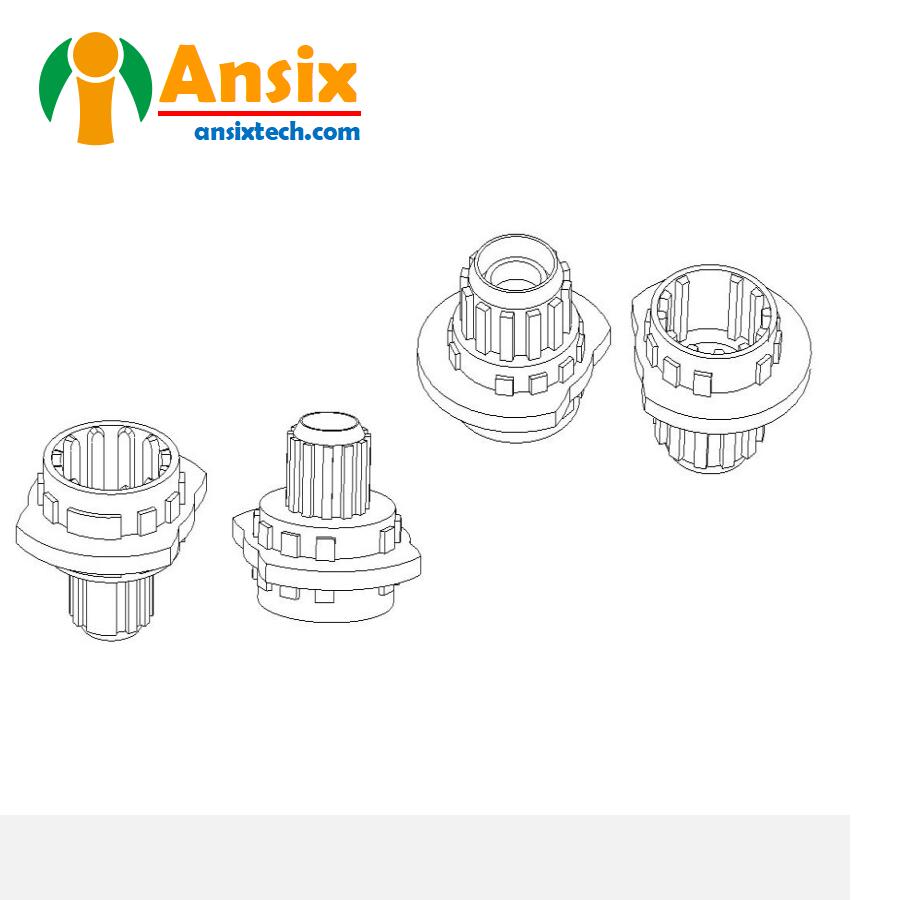

Cam POM plastic injection molding parts

FEATURES

- Cam POM plastic injection molding parts

Cam POM injection molded parts are cam parts made of polyoxymethylene (POM) material. POM is an engineering plastic with excellent physical and mechanical properties and is suitable for manufacturing parts requiring high strength, rigidity and wear resistance. The following are some features and applications of cam POM injection molded parts:application:Cam POM injection molded parts are widely used in various mechanical equipment and industrial fields, such as automobiles, electronics, instrumentation, home appliances, etc. Specific applications include:Automobile engines: Cam injection molded parts are used for camshafts, cam covers and other components of automobile engines.Electronic equipment: Cam injection molded parts are used in transmission mechanisms, switches, buttons and other components in electronic equipment.Instruments: Cam injection molded parts are used in components such as transmission devices, knobs and control rods in instruments.Home appliances: Cam injection molded parts are used in components such as transmission devices, switches and buttons in home appliances.The manufacturing of cam POM injection molded parts usually requires an injection molding process. The POM material is heated and melted and then injected into the mold. After cooling and solidifying, the final cam part is obtained. During the manufacturing process, injection molding process parameters and mold design need to be strictly controlled to ensure the quality and dimensional accuracy of cam injection molded parts.

