Long Key Automotive Interior Injection Mold for AnsixTech

FEATURES

- Long Key Automotive Interior Injection Mold for AnsixTech

The difficulties in two-color molding of automotive interior buttons mainly include the following aspects:1. Material selection: Two-color molding requires the selection of two plastic materials of different colors or materials. These materials need to have good compatibility to ensure that the product after two-color molding has good bonding strength and appearance.2. Molding process: The two-color molding process is complex and requires two injection moldings in the same mold to ensure that the two colors of plastic materials can evenly fill the mold cavity and form a good bonding interface. This requires strict control of injection pressure, speed, temperature and other process parameters.3. Mold design and manufacturing: Two-color molding molds need to have a special structure, including two or more injection units, as well as corresponding injection systems and cooling systems. The design and manufacturing of the mold need to consider the process requirements of alternate injection of two colors of plastic materials, including injection sequence, injection position, product structure, etc.4. Process debugging: The process debugging of two-color molding requires a lot of time and cost. The injection process parameters need to be repeatedly optimized and adjusted to ensure that the two colors of plastic materials can be injected alternately well and form the expected appearance effect. .5. Quality control: Products after two-color molding need to undergo strict quality control and testing, including dimensional measurement, appearance inspection, strength testing, etc. Ensure the dimensional accuracy and appearance quality of the product meet requirements.Taking the above factors into consideration, the difficulties in two-color molding of automotive interior buttons lie in material selection, molding process, mold design and manufacturing, process debugging, and quality control. Extensive experience and expertise are required to ensure the quality and stability of two-color molded products.

-

Mold Description

Product Materials:

ABS+PC

Mold Material:

S136ESR

Number of Cavities:

1*4

Glue Feeding Method:

Cold runner

Cooling Method:

Water cooling

Molding Cycle

21.5s

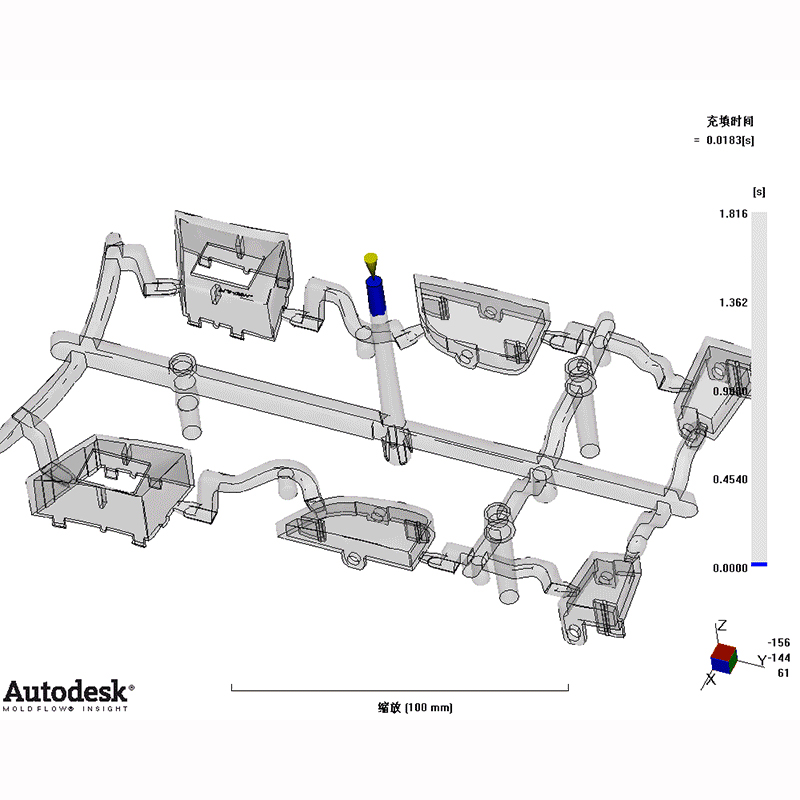

- Long Key Automotive Interior Mold flow analysis and mold designThe design and mold flow analysis of long button molds for automotive interiors are very important links in automotive interiors manufacturing. The design and mold flow analysis of the long button mold for automobile interior will be introduced below.Design of long button mold for automobile interior:a. Collect relevant information about the long button, including size, shape, material, etc.b. According to the design requirements of the long button, design the mold, including mold cavity, mold core, demoulding system, cooling system, etc.c. Ensure that the accuracy and size of the mold meet the requirements to ensure the quality and stability of the long button.Mold flow analysis of automotive interior long button mold:a. Use mold flow analysis software to import the long-press CAD model and set injection molding process parameters, such as injection speed, temperature, pressure, etc.b. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance of long buttons, bubbles, short shots and other defects, and optimize the injection molding process parameters.Design of demoulding system: According to the shape and requirements of the long button, design an appropriate demoulding system to ensure that the long button can be demoulded smoothly and avoid damage and deformation.The design and mold flow analysis of the long button mold for automotive interiors require mold design, optimization of injection molding process parameters, and mold flow analysis. Through reasonable design and control, high-quality car interior long keys can be obtained.

