TOM/OMD automotive interior coating technology trends

2024-01-24 16:27:22

At present, the development trends of automobile interior painting technology include the following aspects: Sustainable materials: As people pay more and more attention to sustainable development, the choice of automotive interior covering materials is also more inclined to use environmentally friendly materials, such as renewable fibers, recycled leather, etc. Personalization: Consumer demand for personalization continues to increase, so automakers and custom carmakers will provide more options to meet consumer demand for personalized interiors. High-tech applications: With the continuous development of technology, the automotive interior painting process also tends to incorporate more high-tech elements, such as smart touch panels, color-changing materials, etc. Lightweight design: In order to improve fuel efficiency and environmental performance, automotive interior covering processes also tend to use lighter materials to reduce the weight of the entire vehicle. These trends will continue to influence the development direction of automotive interior painting processes and promote continuous innovation and improvement in the industry.

Using Japanese CFM vacuum coating machine, the product yield can reach 99.2%

The CFM (Chemical Vapor Deposition) vacuum coating is a common surface treatment technology, which can use chemical reactions to form a thin film on the surface of the material. This technology is usually used to improve the hardness, wear resistance, conductivity and other properties of materials. Vacuum coating equipment usually includes vacuum chambers, chemical vapor delivery systems, heating systems and other components. If you require information on a specific CFM vacuum coating machine, it is recommended that you contact the relevant manufacturer or supplier directly for detailed product specifications and performance characteristics.

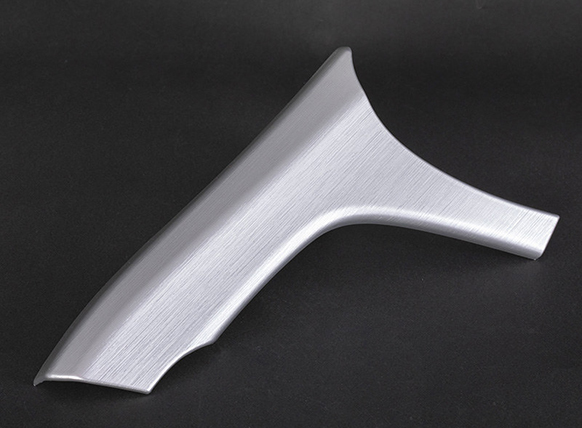

Brushed pattern(TOM/OMD process)

Brushed metal surface decoration(TOM Process) is a common surface treatment method that creates subtle textures on the metal surface to increase its decorativeness and texture. This method of decoration is commonly used on home products, accessories, electronic devices, and more. Wire drawing can be achieved through mechanical drawing, chemical corrosion, electrochemical treatment and other methods, thereby forming different texture effects on the metal surface. This decoration method is also widely used on plastic and metal products.

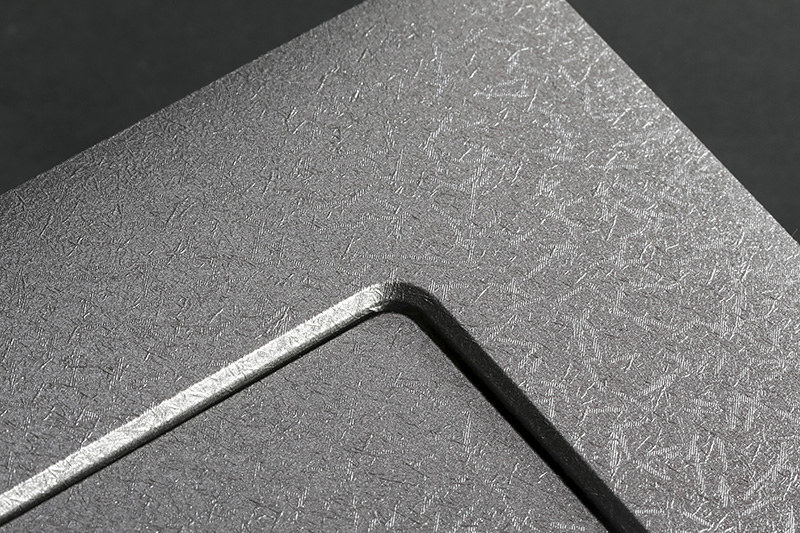

Metallic silver(TOM/OMD process)

The metallic effect can be achieved through a number of methods, including: Brushing: Use tools such as abrasive belts or wire brushes to brush the metal surface to produce a fine line texture. Chemical corrosion: The metal surface is treated with specific chemical solutions or acidic solutions to produce various texture effects. Sandblasting: Using high-pressure air to spray fine abrasive particles onto a metal surface, creating a frosted texture. Anodizing: Suitable for aluminum and other stainless steel materials. Under electrolytic conditions, a reticular or granular texture is generated through surface oxidation. These methods can be used to create various texture effects on metal surfaces to achieve different decorative effects and textures. If you have specific metals and specific application needs, describe them to me in detail and I can provide more specific assistance.The TOM process can improve product qualification and product service life.

Low cost mold (fixture)--TOM/OMD process

We use extremely low-cost tooling fixtures and do not need to choose expensive steel molds, which can greatly reduce the initial investment cost of the product.

-

Wood grain (TOM/OMD process)

Wood grain (TOM/OMD process)

-

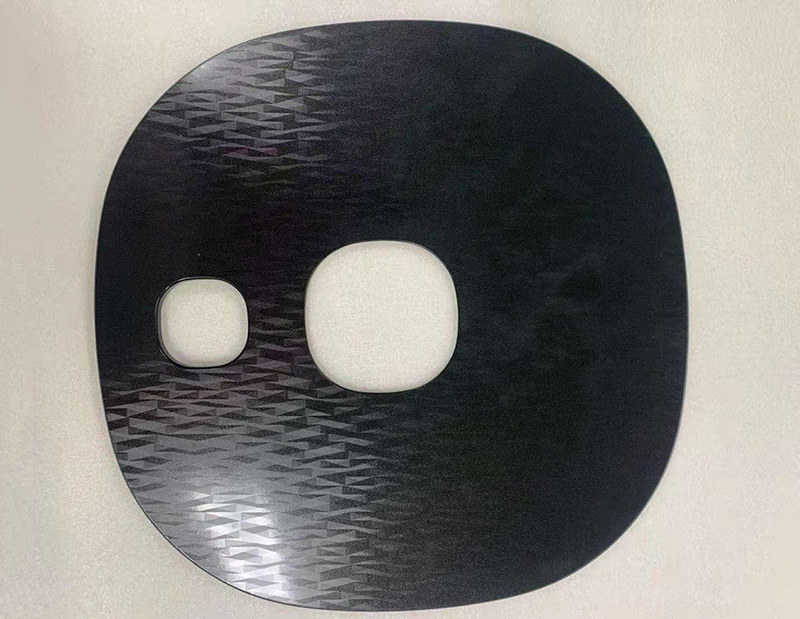

Household appliances panel(TOM/OMD process)

Household appliances panel(TOM/OMD process)

If you want to know more about TOM/OMD injection molding process, We have the most advanced manufacturing equipment in the world, and the mold accuracy can reach 0.002mm. We can provide you with the most effective quality assurance and the most competitive price.please call the official consultation hotline: 0086 13530645990 or enter the official website: https://www.ansixtech.com to learn more.