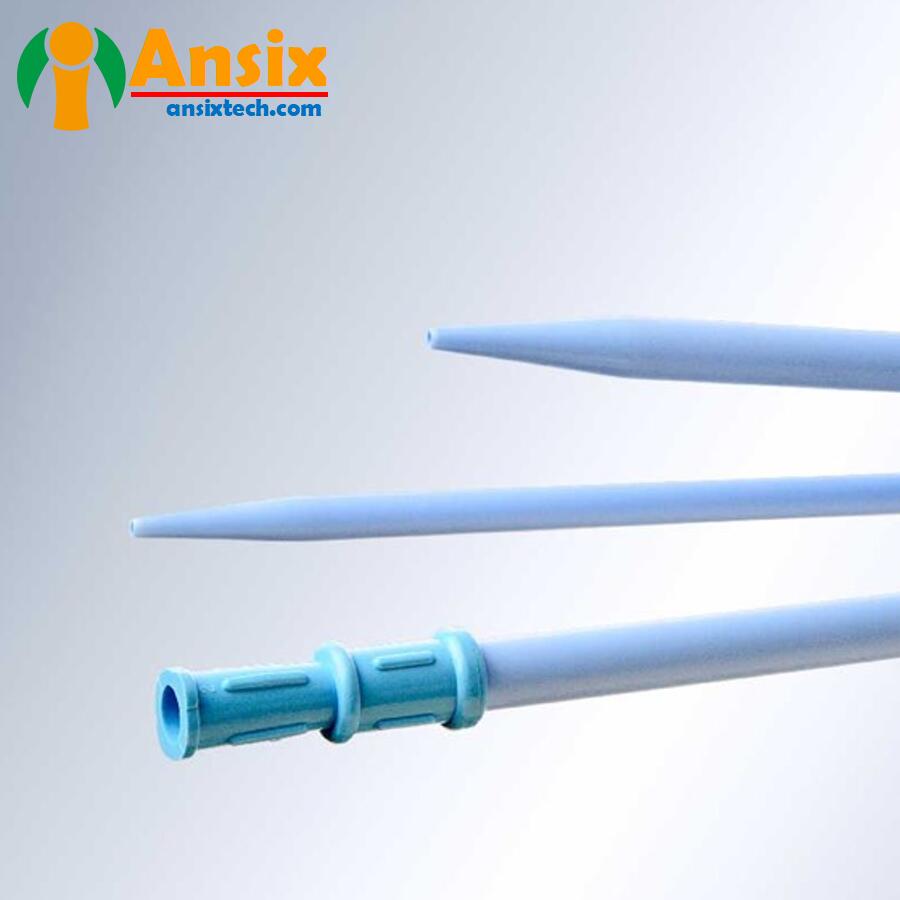

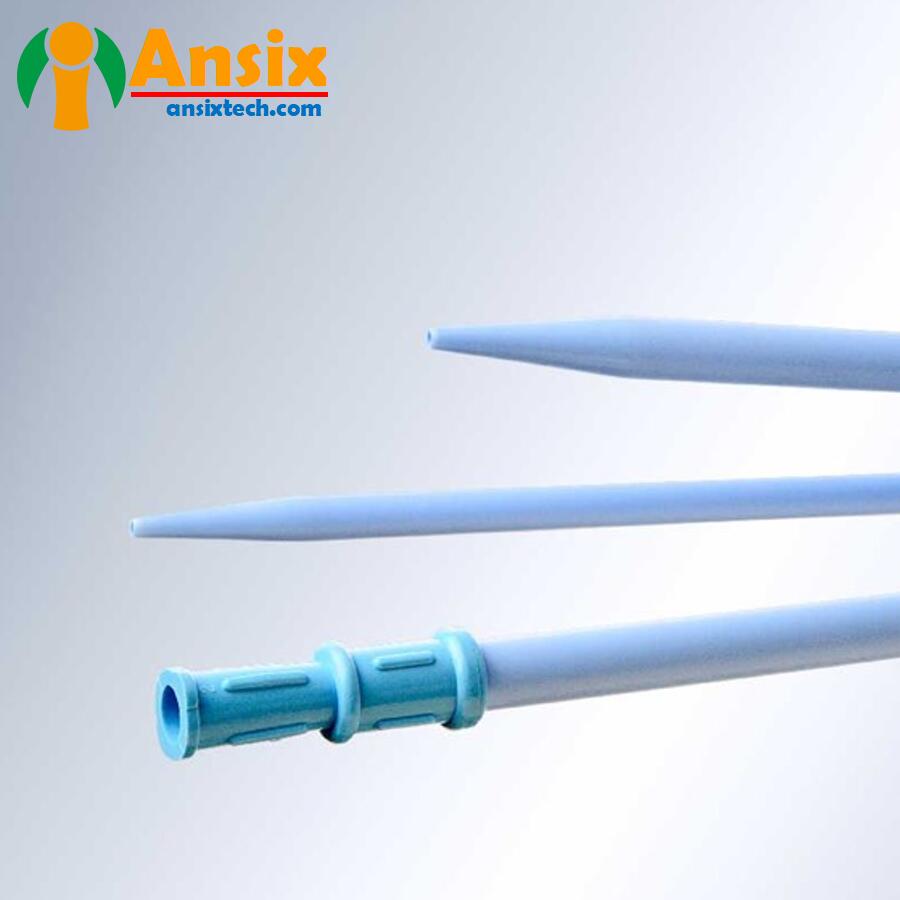

Dilators & Sheaths

FEATURES

- Medical Dilators & Sheaths

The design and manufacture of dilators and sheaths need to take into account the needs and requirements of the specific application. They are usually made of flexible materials to allow for easier insertion and manipulation. In the medical field, the design and manufacturing of dilators and sheaths need to comply with relevant safety standards and regulations to ensure their safe and effective use in medical environments. In addition, quality control and testing are also important aspects to ensure the quality of dilators and sheaths.We’re the market leader in dilator and sheath technologies that support interventional therapies. Our custom vascular access components come in a wide range of sizes, polymers, colors, and value-added operations.

- Off-the-Shelf Dilators & Sheaths for AnsixTech

Off-the-shelf dilators and sheaths are products that are already manufactured and ready for purchase and use. They are usually designed and manufactured based on specific application needs and requirements. Here are some examples of common off-the-shelf dilators and sheaths:Vasodilator: A vasodilator is a device used to widen narrowed or blocked blood vessels. It is usually made of flexible materials such as polyurethane, silicone, etc. Vasodilators can be inserted and expanded to expand the inner diameter of blood vessels to restore normal blood flow. Common vascular dilators include balloon dilators, stent dilators, etc.Catheter jacket: A catheter jacket is an outer structure used to protect and cover the catheter. It is usually made of flexible materials such as polyurethane, polyethylene, etc. Catheter sheaths can provide additional protection and isolation, preventing the catheter from coming into contact with the surrounding environment, reducing the risk of infection and contamination. Common catheter sheaths include urinary catheter sheaths, chest drainage tube sheaths, etc.Guide wire sheath: The guide wire sheath is an outer structure used to protect and cover the guide wire. It is usually made of flexible materials such as polyurethane, polyethylene, etc. Guidewire sheaths provide additional protection and reduce friction to facilitate guidewire insertion and manipulation. Common guidewire sheaths include guidewire sheaths, guidewire catheters, etc.

