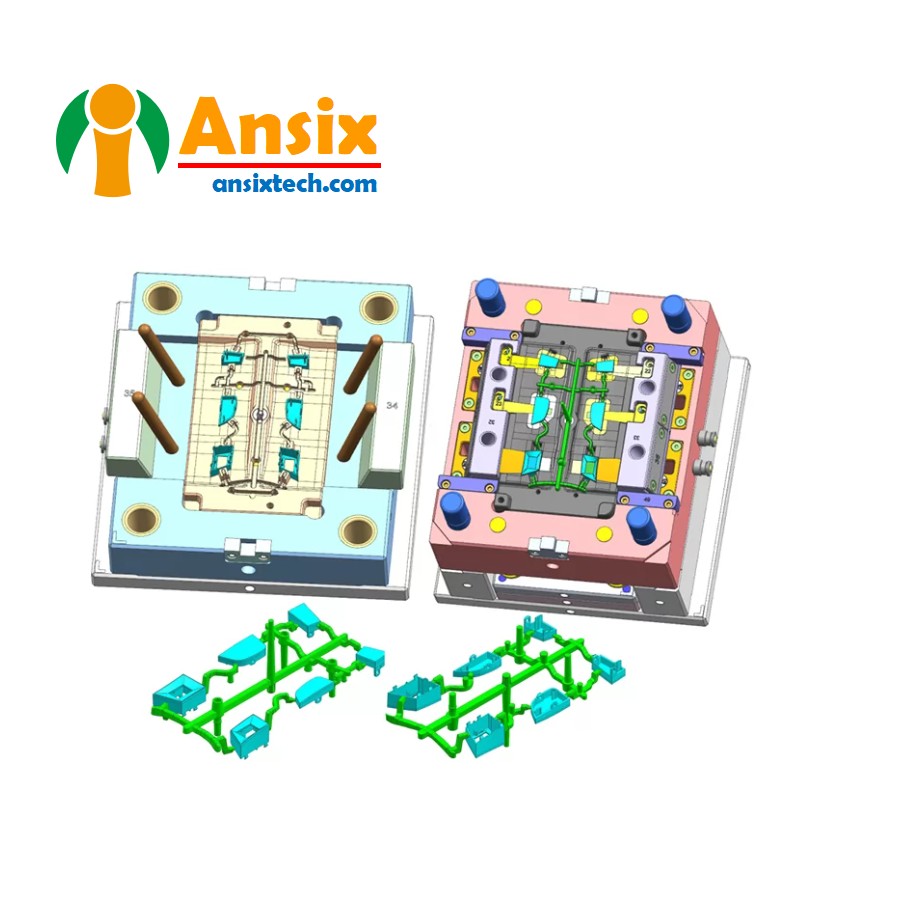

Injection Molding Mold for Automotive Steering Wheel Button

FEATURES

- Injection Molding Mold for Automotive Steering Wheel Button

Inspection and trimming: Inspect injection molded parts to check size, appearance and quality, etc. Trim and post-process if necessary.Maintenance and maintenance: Regular maintenance and upkeep of injection molds, including cleaning, lubrication, replacement of worn parts, etc., to ensure long-term use of the mold.The manufacturing of injection molding molds for automobile steering wheel buttons requires consideration of factors such as the shape, size, and material properties of the steering wheel buttons. At the same time, it is also necessary to design an appropriate mold structure and cooling system according to the requirements of the injection molding process to ensure the quality and efficiency of injection molding. The manufacturing of injection molds requires experienced engineers and technicians to ensure the accuracy and stability of the mold. please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

-

Mold Description

Product Materials:

PC

Mold Material:

S136ESR

Number of Cavities:

1+1+1+1+1+1

Glue Feeding Method:

Cold runner, Side Gate

Cooling Method:

Water cooling

Molding Cycle

22.5s

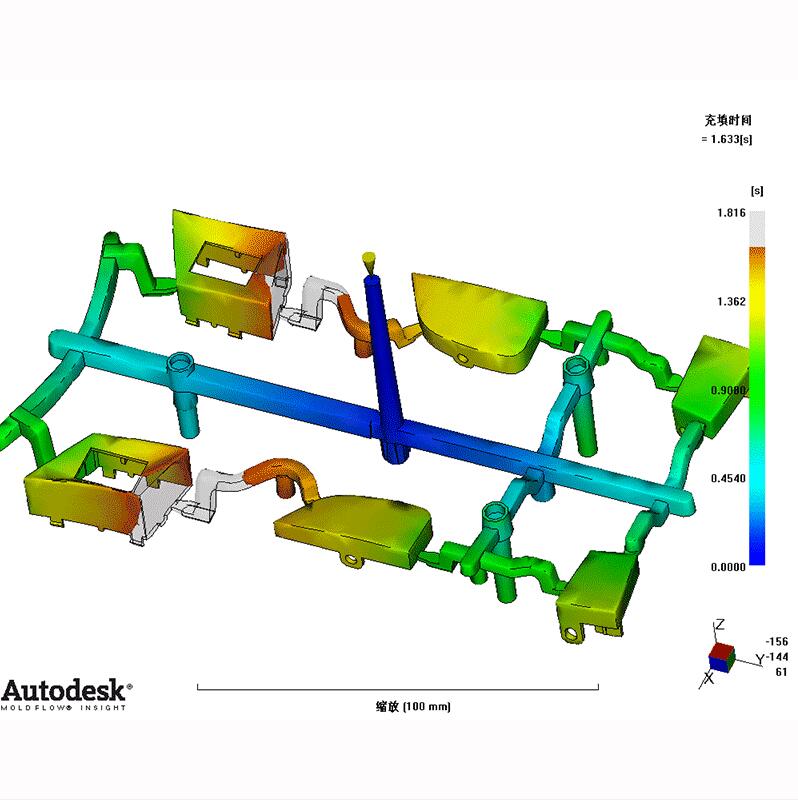

- Automotive Steering Wheel Button Mold flow analysis and mold designMold flow analysis and mold design of automotive steering wheel button molds are very important links in automotive interior manufacturing. The following will introduce the mold flow analysis and mold design of the automobile steering wheel button mold respectively.Mold flow analysis of automobile steering wheel button mold:a. Use mold flow analysis software to import the CAD model of the steering wheel buttons and set the injection molding process parameters, such as injection speed, temperature, pressure, etc.b. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance of the steering wheel buttons, bubbles, short shots and other defects, and optimize the injection molding process parameters.During the mold flow analysis process, you need to pay attention to the following points:Ensure filling performance: Through mold flow analysis, the injection molding process parameters are optimized to ensure good filling performance and avoid defects.Design of cooling system: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.Design of the demoulding system: According to the shape and requirements of the steering wheel buttons, design a suitable demoulding system to ensure that the steering wheel buttons can be demoulded smoothly and avoid damage and deformation.Injection molding sequence and injection point location: Determine the injection sequence and injection point location to ensure that the plastic material can fully fill the mold cavity and avoid voids and defects.Mold design of automobile steering wheel button mold:a. According to the design requirements of the steering wheel buttons, design the mold, including mold cavity, mold core, demoulding system, cooling system, etc.b. Ensure that the accuracy and size of the mold meet the requirements to ensure the quality and stability of the steering wheel buttons.c. Use CAD software to design the mold and generate the three-dimensional model and engineering drawings of the mold.During the mold design process, you need to pay attention to the following points:Processing accuracy and size control: Ensure that the processing accuracy and size of mold parts meet the requirements to ensure the quality and stability of injection molding.Surface treatment of the mold: According to the requirements of the steering wheel buttons, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the steering wheel buttons.Consider the durability and ease of maintenance of the mold: Reasonably design the structure and parts of the mold to improve the durability and ease of maintenance of the mold, and reduce downtime and repair costs.In summary, the mold flow analysis and mold design of the automobile steering wheel button mold require mold flow analysis, optimization of injection molding process parameters, and mold design. Through reasonable design and control, high-quality car steering wheel buttons can be obtained.

