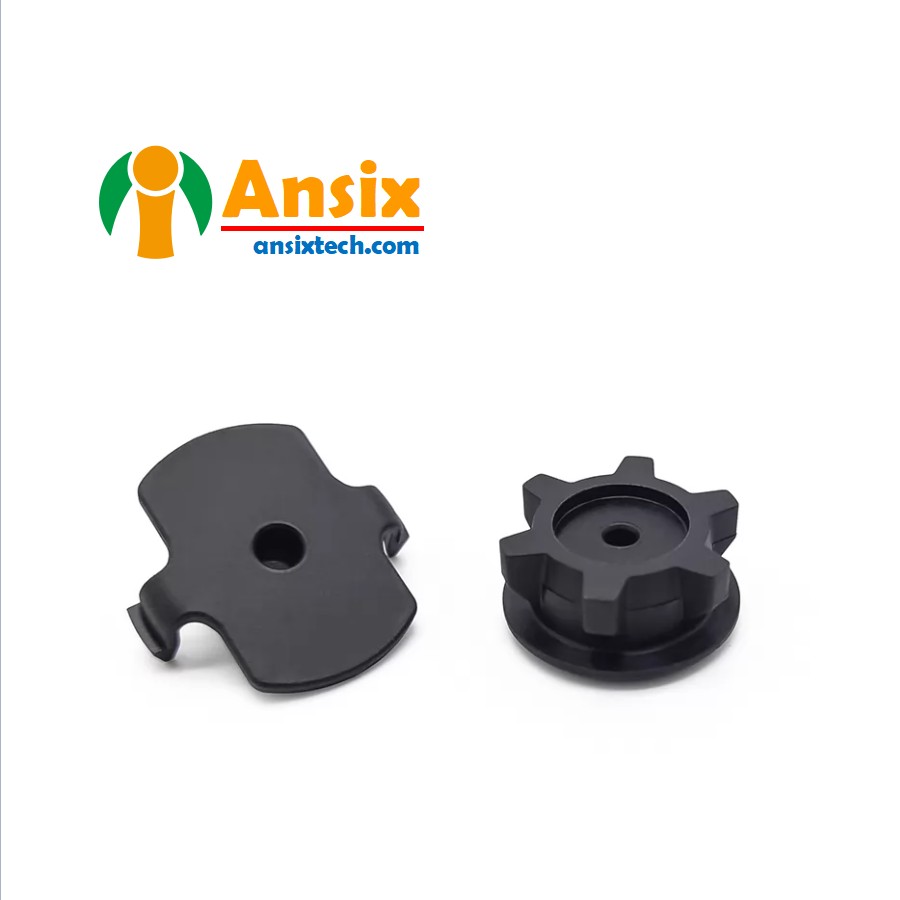

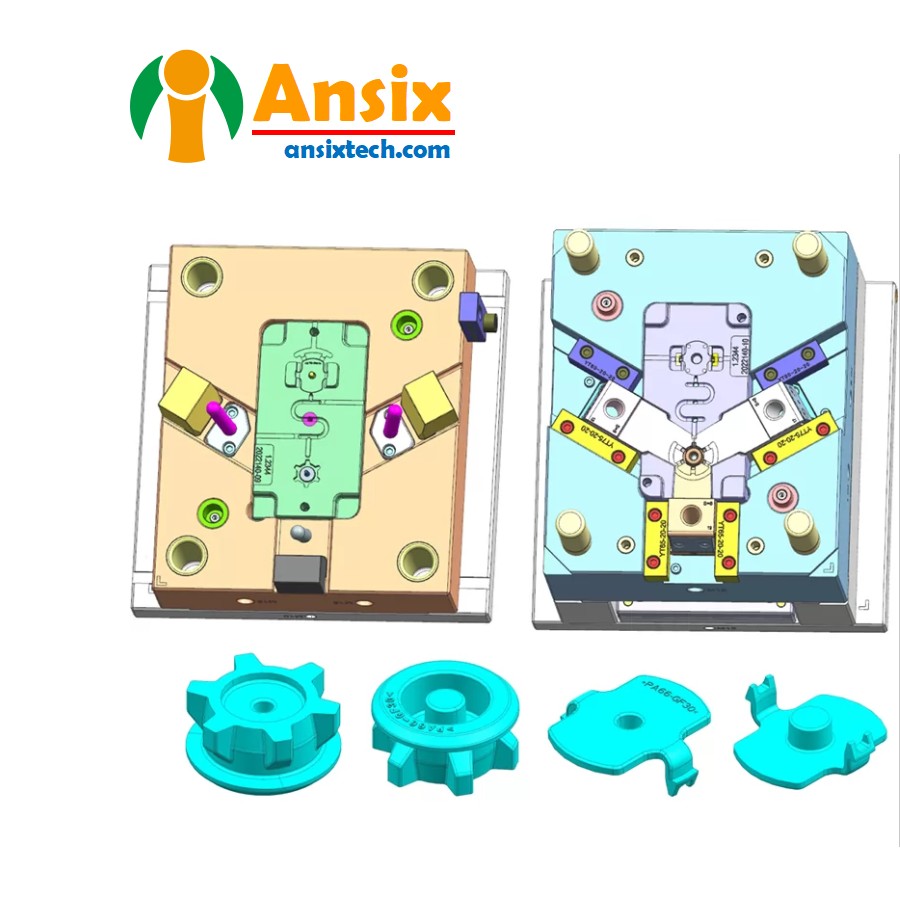

Car Electrical Clip And Valve Injection Mold Inyeccion De Plasticos

FEATURES

- Automobile Thermostat Pump Body Injection mold

Maintenance and maintenance: Regular maintenance and upkeep of injection molds, including cleaning, lubrication, replacement of worn parts, etc., to ensure long-term use of the mold.The manufacturing of automobile thermostat pump body injection molds needs to take into account the shape, size, material properties and other factors of the pump body. At the same time, it is also necessary to design an appropriate mold structure and cooling system according to the requirements of the injection molding process to ensure the quality and efficiency of injection molding. The manufacturing of injection molds requires experienced engineers and technicians to ensure the accuracy and stability of the mold.Please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

-

Mold Description

Product Materials:

PA66+GF30

Mold Material:

2344Number of Cavities:

1*2

Glue Feeding Method:

Cold runner

Cooling Method:

Water cooling

Molding Cycle

22.5s

- Car Electrical Clip And Valve Mold flow analysis and mold designMold flow analysis and mold design of automotive electrical clamp and valve molds are very important links in the manufacturing of automotive electrical clamps and valves. The following will introduce the key points of mold flow analysis and mold design of automotive electrical clamp and valve molds respectively.Mold flow analysis and mold design key points of automotive electrical clamp mold:a. Filling performance analysis: Through mold flow analysis, the filling performance of the automotive electrical clip is evaluated, including the optimization of filling time, filling pressure, filling speed and other parameters to ensure good filling performance of the clamp and avoid the occurrence of defects.b. Cooling system design: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.c. Design of demoulding system: According to the shape and requirements of the fixture, design an appropriate demoulding system to ensure that the fixture can be demoulded smoothly and avoid damage