Two component 2K injection molding of handle switches

FEATURES

- Two component 2K injection molding of handle switches

Injection molding process: The injection molding process of two-color injection molding of handle switch includes the following steps:a. Inject the first color plastic material into one of the injection cavities of the mold.b. The indexing mechanism rotates the mold so that the plastic material of the first color is filled into part of the mold.c. Inject the second color plastic material into another injection cavity of the mold.d. The indexing mechanism rotates again to fill the second color plastic material into another part of the mold.e. After the plastic material cools and solidifies, take out the handle switch two-color injection molded product.Post-processing: Two-color injection molded products of handle switches may require post-processing, such as burr removal, edge trimming, etc., to improve the appearance quality of the product.The two-color injection molding process of the handle switch requires strict control of injection molding parameters and mold design to ensure that the two colors of plastic materials can be well integrated and bonded, while maintaining the size and appearance quality of the product.,please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

-

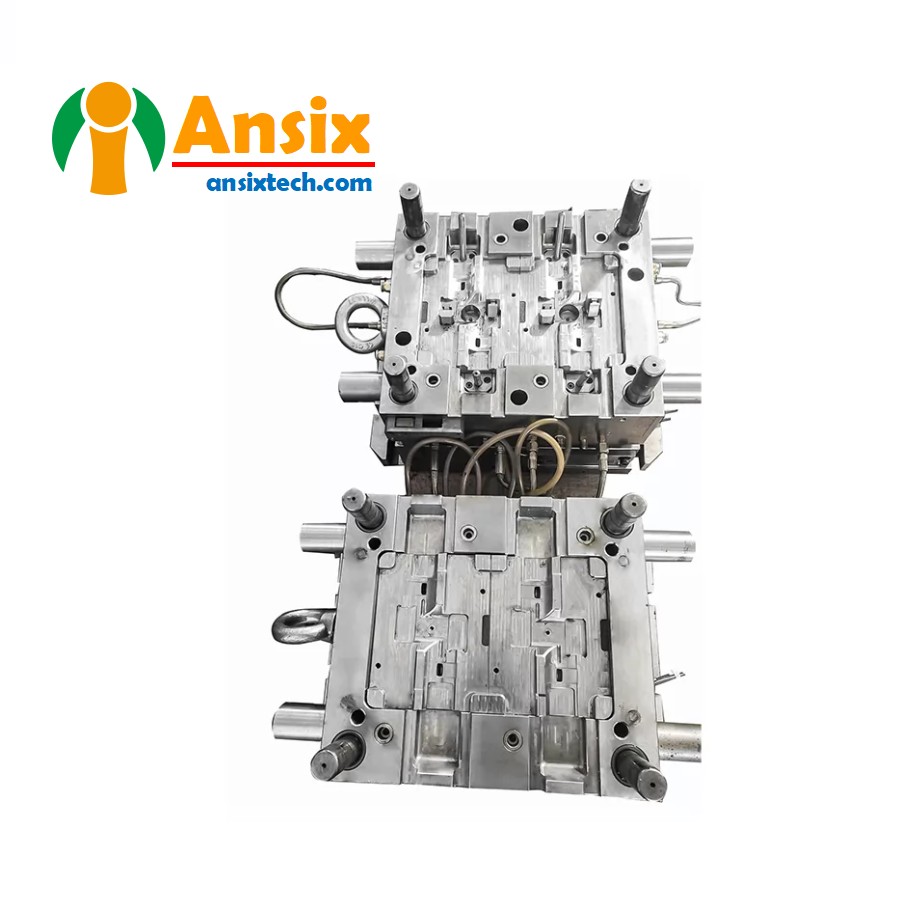

Mold Description

Product Materials:

PC

Soft rubber: TPV

Mold Material:

S136ESR

Number of Cavities:

4+4

Glue Feeding Method:

Cold runner

Cooling Method:

Water cooling

Molding Cycle

32.5s

- handle switches Mold flow analysis and mold designFor the mold flow analysis and 2K two-color mold design of the handle button:Mold flow analysis:a. Collect relevant information about the handle buttons, including size, shape, material, etc.b. Use mold flow analysis software to import the CAD model of the handle buttons and set injection molding process parameters, such as injection speed, temperature, pressure, etc.c. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance of the buttons, bubbles, short shots and other defects, and optimize the injection molding process parameters.2K two-color mold design:a. Determine the structure and size of the 2K two-color mold based on the mold flow analysis results. Taking into account the shape and requirements of the button, design an appropriate mold structure, including mold cavity, mold core, demoulding system, cooling system, etc.b. Determine the process flow of two-color injection molding, including injection sequence, color switching method, etc.c. Carry out detailed design of the mold, including the processing technology of the mold parts, assembly method, design of the demoulding mechanism, etc.d. Use CAD software for mold design and generate three-dimensional models and engineering drawings of the mold.During the mold flow analysis and 2K two-color mold design process, you need to pay attention to the following points:Ensure the filling performance of the buttons: Through mold flow analysis, the injection molding process parameters are optimized to ensure that the filling performance of the handle buttons is good and avoid defects.Design of cooling system: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and avoid problems such as button deformation and shrinkage.Design of demoulding system: According to the shape and requirements of the button, design a suitable demoulding system to ensure that the button can be demoulded smoothly and avoid damage and deformation.Injection molding sequence and color switching: Determine the process flow of two-color injection molding, including the injection sequence and color switching method, to ensure the effect and quality of two-color injection molding.For the mold flow analysis of the two-color mold of the handle button and the design of the 2K two-color mold, it is necessary to conduct a mold flow analysis, optimize the injection molding process parameters, design the appropriate mold structure and size, determine the two-color injection molding process, and conduct a detailed design of the mold. Through reasonable design and control, high-quality two-color injection molded handle buttons can be obtained.

- handle switches of mold manufacturing process and product material selectionFor the manufacturing and processing of two-color molds for handle buttons and the selection of button materials (PC rubber-coated TPV):Mold manufacturing and processing:a. According to the mold design drawings, select appropriate processing technology and equipment, such as CNC machining centers, EDM machines, etc.b. Process mold parts, including mold cavity, mold core, demoulding system, cooling system, etc. Ensure that the processing accuracy and size meet the requirements.c. Assemble the mold parts to ensure accurate fit and adjustment of the parts and ensure the stability and reliability of the mold.Button material selection:a. PC encapsulated TPV is a material that combines PC plastic and TPV elastomer. It has high strength, stiffness and impact resistance, as well as good flexibility and wear resistance.b. PC encapsulated TPV material has good chemical resistance and can resist the erosion of some chemical substances, and is suitable for use under various environmental conditions.c. PC-coated TPV material has good surface texture and touch, and can provide good feel and comfort.During the mold manufacturing process and button material selection process, you need to pay attention to the following points:Processing accuracy and size control: Ensure that the processing accuracy and size of mold parts meet the requirements to ensure the quality and stability of injection molding.Surface treatment: According to the requirements of the keys, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the keys.Heat treatment of materials: According to the requirements of the mold material, appropriate heat treatment, such as quenching, tempering, etc., is performed to improve the hardness and wear resistance of the material.Mold maintenance and upkeep: Regularly maintain and maintain the mold, including cleaning, lubrication, repair, etc., to extend the service life of the mold and ensure the stability of production.In short, for the manufacturing and processing of two-color molds for handle buttons and the selection of button materials (PC rubber-coated TPV), it is necessary to select appropriate processing techniques and equipment to ensure processing accuracy and dimensional control. In terms of button material selection, consider the requirements of the buttons and the use environment, and select PC-coated TPV materials with good mechanical properties, wear resistance and chemical resistance. Through reasonable manufacturing processing and material selection, high-quality two-color injection molded handle buttons can be achieved.

- handle switches Mass production and Quality controlFor the injection mass production and quality assurance of two-color molds for handle buttons:Production planning and scheduling: Develop reasonable production plans and schedules to ensure that production can be carried out on time and reasonably arrange production resources and manpower.Production equipment and process control: Ensure the normal operation of production equipment and stable control of process parameters. Carry out regular equipment maintenance and upkeep to ensure the reliability and stability of the equipment.Raw material procurement and quality control: Establish long-term cooperative relationships with reliable suppliers to ensure the quality and stable supply of raw materials. Strict quality inspection and control of raw materials is carried out to ensure compliance with product requirements.Production process monitoring and control: By real-time monitoring of key parameters in the production process, such as temperature, pressure, speed, etc., timely adjustments and controls are made to ensure product consistency and quality.Quality inspection and control: Establish a complete quality inspection system and conduct sampling inspections on each production batch. Through inspection, ensure that the size, appearance, performance, etc. of the product meet the requirements. For substandard products, take corrective measures in a timely manner to prevent defective products from entering the market.Process improvement and continuous optimization: Regularly evaluate and analyze the production process, find opportunities for improvement, optimize production processes and processes, and improve production efficiency and product quality.Training and skill improvement: Provide necessary training and skill improvement for production personnel to ensure that they have good operating skills and quality awareness, and can effectively control the production process and ensure product quality.For the mass production and quality assurance of injection molding of two-color handle button molds, it is necessary to formulate reasonable production plans and schedules, control production equipment and process parameters, ensure the quality and stable supply of raw materials, monitor and control the production process, and establish a perfect quality system Test systems, conduct process improvements and continuous optimization, and provide training and skill enhancement. Through these measures, high-quality injection molding mass production and product quality assurance can be achieved.