Lasers & Extruded Medical Tubing

FEATURES

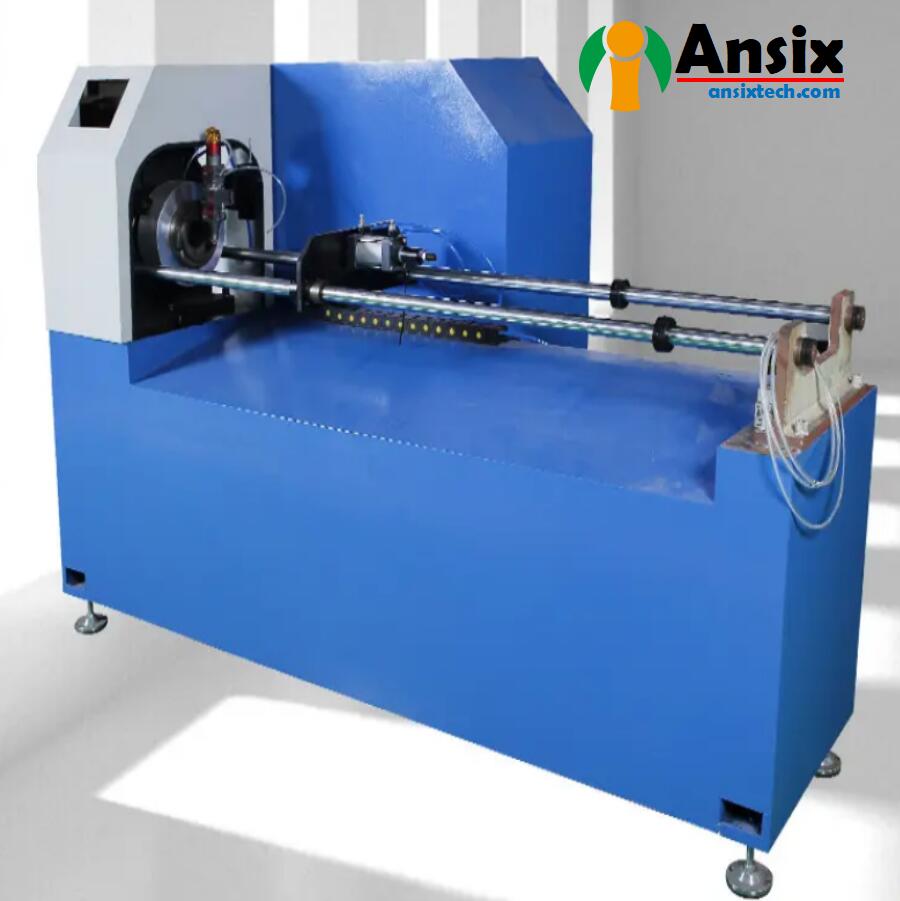

- Lasers & Extruded Medical Tubing for AnsixTech

Laser processing of medical tubing is a common processing method that can be used to cut, drill, and engrave medical tubing. Here is some information about laser processing of medical tubes:Cutting: Laser cutting is a precise cutting method that can be used to cut medical tubing into the desired length or shape. Laser cutting allows for high precision and smooth cutting edges without burrs or chips.Drilling: Laser drilling can create small holes or through-holes in medical tubing for drainage, ventilation, or other specific applications. Laser drilling can achieve precise aperture and position control, and is suitable for medical tubes that require high-precision apertures.Engraving: Laser engraving can engrave marks, patterns or text on the surface of medical tubes. Laser engraving enables high-resolution and precise patterns for marking and identifying medical tubes.Laser processing offers many advantages that make it ideal for medical tube processing:High precision: Laser processing can achieve very precise processing and is suitable for medical tube manufacturing that requires high precision.Non-contact processing: Laser processing is a non-contact processing method that does not cause physical damage or deformation to the medical tube.High efficiency: Laser processing can achieve fast and efficient processing, suitable for mass production.Flexibility: Laser processing can be customized according to different needs and design requirements, and is suitable for medical tubes of various shapes and sizes.It is important to note that the choice of laser processing depends on the specific application needs and manufacturing requirements. Manufacturers typically select the appropriate laser processing method to manufacture medical tubing products based on customer needs and specifications.

