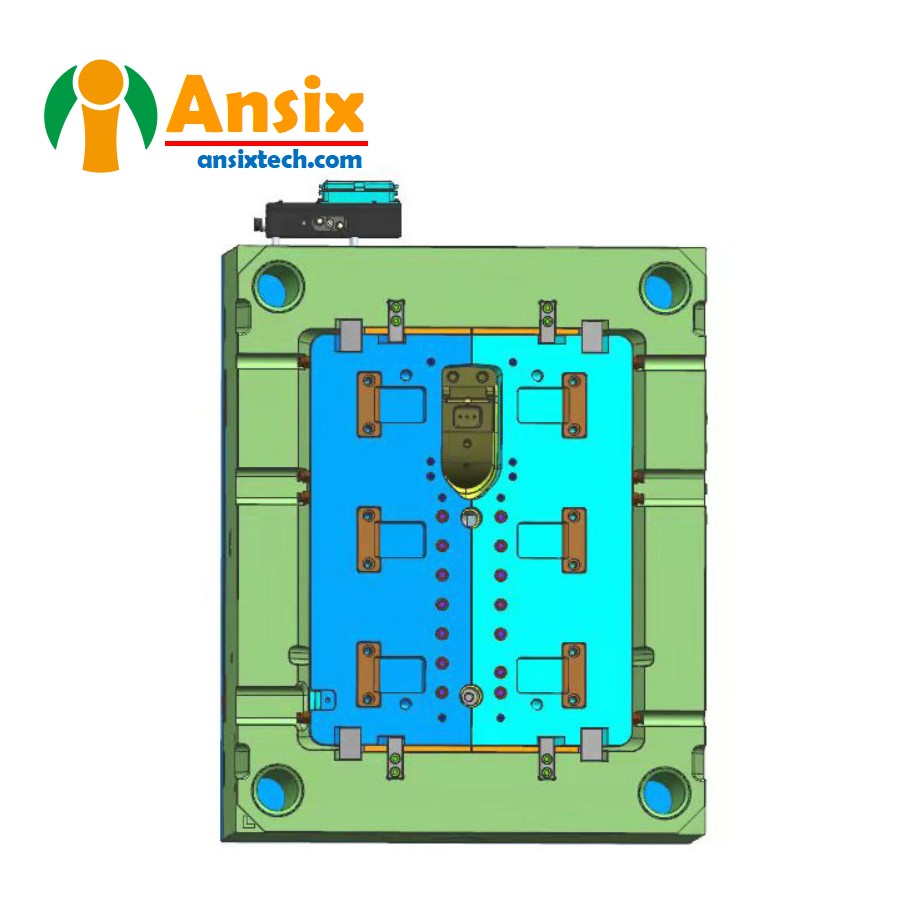

Gas-assisted injection molding for Bike Frame Mold for Kids

FEATURES

-

Mold Description

Product Materials:

PP

Mold Material:

738

Number of Cavities:

1*1

Glue Feeding Method:

Cold runner

Cooling Method:

Oil cooling

Molding Cycle

48.5s

- For mold flow analysis and mold design of gas-assisted molds for children’s bicycle frames, the following are some key considerations:Mold flow analysisGas-Assisted Mold Design: Mold flow analysis needs to consider the design of gas-assisted molds to ensure that gas can fully fill the mold cavity and obtain appropriate exhaust channels during the molding process.Filling simulation: Simulate the filling situation of the gas-assisted mold during the injection molding process to ensure that the gas filling is sufficient and uniform, and to avoid defects such as bubbles and short injection.Cooling Simulation: Conduct cooling simulation to evaluate parameters such as cooling time, temperature distribution and shrinkage to ensure uniform cooling of the entire frame and reduce quality problems caused by uneven deformation and shrinkage.Thermal Stress Analysis: Analyze thermal stress and design reasonable structures and cooling systems to reduce the impact of thermal stress on product quality.Automotive auxiliary mold designMold structure design: Design the mold structure, including mold cavity, cooling system, gas-assisted mold, etc., to ensure that the complex structure and details of the frame can be accurately formed.Material Selection: Choose a suitable mold material, usually tool steel with high hardness, high strength and wear resistance, to ensure the service life and stability of the mold.Gas-assisted mold design: Design a reasonable gas-assisted mold structure to ensure that gas can fully fill the mold cavity and obtain appropriate exhaust channels during the molding process.Gate design: Reasonable gate design can ensure uniform melt filling and reduce defects such as bubbles and short injection.Mold processing accuracy: Mold processing requires high precision to ensure the size and surface quality of the final product.The above are the general key points of mold flow analysis and gas-assisted mold design. These processes and analyzes are crucial to ensuring the production quality and efficiency of gas-assisted molds for children’s bicycle frames.

