AM- 3D Printing

FEATURES

- AnsixTech Advanced Additive Manufacturing

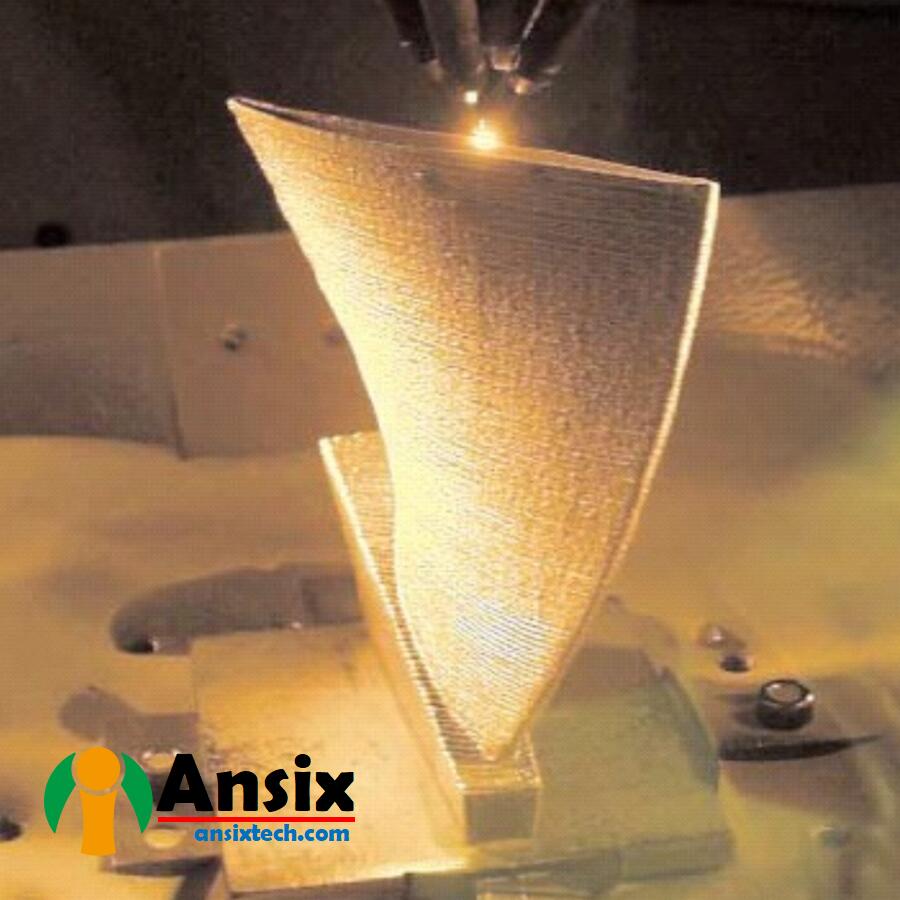

AnsixTech is committed to providing high-quality advanced additive manufacturing solutions to help customers achieve innovation and efficiency improvements. Their professional team will work with clients to ensure successful project implementation and provide technical support and consulting services.AnsixTech has developed groundbreaking additive manufacturing technologies, utilizing proprietary processes and medical-grade materials to create components with complex tolerances, geometries, and features.Advanced Additive Manufacturing Technologies refers to the use of innovative and advanced manufacturing technologies and methods in the field of additive manufacturing. These technologies not only enable greater manufacturing precision and efficiency, but also expand material selection, provide more design freedom, and meet a wider range of application needs.Here are some common advanced additive technologies:Metal 3D printing: Metal 3D printing technology uses lasers or electron beams to melt metal powder, stack and melt the metal layer by layer to build complex metal parts. This technology can produce high-strength, high-precision metal parts suitable for aerospace, automotive, medical and other fields.Multi-material 3D printing: Multi-material 3D printing technology can use different materials in the same build process to achieve multi-functional and complex part manufacturing. This technology can combine different materials, colors and hardnesses to meet specific design and application needs.Bioprinting: Bioprinting technology uses biological materials and cells to create human tissues and organs by stacking and assembling them layer by layer. This technology has huge potential in the medical field and can be used in applications such as tissue engineering, organ transplantation and drug screening.Large-scale 3D printing: Large-scale 3D printing technology can manufacture large-scale parts and structures, such as buildings, bridges, and ships. This technology can improve manufacturing efficiency and reduce costs while providing more design freedom and innovation.High-temperature 3D printing: High-temperature 3D printing technology can be manufactured using high-temperature materials in high-temperature environments, such as ceramics, metal alloys, etc. This technology can produce high-temperature and corrosion-resistant parts suitable for aerospace, energy and chemical industries.Light-curing 3D printing: Light-curing 3D printing technology uses an ultraviolet light source to illuminate photosensitive resin to solidify and build parts layer by layer. This technology enables high resolution and precision for applications such as microparts, optical components and microfluidic devices.

