AnsixTech Injection Mould for Auto Steering Wheel Button Frame

FEATURES

- Ansix Injection Mold for Auto Steering Wheel Button Frame moulding

Car door panel armrest buttons are usually manufactured by injection molding. Injection molding is a common plastic processing process used to produce a variety of plastic products, including automotive interior parts.The following is the general process flow of injection molding of car door panel armrest buttons:1. Mold design: First, carry out the mold design of the car door panel armrest button, including product structure design, mold structure design, injection molding system design, etc. Designers need to design a reasonable mold structure based on the shape, size and functional requirements of the product.2. Material preparation: Select appropriate plastic materials for injection molding. Common automotive interior parts materials include ABS, PC, PP and other engineering plastics, which need to be selected according to the specific requirements of the product.3. Mold manufacturing: According to the design drawings, injection molds for car door panel armrest buttons are manufactured. This includes mold processing, assembly and debugging. Mold manufacturing requires the use of high-precision processing equipment and processes to ensure the quality and life of the mold.4. Raw material pretreatment: The selected plastic raw material is pretreated, usually the granular plastic raw material is heated and melted to facilitate injection molding.5. Injection molding: Inject the preheated plastic raw material into the mold cavity through the screw of the injection molding machine. Under certain pressure and temperature conditions, the plastic raw material fills the mold cavity and forms the shape of the product.6. Cooling and solidification: Cooling in the mold for a period of time allows the plastic raw materials to solidify and form.7. Take out the product: Open the mold and take out the formed car door panel armrest button product.8. Trimming and post-processing: trim the product, remove excess material, remove flash and other post-processing processes.9. Quality inspection: Conduct quality inspection on the formed products. This includes dimensional measurement, visual inspection, functional testing, etc. to ensure that the product meets customer requirements and standards.10. Packaging and shipping: Products that pass quality inspection are packaged and prepared for shipment.The above is the general process flow of injection molding of car door panel armrest buttons. This process requires strict control to ensure product quality and delivery cycle.

-

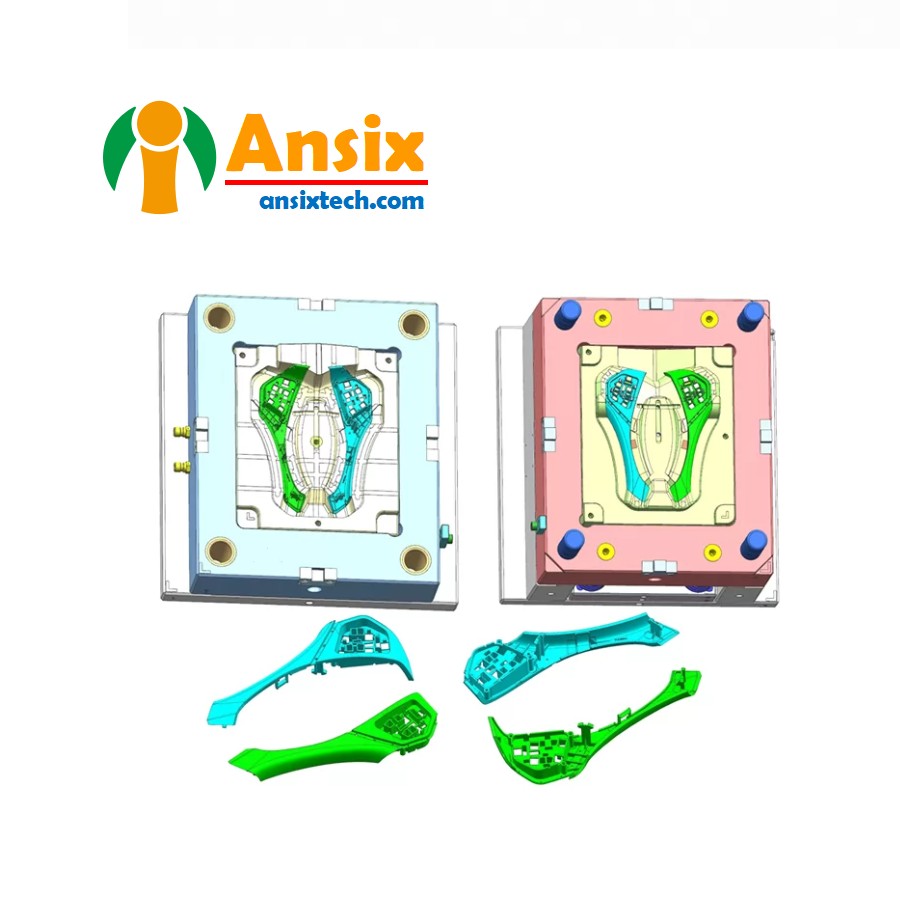

Mold Description

Product Materials:

PC

Mold Material:

S136ESR

Number of Cavities:

2+2+2

Glue Feeding Method:

Cold runner, Side Gate

Cooling Method:

Water cooling

Molding Cycle

22.5s

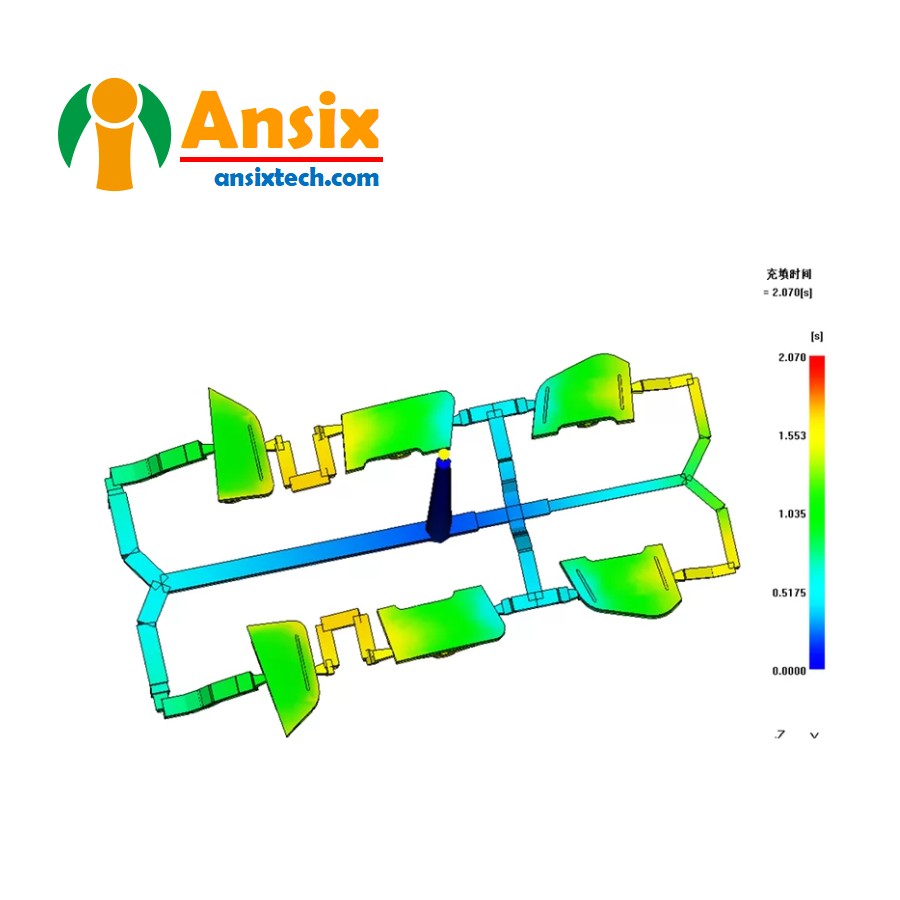

- Auto Steering Wheel Button Frame Mold flow analysis and mold designThe design and mold flow analysis of automobile steering wheel button frame molds are very important links in automobile interior manufacturing. The design and mold flow analysis of the automobile steering wheel button frame mold will.Design of automobile steering wheel button frame mold:a. Collect relevant information about the steering wheel button frame, including size, shape, material, etc.b. According to the design requirements of the steering wheel button frame, design the mold, including mold cavity, mold core, demoulding system, cooling system, etc.c. Ensure that the accuracy and size of the mold meet the requirements to ensure the quality and stability of the steering wheel button frame.Mold flow analysis of automobile steering wheel button frame mold:a. Use mold flow analysis software to import the CAD model of the steering wheel button frame and set the injection molding process parameters, such as injection speed, temperature, pressure, etc.b. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance, bubbles, short shots and other defects of the steering wheel button frame, and optimize the injection molding process parameters.Design of demoulding system: According to the shape and requirements of the steering wheel button frame, design a suitable demoulding system to ensure that the steering wheel button frame can be demoulded smoothly and avoid damage and deformation.The design and mold flow analysis of the automobile steering wheel button frame mold require mold design, optimization of injection molding process parameters, and mold flow analysis. Through reasonable design and control, a high-quality car steering wheel button frame can be obtained.

