Two component 2K molding for hand-held power tool shell wrapped soft rubber

FEATURES

- Two component 2K injection molding of handle switches

Two-color material injection molding process:AnsixTech uses advanced two-color material injection molding technology and combines two-color molds with injection molding technology. First, they choose high-quality two-color injection molding materials, and determine the color and hardness according to the requirements of the handle buttons. These materials are rigorously screened and tested to ensure they meet AnsixTech’s quality standards. They then heated each of the two colors of material until they melted. Utilizing an advanced two-color injection molding machine, AnsixTech injects two colors of molten material into the mold so that it fills the mold’s cavity. The injection molding machine has a precise control system that can accurately control the injection ratio and injection time of the two color materials to ensure the accuracy and consistency of the two-color effect. During the injection molding process, AnsixTech strictly controls injection molding parameters to ensure product quality and performance.Through the two-color mold manufacturing process and two-color material injection molding process of AnsixTech plastic handle buttons, the two-color effect of the buttons can be achieved, increasing the product’s appearance appeal and market competitiveness. Two-color injection molding can also improve the quality and durability of the buttons to meet the needs of different users. AnsixTech is committed to continuous improvement and innovation, and continues to improve the technical level of two-color mold manufacturing and two-color material injection molding processes to meet market needs. Their professional team will continue to work hard to provide customers with high-quality, innovative and reliable plastic handle button products.

-

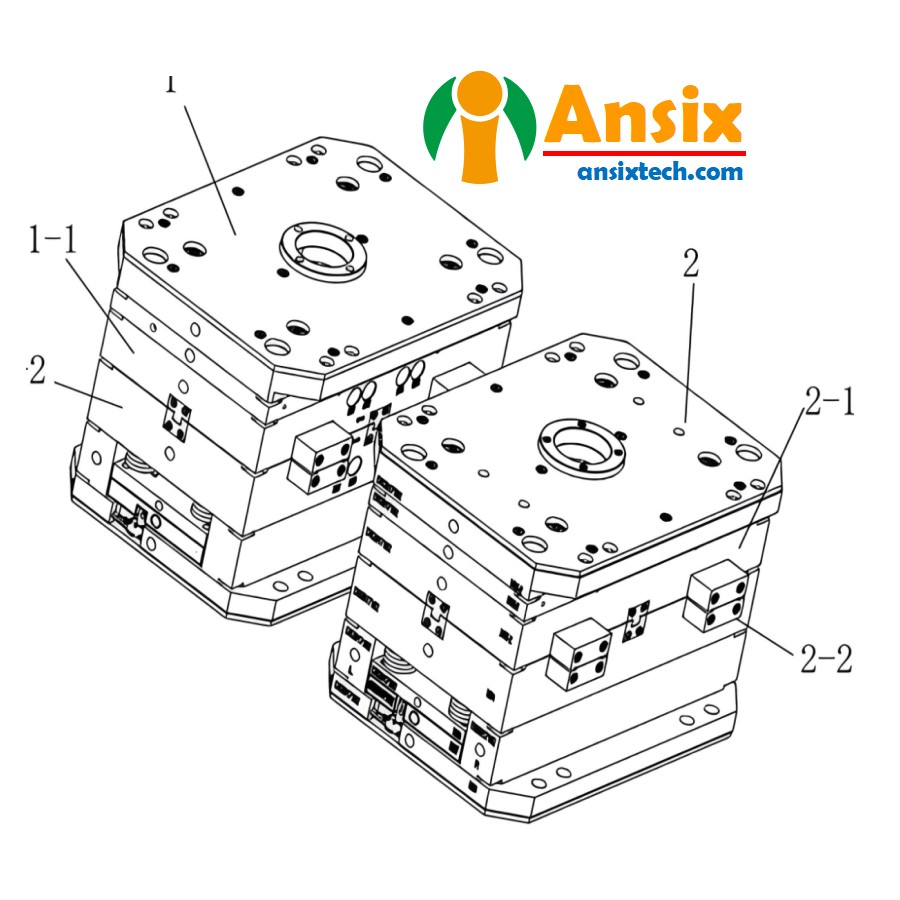

Mold Description

Product Materials:

ABS/PC

Soft rubber: TPR

Mold Material:

S136ESR

Number of Cavities:

2+2

Glue Feeding Method:

Hot runner

Cooling Method:

Water cooling

Molding Cycle

38.5s

- Mold flow analysis and mold design for Two component 2K molding for hand-held power tool shell wrapped soft rubberFor the mold flow analysis and 2K two-color mold design of the handheld power tool shell covered with soft rubber:Mold flow analysis:a. Collect relevant information about the soft rubber of the handheld power tool housing, including size, shape, material, etc.b. Use mold flow analysis software to import the CAD model of the soft plastic shell and set the injection molding process parameters, such as injection speed, temperature, pressure, etc.c. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance, bubbles, short shots and other defects of the soft rubber in the shell package, and optimize the injection molding process parameters.2K two-color mold design:a. Determine the structure and size of the 2K two-color mold based on the mold flow analysis results. Taking into account the shape and requirements of the soft plastic shell, design an appropriate mold structure, including mold cavity, mold core, demoulding system, cooling system, etc.Ensure the filling performance of the soft rubber in the shell package: Through mold flow analysis, the injection molding process parameters are optimized to ensure that the filling performance of the soft rubber in the shell package is good and avoid defects.Design of cooling system: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and avoid problems such as deformation and shrinkage of the soft plastic of the shell package.Design of demoulding system: According to the shape and requirements of the soft rubber shell package, design a suitable demoulding system to ensure that the soft rubber shell package can be demoulded smoothly and avoid damage and deformation.For the mold flow analysis and 2K two-color mold design of the handheld power tool shell covered with soft rubber, it is necessary to conduct mold flow analysis, optimize the injection molding process parameters, design the appropriate mold structure and size, determine the two-color injection molding process, and carry out Detailed design of the mold. Through reasonable design and control, high-quality two-color injection molded shell packaging soft rubber can be obtained.

