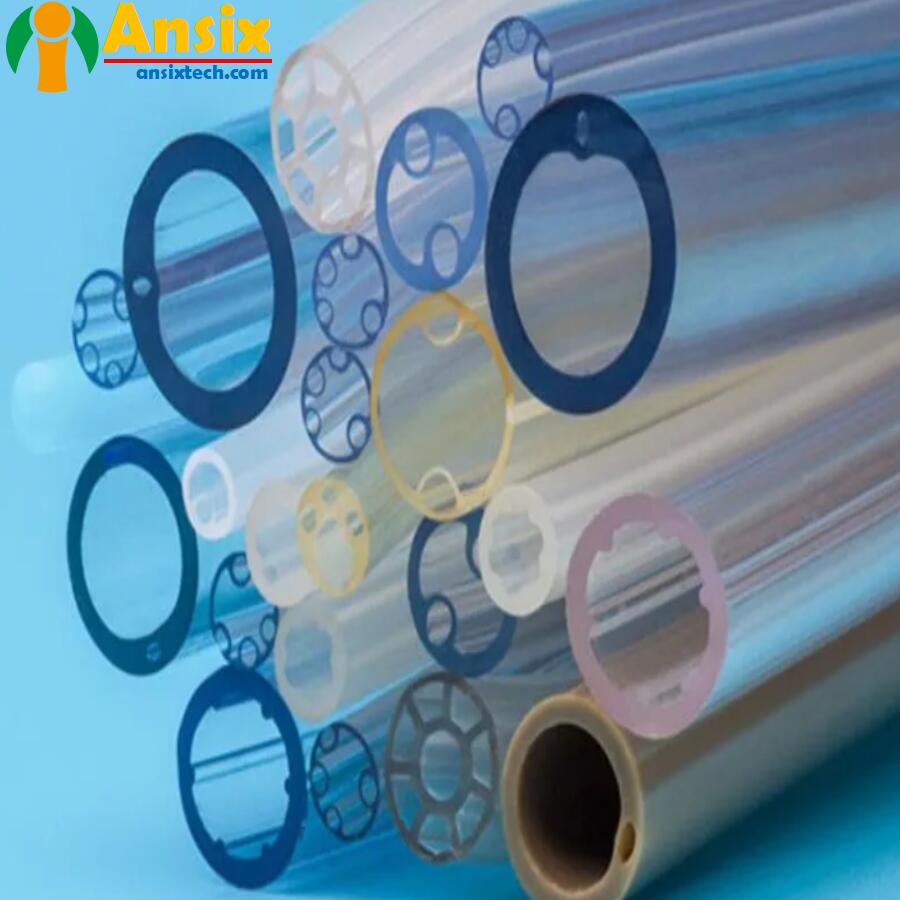

Silicone Extruded Medical Tubing

FEATURES

- Medical Laboratory Supply & Consumables Suppliers

The product properties will affect the results of experiments. From material selection and process planning aspects, we ensure that the laboratory consumables we produce have good performance. AnsixTech medical is a top Chinese supplier of medical laboratory consumables.We offer a range of value-added services with the utmost care for quality during mass production. There are ISO 8 cleanrooms with 260 injection molding machines for standard manufacturing, and our production follows the international quality management system and is certified by ISO 13485:2016. Only safe to use medical plastic is picked for circulation in the healthcare industry for different applications.As a medical laboratory supplies and consumables supplier, AnsixTech can provide the following services and work:Product supply: AnsixTech can provide various consumables and reagents required by medical laboratories, including reagents, culture media, culture equipment, experimental equipment, test tubes and pipettes, membranes and filters, test kits and reagent covers, etc. .Product selection and consultation: AnsixTech can provide appropriate product selection and consultation based on the needs and requirements of the laboratory, helping the laboratory select suitable consumables and reagents.Product quality assurance: AnsixTech cooperates with many well-known brands to provide products with reliable quality and ensure the accuracy and reliability of laboratory experiments and research.Price competitiveness: AnsixTech can provide competitive prices to help laboratories save costs.Ordering and delivery: AnsixTech can accept orders from laboratories and provide timely delivery services to ensure adequate supply of laboratory consumables and reagents.After-sales service: AnsixTech provides after-sales service, including product returns and exchanges, technical support, etc., to ensure laboratory use experience and satisfaction.In short, as a supplier of medical laboratory supplies and consumables, AnsixTech is committed to providing laboratories with a full range of product supply and service support to help laboratories carry out experiments and research smoothly.

