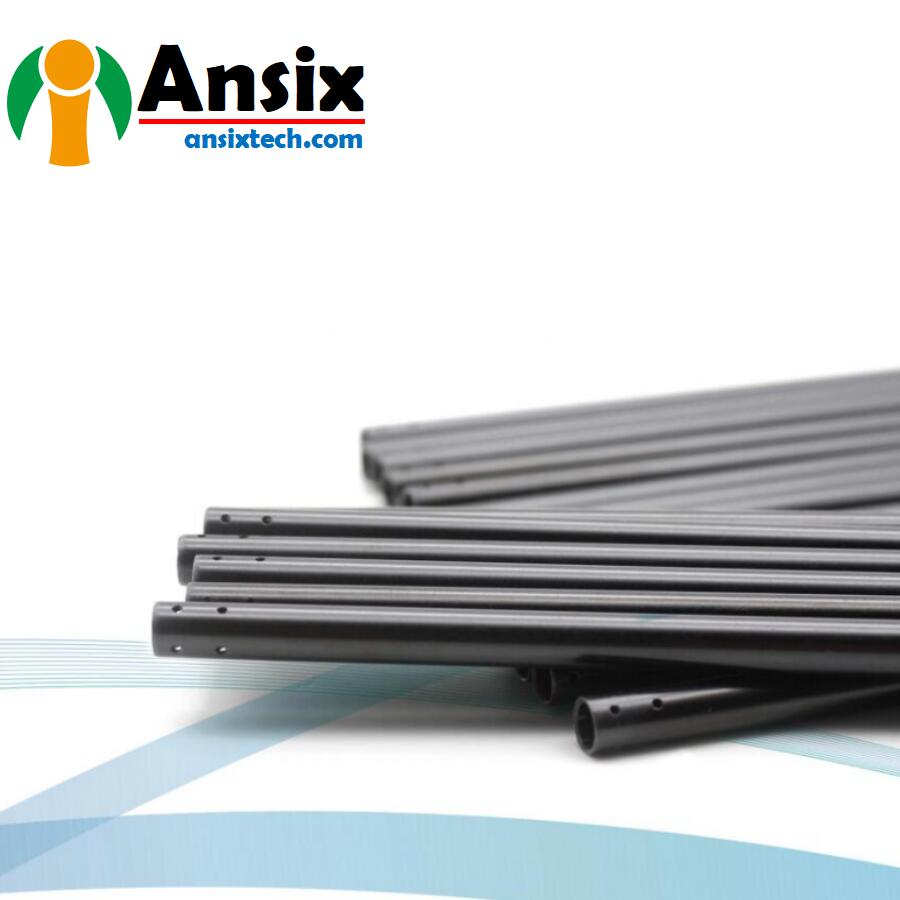

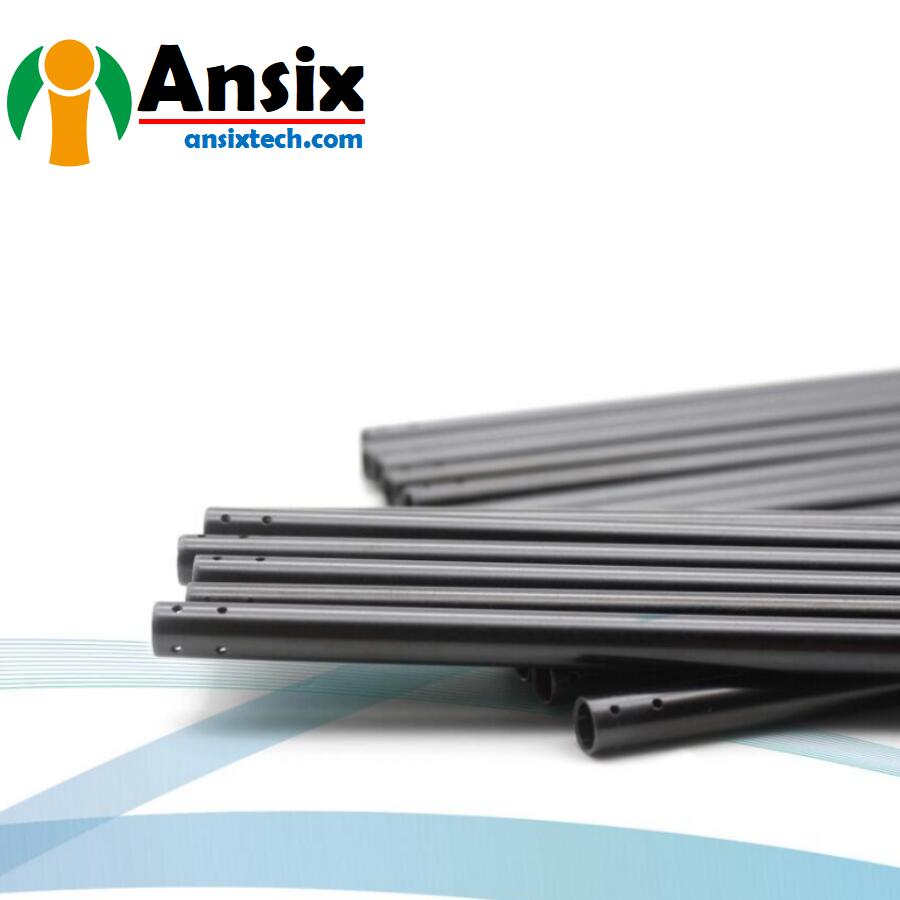

PEEK Tubing

FEATURES

-

Medical PEEK Tubing Application

The applications of medical PEEK tubes include but are not limited to the following aspects:Catheters: Medical PEEK tubes can be used to make various catheters, such as vascular catheters, urinary catheters, bile ducts, etc. Its high temperature resistance and chemical resistance make it suitable for conveying liquids or gases.Implants: Medical PEEK tubes can be used to make implants, such as orthopedic implants, dental implants, etc. Its mechanical strength and biocompatibility allow it to withstand forces within the body and integrate well with tissues.Surgical instruments: Medical PEEK tubes can be used to make surgical instruments, such as surgical forceps, scalpels, etc. Its mechanical strength and chemical resistance allow it to withstand forces and exposure to medications during surgery.Medical PEEK tubes have been widely used in the medical field due to their excellent characteristics. While transporting liquids, gases or drugs, it can also provide good mechanical support and biocompatibility to meet the requirements of medical devices.