- Quick-Turn Standard Designs for Medical Tubing

Of course, as a service provider, you can provide custom medical tube design services to your customers. Here are some key steps and considerations to help you provide your customers with custom medical tube designs:Determine customer needs: Fully communicate and understand customers to ensure an accurate understanding of their needs and expectations. This includes the purpose of the pipeline, application environment, material requirements, size requirements, etc.Analysis and evaluation: Based on customer needs, conduct analysis and evaluation to determine the feasibility and reliability of the design. Taking into account the special requirements of medical tubes, such as biocompatibility, drug resistance, cleanability, etc.Design and modeling: Design and model medical tubes based on customer needs and evaluation results. Using computer-aided design (CAD) software, draw the geometry, dimensions, and structure of the pipe.Material selection: Select appropriate materials according to customer needs and design requirements. Taking into account the special requirements of medical tubes, such as biocompatibility, drug resistance, high temperature resistance, etc.Prototyping and testing: According to the design, prototype the medical tube is made, tested and verified. This helps evaluate the performance and reliability of the design and make necessary adjustments and improvements.Quality control and testing: During the design and manufacturing process, quality control and testing are carried out to ensure that the medical tube meets relevant standards and requirements. This includes material testing, dimensional measurements, performance testing, and more.Safety and Compliance: Ensure medical tubing is designed to comply with relevant safety and regulatory requirements. This includes biocompatibility testing, material certification, product labeling, and more.

