Press powder compact series

FEATURES

- Printable process of Press powder compact series

Products can have customized, injection, spary, vacuum metalizing, 3D printing, silk screen printing, hot stamping, pad painting, soft touch,digital printing,color painting,heat transfer and so on.

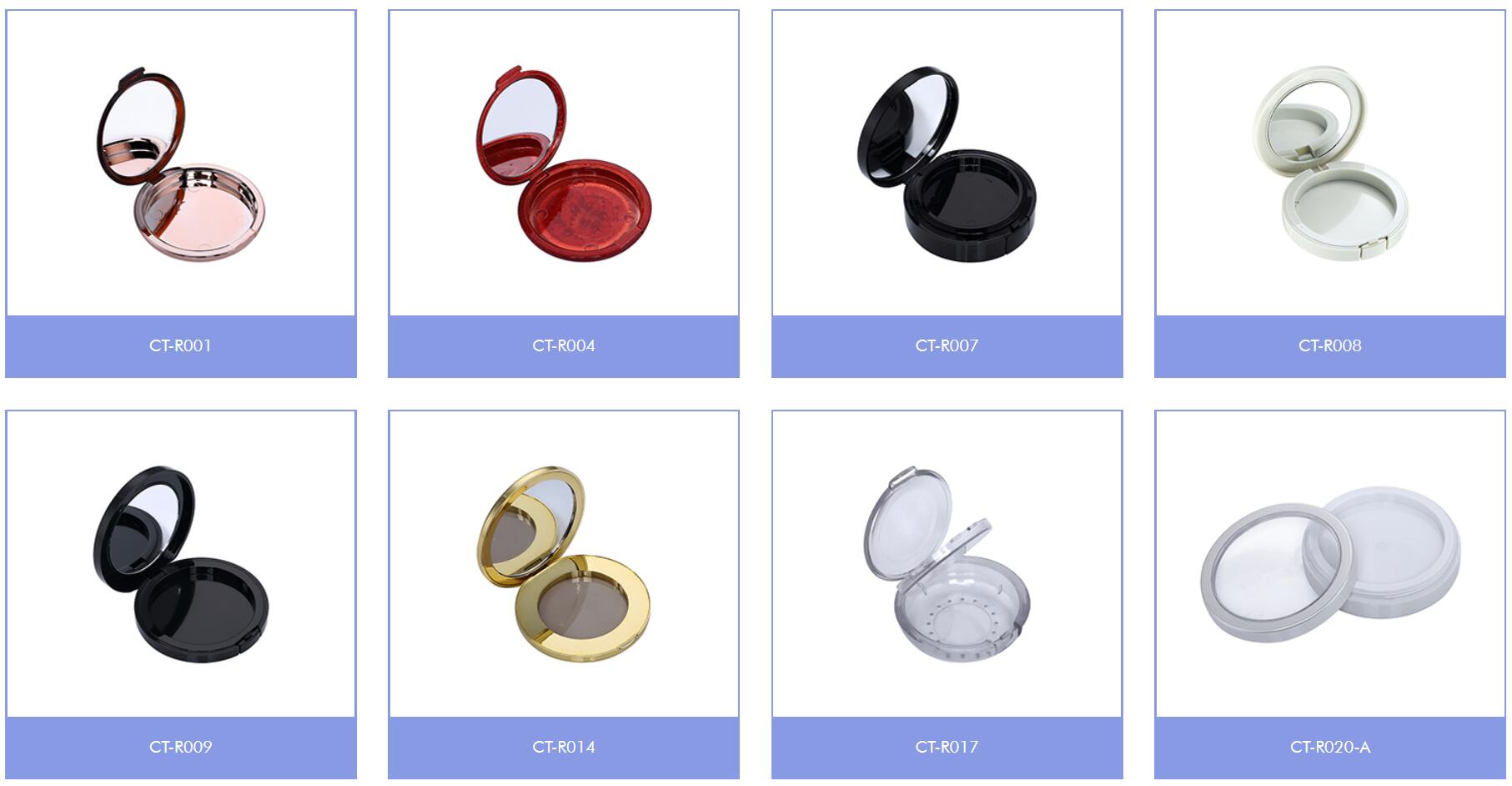

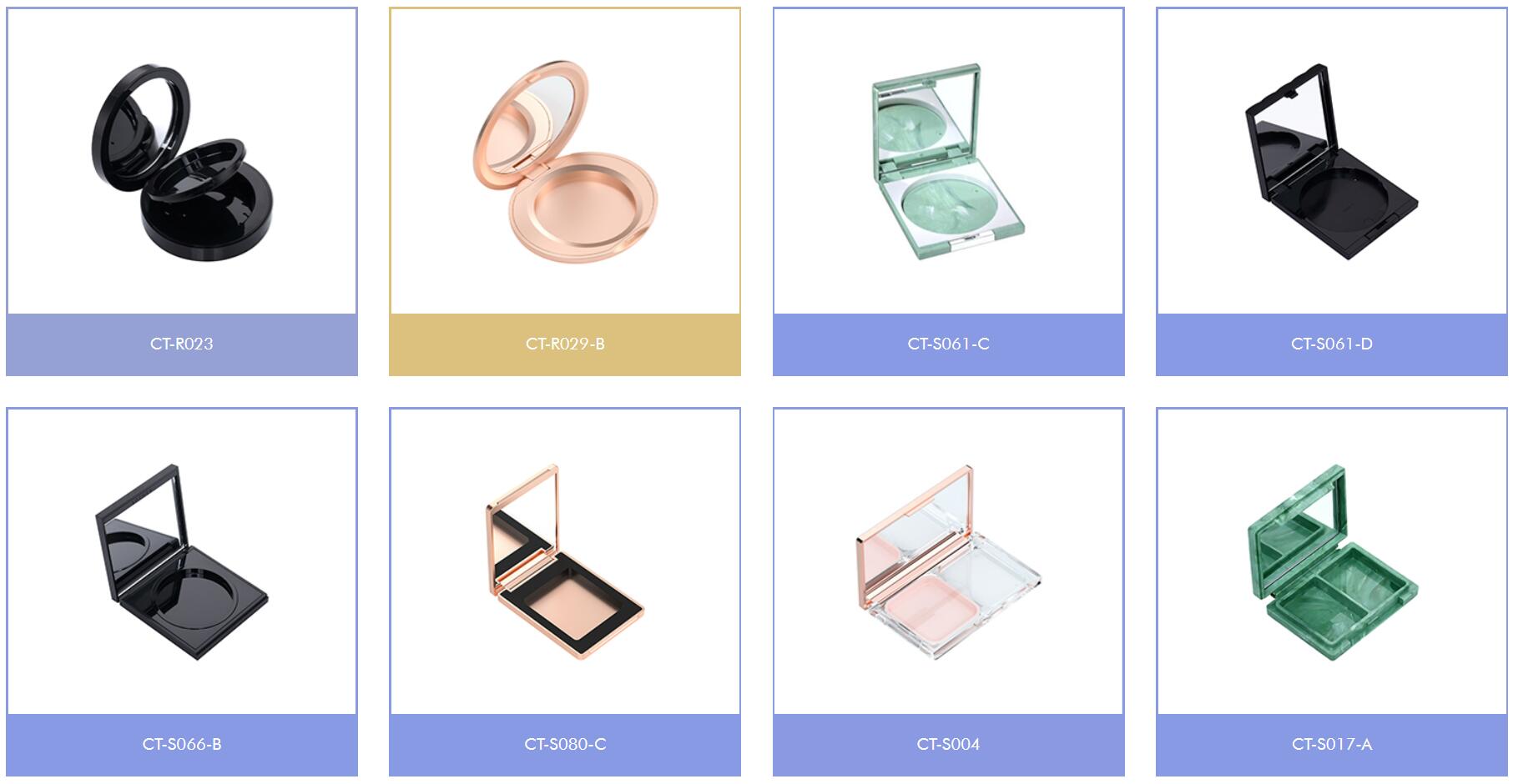

- Press powder compact series Same series products for Press powder compact series:

- Press powder compact series of designThe design and development of Ansix’s cosmetic pressed powder series products is a key process, which involves product appearance design, formula development, quality control and other aspects. The following will introduce in detail the design and development process and characteristics of Ansix’s cosmetic pressed powder series products.Appearance design:Ansix company focuses on the appearance design of its products and strives to create unique products. Their design team pays attention to fashion trends and aesthetic trends and integrates these elements into the appearance design of the products. They pursue simple, sophisticated and fashionable shapes to attract consumers’ attention and enhance the brand image.Formula development:The formulation research and development of Ansix’s cosmetic pressed powder series products is a key link. Their R&D team continuously pursues innovation and excellence, and develops formulas that meet market demand by selecting high-quality raw materials and advanced technology. They focus on product texture, coverage, durability and comfort to meet consumers’ requirements for product performance.Quality control:Ansix Company attaches great importance to the quality control of its products. They have established a strict quality control system, and each link from raw material procurement to production process is strictly monitored and inspected. They ensure that products comply with relevant regulations and standards and pass strict quality inspections and tests to ensure product safety and effectiveness.User experience:Ansix company focuses on user experience. They collect user needs through user research and feedback and integrate them into product design and development. They focus on ease of use, comfort and durability of their products to provide a quality user experience.During the design and development process, Ansix also focuses on cooperation with suppliers and partners. They work with high-quality raw material suppliers to ensure the raw material quality and stability of their products. In addition, they work closely with their production partners to ensure that the production process and quality control of their products meet standards.The design and development process of Ansix’s cosmetic pressed powder series products focuses on appearance design, formula development, quality control and user experience. They pursue fashion, innovation and excellence, and ensure product quality and stability through cooperation with suppliers and partners. Ansix Company will continue to strive for innovation and improvement to provide users with more high-quality cosmetic products.

