Injection Mold for Household Walkie-Talkie Cover for USA

FEATURES

-

Mold Description

Product Materials:

PC

Mold Material:

S136H

Number of Cavities:

1*1

Glue Feeding Method:

Cold runner

Cooling Method:

Water cooling

Molding Cycle

36.5s

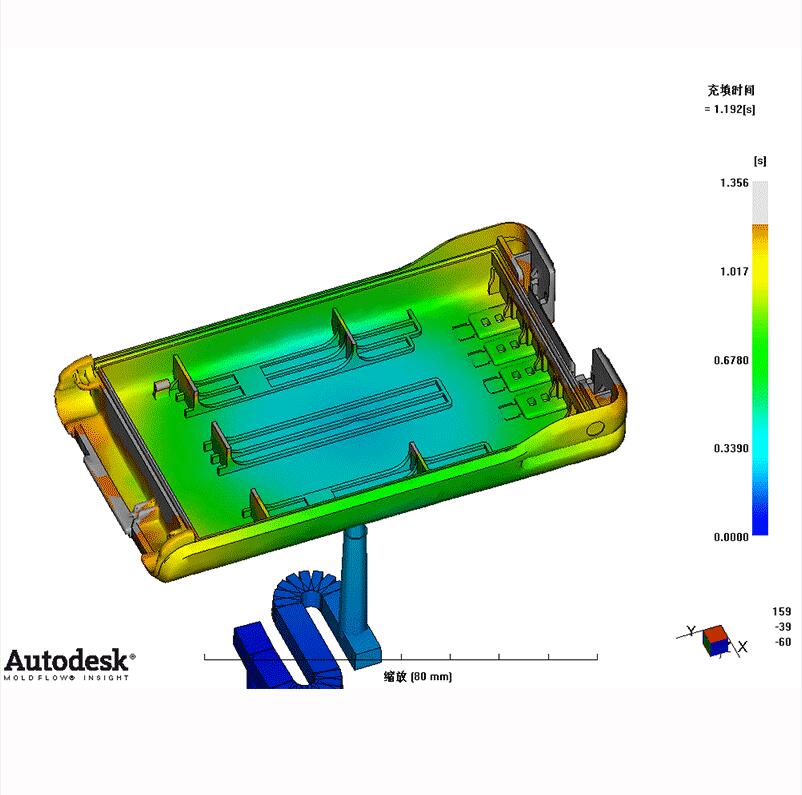

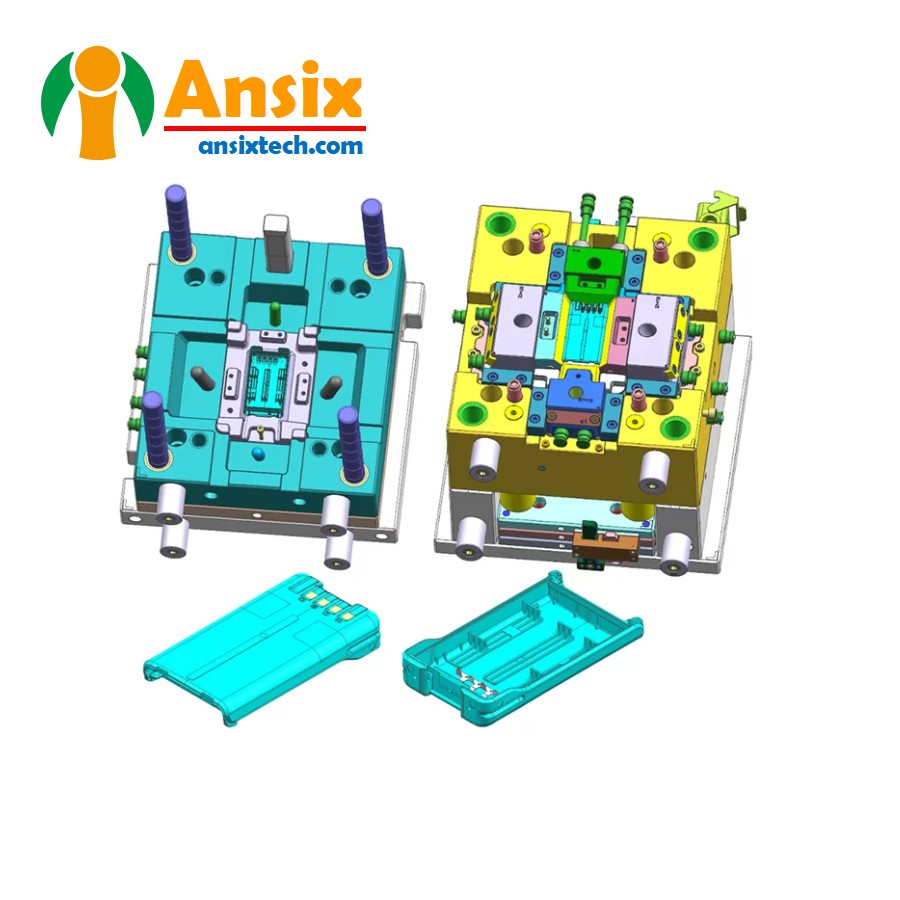

- Injection Mold for Household Walkie-Talkie Cover for USA Mold flow analysis and mold designThe design and mold flow analysis of the American home walkie-talkie shell injection mold:Mold design:According to the design requirements of the home walkie-talkie shell, determine the structure of the mold, including the mold cavity, mold core, demoulding system, cooling system, etc.Ensure that the accuracy and size of the mold meet the requirements to ensure the quality and stability of injection molding.Consider the durability and ease of maintenance of the mold, and rationally design the structure and parts of the mold to improve the life and ease of maintenance of the mold.Mold flow analysis:Use mold flow analysis software to import the CAD model of the home walkie-talkie housing and set the injection molding process parameters, such as injection speed, temperature, pressure, etc.Conduct mold flow analysis to simulate melt flow, filling, cooling and other processes during the injection molding process to evaluate filling performance, bubbles, short shots and other defects, and optimize injection molding process parameters.During the mold design and mold flow analysis process, you need to pay attention to the following points:Ensure filling performance: Through mold flow analysis, the injection molding process parameters are optimized to ensure good filling performance and avoid defects.Design of cooling system: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.Design of demoulding system: According to the shape and requirements of the home walkie-talkie shell, design a suitable demoulding system to ensure that the shell can be demoulded smoothly and avoid damage and deformation.Injection molding sequence and injection point location: Determine the injection sequence and injection point location to ensure that the plastic material can fully fill the mold cavity and avoid voids and defects.Through reasonable mold design and mold flow analysis, high-quality American home walkie-talkie shell injection molds can be obtained. Please note that mold design and mold flow analysis require professional knowledge and experience. It is recommended to cooperate with a professional mold design and mold flow analysis team to ensure the accuracy and reliability of design and analysis.

- Injection Mold for Household Walkie-Talkie Cover for USA of the mold manufacturing process and product material selectionThe manufacturing and processing of American home walkie-talkie shell injection molds and the selection and application of shell materials:Mold manufacturing and processing:According to the mold design, select appropriate processing technology and equipment, such as CNC machining center, EDM machine, etc.Processing of mold parts, including mold cavity, mold core, demoulding system, cooling system, etc. Ensure that the processing accuracy and size meet the requirements.Assemble mold parts to ensure accurate fit and adjustment of parts and ensure the stability and reliability of the mold.Shell material selection:Select the appropriate injection molding material according to the requirements of the home walkie-talkie casing. One of the commonly used materials is PC (polycarbonate).PC material has good strength, rigidity and heat resistance. It is suitable for the manufacture of home walkie-talkie casings and can meet the strength and durability requirements of the product.PC material also has good chemical resistance and wear resistance, and can adapt to the chemicals and wear in the home appliance environment.During the mold manufacturing process and shell material selection and application process, the following points need to be noted:Processing accuracy and size control: Ensure that the processing accuracy and size of mold parts