- Custom Dilators & Sheaths at AnsixTech

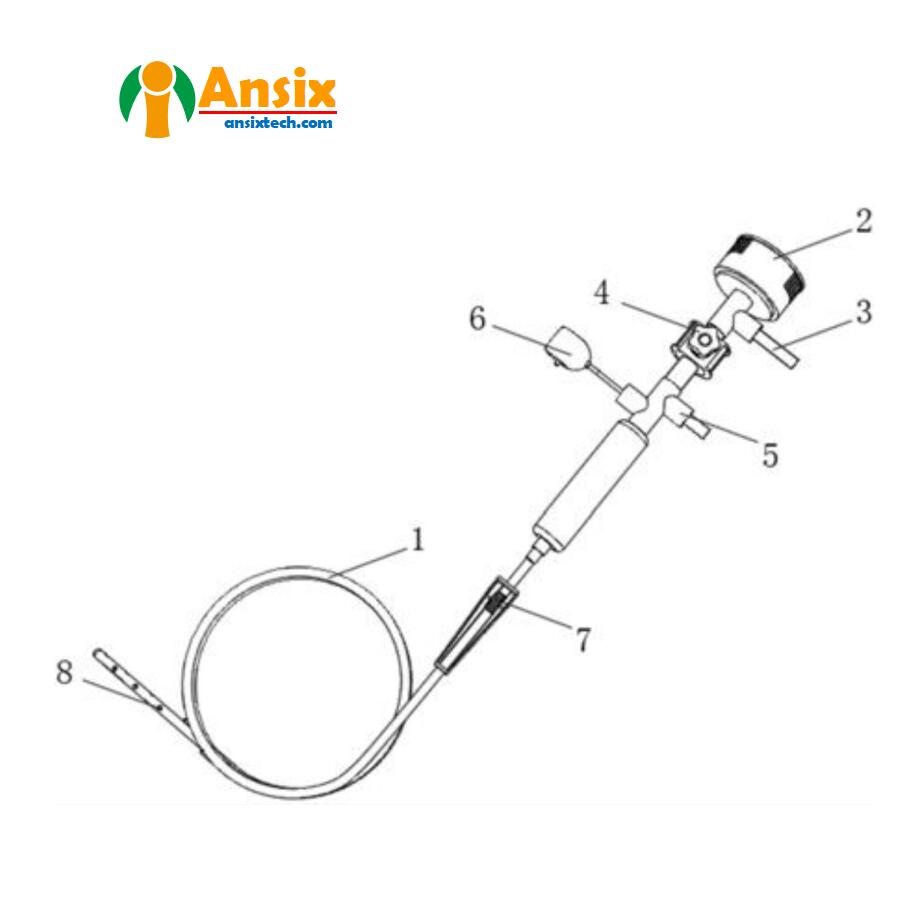

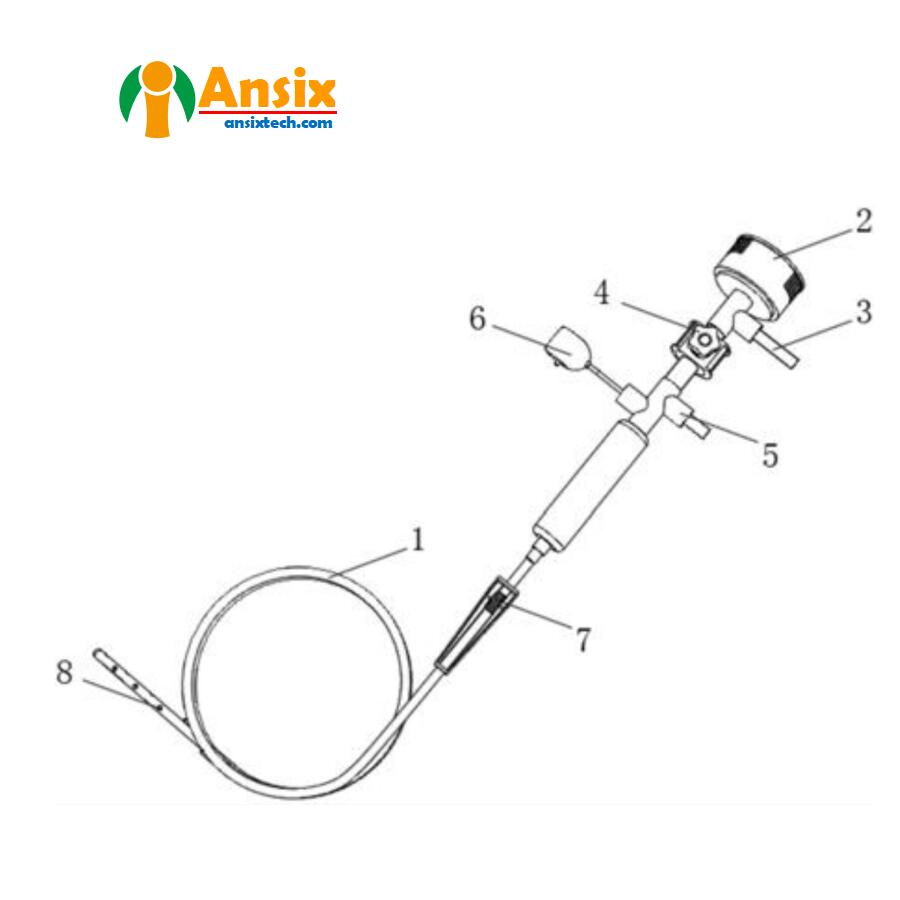

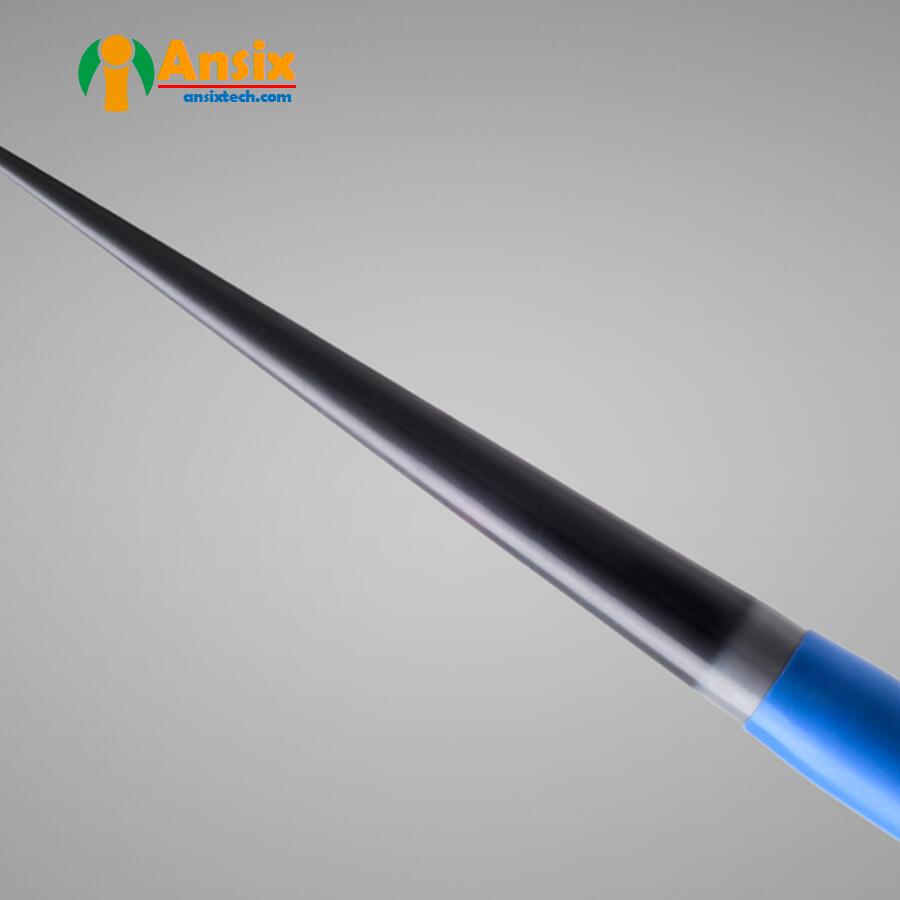

Vascular dilators and introducer sheaths by AnsixTechOur dilator and introducer sheath technologies include custom designs in various materials, sizes, colors, and post-extrusion operations.As a service provider, you can provide custom expander and sheath design services to your customers. Here are some key steps and considerations to help you provide your customers with custom dilator and sheath designs:Determine customer needs: Fully communicate and understand customers to ensure an accurate understanding of their needs and expectations. This includes product requirements, design requirements, application environment, etc.Analysis and evaluation: Based on customer needs, conduct analysis and evaluation to determine the feasibility and reliability of the design. Take into account the special requirements of dilators and sheaths, such as material selection, size requirements, durability, etc.Design and modeling: Design and model the dilator and sheath according to customer needs and evaluation results. Use computer-aided design (CAD) software to draw the device geometry, dimensions, and structure.Material selection: Select appropriate materials according to customer needs and design requirements. Taking into account the special requirements of dilators and sheaths, such as biocompatibility, drug resistance, high temperature resistance, etc.Prototyping and testing: According to the design, prototypes of the dilator and sheath are made, tested and verified. This helps evaluate the performance and reliability of the design and make necessary adjustments and improvements.Quality control and testing: During the design and manufacturing process, quality control and testing are carried out to ensure that the dilator and sheath comply with relevant standards and requirements. This includes material testing, dimensional measurements, performance testing, and more.Safety and Compliance: Ensure that dilators and sheaths are designed to comply with relevant safety and regulatory requirements. This includes biocompatibility testing, material certification, product labeling, and more.Timely delivery and support: Deliver design results to customers in a timely manner in accordance with the design plan, and provide necessary support and services to ensure customer satisfaction.