Product Materials:

POM

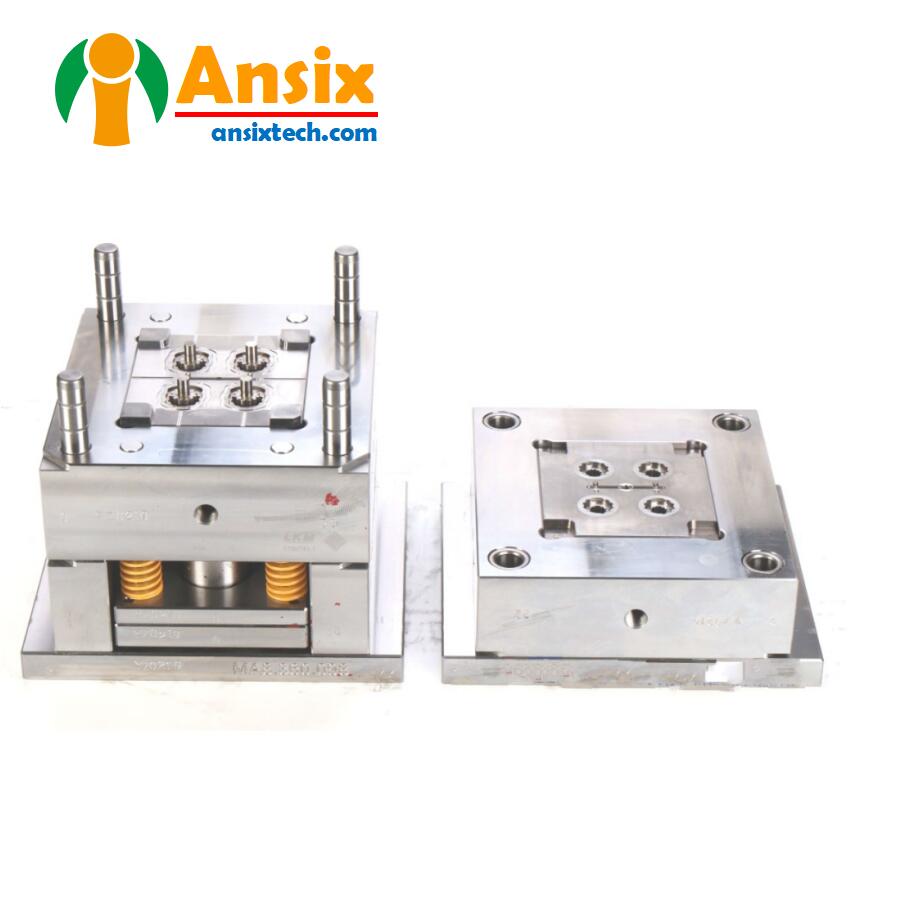

Mold Material:

S136H

Number of Cavities:

1*4

Glue Feeding Method:

Cold runner

Cooling Method:

Water cooling

Molding Cycle

38.5s

- The moldflow analysis and NX mold design

In the manufacturing process of cam POM injection molded parts, mold flow analysis and mold design are very important steps, which can help optimize the injection molding process and mold structure, and improve product quality and production efficiency.Mold flow analysis:a. Collect the design data of the cam injection molded parts, including the shape, size and wall thickness of the cam.b. Establish a three-dimensional model of the cam injection molded part and import it into the mold flow analysis software.c. Set injection molding process parameters, such as injection temperature, injection pressure, injection speed, etc.d. Conduct mold flow analysis to simulate melt flow, filling, cooling, etc. during the injection molding process.e. Analyze mold flow results, evaluate filling conditions, bubbles, short shots and other defects, and make suggestions for improvement.Mold design:a. Optimize the mold structure and design based on the mold flow analysis results. For example, the shape and size of the mold cavity and mold core are adjusted to improve filling performance and cooling effects.b. Design a suitable filling system, including plastic inlet, diversion system, etc., to ensure that the plastic can fully fill the mold cavity.c. Design a suitable cooling system to improve the dimensional stability and quality of the product. Optimize the layout and design of the cooling system to improve cooling effectiveness.d. Design a suitable demoulding system, including ejector pins, ejection devices, release agents, etc., to ensure that the connector can be demoulded smoothly.e. Conduct strength and stiffness analysis of the mold structure to ensure that the mold can withstand the pressure and stress during the injection molding process.f. Improve the mold details, such as cooling water holes, exhaust holes, positioning pins, etc., to improve the service life and stability of the mold.Through mold flow analysis and mold design, the injection molding process and mold structure of cam POM injection molded parts can be optimized to improve product quality and production efficiency. At the same time, it is also necessary to strictly abide by relevant safety regulations and operating procedures to ensure the safety of the working environment and the health of employees.

