Fluid Mangement tubing

FEATURES

- Medical Fluid Management Tubing

Urinary Catheters: Medical fluid management tubes are used to transport urine for urine excretion and urine monitoring. These tubes are often used with equipment such as urine bags and urine meters.Gastrointestinal tube: Medical fluid management tube is used to transport nutritional solutions, drugs or contrast media, etc., for nutritional support, drug administration or diagnostic procedures in the gastrointestinal tract.Drainage tube: Medical fluid management tube is used to drain fluids, such as blood, pleural effusion, ascites, etc. These tubes are usually used in conjunction with drainage bags, drainage bottles and other equipment to drain abnormal fluid accumulation in the body.The design and manufacture of medical fluid management tubes needs to consider the characteristics of the fluid, the pressure resistance of the pipeline, biocompatibility and other factors to ensure safe, reliable and effective fluid management. At the same time, these pipelines usually need to comply with relevant standards and regulatory requirements of the medical industry, such as ISO 13485 quality management system and FDA certification requirements.With tubing fabrication facilities in 4 countries, we offer a scalable, full-service package made to your precise specifications, including tubing, fittings, molded components, subassemblies, and assemblies.

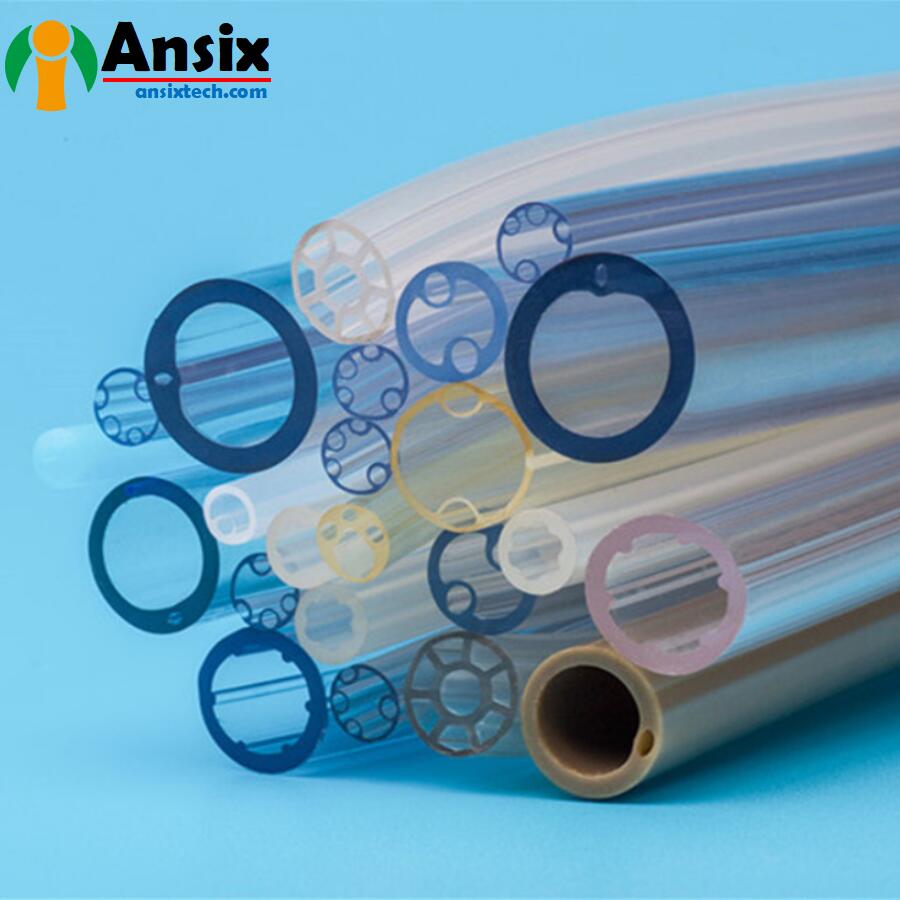

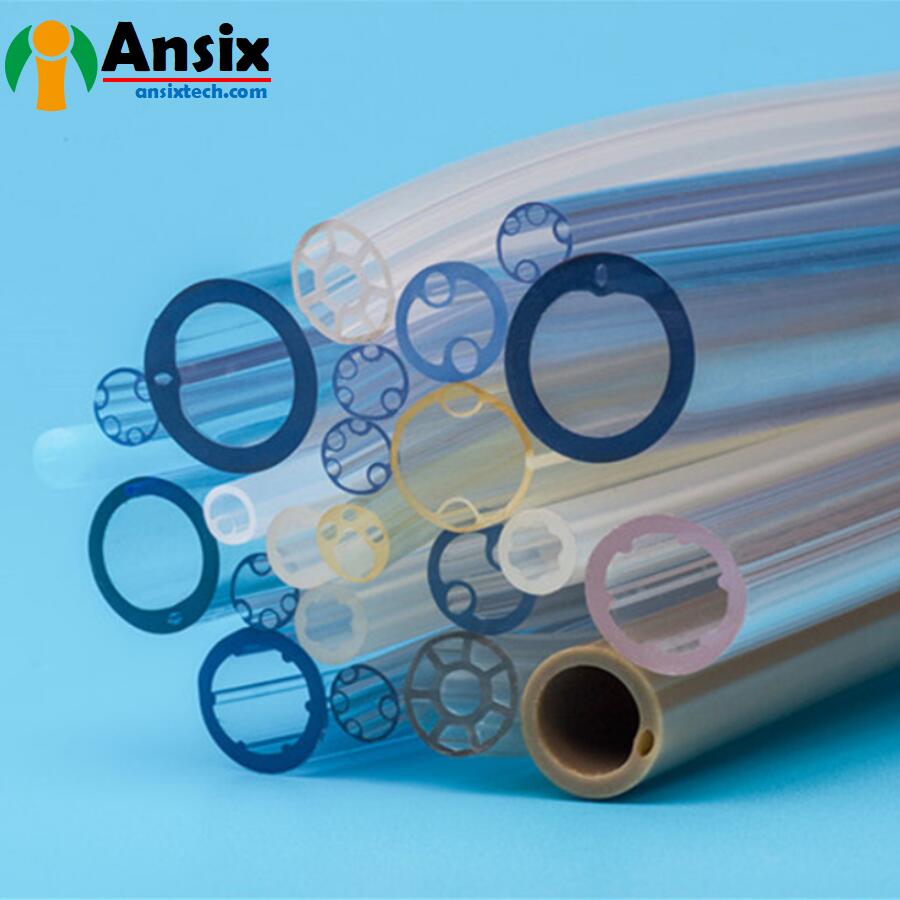

- Single- and Multilumen Tubing for AnsixTech

Medical fluid tubes can be divided into single-lumen tubes and multi-lumen tubes, with different structures and functions.Single-lumen tube: A single-lumen tube refers to a tube with only one chamber inside. It is usually used to deliver a single type of fluid, such as IV tubes, endotracheal tubes, etc. The structure of a single-lumen tube