- Medical Dilator Technologies

Medical tube dilator technology is a technology used to enlarge or open medical tubes or lumens. It can be achieved through different methods and instruments, here are some common medical tube dilator technologies:Balloon Dilators: Balloon dilators are a common medical tube dilator technology. It involves a flexible balloon that is inserted into a narrow duct or lumen through a guidewire, and then the balloon is inflated to dilate the duct or lumen. Balloon dilators are commonly used for blood vessel dilation, stent implantation and other applications.Stent Dilators: Stent dilators are a technology that uses stents to expand tubes or lumens. It consists of a deployable stent that is inserted into a narrow duct or lumen through a guidewire, and then deployed to expand the duct or lumen. Stent expanders are commonly used in applications such as vascular stent implantation and biliary stent implantation.Mechanical Dilators: Mechanical dilators are a technology that uses mechanical force to expand tubes or lumens. It consists of a device with a tapered or spherical head that is inserted into a narrow tube or lumen by rotating or advancing, and then using mechanical force to expand the tube or lumen. Mechanical dilators are commonly used for applications such as urethral dilation and esophageal dilation.Airway Dilators: Airway Dilators are a technology that uses a balloon to expand a tube or lumen. It involves a flexible balloon that is inserted into a narrow duct or lumen through a guidewire, and then inflated to expand the duct or lumen. Balloon dilators are commonly used for applications such as tracheodilation and bronchiectasis.The choice of medical tube dilator technology depends on specific application needs and requirements. When using medical tube dilator technology, evaluation and operation need to be based on the patient’s condition and the experience of the medical professional to ensure safe and effective dilation.