- Cam POM mold manufacturing and the material selection

The mold manufacturing process and product material selection of cam POM injection molded parts are key factors to ensure product quality and production efficiency. The following are the general steps for the cam POM injection molding mold manufacturing process and product material selection:Mold manufacturing process:a. Mold design: Design the mold according to the shape, size and requirements of the cam POM injection molded parts. Mold design includes mold structure design, filling system design, cooling system design, demoulding system design, etc.b. Material preparation: Select suitable mold material, such as tool steel or stainless steel. According to the mold design, prepare the required materials, including mold base plate, mold cavity, mold core and other parts.c. Processing mold parts: Process mold parts according to the mold design. Including cutting, milling, drilling, turning and other process operations to manufacture various parts of the mold.d. Heat treatment: Heat treatment of mold parts to improve the hardness and wear resistance of the material. Common heat treatment methods include quenching, tempering, etc.e. Assemble the mold: Assemble the processed mold parts, including the assembly of the mold base plate, mold cavity, mold core and other parts. Ensure the accuracy and stability of the mold’s structure and size.f. Debugging and mold trial: Carry out debugging and mold trial on the assembled mold. Use the injection molding machine to test the mold, observe and detect the filling performance of the mold, the size and quality of the product, etc.g. Surface treatment: Surface treatment of the mold to improve the corrosion resistance and appearance quality of the mold. Common surface treatment methods include electroplating, spraying, etc.h. Mold maintenance and upkeep: During the use of the mold, clean, lubricate and maintain the mold regularly to extend the service life of the mold. Reasonably arrange the replacement and repair of molds based on production volume and usage.Product material selection:a. Wear resistance: Cam POM injection molded parts need to have good wear resistance to ensure a long service life in an environment of friction and wear. Therefore, it is important to choose POM materials with good wear resistance.b. Strength and rigidity: Cam POM injection molded parts need to have high strength and rigidity to withstand large loads and stresses. Therefore, it is critical to select POM materials with high strength and rigidity.c. Chemical resistance: Cam POM injection molded parts may be exposed to some chemicals, such as lubricating oil, coolant, etc. Therefore, choose POM materials with good chemical resistance that can resist the erosion and corrosion of chemical substances.d. Dimensional stability: Cam POM injection molded parts need to have good dimensional stability to ensure good dimensional accuracy when temperature changes. Therefore, it is important to choose POM materials with lower linear expansion coefficients.Through the above process and material selection, high-quality cam POM injection molded parts can be manufactured. At the same time, it is also necessary to strictly abide by relevant safety regulations and operating procedures to ensure the safety of the working environment and the health of employees.

- Mass production and quality assurance of cam POM

Mass production and quality assurance of cam POM injection molded parts are the key to ensuring product quality and production efficiency.Production planning and scheduling: Develop detailed production plans, including production time, quantity, delivery date, etc. According to the production plan, reasonably arrange production tasks and resources to ensure that production tasks are completed on time.Injection molding process control: Establish strict injection molding process control, including the control of injection temperature, injection pressure, injection speed and other parameters. Through real-time monitoring and adjustment of process parameters, the dimensional accuracy and appearance quality of the product are ensured.Raw material control: Strictly control the quality and source of raw materials. Work with reliable suppliers to ensure raw materials meet product requirements and standards. Conduct inspection and testing of raw materials to ensure stable quality of raw materials.Production process control: Use statistical process control (SPC) methods to monitor and analyze the production process in real time. By collecting and analyzing data, abnormalities and variations in the production process are discovered and corrected in a timely manner to ensure the stability and consistency of product quality.Inspection and testing: Inspection and testing are carried out during the production process, including raw material inspection, process inspection and finished product inspection. Use appropriate testing equipment and methods to test the size, appearance and function of the product to ensure that the product meets the requirements.Capacity planning and scheduling: Capacity planning and scheduling are carried out according to customer needs and delivery time. Arrange production plans reasonably to ensure production tasks are completed on time.After-sales service and customer feedback: Establish a sound after-sales service and customer feedback mechanism to handle customer problems and needs in a timely manner. Through customer feedback, understand product usage and quality issues, and make timely improvements and corrections.Continuous improvement: Improve production efficiency and product quality through continuous improvement and optimization of the production process. Adopt advanced technology and processes, introduce automation and intelligent equipment, and improve the stability and consistency of production.

contact us

Try Our Problem-solving Injection Molding Services Now

ISO 13485 Certified factory

ISO 8 Cleanroom

Robust Expertise for Medical Injection Molding

Advanced mold manufacturing capabilities and plastic injection molding equipment

Quick Response within 12 hours

- If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.