- Over 25+ Experience of Molding Medical Laboratory Consumables

AnsixTech is a company specializing in additive manufacturing and 3D printing technology. They provide advanced additive manufacturing solutions including 3D printing, metal 3D printing and other related technologies.The following is some information about AnsixTech additive manufacturing and 3D printing technology:3D printing technology: AnsixTech uses 3D printing technology to create three-dimensional objects by stacking materials layer by layer. They can use different 3D printing technologies, such as light curing, fused deposition, powder sintering, etc., to choose the most suitable method according to customer needs.Metal 3D printing technology: AnsixTech has the capability of metal 3D printing, which can use laser or electron beam to melt metal powder, stack and melt the metal layer by layer to create complex metal parts. They can manufacture high-strength, high-precision metal parts for aerospace, automotive, medical and other fields.Material selection: AnsixTech can use a variety of different materials for additive manufacturing, including metals, plastics, ceramics, etc. They can select the most suitable material according to the customer’s requirements and ensure that the selected material has the required performance and quality.Design optimization: AnsixTech’s team has extensive design and engineering experience and can help customers optimize product designs to maximize the benefits of additive manufacturing. They can improve product performance and efficiency by reducing parts count, optimizing structure, and reducing weight.Manufacturing customized products: AnsixTech can manufacture customized products according to customer needs. They can use additive manufacturing technology to create unique products based on design documents or requirements provided by customers to meet their specific needs.AnsixTech is committed to providing high-quality additive manufacturing solutions to help customers achieve innovation and efficiency improvements. Their professional team will work with clients to ensure successful project implementation and provide technical support and consulting services. Whether in the field of 3D printing or metal 3D printing, AnsixTech has rich experience and expertise.Additive manufacturing (AM), also known as 3D printing, is an innovative suite of advanced technologies that enables the fabrication of medical components and products with remarkably complex and high-resolution features which often cannot be achieved within the constraints of conventional manufacturing methods. Compared to traditional subtractive machining methods, AM is more efficient and can deliver functional prototypes into the hands of medical engineering teams within a matter of days, instead of weeks. Spectrum has developed groundbreaking, proprietary AM technologies for creating medical products that the competition cannot, such as high-precision, medical-grade single and multi-lumen tubing—a first in the industry. If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

- AnsixTech Industry-Leading, Medical-Grade Additive Manufacturing

Industry-leading medical-grade additive manufacturing company provides high-quality, high-reliability additive manufacturing solutions in the medical field. These companies usually have the following characteristics:Medical-grade materials: Industry-leading medical-grade additive manufacturing companies use certified medical-grade materials to ensure products meet the strict requirements of the medical industry. These materials have good biocompatibility, durability and reliability.High precision and high quality: Industry-leading medical-grade additive manufacturing companies have advanced equipment and technology to achieve high-precision and high-quality manufacturing. They can manufacture products that meet medical industry standards through precise control and optimized processes.Design optimization and customization: Industry-leading medical-grade additive manufacturing companies have extensive design and engineering experience and can help customers optimize product designs to maximize the advantages of additive manufacturing. They can custom manufacture products based on customer needs to meet specific medical application needs.Compliance and Certification: Industry-leading medical-grade additive manufacturing companies follow the regulations and standards of the medical industry to ensure product compliance and safety. They usually have relevant certifications and qualifications, such as ISO 13485 quality management system certification, etc.Innovation and R&D: Industry-leading medical-grade additive manufacturing companies focus on innovation and R&D, and continue to promote the application of additive manufacturing technology in the medical field. They are actively involved in research projects and partnerships that advance medical-grade additive manufacturing.Industry-leading medical-grade additive manufacturing companies play an important role in the medical field, providing high-quality additive manufacturing solutions for medical devices, implants, customized medical products, etc. Their professional team will work with clients to ensure successful project implementation and provide technical support and consulting services.Additive manufacturing is a rapidly advancing field as new technologies, equipment, and specialized materials continue to enter the market. AnsixTech’s industry-leading AM capabilities enable more creative design, innovative rapid prototyping, and seamless transition to high-volume manufacturing.Benefits of AnsixTech’s additive manufacturing capabilities and services include:Customized and/or proprietary processes, equipment, and materials for a wide range of medical applicationsCreating innovative, one-of-a-kind medical device components that advance the manufacturing boundaries of what is possible, especially for minimally invasive surgical processes and life-saving devices such as stentsSpectrum’s dedicated additive manufacturing technical team has the depth of knowledge and experience to determine the best AM approach for your project, meeting even the most challenging timelinesRapid prototyping that can deliver production-ready prototypes in a matter of days instead of weeks, accelerating project development and informed decision-makingBridge manufacturing that utilizes additive manufacturing/3D printing to test low-volume production runs of a product before investing heavily in a mass-production process using standard methods of manufacturing

