Shimmer & Blush compactseries

FEATURES

- Shimmer & Blush compactseries Printable process

Products can have customized, injection, spary, vacuum metalizing, 3D printing, silk screen printing, hot stamping, pad painting, soft touch,digital printing,color painting,heat transfer and so on.

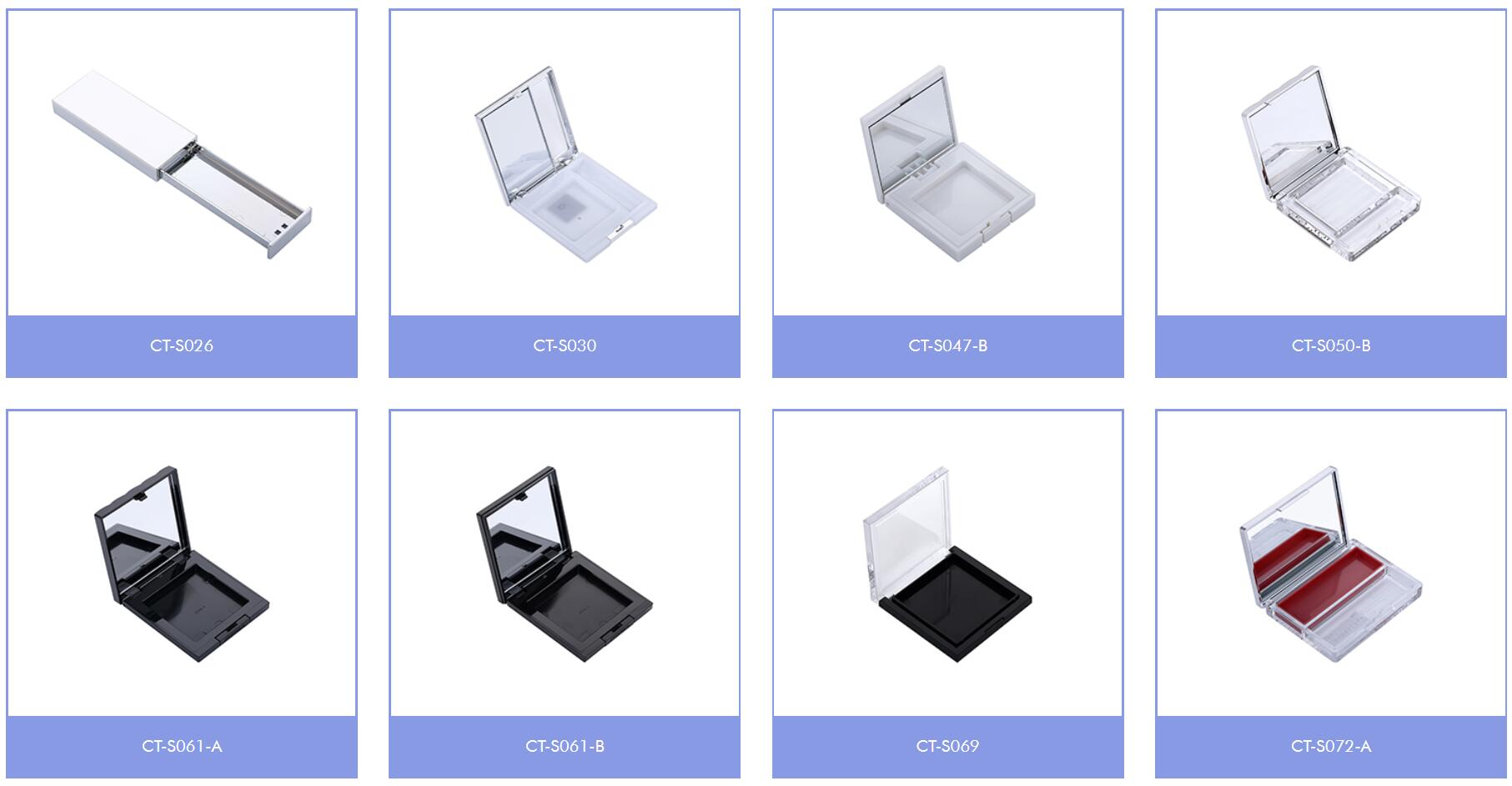

- Shimmer & Blush compactseries Same series products for AnsixTech:

- Shimmer & Blush compactseries DesignAnsix Cosmetics Packaging Box Pearlescent Blush Powder Series products focus on the pursuit of high quality and fashion sense in terms of design, shape, structure and fashion.Design:Ansix company focuses on innovation and uniqueness in product design. Their design team constantly pursues fashion trends and aesthetic trends and incorporates these elements into product design. They strive to create distinctive products that attract consumers’ attention and enhance their brand image.Shape:Ansix’s cosmetic packaging box series of pearlescent blush powder products pursue simplicity, sophistication and fashion in style. They focus on the lines and proportions of their products, striving for an elegant and modern look. The product’s styling design not only meets functional requirements, but also shows fashion sense and brand characteristics.Structure:Ansix’s cosmetic packaging box pearlescent blush powder series products focus on practicality and convenience in structure. They designed a reasonable structure to make the product easy to use and carry. For example, the structural design of powder powder makes it easier for users to apply makeup with a puff or brush, while the structural design of pearlescent blush makes it easier for users to apply makeup with a brush or fingers.Fashion:Ansix’s cosmetic packaging box pearlescent blush powder series products pursue a sense of fashion to meet modern consumers’ pursuit of fashion and beauty. They pay attention to fashion trends and fashion trends and incorporate these elements into the design and packaging of their products. The appearance and packaging design of the product are fashionable and exquisite, which can attract consumers’ attention.Ansix Cosmetics Packaging Box Pearlescent Blush Powder Series products focus on the pursuit of high quality and fashion sense in terms of design, shape, structure and fashion. Their products are unique in design, exquisite in shape, practical in structure, and in line with fashion and aesthetic trends. These features make Ansix’s products popular in the market and able to meet the fashion and beauty needs of modern consumers.