-

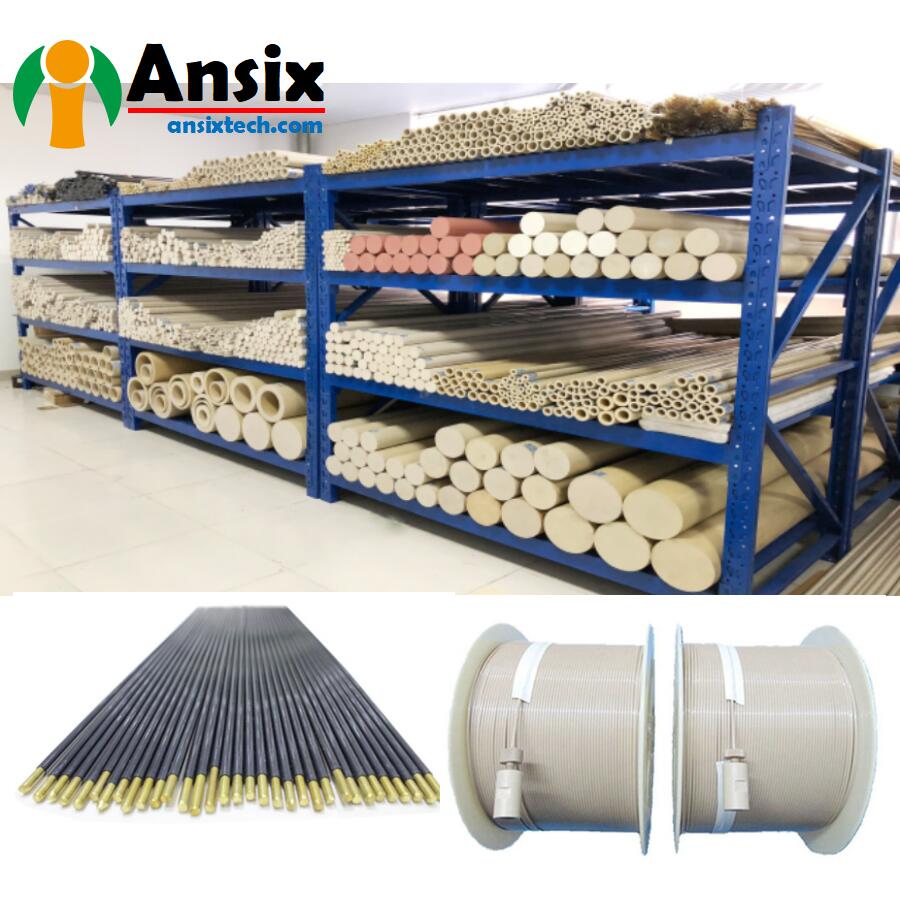

AnsixTech medical PEEK tubing Production Capacity

AnsixTech medical PEEK tube has strong strength in the medical field. The following are some of the advantages of AnsixTech medical PEEK tubes in the field:High-quality materials: AnsixTech uses high-quality polyetheretherketone (PEEK) materials to manufacture medical PEEK tubes to ensure product quality and reliability.Advanced production technology: AnsixTech has advanced production technology and equipment, which can accurately control the size and performance of pipes to ensure product consistency and stability.Strict quality control: AnsixTech implements strict quality control measures during the production process, including raw material testing, production process monitoring and final product inspection, to ensure that products meet the requirements and standards of the medical industry.Diversified product line: AnsixTech provides a variety of specifications and models of medical PEEK tubes to meet the needs of different applications, including different diameters, lengths and connection methods.Customer customization capabilities: AnsixTech can customize according to customer needs, including special sizes, shapes and connection methods, to meet specific application requirements.Wide range of applications: AnsixTech medical PEEK tubes are widely used in medical device manufacturing, including catheters, implants, and surgical instruments, providing high-performance and reliable solutions for the medical industry.AnsixTech medical PEEK tubes have strong strength in the medical field and provide customers with high-quality products and customized solutions through high-quality materials, advanced production processes and strict quality control.AnsixTech understands the challenge of successfully processing high-performance and high-heat polymers for extruded tubing. PEEK is often the preferred polymer for high-performance materials for medical devices and other demanding market applications. Spectrum has the tools, technologies, and expertise to process PEEK and other high-performance thermoplastics for optimum function and longevity.

- Medical PEEK’s Specifications and Dimensions