- AnsixTech Additive Manufacturing Technologies

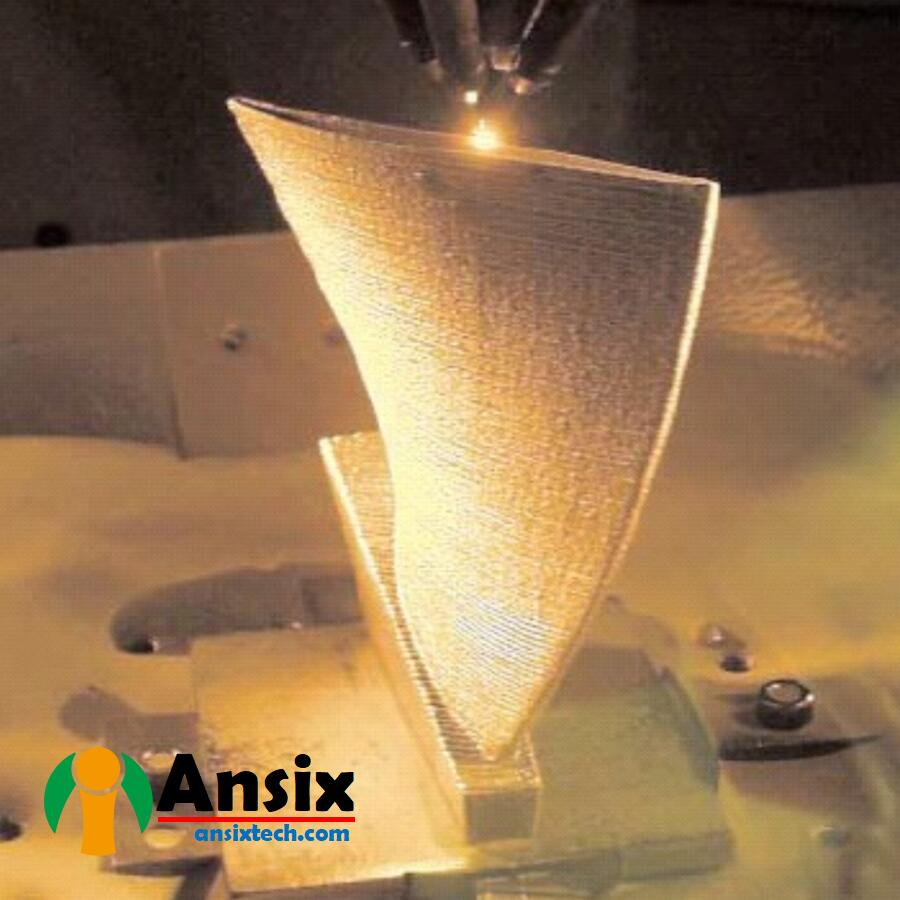

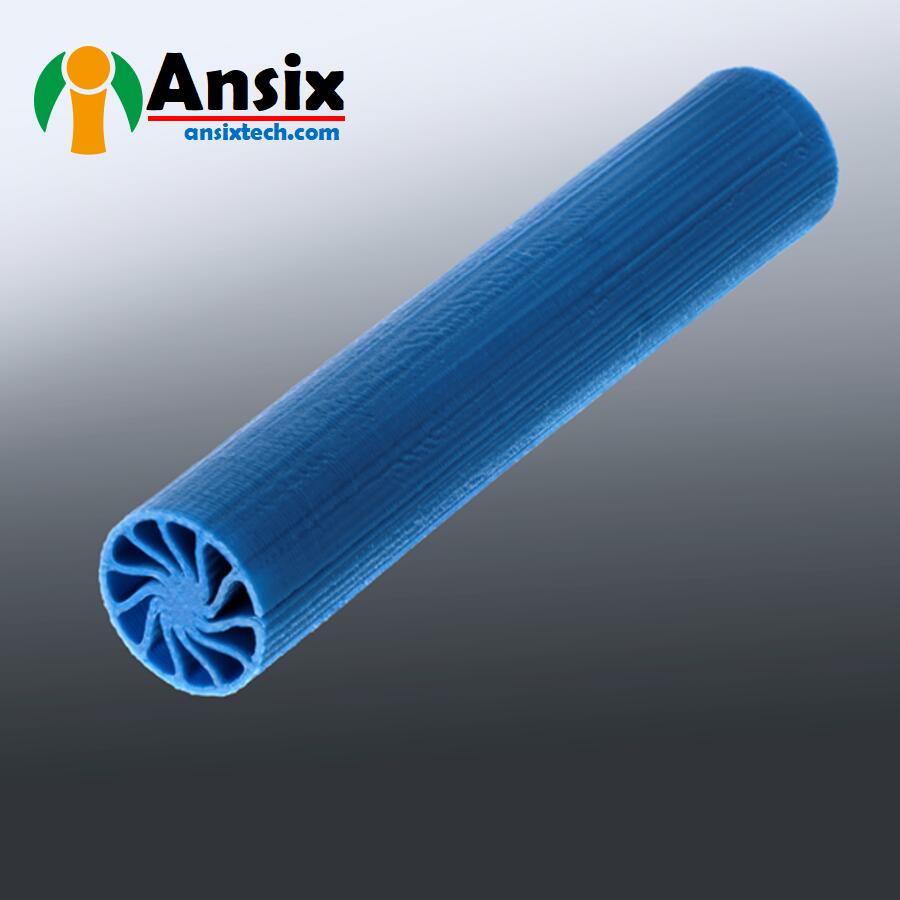

Spectral Additive Manufacturing is an advanced additive manufacturing technology that combines spectroscopy and 3D printing technology. This technology uses the principle of spectroscopy to achieve selective solidification or melting of materials by controlling light sources of different wavelengths to build three-dimensional objects layer by layer.The main features and advantages of spectral additive manufacturing technology include:Multi-material printing: Spectral additive manufacturing technology can use a variety of different materials for printing, including photosensitive resin, metal powder, etc. By controlling light sources of different wavelengths, different materials can be selectively solidified or melted to achieve multi-material printing.High resolution: Spectral additive manufacturing technology can achieve very high printing resolution and can produce very fine and complex structures. By controlling the wavelength and intensity of the light source, micron-level precision and detail can be achieved.Fast printing speed: Spectral additive manufacturing technology can achieve fast printing speed and improve production efficiency. Since multiple light sources can be used at the same time, multiple areas can be printed at the same time, speeding up printing.Design freedom: Spectral additive manufacturing technology can achieve greater design freedom and can manufacture complex geometries and internal structures. By controlling the position and intensity of the light source, more design possibilities can be achieved.Wide application: Spectral additive manufacturing technology is widely used in many fields, including medical, aerospace, automotive, electronics, etc. It can produce high-precision medical equipment, lightweight aviation parts, customized electronic components, etc.It should be noted that spectral additive manufacturing technology is still in the development stage and may not yet have large-scale commercial applications. However, as the technology further develops and matures, spectral additive manufacturing technology is expected to play an important role in the future and bring more innovation and efficiency improvements to the manufacturing industry.AnsixTech’s advanced additive manufacturing technologies create components for medical devices, including:Catheter TechnologiesCatheter tips, hubs and luers with complex features and geometriesDilators, and sheaths, with complex featuresCustomized profile devices with individualized fit“Extrusion profiles” for multi-lumen, single-lumen, and infinite lengthMedical MoldingMold inserts for quick-turn prototypingMicro componentsMulti-material componentsHandles/large components and devicesTubingAnsixTech has developed proprietary additive manufacturing technologies for manufacturing high-precision, medical-grade tubing (single and multilumen tubing) that is not extrusion-based.Medical-Grade 3D Printing FilamentAnsixTech also formulates and manufactures its own medical-grade 3D printing filaments for various materials and sizes in-house, assuring the highest quality, control, and availability.

