PC plastic injection mold moldeo por inyeccion Precision transparent handle parts

FEATURES

| Product Materials: | PC |

| Mold Material: | S136SER |

| Number of Cavities: | 1*2 |

| Glue Feeding Method: | Cold runner |

| Cooling Method: | Water cooling |

| Molding Cycle | 42.5s |

- Mold Marking Process

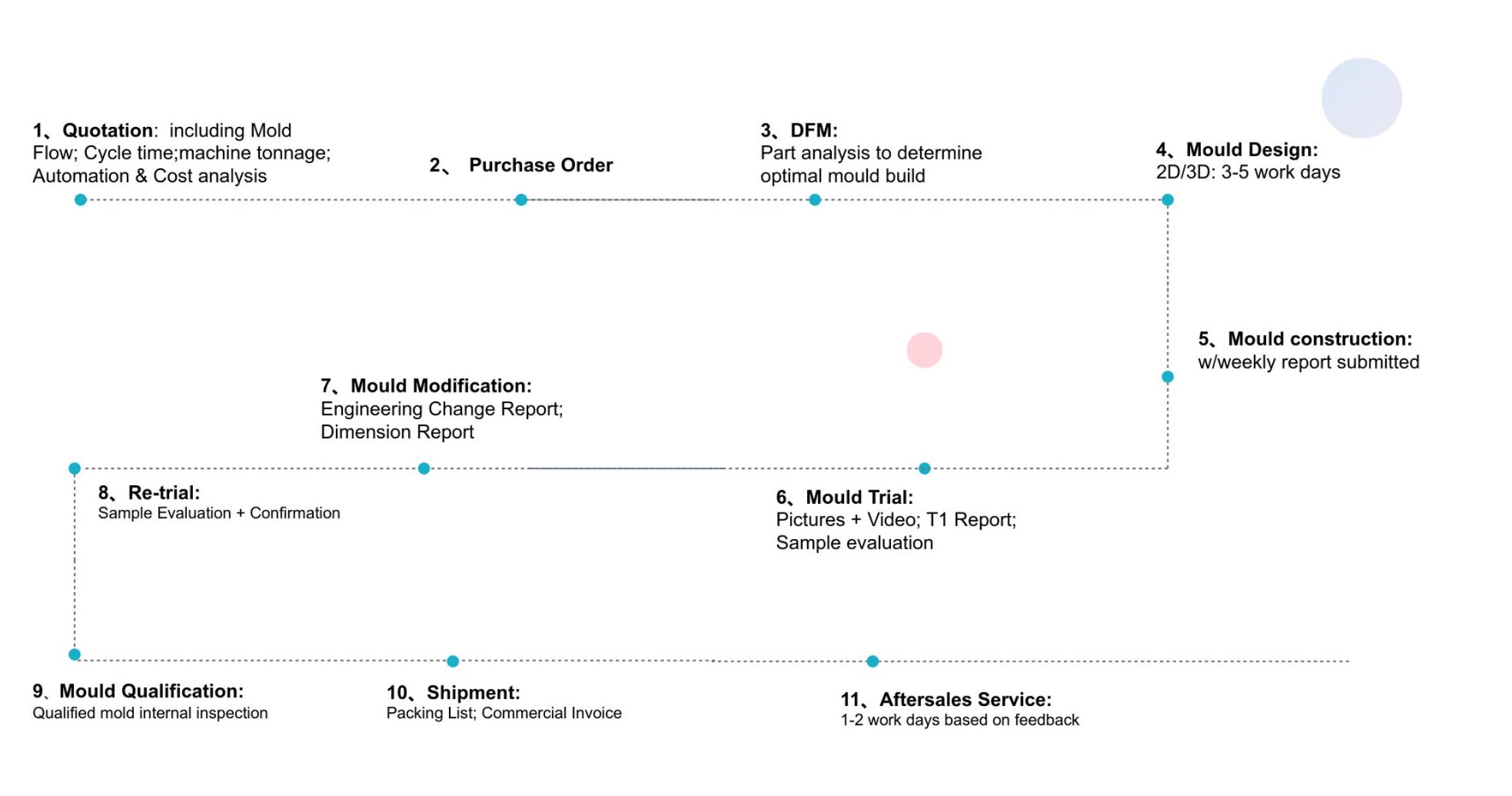

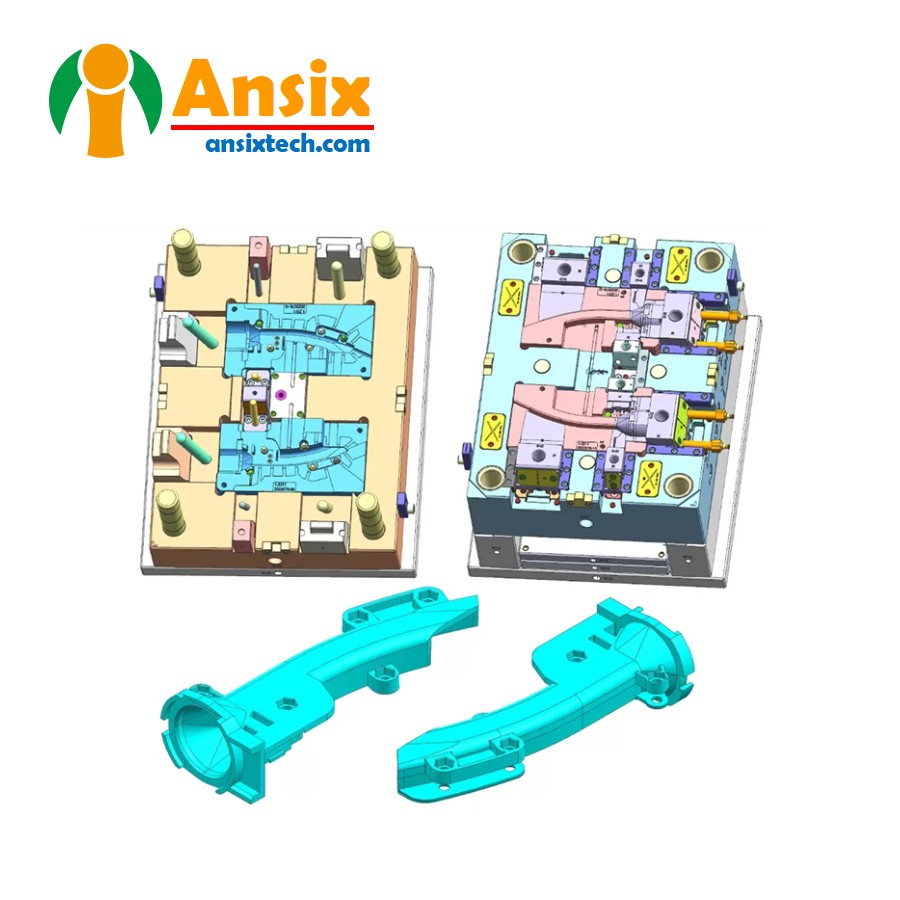

- PC Precision transparent handle Mold flow analysis and mold designPC precision transparent handle mold design and mold flow analysisHandle mold design is one of the key steps in manufacturing PC precision transparent handles. During the design process, aspects such as the handle’s appearance design, internal structure design, material selection, and mold design need to be considered. At the same time, mold flow analysis is also a very important step, which can help optimize the mold design and ensure that the handles produced are of high quality.First of all, appearance design is an important part of handle mold design. The appearance of the handle should be ergonomic, comfortable to hold, and easy to operate. You can refer to existing handle designs on the market, or you can create innovative designs based on personal preferences. The transparent shell can add a sense of technology and fashion to the handle. In the appearance design, factors such as the overall shape of the handle, the layout of the buttons, and the position of the rocker need to be considered.Secondly, the internal structure design is also an important part of the handle mold design. There should be enough space inside the handle to accommodate components such as circuit boards, buttons, joysticks, etc. Consideration needs to be given to the layout and fastening of components to ensure they fit securely inside the handle. At the same time, the connection method between the circuit board and the casing also needs to be considered to ensure the stability and reliability of the circuit board.Material selection is another important aspect of handle mold design. The shell of the