PEEK is a semi-crystalline thermoplastic that exhibits excellent chemical, mechanical, and thermal properties. PEEK is the material of choice for a variety of precision parts because of its high temperature, chemical resistance, durability, and potential for continuous use at HPLC pressure. Its load-bearing capabilities also make it a superior material for orthopedic, spine, and sports medicine implants.AnsixTech’s experienced in-house material experts and extrusion engineers produce some of the most complex and custom profiles in PEEK on the market today, including:Single and multi-lumen PEEK tubing (six lumens or more) up to 1.0 inches in diameterSub-ultra-thin-walled tubing (<0.001 inches)Complex geometriesCustom profiles, solid and hollow rodsAnsixTech provides PEEK tubes in various specifications, and customers can choose suitable specifications according to specific application needs. Here are some common AnsixTech PEEK tube size selection considerations:Diameter (inner diameter and outer diameter): Select the appropriate inner diameter and outer diameter according to the flow requirements of liquid or gas. Smaller diameters are suitable for smaller flow rates, while larger diameters are suitable for larger flow rates.Length: Choose the appropriate length according to the needs of the specific application. Taking into account the actual use conditions, ensure that the length of the PEEK pipe is sufficient to meet the connection and use requirements.Wall thickness: Select the appropriate wall thickness based on the pressure requirements of the application and the strength requirements of the pipeline. Thicker wall thickness provides greater strength and pressure resistance.Connection method: According to the specific application scenario and connection requirements, select the appropriate connection method, such as direct connection, threaded connection, quick connection, etc.Temperature requirements: Considering the temperature requirements of the application environment, select PEEK tubes that can withstand high temperatures. AnsixTech’s PEEK tubing is typically able to withstand temperatures up to 150°C.Chemical corrosion resistance: Choose PEEK pipes with good corrosion resistance based on the chemicals you may be exposed to in your application.Biocompatibility: If the PEEK tube will be in contact with human tissue, choose a PEEK tube with good biocompatibility to ensure safety and reliability.It should be noted that the above factors are for reference only, and specific specification selection should be based on actual application requirements and AnsixTech’s recommendations. Customers can communicate with AnsixTech’s technical team to jointly determine the most suitable PEEK tube specifications.