- The mold manufacturing process and product material selection for Two component 2K molding for hand-held power tool shell wrapped soft rubberFor the processing technology of soft plastic molds for handheld power tool housings and the selection of 2K two-color injection molding materials:Mold processing technology:Mold processing technology refers to various processing methods and processes used to manufacture molds. The development level of mold processing technology directly affects the quality, accuracy and production efficiency of the mold.1. CNC machining: CNC machining is a processing method that uses CNC machine tools for processing, including CNC lathes, CNC milling machines, CNC EDM machines, etc. CNC machining has the characteristics of high precision, high efficiency, and strong adaptability, and is widely used in mold processing.2. Wire cutting processing: Wire cutting processing is a method of processing using a computer-controlled wire cutting machine. It is suitable for processing materials with higher hardness, such as mold steel, etc.3. Electrical discharge machining: Electrical discharge machining is a method of processing using a computer-controlled electric discharge machine. It is suitable for processing high-hardness, high-precision mold parts.4. Grinding: Grinding is a method of processing using grinding machines, including surface grinders, cylindrical grinders, internal cylindrical grinders, etc. It is suitable for processing the surface of molds and precision parts.5. Cutting processing: Cutting processing is a method of processing using cutting machine tools such as lathes and milling machines. It is suitable for processing the shape and structure of molds.2K two-color injection molding material selection:a. Consider the requirements and usage environment of the handheld power tool housing and select the appropriate 2K two-color injection molding material. Commonly used material combinations include ABS/PC, ABS/TPU, PC/TPU, etc.b. According to the requirements of the shell, select a material combination with good mechanical properties, wear resistance and chemical resistance.c. Consider the requirements of two-color injection molding and select a material combination with good adhesion and compatibility.In the mold processing technology and 2K two-color injection molding material selection process, you need to pay attention to the following points:Surface treatment: According to the requirements of the shell, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the shell.Mold maintenance and upkeep: Regularly maintain and maintain the mold, including cleaning, lubrication, repair, etc., to extend the service life of the mold and ensure the stability of production.For the processing technology and 2K two-color injection molding material selection of the soft plastic mold for the handheld power tool housing, it is necessary to select the appropriate processing technology and equipment to ensure processing accuracy and dimensional control. In terms of material selection, consider the requirements of the shell and the use environment, and choose a 2K two-color injection molding material combination with good mechanical properties, wear resistance and chemical resistance. Through reasonable processing technology and material selection, high-quality soft plastic mold processing and 2K two-color injection molding of handheld power tool housing packages can be achieved.

- Two component 2K molding for hand-held power tool shell wrapped soft rubber of Mass production and Quality controlFor the injection molding mass production of soft rubber for handheld power tool housings and the quality control of the housing process:Production planning and scheduling: Develop reasonable production plans and schedules to ensure that production can be carried out on time and reasonably arrange production resources and manpower.Process improvement and continuous optimization: Regularly evaluate and analyze the production process, find opportunities for improvement, optimize production processes and processes, and improve production efficiency and product quality.Training and skill improvement: Provide necessary training and skill improvement for production personnel to ensure that they have good operating skills and quality awareness, and can effectively control the production process and ensure product quality.In short, for the mass production of injection molding of soft rubber for handheld power tool shells and the quality control of the shell process, it is necessary to formulate reasonable production plans and schedules, control production equipment and process parameters, ensure the quality and stable supply of raw materials, and monitor and control injection molding process, establish a complete quality inspection system, carry out process improvement and continuous optimization, and provide training and skills improvement. Through these measures, high-quality injection molding mass production and product quality assurance can be achieved.Mass production of soft plastic injection molding of handheld power tool housing packages has the following advantages and efficiency:Efficient production: Injection molding is an efficient and fast production method suitable for mass production. Through reasonable production planning and scheduling, high output and stable production efficiency can be achieved.Accurate replication: Injection molding can accurately replicate the shape and details of the mold, ensuring the consistency and quality of the soft glue for each shell package.Multiple material selection: Injection molding can use a variety of materials, including plastics, rubber, etc. The appropriate material is selected according to the requirements of the soft rubber for the shell to meet the functional and performance requirements of the product.Complex shapes and structures: Injection molding can realize the production of soft plastic shells with complex shapes and structures to meet the design requirements of handheld power tool shells.Automated production: Injection molding can realize automated production. Through automated injection molding machines and robot systems, production efficiency can be improved and labor costs reduced.Save materials and costs: Injection molding can maximize the use of raw materials and reduce waste. At the same time, production costs can be reduced due to the advantages of efficient production and automated production.Consistency and stability: Injection molding can achieve the consistency and stability of the soft rubber in the shell, ensuring that the quality and performance of each product meet the requirements.The mass production of soft plastic injection molding for handheld power tool housing packages has the advantages and efficiency of high efficiency, precise reproduction, multiple material selections, complex shapes and structures, automated production, material and cost savings, consistency and stability. Through reasonable production planning and process control, high-quality, high-efficiency injection molding mass production can be achieved.