- Shimmer & Blush compactseries of the mold manufacturing process and product material selectionThe mold manufacturing and material selection of Ansix’s cosmetic packaging box pearlescent blush powder series products have an important impact on the quality and cost of the product.Cost advantages of mold manufacturing and mold processing:Mold manufacturing is one of the key steps in the production of cosmetic packaging box pearlescent blush powder series products. Ansix companies can achieve cost advantages in mold manufacturing and mold processing through:Mold design optimization: Through reasonable mold design, material waste and processing procedures are reduced, and mold manufacturing costs are reduced.Mold material selection: Choose appropriate mold materials, such as high-quality alloy steel or stainless steel, to ensure the hardness, wear resistance and corrosion resistance of the mold, extend the service life of the mold, and reduce mold replacement costs.Mold processing process optimization: By optimizing mold processing processes, such as CNC machining, EDM and wire cutting, etc., we can improve processing efficiency and accuracy and reduce processing costs.Cosmetic box material selection and material injection molding advantages:The material selection of cosmetic packaging boxes is crucial to the appearance quality and brand image of the product. Ansix company can choose the following materials and manufacture the cosmetic box by injection molding to realize the advantages:High-quality plastic materials: Choose high-quality plastic materials, such as polypropylene (PP) or polyethylene (PE), with good transparency, heat resistance and pressure resistance, which can protect the quality and stability of cosmetic products.Injection molding advantages: Injection molding is an efficient and precise production process that allows for rapid production and consistency of cosmetic boxes. Injection molding can produce cosmetic boxes with complex shapes and details, meet design requirements, and improve production efficiency.In summary, the cost advantages of mold manufacturing and mold processing for Ansix’s cosmetic packaging box pearlescent blush powder series can be achieved through mold design optimization, mold material selection, and mold processing process optimization. The material selection and material injection molding advantages of cosmetic boxes can be achieved by selecting high-quality plastic materials and injection molding processes to improve the appearance quality and production efficiency of cosmetic boxes. These measures can reduce production costs, improve production efficiency, and ensure product quality and stability.

- Shimmer & Blush compactseries Mass production and Quality controlThe mass production of Ansix’s cosmetic packaging box pearlescent blush powder series products can be achieved through injection molding mass production to improve production efficiency, reduce costs and ensure product quality. The advantages and measures in these areas are described in detail below.Advantages of injection molding mass production:Injection molding mass production is an efficient and precise production process, suitable for mass production of cosmetic packaging boxes, pearlescent blush powder series products. It has the following advantages:Efficient production: Injection molding can achieve fast and continuous production, greatly improving production efficiency.Consistency and stability: Injection molding can ensure product consistency and stability, with each product having the same size, shape and appearance quality.Complex shapes and details: Injection molding can produce products with complex shapes and details to meet design requirements.Improvement of production efficiency:To improve productivity, Ansix companies can take the following measures:Automated equipment configuration: introduce automated equipment and production lines to achieve efficient operation of automated injection molding and production processes, reduce manual operations and increase production speed.Parallel production: Parallel production is adopted to carry out multiple processes at the same time to shorten the production cycle.Optimize process flow: Improve production efficiency and quality by optimizing injection molding process parameters, adjusting production flow and process control.Process cost control:Ansix companies can control process costs through:Raw material procurement optimization: Cooperate with suppliers to optimize raw material procurement and reduce costs.Equipment maintenance and management: Regularly maintain and manage production equipment to ensure the normal operation and life of the equipment and reduce repair and replacement costs.Energy and resource management: optimize the use of energy and resources, reduce waste and costs.Product quality assurance:In order to ensure product quality, Ansix Company can take the following measures:Quality control plan: Develop a quality control plan to clarify the quality requirements and control methods for each link.Inspection and testing: Conduct product inspection and testing, such as appearance inspection, dimensional measurement, functional testing, etc., to ensure that the product meets the requirements.Process monitoring: Monitor the production process, such as temperature control, injection pressure control, etc., to ensure product consistency and stability.In summary, the mass production of Ansix’s cosmetic packaging box pearlescent blush powder series products can be achieved through injection molding mass production to improve production efficiency, reduce costs and ensure product quality. Through measures such as automated equipment configuration, process optimization, process cost control and product quality assurance, Ansix can achieve efficient, stable and high-quality mass production.