- Medical PEEK’s Characteristics and Properties

Medical PEEK tube has the following characteristics and performance:High temperature resistance: Medical PEEK tubes are able to withstand high temperature sterilization processes and can typically withstand temperatures up to 150°C.Chemical corrosion resistance: Medical PEEK tubes have good corrosion resistance to a variety of chemical substances, including acids, alkalis, solvents, etc.Excellent mechanical strength: Medical PEEK tube has excellent mechanical strength and rigidity, can withstand large pressure and force, and is not easy to deform or break.Biocompatibility: Medical PEEK tubes have good biocompatibility, will not cause allergies or rejection reactions, and are suitable for contact with human tissues.Low friction coefficient: Medical PEEK tube has a low friction coefficient, which allows it to reduce resistance and energy loss when transporting liquid or gas.Transparency: Medical PEEK tube has high transparency, and the flow of liquid or gas in the tube can be observed.Lightweight: Medical PEEK tubes are lighter than metal tubes, which helps reduce the weight of implants or devices.Processability: Medical PEEK tubes have good processability and can be cut, drilled, welded and other processing operations to meet different application needs.

-

Medical PEEK Tubes Applications

PEEK tubes are widely used in the medical field, including but not limited to the following aspects:

Catheters: PEEK tubes can be used to make various catheters, such as vascular catheters, urinary catheters, bile ducts, etc. Its high temperature resistance and chemical resistance make it suitable for conveying liquids or gases.

Implants: PEEK tubes can be used to make implants, such as orthopedic implants, dental implants, etc. Its mechanical strength and biocompatibility allow it to withstand forces within the body and integrate well with tissues.

Surgical instruments: PEEK tubes can be used to make surgical instruments, such as surgical forceps, scalpels, etc. Its mechanical strength and chemical resistance allow it to withstand forces and exposure to medications during surgery.

Medical equipment connectors: PEEK tubes can be used to make connectors for medical equipment, such as infusion connectors, gas connectors, etc. Its chemical resistance and biocompatibility allow it to connect different devices safely and reliably.

Drug delivery system: PEEK tubes can be used to manufacture drug delivery systems, such as drug infusion tubes, drug pump tubes, etc. Its chemical resistance and low coefficient of friction enable it to reduce drug adhesion and loss.

Laboratory applications: PEEK tubes can be used for various applications in laboratories, such as sample transportation, reagent preparation, etc. Its chemical resistance and workability make it suitable for laboratory needs.

In short, PEEK tubes are widely used in the medical field due to their excellent properties. While delivering liquids, gases or drugs, it can also provide good mechanical support and biocompatibility to meet the requirements of medical devices and equipment.