and deformation.d. Injection molding sequence and injection point location: Determine the injection sequence and injection point location to ensure that the plastic material can fully fill the mold cavity and avoid voids and defects.Mold flow analysis and mold design key points of valve mold:a. Filling performance analysis: Evaluate the filling performance of the valve through mold flow analysis, including optimization of filling time, filling pressure, filling speed and other parameters to ensure good filling performance of the valve and avoid defects.b. Cooling system design: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.c. Design of demoulding system: According to the shape and requirements of the valve, design an appropriate demoulding system to ensure that the valve can be demoulded smoothly and avoid damage and deformation.d. Injection molding sequence and injection point location: Determine the injection sequence and injection point location to ensure that the plastic material can fully fill the mold cavity and avoid voids and defects.During the mold flow analysis and mold design process, you need to pay attention to the following points:Ensure filling performance: Through mold flow analysis, the injection molding process parameters are optimized to ensure good filling performance and avoid defects.Design of cooling system: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.Design of demoulding system: According to the shape and requirements of the product, design an appropriate demoulding system to ensure that the product can be demoulded smoothly and avoid damage and deformation.Injection molding sequence and injection point location: Determine the injection sequence and injection point location to ensure that the plastic material can fully fill the mold cavity and avoid voids and defects.In summary, the mold flow analysis and mold design of automotive electrical clamp and valve molds require filling performance analysis, cooling system design, demoulding system design, and determination of the injection sequence and injection point location. Through reasonable design and control, high-quality automotive electrical clamps and valve molds can be obtained.