-

Single-lumen Extrusion of Medical Silicone Tubing

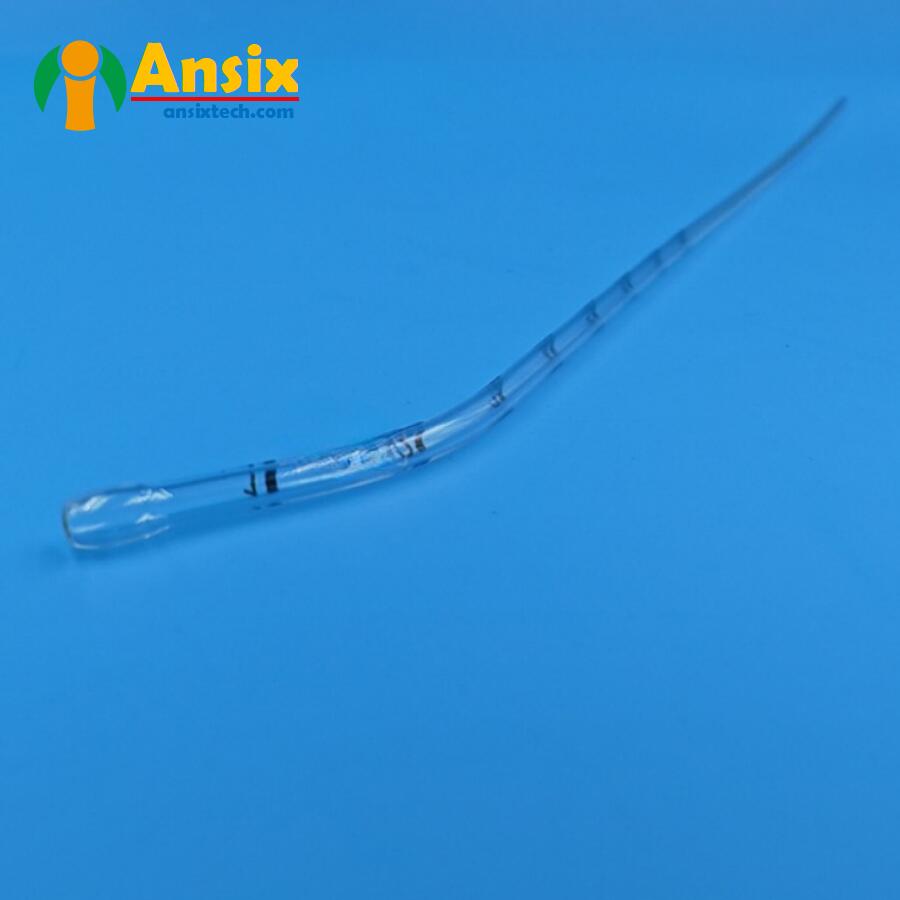

Single-lumen extrusion of medical silicone tubing is a common manufacturing method used to produce medical silicone tubing with a single lumen. This extrusion method typically involves the following steps:Material preparation: Select medical-grade silicone materials suitable for medical applications. Silicone materials generally have good biocompatibility, high temperature resistance and chemical stability.Extruder: Add the silicone material into the hopper of the extruder. The extruder heats the silicone material to a molten state and pushes the molten silicone through the screw to the extrusion head.Extrusion head: The extrusion head is a metal mold with a single lumen shape, used to extrude silicone materials. The silicone material is extruded through the small hole of the extrusion head to form a single-cavity silicone tube.Cooling and solidification: After the extruded silicone tube passes through the extrusion head, it enters the cooling area. In the cooling zone, the silicone tube is cooled and solidified so that it maintains the desired shape and size.Cutting and shaping: The cooled and solidified silicone tube is cut and shaped to obtain the required length and shape.Inspection and quality control: Carry out inspection and quality control on the extruded silicone tube to ensure that it meets the design requirements and relevant standards of the medical industry. Inspection can include visual inspection, dimensional measurements, physical property testing, etc.The single-lumen extrusion method of medical silicone tubes can produce silicone tubes with a single lumen, which are suitable for infusion, drainage, airway management and other applications in various medical devices and equipment. It is necessary to select the appropriate medical silicone tube according to the specific application requirements and relevant standards of the medical industry.Manufacturers usually base on customer needsOD 0.030” (0.762 mm) min; 0.625” (15.875mm) maxID 0.010” (0.254 mm) min; 0.585” (14.859 mm) maxTolerances may vary depending on durometer, material, and tube sizewe can provide customized medical catheters with diverse design and shape options. The following is our service commitment:Material selection: According to customer requirements, we can provide medical catheters of different materials, such as medical-grade silicone, polyurethane, etc. These materials have good biocompatibility and durability.Color customization: We can provide medical catheters in different colors according to customer requirements to meet personalized needs or specific identification requirements.Size customization: According to customer requirements, we can customize medical catheters of different sizes to suit different application needs.Performance requirements: We can provide medical catheters with specific properties according to customer requirements, such as high temperature resistance, chemical corrosion resistance, antibacterial, etc.Diversified shape design: We can design and produce medical catheters of different shapes according to customer requirements, such as round, oval, square, triangle, crescent, etc.Rapid delivery: We promise to provide rapid delivery services to meet customer time requirements.Stable quality: We strictly control the production process to ensure that the quality of medical catheters is stable and meets relevant quality standards.High cost-effectiveness: We provide competitive prices to ensure that customers receive cost-effective products.