transparent handle can be made of transparent plastic material, such as polycarbonate (PC) or polymethylmethacrylate (PMMA). These materials have good transparency and durability, can meet the appearance requirements of the handle, and have sufficient strength and wear resistance.Finally, mold design is a key part of handle mold design. According to the appearance design and internal structure design of the handle, the mold of the handle is made. The mold should be highly precise and durable to ensure consistent appearance and size of the handles produced. Mold design needs to consider factors such as the overall shape of the handle, the mold parting method, and the cooling system. At the same time, the manufacturing process and cost of the mold also need to be considered to ensure the manufacturing efficiency and economy of the mold.Mold flow analysis is an important step in the handle mold design process. Through mold flow analysis, the flow of plastic during the injection process can be simulated to help optimize mold design and avoid defects such as bubbles, short shots, and warpage. Mold flow analysis can be carried out using professional mold flow analysis software. According to the geometry of the mold and injection molding process parameters, the flow of plastic in the mold is simulated and corresponding analysis results and suggestions are given. Through mold flow analysis, the design of the mold can be optimized and the production efficiency and quality of the handle can be improved.In summary, PC precision transparent handle mold design and mold flow analysis are key steps in manufacturing PC precision transparent handles. During the design process, aspects such as appearance design, internal structure design, material selection and mold design need to be considered. At the same time, mold flow analysis can help optimize mold design to ensure that the handles produced are of high quality. Through reasonable design and analysis, PC precision transparent handles with beautiful appearance and reliable quality can be produced.