- AnsixTech Next-Generation Materials and Tolerances

Additive Manufacturing uses various materials for manufacturing, including metals, plastics, ceramics, composite materials, etc. Different materials have different characteristics and application ranges, and the appropriate material can be selected according to specific application requirements.Here are some common additive manufacturing materials and their characteristics:Metal materials: Metal materials are often used in metal 3D printing technology, such as laser melting metal powder. Metallic materials offer high strength, heat resistance and electrical conductivity, making them suitable for manufacturing high-performance parts and components.Plastic materials: Plastic materials are often used in light-curing 3D printing technology, such as photosensitive resin. Plastic materials have good plasticity, lightweight and corrosion resistance, and are suitable for manufacturing complex parts and models.Ceramic materials: Ceramic materials are often used in ceramic 3D printing technology, such as ceramic powder sintering. Ceramic materials have high temperature resistance, wear resistance and insulation, and are suitable for manufacturing high temperature parts and wear-resistant parts.Composite materials: Composite materials are materials made from a combination of two or more different materials and are often used in additive manufacturing. Composites are high-strength, lightweight and corrosion-resistant, making them suitable for manufacturing high-performance structures and parts.Tolerance refers to the allowable dimensional deviation range during the manufacturing process. In additive manufacturing, tolerances are typically tighter than with traditional manufacturing methods because additive manufacturing allows for greater precision and finesse. The size of the tolerance depends on the material used, printing technology and design requirements.Tolerances for additive manufacturing are often expressed as percentages or absolute values, such as a dimensional tolerance of ±0.1 mm or a tolerance of ±0.1%. Tolerance selection should be evaluated against specific application needs and design requirements to ensure that the manufactured part meets the required functionality and performance.It is important to note that different additive manufacturing technologies and materials may have different tolerance requirements. When selecting additive manufacturing technologies and materials, the required tolerance ranges should be taken into account and discussed and confirmed in detail with the supplier or manufacturer.AnsixTech uses additive manufacturing technologies to process all medical-grade thermoplastic materials. These include Nylon, Pebax®, polypropylene, polycarbonate, acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), PEEK, polyetherketone (PEK), high impact polystyrene (HIPS), Urethanes, and custom materials.

- Quick-Turn Prototyping for AnsixTech

Rapid prototyping is a rapid manufacturing technology that aims to quickly produce physical models or samples of products to verify design concepts, conduct functional testing, and conduct market evaluation. It can help designers and engineers iterate and improve product designs faster, reducing development cycles and costs.Here are some common rapid prototyping methods:3D printing: 3D printing is one of the most commonly used rapid prototyping methods. It creates three-dimensional objects by stacking materials layer by layer. 3D printing can use different materials and technologies, such as light curing, fused deposition, powder sintering, etc., to create prototypes with high precision and complex geometries.CNC machining: Computer numerical control (CNC) machining is a method of automating cutting or engraving by controlling a machine tool. It can use various materials such as metal, plastic, wood, etc. to create prototypes with high precision and fine surfaces.Rapid injection molding: Rapid injection molding is a method of manufacturing plastic parts through injection molding. It uses rapidly manufactured molds and injection molding machines to produce high-volume plastic prototypes in a short time.Vacuum casting: Vacuum casting is a method of manufacturing metal parts by injecting molten metal into a mold in a vacuum environment. It can produce metal prototypes with high precision and complex shapes.Rapid Casting: Rapid casting is a method of manufacturing metal parts by using rapidly manufactured molds and casting processes. It can produce large quantities of metal prototypes in a short time.Rapid prototyping can help designers and engineers verify and improve product designs faster, reducing development risks and costs. Selecting an appropriate rapid prototyping method should be evaluated based on specific needs and requirements, including factors such as required materials, accuracy, manufacturing time, and cost.