-

Laser Methods for Medical Tubing

In the medical industry, lasers can be used for processing and processing a variety of medical tubing. Here are some examples of common laser methods applied to medical tubing:Laser cutting: Laser cutting is a common laser processing method that can be used to cut medical tubing. Laser cutting allows for precise cutting edges without burrs or chips. This method is suitable for situations where medical tubing needs to be cut to the desired length or shape.Laser drilling: Laser drilling can create small holes or through holes in medical tubing. This method can achieve precise hole diameter and position control, and is suitable for applications that require drilling holes in medical tubing, such as drainage, ventilation, etc.Laser welding: Laser welding is a method of joining two or more medical tubing together. Laser welding can achieve high-strength and sealed connections, and is suitable for situations where connections need to be made on medical tubing, such as infusion tubes.Laser etching: Laser etching can engrave marks, patterns or text on the surface of medical tubing. This method enables high-resolution and precise patterns for marking and identifying medical tubing.Laser cleaning: Laser cleaning is a method of using a laser beam to remove dirt and contaminants from the surface of medical tubing. Laser cleaning can achieve non-contact cleaning without causing physical damage to medical tubing.These laser methods can be customized to specific medical tubing and application needs. Manufacturers typically select the appropriate laser method for processing and processing medical tubing based on customer needs and specifications.High-precision laser methods that are frequently used for medical tubing include:Laser ablation— “vaporizes” material from the tubing’s surface at the micron level, with little or no negative thermal or structural damage to surrounding materialLaser cutting—cuts miniaturized, complex features as small as 0.0002 inches (5 microns) with no heat effects, in a variety of materialsLaser drilling—common requests include micron-size holes, spiral arrays, blind wells, and specialized portals that can be drilled in a variety of patterns with the highest precision, without burrs

-

Medical Tubing Applications

Medical tubing is widely used in the medical industry, covering multiple fields and application scenarios. Here are some common medical tubing applications:Infusion and blood transfusion: Medical tubing is used in infusion and blood transfusion systems to transport liquids and drugs. Common medical pipes include polyvinyl chloride (PVC) pipes, polyethylene (PE) pipes, silicone pipes, etc.Drainage and drainage: Medical tubes are used in drainage and drainage systems such as drainage tubes, gastric tubes, and urinary catheters to remove fluids and waste from the body. Common medical pipes include silicone pipes, polyvinyl chloride (PVC) pipes, etc.Airway management: Medical tubing is used in airway management equipment such as endotracheal tubes and ventilator connecting tubes to transport gas and maintain respiratory function. Common medical pipes include polyvinyl chloride (PVC) pipes, silicone pipes, etc.Guide wires and catheters: Medical tubing is used in guide wire and catheter systems for guidance and positioning. Common medical pipes include polyvinyl chloride (PVC) pipes, polyethylene (PE) pipes, silicone pipes, etc.Implants and surgical instruments: Medical tubing is also used in implants and surgical instruments, such as pacemaker leads, artificial joints, etc. Common medical pipes include polyethylene (PE) pipes, polyvinyl chloride (PVC) pipes, silicone pipes, etc.Drug delivery: Medical tubing can be used in drug delivery systems, such as drug delivery tubes, syringes, etc. Common medical pipes include polyvinyl chloride (PVC) pipes, silicone pipes, etc.Laboratory and diagnostic applications: Medical tubing is also used in laboratory and diagnostic applications such as blood collection, urinalysis, biochemical analysis, etc. Common medical pipes include polyethylene (PE) pipes, silicone pipes, etc.Medical tubing is used in a wide range of applications and can be customized to specific needs and requirements. Manufacturers often provide medical tubing products with application-specific features based on customer needs and specifications.

- Off-the-Shelf Medical Tubing Extrusions at AnsixTech

Our “off-the-shelf “extruded tubing with laser-cut hole configurations for various medical applications is available。PVC (polyvinyl chloride) pipe: PVC pipe is a common medical extruded pipe used for various applications such as infusion, drainage, and airway management. It has good softness and chemical resistance and is suitable for various medical environments.PE (polyethylene) tube: PE tube is another common medical extruded tube used for infusion, drainage, airway management and other applications. It has good softness and durability and is suitable for long-term use and repeated cleaning and disinfection.TPE (thermoplastic elastomer) tube: TPE tube is a medical extruded tube with good elasticity and softness, used for infusion, drainage, airway management and other applications. It has good biocompatibility and durability.Silicone tube: Silicone tube is a common medical extruded tube used for infusion, drainage, airway management and other applications. It has good biocompatibility, high temperature resistance and softness, and is suitable for various medical environments.These off-the-shelf medical extruded tubing can often be customized to customer needs and specifications, including size, shape, lumen design and material properties. Manufacturers typically offer off-the-shelf medical extruded tubing products with specific features and properties based on customer needs and application requirements.Tubing sizes: 4 Fr–12 FrWall sizes: 0.005"–0.010"Materials: Pebax® 55D and Nylon 12Laser-cut hole configurations in various arrays

contact us

Try Our Problem-solving Injection Molding Services Now

AnsixTech Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

ISO 13485 Certified factory

ISO 8 Cleanroom

Robust Expertise for Medical Injection Molding

Advanced mold manufacturing capabilities and plastic injection molding equipment

Quick Response within 12 hours

- If you have any questions about products in the medical field, please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.