- Automotive Steering Wheel Button of the mold manufacturing process and product material selectionThe manufacturing, processing and injection molding material selection of automobile steering wheel button molds:Mold manufacturing and processing:According to the mold design, select appropriate processing technology and equipment, such as CNC machining center, EDM machine, etc.Processing of mold parts, including mold cavity, mold core, demoulding system, cooling system, etc. Ensure that the processing accuracy and size meet the requirements.Assemble mold parts to ensure accurate fit and adjustment of parts and ensure the stability and reliability of the mold.Injection molding material selection:Select the appropriate injection molding material according to the requirements of the steering wheel buttons. Commonly used materials include PC, ABS, PC/ABS, etc.PC material has excellent high temperature resistance, chemical resistance and weather resistance. It is suitable for the functional parts of the steering wheel buttons and can meet the requirements of high temperature environments and chemical substances.ABS material has good toughness, impact resistance and wear resistance. It is suitable for the shell part of the steering wheel button and can provide better appearance and durability.PC/ABS material combines the advantages of PC and ABS, has good mechanical properties, high temperature resistance and chemical resistance, and is suitable for the overall structure of steering wheel buttons.In the process of automobile steering wheel button mold manufacturing and injection molding material selection, you need to pay attention to the following points:Processing accuracy and size control: Ensure that the processing accuracy and size of mold parts meet the requirements to ensure the quality and stability of injection molding.Surface treatment of the mold: According to the requirements of the steering wheel buttons, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the steering wheel buttons.Control of injection molding process parameters: According to the characteristics of the injection molding material, reasonably design and control the injection molding process parameters to ensure that the filling performance and curing effect of the material meet the requirements.Material selection and certification: Select injection molding materials that meet relevant standards and certification requirements to ensure product safety and hygiene.The manufacturing and processing of automobile steering wheel button molds and the selection of injection molding materials require the selection of appropriate processing techniques and equipment, and the selection of materials with excellent high temperature resistance, chemical resistance and weather resistance. Through reasonable processing and control of injection molding process parameters, high-quality automobile steering wheel buttons can be realized.

- Automotive Steering Wheel Button Mass production and Quality controlThe injection molding mass production of automobile steering wheel buttons involves aspects such as tooling and fixtures, production efficiency, cost control, and process quality assurance.Tooling fixtures:Proper design of tooling fixtures can improve production efficiency and quality stability. According to the shape and requirements of the steering wheel buttons, a suitable tooling fixture is designed to ensure the fixation and positioning of the injection molded parts.The design of tooling fixtures should also consider ease of operation and maintenance to improve production efficiency and reduce labor costs.Production efficiency:Optimize injection molding process parameters, such as injection speed, temperature, pressure, etc., to improve filling performance and reduce production cycle.Use automated injection molding machines and robotic systems to achieve automated production, reduce manual operations and improve production efficiency.Use multi-cavity molds and multi-machine production for simultaneous production to increase output and production efficiency.Cost control:Reasonable selection of injection molding materials and mold materials to reduce material costs and mold manufacturing costs.Optimize the production process, reduce scrap rate and energy consumption, and reduce production costs.Through mass production, the mold manufacturing cost is shared and the production cost per unit product is reduced.Process quality assurance:Establish a complete quality control system, including quality inspection, process control and defective product processing, to ensure that products meet quality standards.Conduct inspections and tests on product appearance quality, dimensional accuracy, physical properties, etc. to ensure product quality and consistency.Continuously improve the production process and optimize injection molding process parameters and mold design to improve product quality and production efficiency.Continuous improvement:Continuously improve production processes and techniques, optimize injection molding process parameters and mold design to improve product quality and production efficiency.Carry out fault analysis and problem solving, handle abnormal situations in production in a timely manner, and avoid the production of defective products.Through reasonable tooling and fixture design, optimizing production efficiency, controlling costs and ensuring process quality, injection molding mass production and process quality assurance of automobile steering wheel buttons can be achieved. This ensures product consistency, quality stability and improved production efficiency.