- Press powder compact series of the mold manufacturing process and product material selectionThe mold manufacturing and material selection of Ansix’s cosmetic pressed powder series products have an important impact on product quality and cost.Cost advantages of mold manufacturing and mold processing:Mold manufacturing is one of the key steps in the production of cosmetic pressed powder cake series products. Ansix companies can achieve cost advantages in mold manufacturing and mold processing through:Mold design optimization: Through reasonable mold design, material waste and processing procedures are reduced, and mold manufacturing costs are reduced.Mold material selection: Choose appropriate mold materials, such as high-quality alloy steel or stainless steel, to ensure the hardness, wear resistance and corrosion resistance of the mold, extend the service life of the mold, and reduce mold replacement costs.Mold processing process optimization: By optimizing mold processing processes, such as CNC machining, EDM and wire cutting, etc., we can improve processing efficiency and accuracy and reduce processing costs.Pressed powder compact box material selection and material injection molding advantages:The material selection of pressed powder compact box is crucial to the appearance quality and brand image of the product. Ansix can choose from the following materials and injection mold the pressed powder compact to realize the advantages:High-quality plastic materials: Choose high-quality plastic materials, such as polypropylene (PP) or polyethylene (PE), which have good transparency, heat resistance and pressure resistance, and can protect the quality and stability of the pressed powder cake.Injection Molding Advantages: Injection molding is an efficient and precise production process that allows for rapid production and consistency of pressed powder compact boxes. Injection molding can produce pressed powder compacts with complex shapes and details to meet design requirements and increase production efficiency.In summary, the cost advantages of mold manufacturing and mold processing for Ansix’s cosmetic pressed powder cake series can be achieved through mold design optimization, mold material selection, and mold processing process optimization. Advantages of material selection and material injection molding for pressed powder compact boxes. By selecting high-quality plastic materials and injection molding processes, the appearance quality and production efficiency of pressed powder compact boxes can be improved. These measures can reduce production costs, improve production efficiency, and ensure product quality and stability.

- Press powder compact series Mass production and Quality controlThe mass production of Ansix’s cosmetic pressed powder cake series can be achieved through injection molding mass production to improve production efficiency, reduce costs and ensure product quality.Advantages of injection molding mass production:Injection molding mass production is an efficient and precise production process suitable for mass production of cosmetic pressed powder cake series products. It has the following advantages:Efficient production: Injection molding can achieve fast and continuous production, greatly improving production efficiency.Consistency and stability: Injection molding can ensure product consistency and stability, with each product having the same size, shape and appearance quality.Complex shapes and details: Injection molding can produce products with complex shapes and details to meet design requirements.Improvement of production efficiency:To improve productivity, Ansix companies can take the following measures:Automated equipment configuration: introduce automated equipment and production lines to achieve efficient operation of automated injection molding and production processes, reduce manual operations and increase production speed.Parallel production: Parallel production is adopted to carry out multiple processes at the same time to shorten the production cycle.Optimize process flow: Improve production efficiency and quality by optimizing injection molding process parameters, adjusting production flow and process control.Process cost control:Ansix companies can control process costs through:Raw material procurement optimization: Cooperate with suppliers to optimize raw material procurement and reduce costs.Equipment maintenance and management: Regularly maintain and manage production equipment to ensure the normal operation and life of the equipment and reduce repair and replacement costs.Energy and resource management: optimize the use of energy and resources, reduce waste and costs.Product quality assurance:In order to ensure product quality, Ansix Company can take the following measures:Quality control plan: Develop a quality control plan to clarify the quality requirements and control methods for each link.Inspection and testing: Conduct product inspection and testing, such as appearance inspection, dimensional measurement, functional testing, etc., to ensure that the product meets the requirements.Process monitoring: Monitor the production process, such as temperature control, injection pressure control, etc., to ensure product consistency and stability.In summary, the mass production of Ansix’s cosmetic pressed powder series products can be achieved through injection molding mass production to improve production efficiency, reduce costs and ensure product quality. Through measures such as automated equipment configuration, process optimization, process cost control and product quality assurance, Ansix can achieve efficient, stable and high-quality mass production.