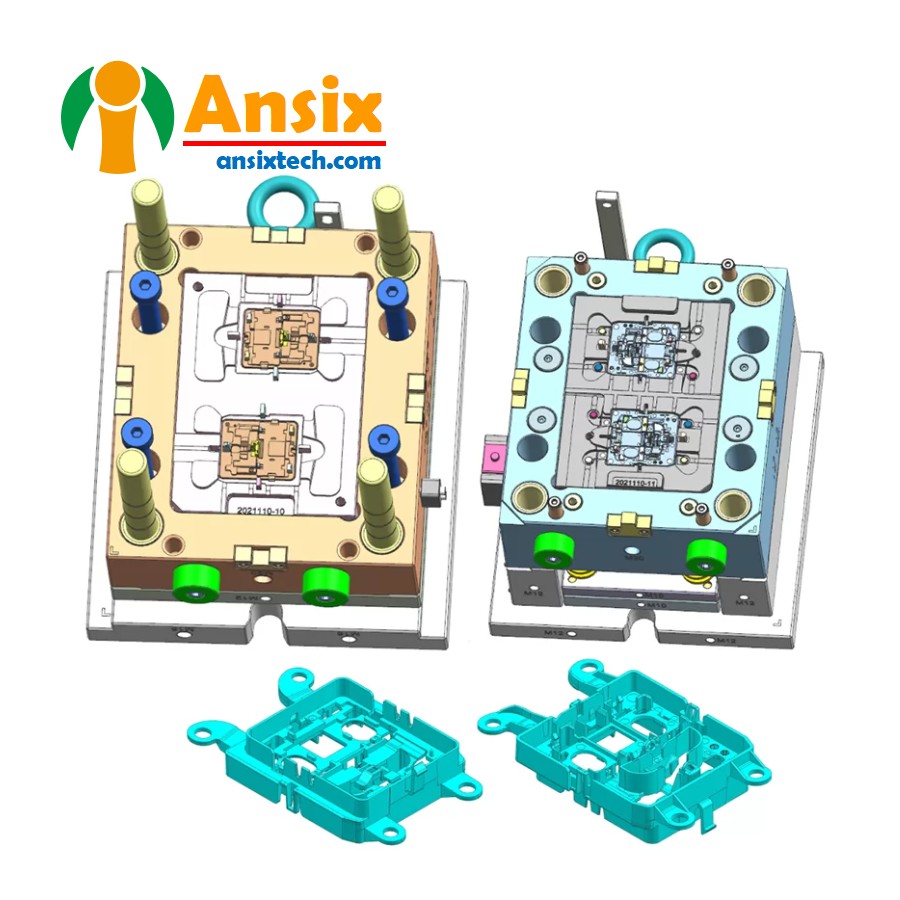

Automotive Plastic Injection Mold Reading Light Housing

FEATURES

- Automotive Plastic Injection Mold Reading Light Housing

Quality control: Quality control of automotive reading light housings requires inspection of the size, appearance and function of injection molded parts. This includes dimensional measurements, visual inspections and functional tests using suitable measuring tools.As an important part of the car’s interior lighting system, the car reading light housing needs to have good quality and reliability. Therefore, during the design and manufacturing process, relevant automotive industry standards and quality requirements need to be strictly adhered to to ensure the performance and safety of the housing.Please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

-

Mold Description

Product Materials:

PC+ABS

Mold Material:

738H

Number of Cavities:

1*2

Glue Feeding Method:

Hot runner

Cooling Method:

Water cooling

Molding Cycle

22.5s

- Automotive Reading Light Housing Mold flow analysis and mold designMold flow analysis and mold design of automobile reading lamp housing molds are very important links in the manufacturing of automobile reading lamp housings. The mold flow analysis and mold design of the automotive reading lamp housing mold :Mold flow analysis of automobile reading lamp housing mold:a. Collect relevant information about the car reading light housing, including size, shape, material, etc.b. Use mold flow analysis software to import the CAD model of the car reading lamp housing and set the injection molding process parameters, such as injection speed, temperature, pressure, etc.c. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance, bubbles, short shots and other defects of the shell, and optimize the injection molding process parameters.Design of car reading lamp housing mold:a. According to the requirements of the shell, design the mold, including mold cavity, mold core, demoulding system, cooling system, etc.b. Ensure that the accuracy and size of the mold meet the requirements to ensure the quality and stability of the shell.c. Use CAD software to design the mold and generate the three-dimensional model and engineering drawings of the mold.Design of demoulding system: According to the shape and requirements of the shell, design a suitable demoulding system to ensure that the shell can be demoulded smoothly and avoid damage and deformation.The mold flow analysis and mold design of the automotive reading lamp housing mold require mold design, optimization of injection molding process parameters, and mold flow analysis. Through reasonable design and control, high-quality car reading light housings can be obtained.

- Automotive Reading Light Housing of the mold manufacturing process and product material selectionComponent material selection:Select the appropriate material according to the requirements of the reading lamp housing. Commonly used materials include ABS, PC, PP, etc.Taking into account the requirements of the housing, select materials with good mechanical properties, high temperature resistance, chemical resistance and wear resistance.Depending on the characteristics of the shell, choose a material with good surface quality and weather resistance.During the manufacturing and processing of automobile reading lamp housing molds and the selection and application of component materials, the following points need to be noted:Surface treatment of the mold: According to the requirements of the shell, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the shell.The manufacturing and processing of automobile reading lamp housing molds and the selection and application of component materials require the selection of appropriate processing techniques and equipment, and the selection of materials with good mechanical properties, high temperature resistance, chemical resistance and wear resistance. Through reasonable processing and control of injection molding process parameters, high-quality automotive reading light housings can be achieved.

- Automotive Reading Light Housing Mass production and Quality controlMass production of automobile reading lamp housing mold injection molding involves aspects such as efficiency, cost, tooling and quality control.Efficiency:Mold injection molding production can achieve high efficiency production. By using molds for injection molding, a large number of products can be produced in a short time and production efficiency can be improved.Automated production can further improve production efficiency. Equipped with automated injection molding machines and robot systems, it can realize automated production processes, reduce manual operations and improve production efficiency.Cost:Although the cost of mold manufacturing is higher, in mass production, the cost of the mold can be allocated to each product, thereby reducing the production cost of the unit product.Mold injection molding production can also reduce manual operations and reduce the scrap rate, further reducing production costs.Workwear:Proper design of tooling fixtures can improve production efficiency and quality stability. According to the shape and requirements of the shell, design appropriate tooling fixtures to ensure the fixation and positioning of the injection molded parts.Quality control:Establishing a complete quality control system can ensure product quality. Including quality inspection, process control and defective product handling to ensure that products meet quality standards.In the mass production process of automobile reading lamp housing mold injection molding, factors such as efficiency, cost, tooling and quality control need to be comprehensively considered. Through reasonable tooling design, optimization of production processes, cost control and the establishment of a quality control system, high-efficiency, low-cost, and high-quality mass production of automotive reading lamp shell injection molding can be achieved.