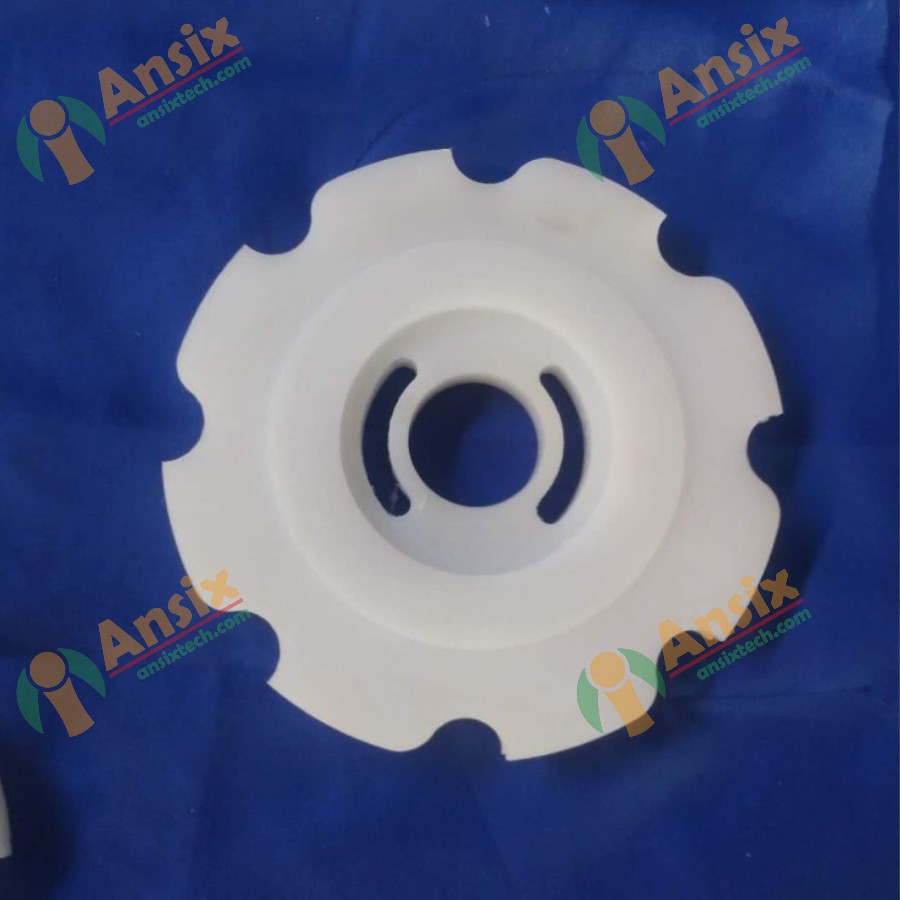

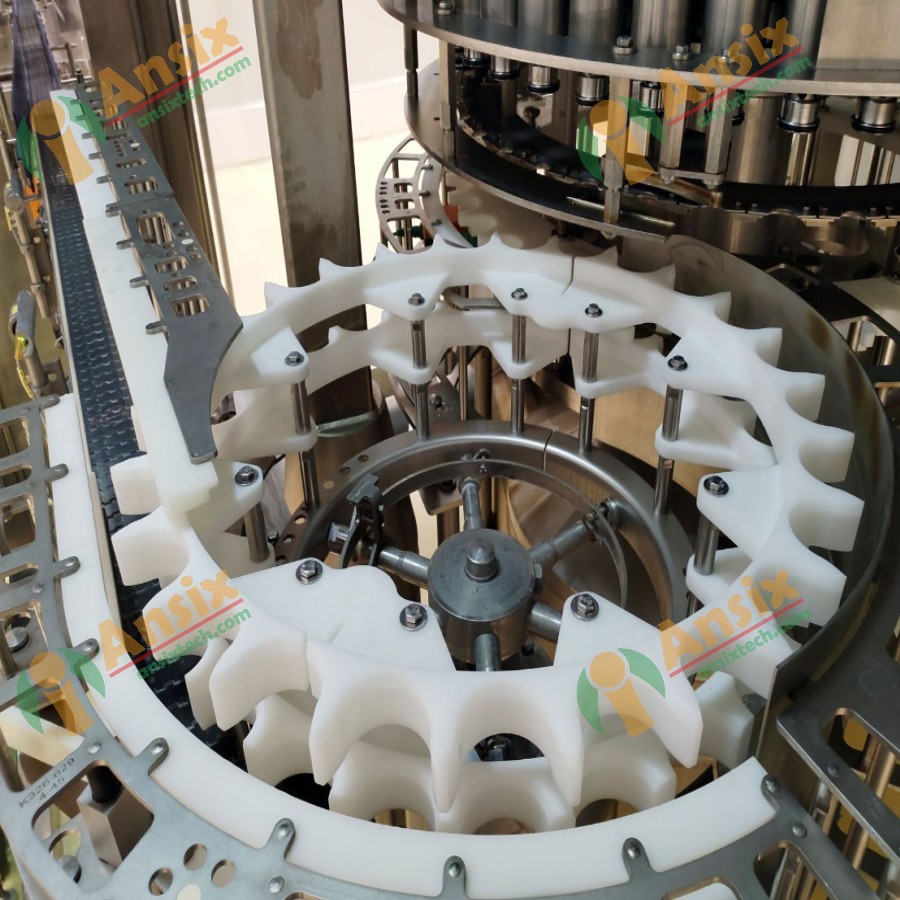

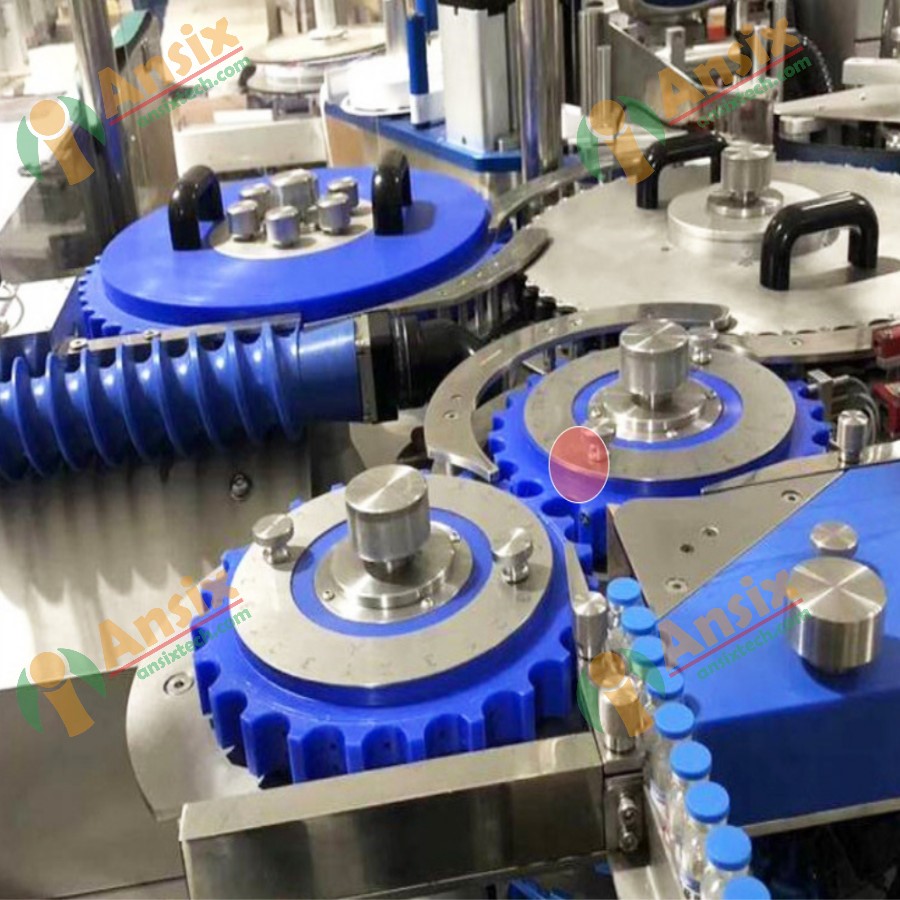

Automation equipment customized star gear transmission star wheel PA66 star wheel Plastic PA66 Star Wheel

FEATURES

- Automation equipment customized star gear transmission star wheel PA66 star wheel Plastic PA66 Star Wheel

In short, nylon star gears have the advantages of wear resistance, self-lubrication, corrosion resistance and lightweight, and are suitable for transmission devices, automation equipment, instrumentation and power tools. It can realize the functions of power transmission, motion control and measurement indication.., please send us a message (Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