- Medical Sheath Technologies

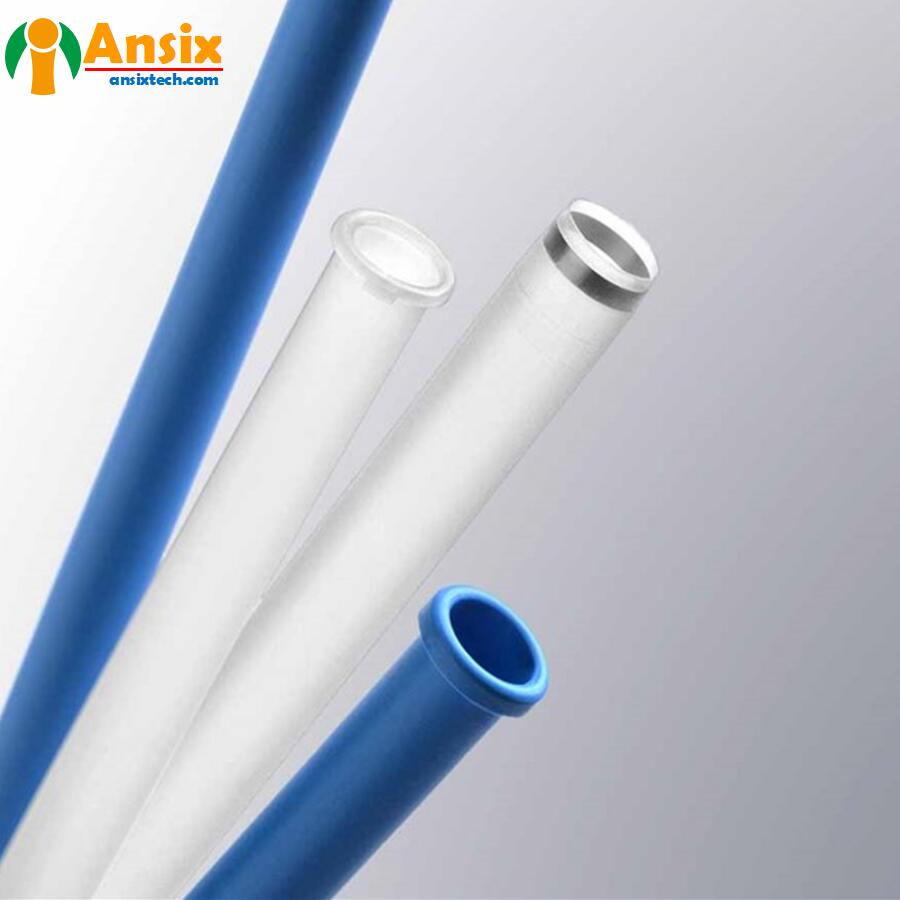

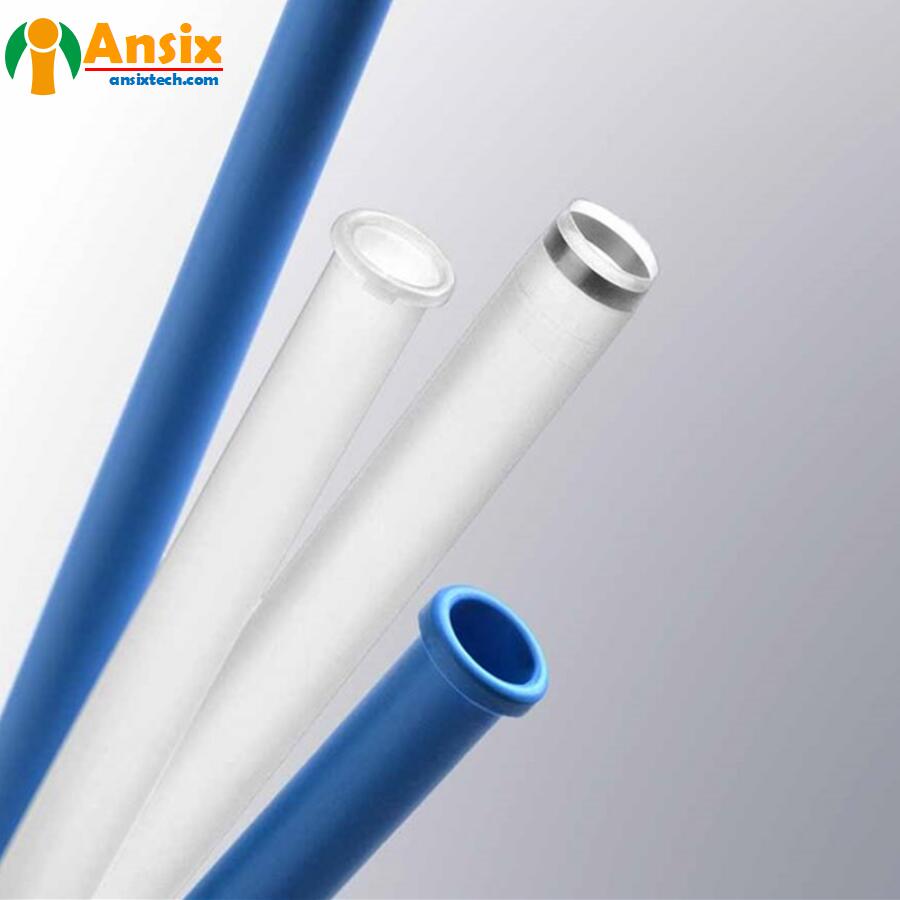

Medical sheathing technology is a technology used to protect and cover medical devices or tubing. It provides additional protection and isolation, preventing the instrument or tubing from coming into contact with the surrounding environment, reducing the risk of infection and contamination. Here are some common medical sheath technologies:

Catheter Sheaths: Catheter Sheaths are an outer structure used to protect and cover catheters. It is usually made of flexible materials such as polyurethane, polyethylene, etc. Catheter sheaths can provide additional protection and isolation, preventing the catheter from coming into contact with the surrounding environment, reducing the risk of infection and contamination. Catheter sheaths are commonly used in applications such as urinary catheters and vascular catheters.

Guide Wire Sheaths: Guide Wire Sheaths are an outer structure used to protect and cover the guide wire. It is usually made of flexible materials such as polyurethane, polyethylene, etc. Guidewire sheaths provide additional protection and reduce friction to facilitate guidewire insertion and manipulation. Guidewire sheaths are commonly used for guidewire guidance, vascular intervention and other applications.