- Gas-assisted mold of the mold manufacturing process and product material selectionThe difficulties in the manufacturing and processing of gas-assisted molds for children’s bicycle frames and the assembly process of gas-assisted molds mainly include the following aspects:Complex gas-assisted mold design: Gas-assisted molds need to consider the design of the gas channel, the processing and assembly of the gas-assisted mold, which require a high degree of precision and expertise.Gas-assisted mold processing is difficult: The processing of gas-assisted molds requires high-precision processing equipment and technology to ensure the accuracy and surface quality of the gas channel.Complex assembly of gas-assisted molds: The assembly of gas-assisted molds requires strict process requirements to ensure the connection and sealing performance of the gas channels.The gas-assisted injection molding process is difficult to control: The gas-assisted injection molding process requires strict control of the gas filling and exhaust process to ensure product molding quality.In terms of gas-assisted injection molding material selection, it is usually necessary to select materials with good fluidity and melt stability to ensure that the gas can fully fill the mold cavity and obtain appropriate exhaust channels during the molding process. Common gas-assisted injection molding materials include:Polypropylene (PP): It has good fluidity and molding properties and is suitable for gas-assisted injection molding.Polystyrene (PS): It has good fluidity and molding properties and is suitable for gas-assisted injection molding of some children’s bicycle frames.Polycarbonate (PC): It has good melt stability and impact resistance, and is suitable for use in some parts that require higher strength and durability.The above materials have good fluidity and molding properties and can meet the requirements of gas-assisted injection molding. When selecting gas-assisted injection molding materials, the selection needs to be based on specific product requirements and cost considerations to ensure good performance and economics of the final product.

- Mass production and Quality controlThe advantages of mass production of gas-assisted mold injection molding for children’s bicycle frames and the automated configuration and process quality assurance of frame gas-assisted injection molding require comprehensive consideration of production efficiency, product quality and production costs. Here are some possible measures:Advantages of mass productionEfficient production: Gas-assisted injection molding can achieve high-speed, efficient production, is suitable for mass production needs, and improves production efficiency.One-time molding: Gas-assisted injection molding can realize one-time molding of complex structures, reducing subsequent processing steps and improving production efficiency.Product consistency: Gas-assisted injection molding can ensure the consistency of product size and appearance, and improve product quality stability.Automated configurationAutomated injection molding production line: Introduce an automated injection molding production line, including automatic feeding, automatic molding, automatic demoulding and other links to improve production efficiency and reduce manual intervention.Intelligent injection molding equipment: Use intelligent injection molding equipment to achieve high-speed, high-precision injection molding, improving production efficiency and product consistency.Automated mold changing system: Use an automated mold changing system to reduce mold changing time and improve production line utilization.Process Quality AssuranceInjection molding process parameter control: Strictly control the injection molding process parameters to ensure stable product molding quality.Product size inspection: Use automated size inspection equipment to conduct online inspection of product size to ensure product size stability.Appearance quality inspection: Introduce automated appearance quality inspection equipment to conduct online inspection of product appearance to ensure stable product appearance quality.Quality Record Traceability: Establish a complete quality record traceability system to record and trace quality data during the production process to ensure product quality is controllable.Through the above measures, the efficiency and product quality of mass production of gas-assisted mold injection molding of children’s bicycle frames can be improved, ensuring that products can meet market demand and improving the competitiveness of enterprises.