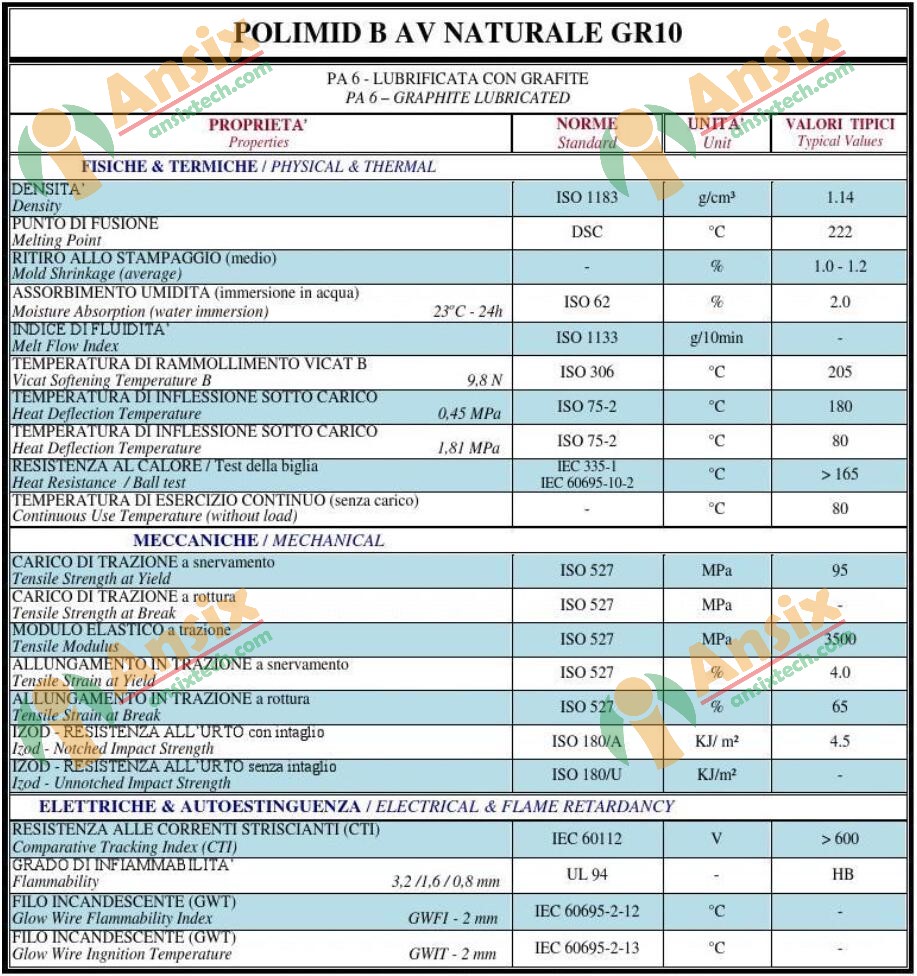

- PA66 Material Parameter SheetPA66 refers to polyamide 66, usually polyadipamide (Nylon 66). It is a thermoplastic polymer material synthesized from adipic acid and hexamethylenediamine through a polycondensation reaction. Therefore, the components of PA66 mainly include the monomers of adipic acid and hexamethylenediamine. This material usually has excellent heat resistance, wear resistance and mechanical properties, so it is widely used in the field of engineering plastics.

- Plastic Sheets CNC Cutting for star wheel

Machining the star wheel refers to the process of processing the star wheel using mechanical processing equipment. A star wheel is a gear-shaped part that is often used in transmission systems to transmit force and rotation.In the process of machining a star wheel, the following steps can be used:Design and planning: Carry out process planning and tool selection according to the requirements and drawings of the star wheel. Determine the size, number of teeth, tooth shape and other parameters of the star wheel.Material preparation: Prepare materials suitable for the star wheel, such as metal materials (such as steel, aluminum, etc.) or engineering plastics. Ensure the quality and compliance of materials.Processing technology: According to the design requirements of the star wheel, select appropriate mechanical processing equipment, such as lathes, milling machines, gear processing machines, etc. Depending on the shape and size of the star wheel, processing operations such as turning, milling, and gear cutting are performed.Cutting parameters: Set the cutting speed, feed speed and cutting depth reasonably according to the characteristics of the material and the requirements of the star wheel. Pay attention to controlling the cutting temperature to avoid material deformation or burning due to overheating.Surface treatment: As needed, the surface of the star wheel can be polished, grinded or sandblasted to improve surface quality and smoothness.Quality inspection: During the processing process, quality inspection is carried out to ensure that the size, tooth shape and surface quality of the star wheel meet the requirements. Measuring tools such as calipers, vernier calipers, etc. can be used for detection.Assembly and testing: If necessary, assemble the star wheel with other parts and perform testing and debugging to ensure its normal operation and performance.In short, machining star wheels requires reasonable process planning, cutting parameter settings and quality inspection. With appropriate machining equipment and operating skills, a star wheel that meets the requirements can be produced.

- Quality Assurance of star wheel

Ansix takes the following measures to ensure quality, size and structural accuracy during the machining process of the star wheel:Strict quality control system: Ansix has established a strict quality control system, including formulating standard operating procedures (SOP), setting up inspection points and quality inspection processes, etc. Each processing step will be inspected and recorded to ensure that every link meets quality requirements.Advanced processing equipment: Ansix is equipped with advanced mechanical processing equipment, such as high-precision CNC machine tools, gear processing machines, etc. These devices have high precision and stability and can ensure the processing accuracy and quality of the star wheel.Accurate measurement and inspection: Ansix uses precision measurement tools and equipment, such as three-dimensional coordinate measuring machines, projectors, etc., to accurately measure and inspect the size, tooth shape and surface quality of the star wheel. Make sure the size and shape of the star wheel meet design requirements.High-quality raw materials: Ansix selects high-quality raw materials, such as high-quality metal materials or engineering plastics. Ensure that raw materials meet relevant standards and requirements and have good mechanical properties and wear resistance.Professional knowledge and experience of technical team: Ansix has a professional technical team with rich processing experience and professional knowledge. They can formulate appropriate processing technology and cutting parameters based on the design requirements and material characteristics of the star wheel to ensure quality and dimensional accuracy.Continuous improvement and optimization: Ansix continuously improves and optimizes quality. By analyzing and evaluating problems and defects in the processing process, corresponding improvement measures are taken to improve the quality and dimensional accuracy of the star wheel.In short, Ansix ensures the quality, size and structural accuracy of machined star wheels through strict quality control systems, advanced processing equipment, precise measurement and testing, high-quality raw materials, professional technical teams, and continuous improvement and optimization. .