meet the requirements to ensure the quality and stability of injection molding.Surface treatment of the mold: According to the requirements of the home walkie-talkie shell, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the shell.Control of injection molding process parameters: According to the characteristics of the PC material, the injection molding process parameters are reasonably designed and controlled to ensure that the filling performance and curing effect of the material meet the requirements.Material selection and certification: Select injection molding materials that meet relevant standards and certification requirements to ensure product safety and hygiene.The manufacturing and processing of American home walkie-talkie shell injection molds has the advantages of efficient production, precision control, multi-functional design and cost saving. When selecting housing materials, factors such as strength, heat resistance, chemical resistance, and abrasion resistance need to be considered. Through reasonable processing and material selection, high-quality shell production can be achieved. It is recommended to work with professional mold manufacturing and injection molding material suppliers to ensure accuracy and reliability of manufacturing and selection.

- Injection Mold for Household Walkie-Talkie Cover for USA Mass production and Quality controlTo achieve mass production of injection molding, secondary processing, painting, silk screen printing and laser engraving of LOGO for American home walkie-talkie casings, and to ensure process quality control:Production process optimization:Optimize production plans and schedules, reasonably arrange production tasks, and ensure the efficiency and smoothness of the production process.Optimize the material supply chain to ensure timely supply of raw materials and avoid production interruptions and delays.Optimize the process flow, reduce non-production time and improve production efficiency.Automated production equipment:Use automated injection molding machines and robotic systems to achieve automated production, reduce manual operations and improve production efficiency.Automated equipment can increase production speed and consistency and reduce the occurrence of human error.Secondary processing and painting:According to the design requirements, perform secondary processing of the shell, such as deburring, grinding, etc., to improve the appearance quality.Carry out spray painting and spray paint on the shell according to the design requirements, such as color, texture, etc. Use spray painting equipment and suitable spray paint materials to ensure paint results and durability.Silk screen printing and laser engraving LOGO:Perform silk printing on the shell according to the design requirements, such as logos, patterns, etc. Use screen printing equipment and appropriate inks to ensure screen printing quality and durability.Carry out laser engraving of the LOGO, use laser equipment to perform laser engraving of the LOGO to improve the quality and uniqueness of the casing.Tooling, fixtures and process quality control:Design and manufacture appropriate tooling fixtures to secure and position the housing to ensure accuracy and consistency in machining and painting.Establish a complete quality control system, including quality inspection, process control and defective product processing, to ensure that products meet quality standards.Conduct inspections and tests on product appearance quality, dimensional accuracy, physical properties, etc. to ensure product quality and consistency.Through reasonable production process optimization, automated production equipment, secondary processing, spray painting, silk screen printing, laser engraving LOGO, tooling fixtures and process quality control measures, we can achieve mass production of injection molding of American home walkie-talkie casings and ensure process quality control. . It is recommended to work with a professional mold manufacturing and injection molding processing team to ensure accuracy and reliability of manufacturing and processing.