- Auto Steering Wheel Button Frame of the mold manufacturing process and product material selectionThe manufacturing process and injection molding material selection of automobile steering wheel button frame molds:Button mold processing usually includes the following processes:1. Mold design: First, design the button mold, including product structure design, mold structure design, injection molding system design, etc. Designers need to design a reasonable mold structure based on customer needs and product characteristics.2. Material preparation: Selecting the appropriate mold material is crucial to the quality and life of the mold. Common mold materials include tool steel, carbide, etc. The selection of materials should take into account factors such as the use environment of the mold, processing technology and cost.3. Mold processing: Mold processing usually includes CNC machining, EDM, wire cutting and other processes. CNC machining is one of the main methods of mold processing, which can achieve high-precision and high-efficiency processing. EDM and wire cutting are suitable for processing high-hardness, high-precision mold parts.4. Mold assembly and debugging: After the mold processing is completed, the mold needs to be assembled and debugged. This includes assembly of mold parts, debugging and testing of molds, etc.Button materials are usually engineering plastics. Common button materials include:1. ABS: It has good strength and toughness, is oil-resistant, wear-resistant, and high-temperature resistant, and is suitable for making durable button products.2. PC (polycarbonate): It has excellent heat resistance and impact resistance, high transparency, and is suitable for key products that require transparency or translucency.3. PA (nylon): It has good wear resistance and corrosion resistance, and is suitable for key products that require wear resistance.4. POM (polyoxymethylene): It has good mechanical properties and wear resistance, and is suitable for making wear-resistant button products.The above are the general button mold processing procedures and common button materials. In actual production, it is also necessary to select appropriate mold materials and button materials according to specific product requirements and use environment.Injection molding material selection:Select the appropriate injection molding material according to the requirements of the steering wheel button frame. Commonly used materials include ABS, PC, PP, etc.ABS material has good toughness, impact resistance and wear resistance. It is suitable for the shell part of the steering wheel button frame and can provide better appearance and durability.PC material has excellent high temperature resistance, chemical resistance and weather resistance. It is suitable for the functional parts of the steering wheel button frame and can meet the requirements of high temperature environments and chemical substances.PP material has good chemical resistance and weather resistance. It is suitable for the flexible part of the steering wheel button frame and can provide good flexibility and durability.In the automotive steering wheel button frame mold manufacturing process and injection molding material selection process, you need to pay attention to the following points:Surface treatment of the mold: According to the requirements of the steering wheel button frame, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the steering wheel button frame.The manufacturing process and injection molding material selection of the automobile steering wheel button frame mold require the selection of appropriate processing technology and equipment, and the selection of materials with good mechanical properties, high temperature resistance and wear resistance. Through reasonable processing and control of injection molding process parameters, high-quality automobile steering wheel button frames can be realized.

- Auto Steering Wheel Button Frame Mass production and Quality controlThe injection molding mass production and process quality control of automobile steering wheel button frames :Production planning and scheduling:Develop reasonable production plans and schedules to ensure orders are completed on time and rationally arrange production resources and manpower.Optimization of injection molding process parameters:Improve filling performance and reduce production cycle by optimizing injection molding process parameters, such as injection speed, temperature, pressure, etc.Conduct mold flow analysis to simulate melt flow, filling, cooling and other processes during the injection molding process to evaluate and optimize injection molding process parameters.Injection molding equipment and automation:Use advanced injection molding equipment and automation systems to improve production efficiency and stability, and reduce the impact of manual operations and human factors.Quality control:Conduct inspections and tests on product appearance quality, dimensional accuracy, physical properties, etc. to ensure product quality and consistency.Use statistical process control (SPC) and other methods to monitor key parameters in the production process and detect and correct abnormal situations in a timely manner.Continuous improvement:Continuously improve production processes and techniques, optimize injection molding process parameters and mold design to improve product quality and production efficiency.Carry out fault analysis and problem solving, handle abnormal situations in production in a timely manner, and avoid the production of defective products.Through reasonable production planning and scheduling, optimizing injection molding process parameters, using advanced equipment and automation systems, establishing a complete quality control system and continuous improvement, injection molding mass production and process quality control of automobile steering wheel button frames can be achieved. This ensures product consistency, quality stability and improved production efficiency.