit.By applying appropriate pressure, you can ensure the tight fit of the decorative material and the product base material to achieve better decorative effects. When performing the pressure application process, attention needs to be paid to controlling the intensity and time of the pressure to avoid damage to the product and decorative materials. At the same time, the pressure parameters should be adjusted according to the specific decorative materials and product requirements to obtain the best decorative effect.

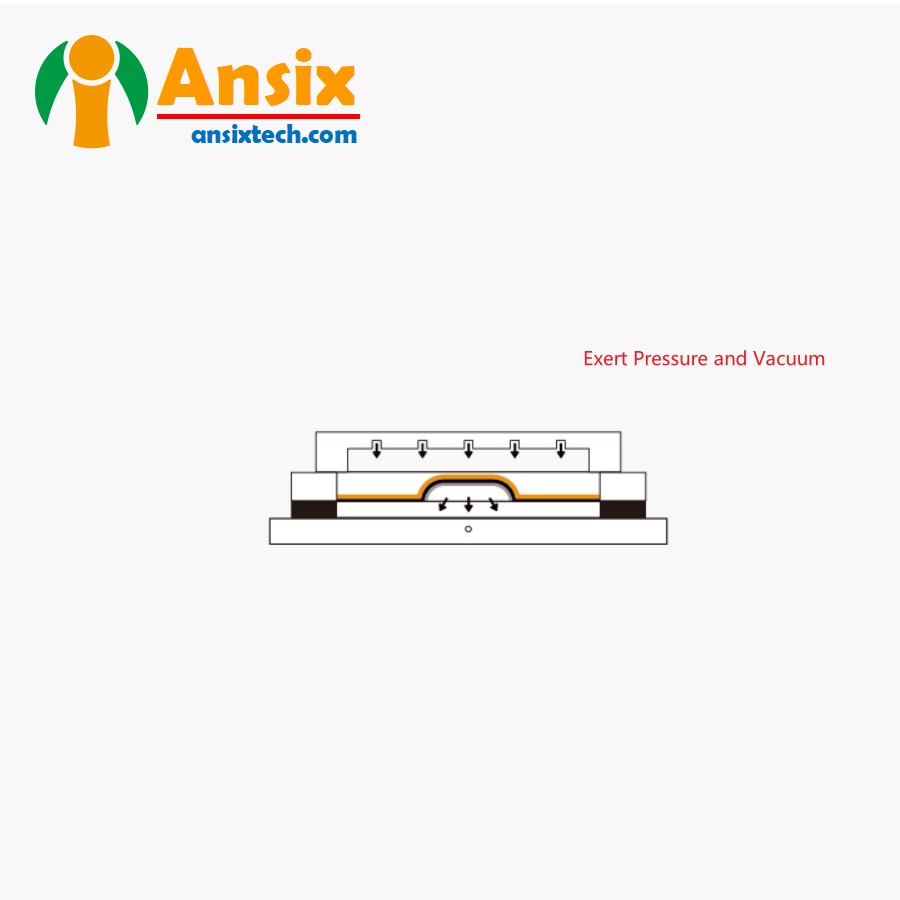

- Exert Pressure and Vacuum

During the OMD out-of-mold decoration process, vacuuming is a commonly used technique to ensure a tight fit between the decoration material and the product base material, and to eliminate problems such as bubbles and wrinkles. By vacuuming, a low-pressure environment can be created to allow the decorative material to better adhere to the product surface.The following are the general steps for vacuuming in OMD out-of-mold decoration:Prepare decorative materials: Choose suitable decorative materials, such as film, stickers or printed patterns. Make sure that the quality and size of the decorative materials are as requiredPrepare vacuum equipment: Use special vacuum equipment, such as a vacuum table or vacuum adsorption device. Ensure proper performance and operation of vacuum equipment.Place the decorative material on the product surface: Carefully place the decorative material on the product surface to ensure a tight fit with the product base material.Enclose the decorative area: Use sealing materials or vacuum gaskets to seal the decorative area to ensure the formation of a vacuum environment.Start the vacuum equipment: Start the vacuum equipment and start extracting the air in the decorative area. According to the requirements of decorative materials and products, control the vacuum pressure and time.Observe the fit of the decorative materials: During the vacuuming process, observe the fit of the decorative materials and the base material of the product. Make sure the upholstery material has no bubbles, wrinkles or poor fit.Stop vacuuming and release the pressure: When the decorative material and the product base material fit well, stop vacuuming and gradually release the pressure of the vacuum equipment.By vacuuming, bubbles and wrinkles that may occur during the decoration process can be effectively eliminated, ensuring a tight fit between the decoration material and the product base material. When performing the vacuuming process, attention needs to be paid to controlling the vacuuming pressure and time to avoid damage to products and decorative materials. At the same time, the vacuum parameters should be adjusted according to the specific decorative materials and product requirements to obtain the best decorative effect.