- Long Key Automotive Interior of the mold manufacturing process and product material selectionMold manufacturing and processing:1. Complex mold design: Two-color molds need to be designed with a structure of two or more injection units, as well as corresponding injection systems and cooling systems. This requires considering the process requirements for alternating injection of two colors of plastic materials, including injection sequence, injection location, product structure, etc.2. Material selection and compatibility: Two-color molds require the use of two plastic materials of different colors or materials. These materials need to have good compatibility to ensure that the product after two-color molding has good bonding strength and appearance.3. Injection molding process control: Two-color injection molding requires strict control of injection pressure, speed, temperature and other process parameters. The two colors of plastic materials need to fill the mold cavity evenly and form a good bonding interface, which requires precise process control and debugging.4. Difficulty in process debugging: Process debugging of two-color molds requires a lot of time and cost. The injection process parameters need to be repeatedly optimized and adjusted to ensure that the two colors of plastic materials can be injected alternately well and form the desired appearance.5. Quality control: Products after two-color molding need to undergo strict quality control and testing, including dimensional measurement, appearance inspection, strength testing, etc. Ensure the dimensional accuracy and appearance quality of the product meet requirements.Injection molding material selection:Select the appropriate injection molding material according to the requirements of the long button. Commonly used materials include ABS, PC, PP, etc.Considering the appearance requirements, wear resistance and high temperature resistance of the long button, choose materials with good mechanical properties and durability.Choose materials with chemical resistance and weather resistance based on the function of the long button and the environment in which it is used.During the manufacturing and processing of automotive interior long button molds and the selection of injection molding materials, the following points need to be noted:Surface treatment of the mold: According to the requirements of the long button, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the long button.The manufacturing and processing of automobile interior long button molds and the selection of injection molding materials require the selection of appropriate processing techniques and equipment, and the selection of materials with good mechanical properties, high temperature resistance and wear resistance. Through reasonable processing and control of injection molding process parameters, high-quality automotive interior long buttons can be achieved.

- Long Key Automotive Interior Mass production and Quality controlThe injection molding mass production of long buttons for automotive interiors involves material selection, production efficiency improvement, parts cost control and process quality assurance.Material selection: ABS and PC are commonly used injection molding materials. They have the following advantages:ABS material has good toughness, impact resistance and wear resistance. It is suitable for the shell part of long buttons and can provide better appearance and durability.PC material has excellent high temperature resistance, chemical resistance and weather resistance. It is suitable for the functional part of long button and can meet the requirements of high temperature environment and chemical substances.Improvement of production efficiency:Parts cost control:Reasonably select materials, and select suitable ABS or PC materials based on the requirements of long-press keys and cost considerations to reduce material costs.Mass production of two-color mold injection molding for automotive interior buttons has the following advantages:1. Appearance effect: Two-color injection molding can realize the two-color design of automotive interior button products, increase the aesthetics and personalization of the product, and enhance the market competitiveness of the product.2. Structural function: Two-color injection molding can combine the characteristics of different materials to realize the structural and functional design of the product, such as the combination of soft and hard materials, anti-slip design, etc., to improve the practicality and comfort of the product.3. Save production costs: Compared with traditional assembly processes, two-color injection molding can reduce the number of parts, simplify the production process, and reduce production costs.4. Improve production efficiency: Two-color injection molding can complete injection molding of two colors at one time, reducing the production cycle and improving production efficiency.5. Reduce manual intervention: Automated injection molding production lines can reduce human intervention, improve production stability, and reduce labor costs.6. Product consistency: Two-color injection molding can ensure product consistency and stability and avoid product differences caused by assembly processes.7. Save raw materials: Two-color injection molding can reduce the number of parts, reduce raw material waste, and improve raw material utilization.8. Environmental protection and energy saving: Two-color injection molding can reduce waste and energy consumption during the production process, and is in line with the production concept of environmental protection and energy saving.To sum up, the injection molding mass production of long-press buttons for automotive interiors requires the selection of appropriate materials, such as ABS and PC, to meet the requirements of long-press buttons. By optimizing production efficiency, controlling parts costs and establishing a quality control system, high-efficiency, low-cost and high-quality mass production of long-button injection molding for automotive interiors can be achieved.