- AnsixTech Cleanroom Certification

Cleanroom Facility is a special production environment used to control the concentration of particles, microorganisms and other pollutants in the air to ensure product quality and the reliability of the production process. Clean room workshops are usually used in industries that require a highly clean environment, such as medical, pharmaceutical, electronics, semiconductor, etc.The design and construction of clean room workshops need to consider the following key factors:Cleanliness level: The cleanliness level of a clean room workshop is determined based on the required environmental requirements. Cleanliness levels are usually classified according to the international standard ISO 14644, such as ISO 5, ISO 7, etc. Different cleanliness levels require different air filtration and control measures.Air filtration system: Clean room workshops need to be equipped with high-efficiency air filtration systems to remove particles and microorganisms in the air. Common filters include high-efficiency filters (HEPA) and ultra-high-efficiency filters (ULPA).Temperature and humidity control: Clean room workshops require precise control of temperature and humidity to meet product requirements. Temperature and humidity control systems typically include equipment such as air conditioning systems, humidifiers, and dehumidifiers.Pressure control: Clean room workshops usually use positive or negative pressure control to prevent external air or pollutants from entering the clean room. Pressure control systems usually include air flow regulation and differential pressure control equipment.Material selection: Surfaces such as walls, floors, and ceilings in clean room workshops are usually made of materials that are easy to clean, dust-free, and corrosion-resistant to ensure the cleanliness and hygiene of the clean room.The design and operation of clean room workshops need to comply with relevant international standards and specifications, such as ISO 14644, GMP (Good Manufacturing Practice), etc. Certification and maintenance of cleanroom workshops are typically performed by third-party certification bodies to ensure they meet standards and requirements.AnsixTech has constructed a state-of-the-art cleanroom for its additive manufacturing operations, which allows sensitive and/or mission-critical materials and components to be processed inside a cleanroom environment. The cleanroom houses additive manufacturing equipment and materials, including 12 production proprietary thermoplastic machines capable of running 24/7 and remotely monitored anywhere in the world. Applications vary from R&D prototypes to production-ready medical use parts, including in-human devices. The cleanroom is certified Class 8.

- Partner with AnsixTech’s Additive Manufacturing Technical Team

Bringing a medical device to market can take years and requires deep expertise in identifying product requirements and the best product design to meet clinical needs. AnsixTech’s additive manufacturing capabilities allow medical-device designers to select from a wide range of medical-grade plastics with specifically engineered material characteristics and design components, including, multi-material and multi-dimensional builds.The additive manufacturing technical team is a team of professionals who have professional knowledge and skills in the field of additive manufacturing. This team usually consists of the following types of members:Engineers: Engineers play an important role in the additive manufacturing technology team. They are responsible for designing and optimizing the additive manufacturing process, selecting appropriate materials and equipment, and solving technical problems and challenges.Designer: Designers are responsible for converting product designs into models that can be additively manufactured. They use CAD software to create 3D models and consider the limitations and requirements of additive manufacturing to ensure the design is manufacturable.Materials experts: Materials experts are responsible for selecting and evaluating materials suitable for additive manufacturing. They understand the properties and performance of different materials and select the most appropriate material based on application needs.Operator: Operators are responsible for operating and maintaining additive manufacturing equipment. They are familiar with the equipment’s operating procedures and parameter settings, and ensure that the equipment operates normally and produces high-quality products.Quality Control Specialist: Quality Control Specialist is responsible for supervising and ensuring the quality of the additive manufacturing process. They conduct quality checks and tests to ensure that products comply with prescribed standards and requirements.Project Manager: The project manager is responsible for coordinating and managing additive manufacturing projects. They develop project plans, allocate resources, monitor progress, and communicate and coordinate with clients and team members.R&D personnel: R&D personnel are responsible for promoting the innovation and development of additive manufacturing technology. They conduct research and experiments to explore new materials, processes and applications to improve the efficiency and performance of additive manufacturing.Successful collaboration in an additive manufacturing technology team requires good communication, collaboration, and mutual support among team members. They work together to solve technical problems and promote the development and application of additive manufacturing technology.

contact us

Try Our Problem-solving Injection Molding Services Now

AnsixTech Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

ISO 13485 Certified factory

ISO 8 Cleanroom

Robust Expertise for Medical Injection Molding

Advanced mold manufacturing capabilities and plastic injection molding equipment

Quick Response within 12 hours

- If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.