- Car Electrical Clip And Valve the mold manufacturing process and product material selectionThe manufacturing and processing of automotive electrical clamps and valve molds and the application of injection molding materials PA66+GF30% have the following advantages:Advantages of mold manufacturing and processing:a. High strength and rigidity: PA66+GF30% material has good strength and rigidity and is suitable for manufacturing molds requiring high strength and rigidity.b. Good wear resistance: PA66+GF30% material has good wear resistance, can resist friction and wear, and prolong the service life of the mold.c. Good processing performance: PA66+GF30% material is easy to process and mold, suitable for injection molding process, and can achieve high-efficiency production.Application advantages of injection molding material PA66+GF30%:a. High strength and rigidity: PA66+GF30% material has high strength and rigidity, which can meet the strength requirements of automotive electrical clamps and valves and provide stable performance.b. Good heat resistance: PA66+GF30% material has good heat resistance and can maintain stability in high temperature environments without softening or deformation.c. Good chemical resistance: PA66+GF30% material has good chemical resistance and can resist the erosion and corrosion of chemical substances, improving the durability of the product.d. Good wear resistance: PA66+GF30% material has good wear resistance and can resist friction and wear, extending the service life of the product.In summary, the manufacturing and processing of automotive electrical clamps and valve molds and the application of injection molding materials PA66+GF30% have the advantages of high strength and rigidity, good heat resistance, good chemical resistance and good wear resistance. These advantages make the application of automotive electrical clamp and valve mold manufacturing and injection molding materials PA66+GF30% an ideal choice in automotive manufacturing, which can meet product quality requirements and market demand.

- Car Electrical Clip And Valve Mass production and Quality controlThe mass production of automotive electrical clamps and valves involves the following aspects:Production equipment and processes:Select appropriate injection molding machines and automation equipment to meet mass production needs.Design and optimize injection molding process parameters, including injection speed, temperature, pressure, etc., to ensure product quality and stability.Determine the injection sequence and injection point location to ensure that the plastic material can fully fill the mold cavity and avoid voids and defects.Mold manufacturing and maintenance:Design and manufacture appropriate molds, including mold cavities, mold cores, demoulding systems, cooling systems, etc.Ensure that the accuracy and size of the mold meet the requirements to ensure product quality and stability.Carry out regular mold maintenance and upkeep to extend the service life of the mold and ensure the continuity of production.Quality control:Establish a complete quality control system, including quality inspection, process control and defective product processing, to ensure that products meet quality standards.Conduct inspections and tests on product appearance quality, dimensional accuracy, physical properties, etc. to ensure product quality and consistency.Production planning and scheduling:Develop reasonable production plans and schedules, and rationally arrange production tasks and resources to improve production efficiency and reduce production downtime.Adjust and optimize production plans based on market demand and customer orders to meet customer needs.Through the above steps, mass production of automotive electrical clamps and valves can be achieved. During the entire production process, injection molding process parameters, mold manufacturing and maintenance, quality control, and reasonable arrangements for production plans need to be strictly controlled to ensure product quality and production efficiency.