-

Multilumen Extrusion for AnsixTech

We can provide customized services for multi-lumen tubes to meet your needs. The following is our service commitment:Channel design: We can design multi-lumen tubes with 2-12 channels according to your requirements to meet the transmission needs of guidewires, catheters, liquids and gases. Each cavity can be used for different functions to provide effective access.Diversified shapes: We can design diverse multi-lumen tube shapes according to your requirements, including but not limited to circular, oval, T-shaped, triangular or other shapes. This provides better adaptability and functionality based on the needs of specific applications.Material selection: We use high-quality materials such as medical-grade silicone to manufacture multi-lumen tubes to ensure they have good biocompatibility, high temperature resistance and chemical stability.Size customization: We can customize the size of multi-lumen tubes according to your requirements to adapt to different application needs.Stable quality: We strictly control the production process to ensure that the quality of multi-lumen tubes is stable and meets relevant quality standards.

- Silicone Medical Tubing Capabilities

Silicone medical tubing is versatile and suitable for different applications in a variety of medical devices and equipment. Here are some common silicone medical tubing functions:Infusion and blood transfusion: Silicone medical tubes are used in infusion and blood transfusion systems to deliver liquids and drugs. They have good resistance to drugs and chemicals, ensuring safe delivery of drugs.Drainage and drainage: Silicone medical tubes are used in drainage and drainage systems such as drainage tubes, gastric tubes, and urinary catheters to remove fluids and waste from the body. They have good softness and corrosion resistance, ensuring effective drainage and drainage.Airway management: Silicone medical tubes are used in airway management equipment such as endotracheal tubes and ventilator connecting tubes to transport gas and maintain respiratory function. They have good biocompatibility and high temperature resistance, ensuring safe and reliable airway management.Guide wires and catheters: Silicone medical tubing is used in guide wire and catheter systems for guidance and positioning. They have good elasticity and softness, which facilitates the manipulation of guidewires and catheters in the body.Implants and surgical instruments: Silicone medical tubes are also used in implants and surgical instruments, such as pacemaker leads, artificial joints, etc. They have good biocompatibility and durability, ensuring safe and effective use of implants and devices.Drug delivery: Silicone medical tubes can be used in drug delivery systems, such as administration tubes, syringes, etc. They have good resistance to drugs and chemicals, ensuring accurate delivery of drugs.The functionality of silicone medical tubing can be customized based on specific application needs and relevant standards in the medical industry. Manufacturers typically offer silicone medical tubing products with specific features based on customer needs and specifications. If you have specific functional requirements, please contact the manufacturer or supplier for more detailed information and customized solutions.

