Center Console Button Automotive Interior Injection Mold Moldeo Por Inyeccion

FEATURES

-

Mold Description

Product Materials:

ABS+PC

Mold Material:

S136ESR

Number of Cavities:

1*2

Glue Feeding Method:

Cold runner

Cooling Method:

Water cooling

Molding Cycle

21.5s

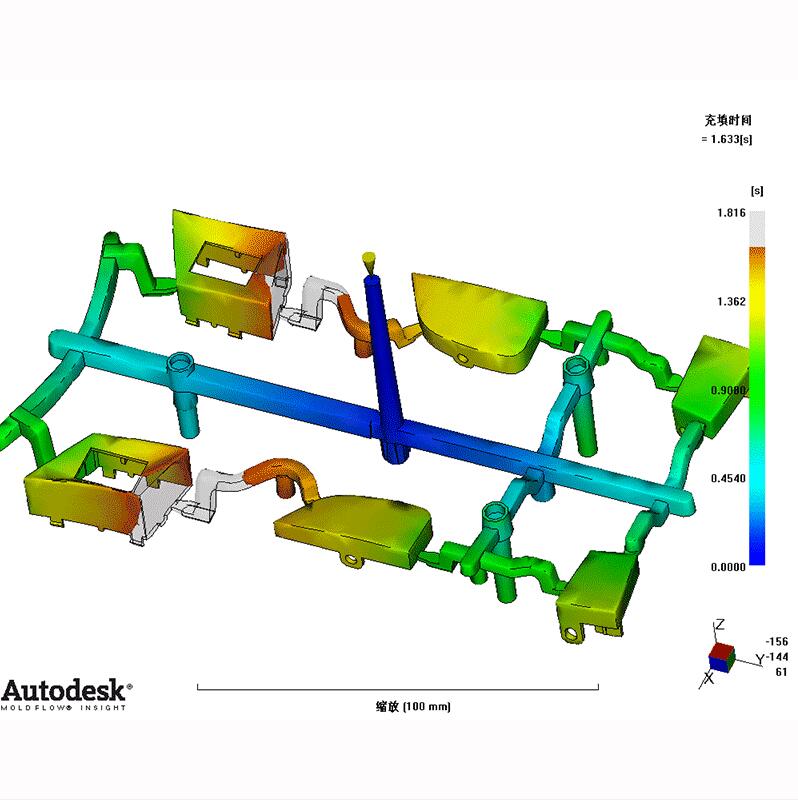

- Center Console Button Automotive Interior Mold flow analysis and mold designThe design and mold flow analysis of automotive interior center console button molds are very important links in automotive interior manufacturing. The design and mold flow analysis of the automotive interior center console button mold will.Design of car interior center console button mold:a. Collect relevant information about the center console buttons, including size, shape, material, etc.b. According to the design requirements of the center console button, design the mold, including mold cavity, mold core, demoulding system, cooling system, etc.c. Ensure that the accuracy and size of the mold meet the requirements to ensure the quality and stability of the center console buttons.d. Use CAE/CAD/CAM software for mold design and generate three-dimensional models and engineering drawings of the mold.Mold flow analysis of automobile interior center console button mold:a. Use mold flow analysis software to import the CAD model of the center console button and set the injection molding process parameters, such as injection speed, temperature, pressure, etc.b. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance, bubbles, short shots and other defects of the center console button, and optimize the injection molding process parameters.Design of the demoulding system: According to the shape and requirements of the center console button, design an appropriate demoulding system to ensure that the center console button can be demoulded smoothly and avoid damage and deformation.In summary, the design and mold flow analysis of the automotive interior center console button mold require mold design, optimization of injection molding process parameters, and mold flow analysis. Through reasonable design and control, high-quality car interior center console buttons can be obtained.

- Center Console Button Automotive Interior of the mold manufacturing process and product material selectionThe manufacturing, processing and injection molding material selection of automotive interior center console button molds involve the following aspects:Mold manufacturing and processing:Keyboard two-color button mold manufacturing and secondary processing usually include the following steps:1. Mold design: First, design the two-color mold, including product structure design, mold structure design, injection molding system design, etc. Designers need to design a reasonable mold structure based on customer needs and product characteristics.2. Mold manufacturing: According to the design drawings, two-color button molds are manufactured. This includes mold processing, assembly and debugging. Mold manufacturing requires the use of high-precision processing equipment and processes to ensure the quality and life of the mold.3. Injection molding: Use a two-color injection molding machine to perform injection molding. Inject two different colors of plastic materials into the mold to complete the molding of the two-color button.4. Secondary processing: For some two-color button products that require special surface treatment or assembly, secondary processing may be required. This includes surface spraying, printing, coating and other processes, as well as assembly, lamination and other processes.5. Quality control: Conduct quality inspection on the formed two-color button products. This includes dimensional measurement, visual inspection, functional testing, etc. to ensure that the product meets customer requirements and standards.6. Packaging and shipment: Pack the two-color button products that have passed the quality inspection and prepare them for shipment.Injection molding material selection:Select the appropriate injection molding material according to the requirements of the center console button. Commonly used materials include ABS, PC, PP, etc.Considering the appearance requirements, wear resistance and high temperature resistance of the center console buttons, choose materials with good mechanical properties and durability.Select materials with chemical resistance and weather resistance based on the function of the center console buttons and the environment in which they are used.During the manufacturing and processing of automotive interior center console button molds and the selection of injection molding materials, the following points need to be noted:Surface treatment of the mold: According to the requirements of the center console button, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the center console button.The manufacturing and processing of automobile interior center console button molds and the selection of injection molding materials require the selection of appropriate processing techniques and equipment, and the selection of materials with good mechanical properties, high temperature resistance and wear resistance. Through reasonable processing and control of injection molding process parameters, high-quality automotive interior center console buttons can be realized.

- Center Console Button Automotive Interior Mass production and Quality controlThe injection molding mass production of car interior center console buttons involves the following aspects:Mold preparation:According to the design requirements of the center console button, prepare the corresponding injection mold. Ensure the quality and stability of the mold to meet the needs of mass production.Material preparation:According to the requirements of the center console button, prepare appropriate injection molding materials, such as ABS, PC, PP, etc. Ensure the quality and stability of materials to ensure product consistency.Injection molding production:Set appropriate injection molding process parameters, such as injection speed, temperature, pressure, etc. According to the characteristics of the material and the requirements of the product, the process parameters are optimized to obtain the best injection molding effect.For injection molding production, molten plastic material is injected into the mold, fills the mold cavity, and is cooled and solidified.Control the injection molding cycle to ensure the stability and consistency of the injection molding process.Quality control:Improvement of production efficiency:Optimize injection molding process parameters and mold design to improve production efficiency and reduce production costs.Through reasonable mold preparation, material preparation, injection molding production and quality control, injection molding mass production of automobile interior center console buttons can be achieved. At the same time, by optimizing production efficiency and improving quality control, production efficiency can be improved and product quality guaranteed.