is relatively simple, usually consisting of a pipe, and is suitable for one-to-one fluid delivery.Multi-lumen tube: Multi-lumen tube refers to a pipe with multiple independent chambers inside. Each chamber can be used to deliver different fluids or perform different functions. Multi-lumen tubes are usually composed of multiple parallel or intersecting tubes, each tube corresponding to a chamber. Multi-lumen tubing can be used for complex fluid management needs, such as drug delivery systems, multifunctional catheters, etc.The advantage of multi-lumen tubing is that it can deliver multiple different fluids or perform multiple functions at the same time, thereby increasing the flexibility and efficiency of fluid management. For example, in drug delivery systems, multi-lumen tubes can deliver different drugs at the same time, avoiding the use and connection of multiple single-lumen tubes. In multifunctional catheters, different chambers can be used for different functions such as transporting liquids, gases, and drainage.If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.It should be noted that the design and manufacturing of multi-lumen tubes are relatively complex, and factors such as isolation between chambers, connection methods, and fluid cross-contamination need to be considered. At the same time, the use of multi-lumen tubes also needs to be selected and operated according to specific application requirements and relevant standards in the medical industry to ensure safe and effective fluid management.Single- and Multilumen Tubing Materials:Standard materials including PVC (DEHP, non DEHP) polycarbonate, HDPE, LDPE, and polyurethaneDimensionsOD range: 0.020” (0.508 mm) min; 1.250” (31.75 mm) maxID range: 0.010” (0.254 mm) min; 1.200” (30.48 mm) maxTolerances may vary depending on durometer, material, and size of tubingUp to 6 lumens depending upon size or material