PEEK is a preferred material for medical device applications that require high chemical and heat resistance, high tensile strength, flexural properties, and lubricity. It is especially popular for single or multi-lumen tubing for a variety of products, including catheters, and electro-surgical tools and instruments. For example, medical device applications include:

Neurovascular microcatheters

Orthopedic implants

Catheter components

Mechanical components of medical and access devices

Replacement for metal and composite components

Spacers and bushings

Mandrels for secondary operations

MRI-compatible metal replacements

Non-orthopedic implants for spinal, trauma, cardiovascular, and dental applications

- Extrusion Secondary Operations for AnsixTech

PEEK pipe can be secondary processed by extrusion to meet specific application needs. Extrusion secondary processing refers to further processing and transformation on the basis of PEEK pipes to obtain specific shapes, sizes or functions. The following are some common secondary processing methods for PEEK pipe extrusion:Cutting: By cutting PEEK pipe, the required length can be obtained. Cutting can be done using traditional cutting tools such as dicing knives or saw blades, or using high-precision methods such as laser cutting.Drilling: By drilling PEEK pipes, holes can be made in the pipe wall to connect other components or achieve specific functions. Drilling can be done using traditional drilling tools, such as drill bits, or using high-precision methods such as laser drilling.Welding: By welding PEEK pipe, multiple pipe sections can be connected together to form longer pipes. Welding can use methods such as hot melt welding or ultrasonic welding.Bending: By bending PEEK tubes, the desired curved shape can be obtained to suit specific application needs. Bending can use methods such as thermal bending or mechanical bending.Compression: By compressing PEEK tubing, its diameter or wall thickness can be changed to suit specific application needs. Compression can use methods such as thermal compression or mechanical compression.It should be noted that secondary extrusion processing needs to be carried out according to specific application needs and process requirements. It is recommended to consult and communicate with a professional processing manufacturer or technical team before performing secondary extrusion processing to ensure the accuracy of the processing process and results. Quality and reliability.Secondary operations that AnsixTech performs for PEEK extrusions include flaring, tipping, laser cutting, radiofrequency welding, ultrasonic welding, heat forming/tube bending, and hole punching.AnsixTech also provides automated and manual assembly in addition to sterile and nonsterile packaging, which shortens the customer’s supply chain, improves communication and quality, and delivers products to market faster.

- Off-the-Shelf Solutions for AnsixTech PEEK Tubing

PEEK pipe ready-made solutions refer to standardized PEEK pipe products that have been processed and manufactured and can be purchased and used directly without additional processing or customization. Here are some common PEEK tube ready-made solutions:Standard Size Pipe: Suppliers typically offer a range of standard sizes of PEEK pipe, including varying diameters, lengths and wall thicknesses. These standard size tubes meet the needs of general applications such as catheters, implants, and surgical instruments.Connectors and fittings: Suppliers also provide standard connectors and fittings that match PEEK pipes for easy connection and assembly. These connectors and fittings ensure a safe and secure connection of PEEK tubing to other components.Prefabricated components: Some suppliers offer prefabricated PEEK pipe components such as Y-tubes, T-tubes, elbows, etc. These components can be used directly for specific applications, reducing additional processing and assembly steps.Customized solutions: Suppliers can also provide customized PEEK pipe solutions according to customers’ specific needs, including special sizes, shapes and functions. These customized solutions can meet the needs of specific applications, such as special surgical instruments or implants.It is important to note that when selecting an off-the-shelf PEEK tube solution, the selection should be based on the specific application needs and the supplier’s product specifications. At the same time, communicate and consult with suppliers to understand the quality, performance and reliability of their products to ensure the selection of suitable PEEK pipe solutions.Product development is also accelerated through the use of AnsixTech’s “off-the-shelf” PEEK extruded tubing, which is available via AnsixTech Plastics Group’s webstore and includes:PEEK single-lumen tubing and PEEK beadingTubing sizes: 2-12 French ODWall thicknesses: 0.003, 0.005, and 0.008 inchesAnsixTech’s biocompatible PEEK filament is also an ideal material for injection-molded or additively-manufactured components and devices.Although PEEK has been used for decades, its material properties continue to be engineered to provide specific characteristics for challenging end-use environments. Creating high-precision, tight-tolerance parts and products from PEEK requires experienced and knowledgeable material experts, extrusion engineers, and operators who are skilled with the latest advancements.

contact us

AnsixTech Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

ISO 13485 Certified factory

ISO 8 Cleanroom

Robust Expertise for Medical Injection Molding

Advanced mold manufacturing capabilities and plastic injection molding equipment

Quick Response within 12 hours

- If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.