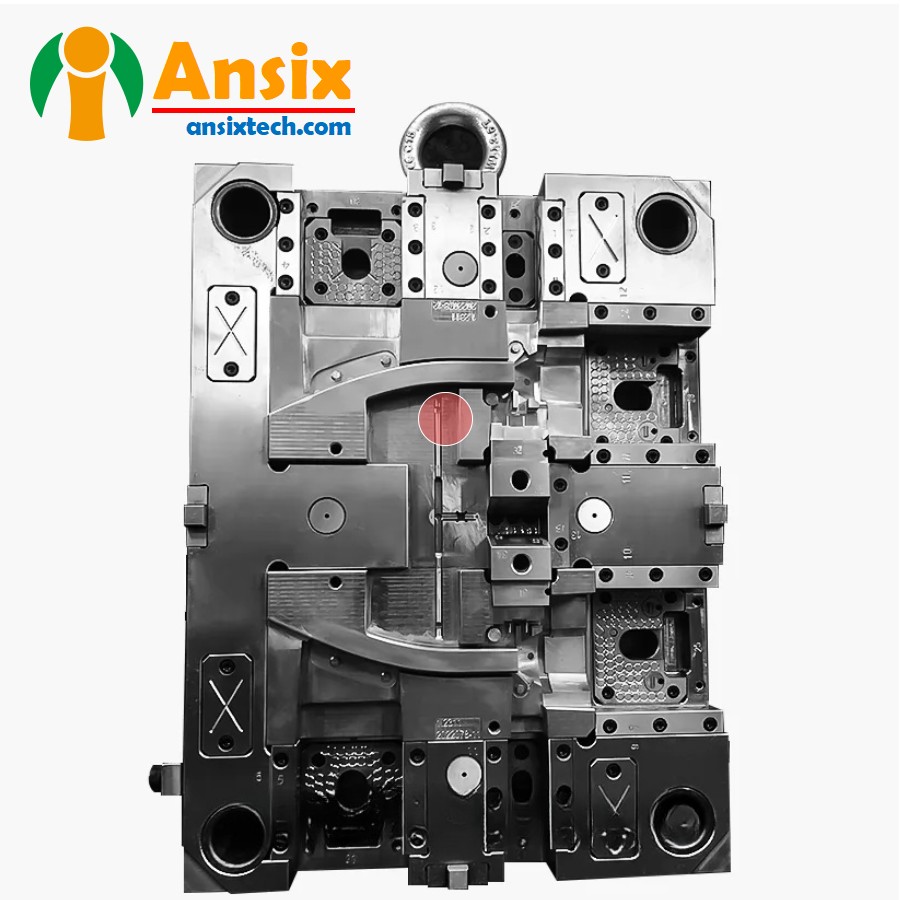

- PC Precision transparent handle of the mold manufacturing process and product material selectionPC material precision transparent handle mold manufacturing and processing, component material PC selection and mold surface treatment are one of the key steps in manufacturing PC precision transparent handle:PC material selection:PC material is an engineering plastic with excellent transparency, high strength and heat resistance, which is very suitable for manufacturing precision transparent handles. When choosing PC materials, you need to consider the following factors:Transparency: PC material has good transparency, which can make the handle shell show a clear transparent effect.-Strength: PC material has high strength, which can ensure the durability and impact resistance of the handle.Heat resistance: PC material has high heat resistance and can maintain stable performance over long periods of use.Processing performance: PC material has good fluidity and formability, and is suitable for injection molding and other processing methods.Mold manufacturing and processing:Mold manufacturing and processing is one of the key steps in manufacturing PC precision transparent handles. During the mold manufacturing process, the following aspects need to be considered:Mold material: The mold material should have high hardness, high wear resistance and high corrosion resistance to ensure the service life and stability of the mold. Commonly used mold materials include high-quality alloy steel, stainless steel, etc.Mold design: The mold design should be based on the appearance design and internal structure design of the handle to ensure the consistency of the size and shape of the handle. At the same time, factors such as the mold parting method and cooling system also need to be considered.Mold processing: Mold processing includes CNC machining, EDM, wire cutting and other processes to create precision mold parts. High precision and quality need to be ensured during processing.Mold surface treatment:Mold surface treatment is to improve the wear resistance of the mold, reduce the friction coefficient, and increase the service life of the mold. Commonly used mold surface treatment methods include:High-gloss surface treatment: Through processes such as polishing and grinding, the surface of the mold is smoothed, improving transparency and appearance quality.Coating treatment: You can choose chrome plating, nickel plating and other treatments to increase the hardness and corrosion resistance of the mold.Nitriding treatment: Through the nitriding process, the hardness and wear resistance of the mold can be improved and the service life of the mold can be extended.In summary, PC material precision transparent handle mold manufacturing and processing, component material PC selection and mold surface treatment are one of the key steps in manufacturing PC precision transparent handles. Selecting suitable PC materials, manufacturing high-quality molds, and performing appropriate mold surface treatment can ensure the production of PC precision transparent handles with beautiful appearance and reliable quality.Injection molding material: Select the appropriate injection molding material according to the requirements of the plastic product and the application environment. Common plastic materials include ABS,PP,PC,ABS/PC,PBT,PMMA,SAN,PA,PA66,PA6,POM,PET,PE,PVT,TPE,TPR,SILICONE,PEEK,PEI,PS,PES,PI,PPSU,PETG,PCTG,PFA,NBR,PTFE,PAEK,PAA,PEAA etc. According to the characteristics and requirements of the product, select materials with appropriate hardness, wear resistance, chemical resistance and other properties.Mold material selection:The selection of mold materials should take into account the shape, size and requirements of the plastic product, as well as the service life and production volume of the mold. Common mold materials include tool steel, stainless steel,738、2738H 、718、718H、NAK80、2083、2316、2344、2083H、2316H、S136、S136H、S136-D、HPM38、M300、S-STAR、M333、S196 etc., which have high hardness and wear resistance.