- Co-, Tri-, and Multilayer Extrusion Medical Tubing for Medical

In the medical field, fluid tube extrusion processing technology can achieve different levels of structures, including co-layer, three-layer and multi-layer extruded medical tubes.Co-layer extrusion medical tube: Co-layer extrusion refers to the tube formed by extruding the hierarchical structures of different materials together during the extrusion process. Co-layered extruded medical tubing usually consists of an inner layer, a middle layer and an outer layer, with each layer of material having different properties and functions. For example, the inner layer can use biocompatible materials, the middle layer can use reinforcing materials to improve the mechanical strength of the pipeline, and the outer layer can use chemically resistant materials to protect the pipeline.Three-layer extruded medical tube: Three-layer extrusion refers to a tube formed by extruding three different materials separately during the extrusion process. Three-layer extruded medical tubing usually consists of an inner layer, a middle layer and an outer layer, with each layer of material having different properties and functions. For example, the inner layer can use biocompatible materials, the middle layer can use reinforcing materials to improve the mechanical strength of the pipeline, and the outer layer can use chemically resistant materials to protect the pipeline.Multi-layer extruded medical tube: Multi-layer extrusion refers to the tube formed by extruding multiple different materials separately during the extrusion process. Multi-layer extruded medical tubing can be selected from different materials and number of layers based on specific application needs. Each layer of material can have different properties and functions to meet specific application requirements.The advantage of co-, triple- and multi-layer extruded medical tubing is that the properties and functions of different materials can be combined to achieve more complex tubing structures and performance. These pipes can be used to transport different fluids and perform multiple functions, such as drug delivery, drainage, monitoring, etc. At the same time, extrusion processing technology can achieve efficient and continuous production, improving production efficiency and product quality.It is important to note that the design and manufacturing of co-, triple- and multi-layer extruded medical tubing need to be selected and operated based on specific application needs and relevant standards in the medical industry to ensure safe and effective fluid management.

- Braided tubing by SPG

Medical high-pressure braided pipe is a pipe system used to withstand high-pressure fluids, usually consisting of a braided layer and an inner pipe. The braided layer is usually made of high-strength fiber materials (such as polyester fiber, nylon fiber, etc.) and is used to enhance the pressure resistance and mechanical strength of the pipeline. The inner pipe is usually made of medical-grade materials such as polyurethane, polyetheretherketone (PEEK), etc. and is used to transport fluids.Medical high-pressure braided tube has the following characteristics and applications:Pressure resistance: The existence of the braided layer makes the medical high-pressure braided tube have a high pressure resistance, can withstand high pressure, and is suitable for the transportation of high-pressure fluids.Mechanical strength: The high-strength fiber material of the braided layer enhances the mechanical strength of the pipe, enabling it to resist external forces and stresses and reduce the risk of deformation and rupture.Wear resistance: The existence of the braided layer also improves the wear resistance of the medical high-pressure braided tube, allowing it to be used for a long time in an environment of friction and wear.Biocompatibility: The inner pipeline is usually made of medical-grade materials, which has good biocompatibility and can come into contact with human tissue without causing allergic or rejection reactions.Application fields: Medical high-pressure braided tubes are widely used in medical devices and equipment, such as high-pressure infusion pumps, hemodialysis machines, heart support equipment, etc. They are used to transport high-pressure liquids or gases, providing stable and reliable fluid management.It should be noted that the design and manufacture of medical high-pressure braided tubing needs to be selected and operated according to specific application needs and relevant standards of the medical industry to ensure safe and effective fluid management. At the same time, when using medical high-pressure braided pipes, they need to be installed and used correctly according to the pressure requirements and usage environment to ensure the performance and reliability of the pipes.Known for its high quality, our AnsixTech® High-Pressure Braided Tubing was developed in the early 1990s. Since then, we’ve become the world’s leading manufacturer of high-pressure braided tubing for vascular balloon inflation, contrast injection, and vacuum procedures.

contact us

Try Our Problem-solving Injection Molding Services Now

AnsixTech Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

ISO 13485 Certified factory

ISO 8 Cleanroom

Robust Expertise for Medical Injection Molding

Advanced mold manufacturing capabilities and plastic injection molding equipment

Quick Response within 12 hours

- If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.