Tubing Sheaths: Pipe sheathing is an outer structure used to protect and cover pipelines. It is usually made of flexible materials such as polyurethane, polyethylene, etc. Pipe jacketing can provide additional protection and isolation, preventing pipes from coming into contact with the surrounding environment, reducing the risk of infection and contamination. Pipe jackets are commonly used in applications such as infusion tubes and drainage tubes.

Cable Sheaths: Cable sheaths are an outer structure used to protect and cover cables. It is usually made of flexible materials such as polyurethane, polyethylene, etc. Cable jacketing can provide additional protection and isolation, preventing the cable from coming into contact with the surrounding environment, reducing the risk of damage and failure. Cable jackets are commonly used in applications such as medical equipment and monitoring instruments.

The choice of medical sheath technology depends on specific application needs and requirements. When using medical sheath technology, it needs to be evaluated and operated based on the patient’s condition and the experience of the medical professional to ensure safe and effective protection and isolation.

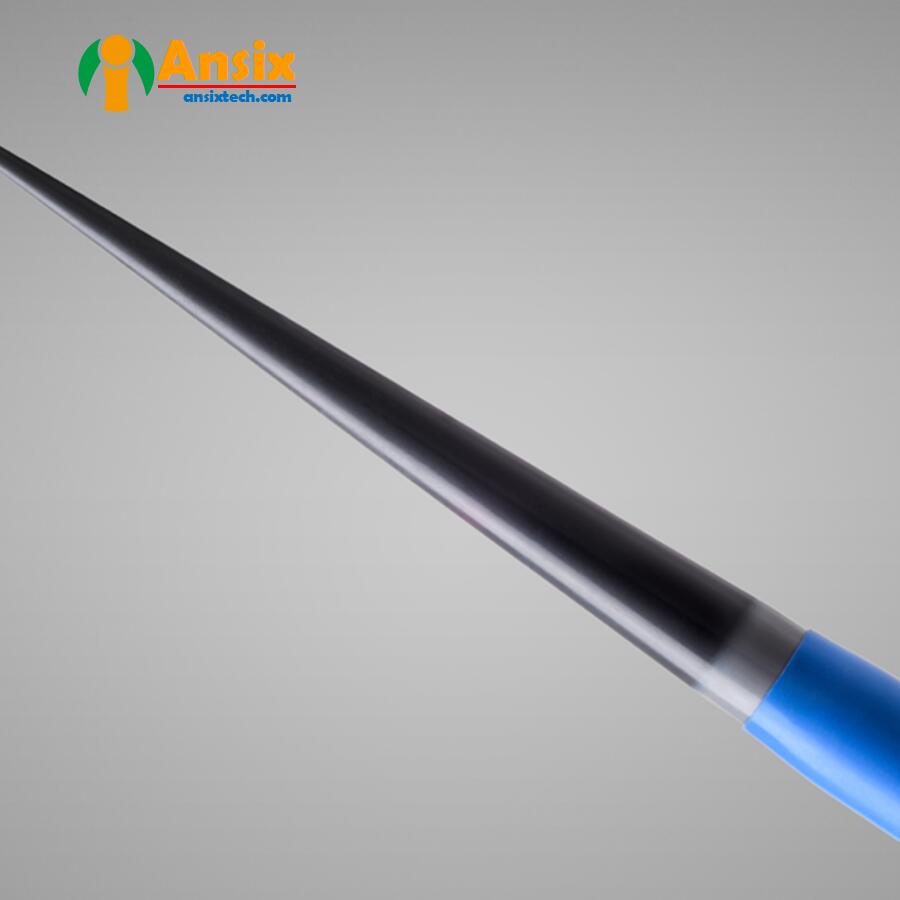

Thermoplastic resins with radiopaque additives

Tipping, flaring & cuffing

Variable-stiffness shafts

Electrode embedding

Insulation sheath for robotic surgery applications

Encapsulated radiopaque or nonmetallic marker bands

Braid- or coil-reinforced shafts

Laser marking & pad printing

Complex subassemblies

Steerable and deflectable sheaths

If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.