- PC Precision transparent handle Mass production and Quality controlThe mass production of precision transparent handles made of PC material involves multiple links such as mold polishing, secondary product processing, spray painting, and silk screen printing. During these processes, it is necessary to ensure product quality and production efficiency, and at the same time conduct cost control.Mold polishing:Mold polishing is to improve the smoothness and transparency of the mold surface and ensure the appearance quality of the product. The following points need to be noted during the polishing process:Polishing process: Choose an appropriate polishing process, such as manual polishing, mechanical polishing, etc., to ensure the smoothness and consistency of the mold surface.Polishing materials: Choose appropriate polishing materials, such as abrasive paste, polishing cloth, etc., to ensure the polishing effect and the wear resistance of the mold.Polishing quality control: Carry out quality control during the polishing process, such as checking the polishing effect, testing the smoothness of the mold surface, etc., to ensure that the polishing quality meets the requirements.Secondary processing of products:Secondary processing of products is to further improve the quality and functionality of the product. Common secondary processing includes:Spray painting: Through the spray painting process, a wide range of color options are provided for the product, increasing the appearance quality and attractiveness of the product.Silk screen printing: Through the screen printing process, patterns, text, etc. are printed on the surface of the product to increase the personalization and brand value of the product.Assembly: Assemble the various parts of the handle to ensure the stability and reliability of the product.Process quality assurance:During mass production, process quality assurance is required to ensure product consistency and stability. Common quality assurance measures include:Quality control plan: Develop a quality control plan to clarify the quality requirements and control methods for each link.Inspection and testing: Conduct product inspection and testing, such as appearance inspection, dimensional measurement, functional testing, etc., to ensure that the product meets the requirements.Process monitoring: Monitor the production process, such as temperature control, injection pressure control, etc., to ensure product consistency and stability.Production efficiency and cost control:In the mass production process, it is necessary to pay attention to production efficiency and cost control to improve production efficiency and reduce costs. Common measures include:Automated production: Use automated equipment and production lines to improve production efficiency and stability.Process optimization: Optimize the production process, improve production efficiency and quality, and reduce the scrap rate.Cost control: Reasonably control raw material costs, labor costs and equipment costs to reduce production costs.To sum up, the mass production of precision transparent handles made of PC material involves multiple links such as mold polishing, secondary product processing, spray painting, and silk screen printing. During the production process, it is necessary to ensure product quality and production efficiency, and conduct cost control. Through reasonable quality assurance measures, production efficiency improvement and cost control, high-quality, high-efficiency and low-cost PC precision transparent handle production can be achieved.