- Silicone Medical Tubing Benefits

Silicone medical tubing has many advantages that make it a widely used material in medical devices and equipment. Here are some of the main benefits of silicone medical tubing:

Biocompatibility: Silicone medical tube has good biocompatibility and will not cause allergic reactions or tissue irritation. They are highly compatible with human tissue and can be safely used in medical applications that come into contact with the human body.

High temperature resistance: Silicone medical tube has good high temperature resistance and can withstand high temperature sterilization and disinfection processes. This makes them suitable for use in medical devices and equipment that require high temperature processing.

Softness and elasticity: Silicone medical tubing has good softness and elasticity, making it easy to bend and connect in medical devices and equipment. They can adapt to different shapes and curves, providing better fit and comfort.

Chemical resistance: Silicone medical tube has good chemical resistance and will not be corroded or dissolved by common chemicals and drugs. This makes them safe for use in medical applications that come into contact with a variety of drugs and chemicals.

Transparency: Some silicone medical tubes have high transparency, allowing you to observe the flow of fluid and the delivery of drugs. This helps medical staff monitor and control the course of treatment.

Durability: Silicone medical tubing has good durability and can withstand long-term use and repeated cleaning and disinfection. This makes them reliable and durable components of medical devices and equipment.

Customizability: Silicone medical tubes can be customized according to customer requirements, including size, shape, channel design and material properties. This makes them suitable for a variety of specific medical application needs.

These advantages of silicone medical tubing make it an ideal choice in the medical industry, where it is widely used in a variety of applications including infusion, drainage, airway management, implants, and surgical instruments.

- Experimental equipment for Medical

Silicone medical tubing has many advantages that make it a widely used material in the medical industry. Here are some of the main benefits of silicone medical tubing:Biocompatibility: Silicone medical tube has good biocompatibility and will not cause allergic reactions or tissue irritation. They are highly compatible with human tissue and can be safely used in medical applications that come into contact with the human body.High temperature resistance: Silicone medical tube has good high temperature resistance and can withstand high temperature sterilization and disinfection processes. This makes them suitable for use in medical devices and equipment that require high temperature processing.Softness and elasticity: Silicone medical tubing has good softness and elasticity, making it easy to bend and connect in medical devices and equipment. They can adapt to different shapes and curves, providing better fit and comfort.Chemical resistance: Silicone medical tube has good chemical resistance and will not be corroded or dissolved by common chemicals and drugs. This makes them safe for use in medical applications that come into contact with a variety of drugs and chemicals.Transparency: Some silicone medical tubes have high transparency, allowing you to observe the flow of fluid and the delivery of drugs. This helps medical staff monitor and control the course of treatment.Durability: Silicone medical tubing has good durability and can withstand long-term use and repeated cleaning and disinfection. This makes them reliable and durable components of medical devices and equipment.Customizability: Silicone medical tubes can be customized according to customer requirements, including size, shape, channel design and material properties. This makes them suitable for a variety of specific medical application needs.These advantages of silicone medical tubing make it an ideal choice in the medical industry, where it is widely used in a variety of applications including infusion, drainage, airway management, implants, and surgical instruments.

contact us

AnsixTech Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

ISO 13485 Certified factory

ISO 8 Cleanroom

Robust Expertise for Medical Injection Molding

Advanced mold manufacturing capabilities and plastic injection molding equipment

Quick Response within 12 hours

- If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.