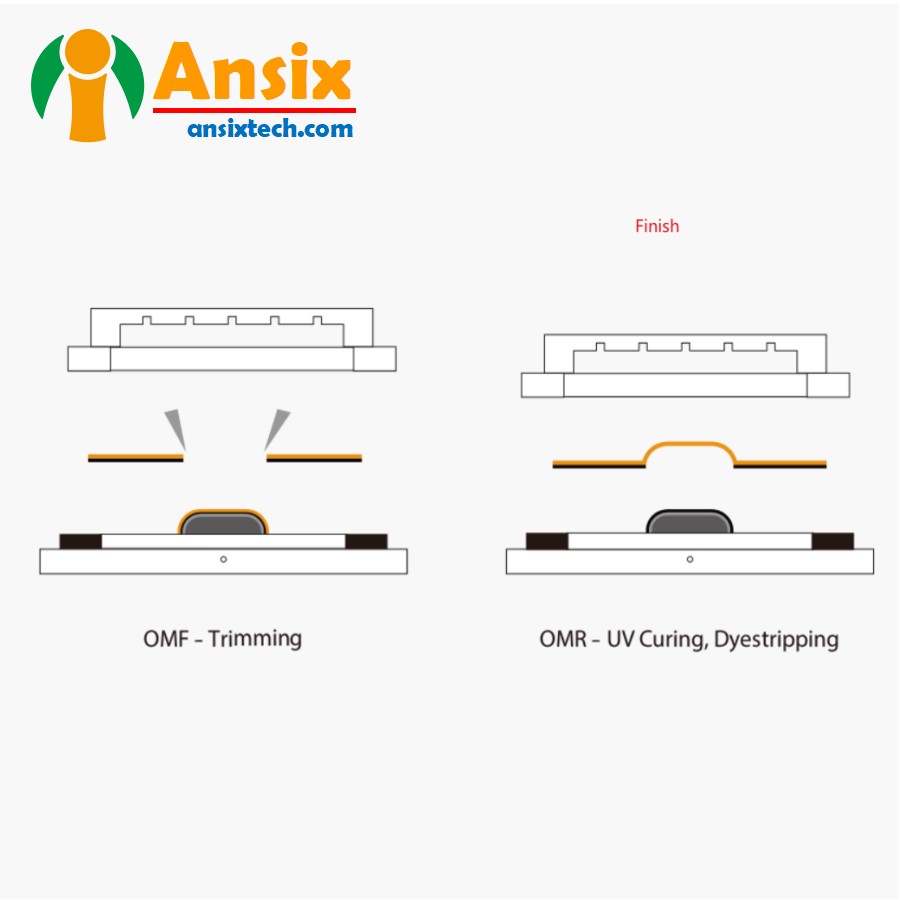

- Finish

When the OMD out-of-mold decoration is complete, the following steps to process and inspect the final product:Take out the product: Take out the decorated product from the decoration area. Be careful to remove it gently to avoid damaging the decorative material or product substrate.Check the decorative effect: Carefully check the decorative effect of the product to ensure that the decorative material is tightly attached to the product base material, and there are no bubbles, wrinkles or poor fit.Cleaning and finishing: If necessary, use a soft cloth or detergent to gently wipe the surface of the product to remove dust or stains. At the same time, you can use trimming tools or sandpaper to trim the edges of the product to make it smoother and neater.Functional testing: Carry out functional testing of the product to ensure that the decoration process does not affect the normal use of the product. For example, for electronic products, you can test the sensitivity and tactile feel of the keys.Packaging and quality inspection: Packaging and quality inspection are carried out according to product requirements. Ensure that the product’s packaging is intact and conduct quality checks to ensure that the product meets relevant standards and requirements.After the OMD out-of-mold decoration is completed, the product can enter the next step of the process, Logistics and transportation delivered to customersThroughout the process, attention is paid to maintaining the quality and appearance of the product to provide a satisfactory user experience. If you have any questions about products in the plastic molding and mold field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

- There are several reasons to choose AnsixTech for TOM, OMD and DOD processesThere may be the following reasons for choosing AnsixTech to manufacture TOM (Transfer Over Molding), DOD (Drop On Demand) and OMD (Optical Molding Decoration) out-of-mold decoration technologies:Professional knowledge and experience: AnsixTech may have extensive professional knowledge and experience in TOM, DOD and OMD out-of-mold decoration technology and be able to provide high-quality manufacturing services.Technical capabilities: AnsixTech may have advanced equipment and technology to implement TOM, DOD and OMD out-of-mold decoration technologies and meet customer requirements.Innovation and uniqueness: TOM, DOD and OMD out-of-mold decoration technologies are relatively new and unique decoration technologies. Choosing AnsixTech can gain its innovative capabilities and unique solutions in these technologies.Customized Solutions: AnsixTech may be able to provide customized solutions based on customer needs to meet specific product requirements and designs.Quality control and quality assurance: AnsixTech may have strict quality control measures and quality assurance systems to ensure that manufactured products meet customer requirements and standards.Service and support: AnsixTech may provide comprehensive services and support, including technical consulting, design support, production management, etc., to ensure the successful implementation of the project.