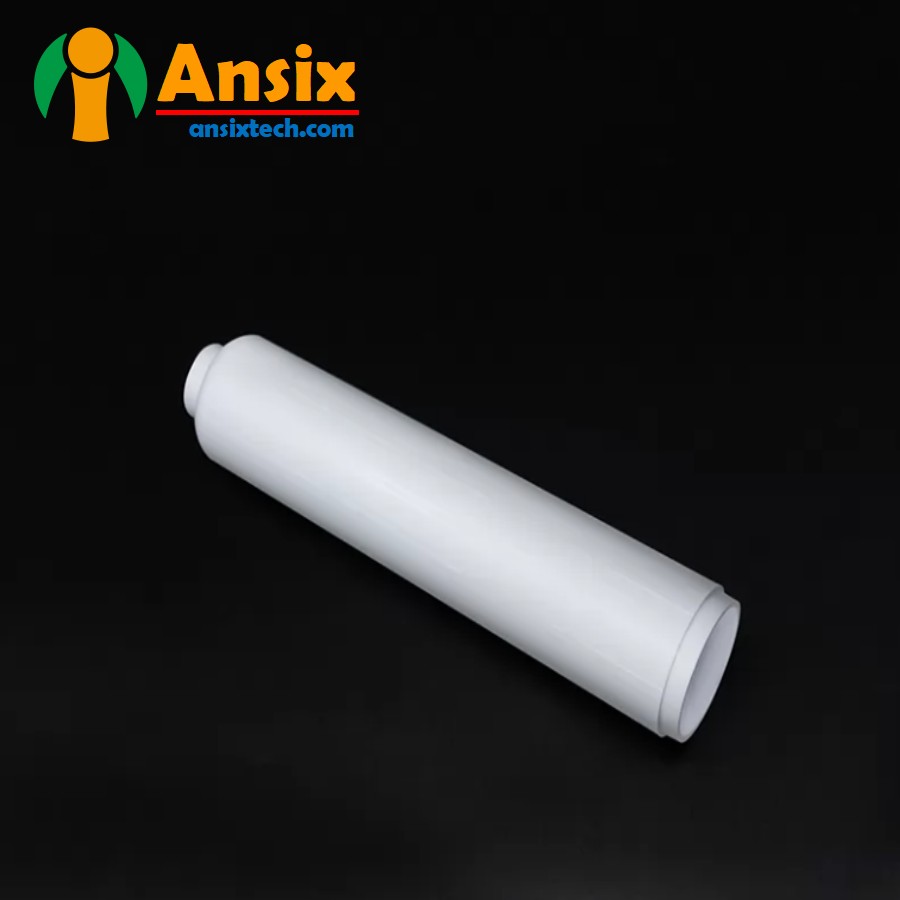

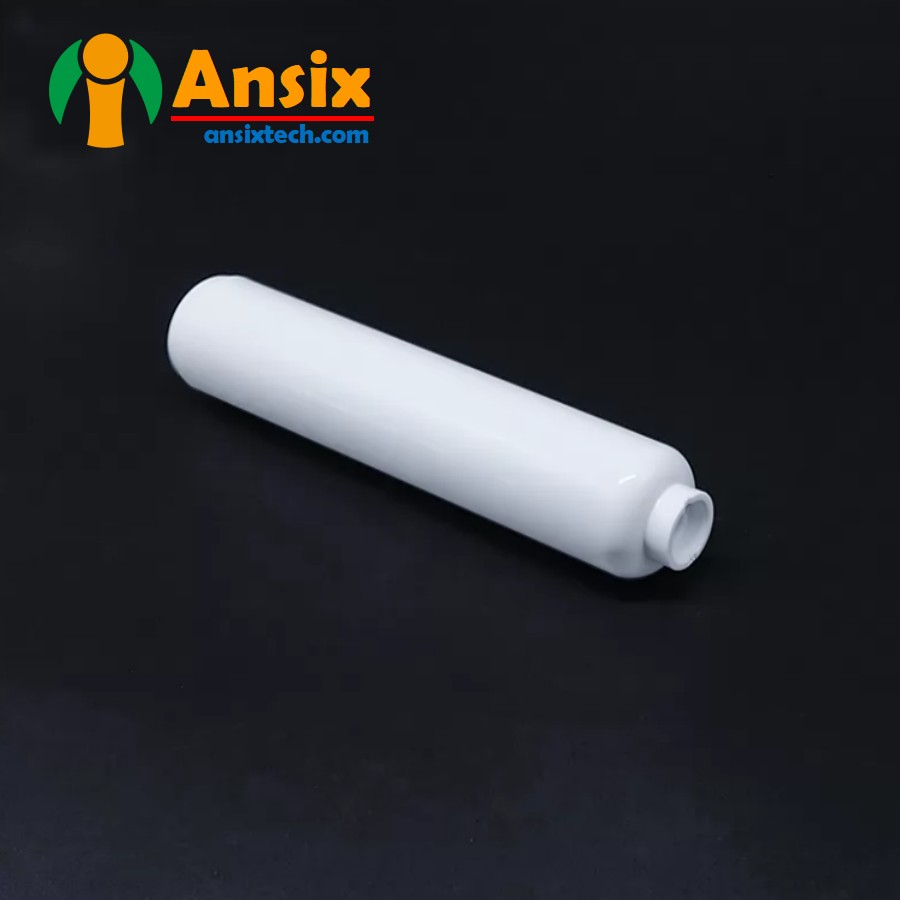

10 Inch Household Water Purifier Injection Mould for RO membrane shell

FEATURES

-

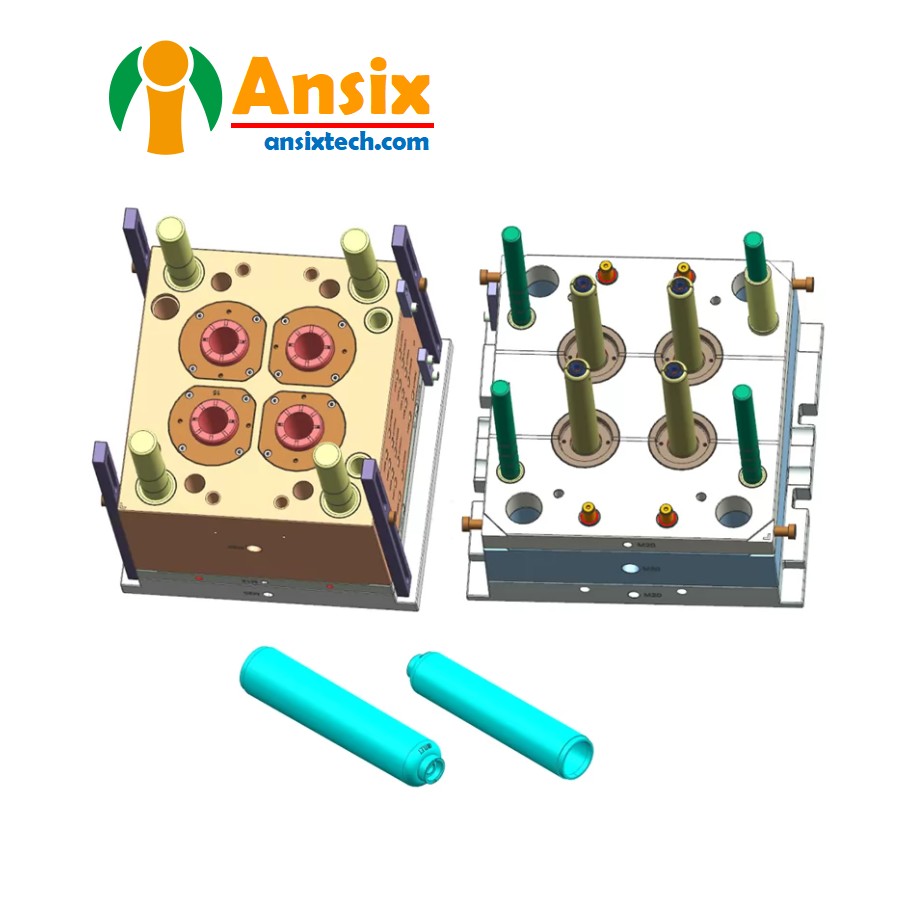

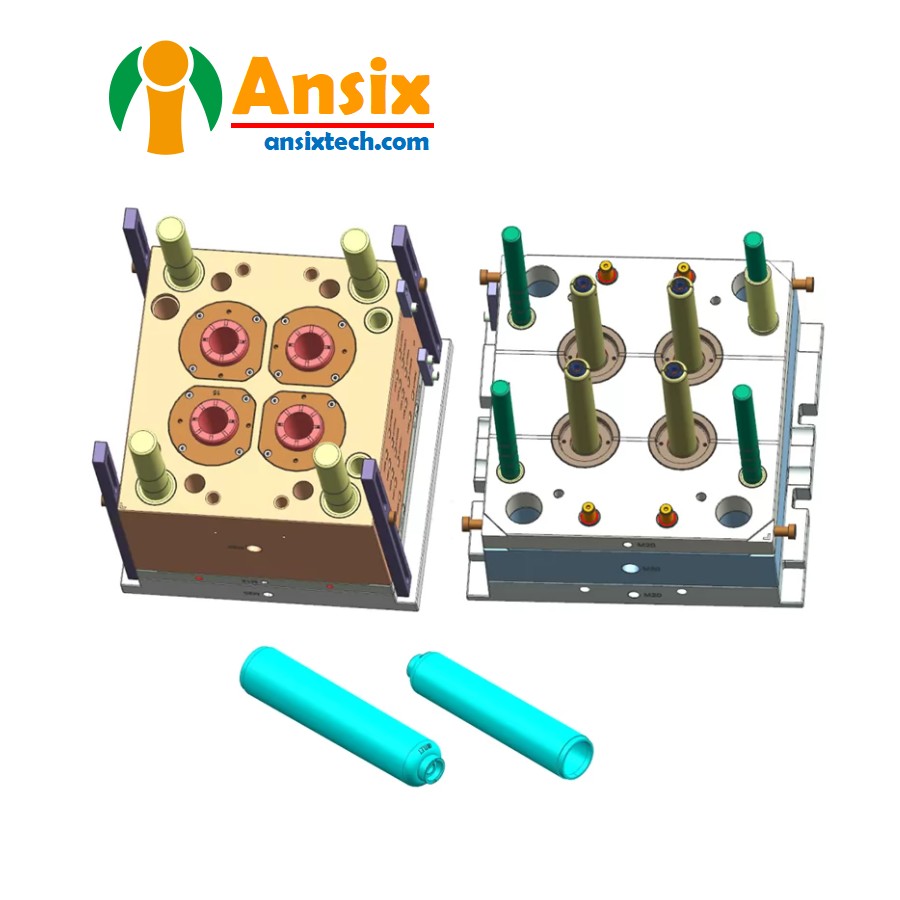

Mold Description

Product Materials:

PP

Mold Material:

738

Number of Cavities:

1*4

Glue Feeding Method:

Hot runner

Cooling Method:

Water cooling

Molding Cycle

31.5s

- 10 Inch Household Water Purifier Injection Mould for RO membrane shell Mold flow analysis and mold designWhen designing a 10-inch household water purifier RO membrane shell PP casing mold, you can follow the following steps for design and mold flow analysis:Mold structure design:According to the design requirements of the RO membrane shell, determine the structure of the mold, including the mold cavity, mold core, demoulding system, cooling system, etc.Ensure that the accuracy and size of the mold meet the requirements to ensure the quality and stability of injection molding.Consider the durability and ease of maintenance of the mold, and rationally design the structure and parts of the mold to improve the life and ease of maintenance of the mold.Injection molding process parameter design:Determine the appropriate injection molding process parameters, such as injection speed, temperature, pressure, etc., based on the characteristics of the PP material and the requirements of the RO membrane shell.Optimize injection molding process parameters through mold flow analysis and experiments to ensure filling performance and product quality.Cooling system design:Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.Consider the shape and size of the RO membrane shell to determine the layout of the cooling system and the flow path of the cooling medium to improve the cooling effect.Design of demoulding system:According to the shape and requirements of the RO membrane shell, design a suitable demoulding system to ensure that the RO membrane shell can be demoulded smoothly and avoid damage and deformation.Consider the demoulding force and demoulding angle to determine the structure and parts of the demoulding system to improve the demoulding effect.Mold material selection:Choose suitable mold materials, such as high-quality steel, to ensure the durability and stability of the mold.According to the requirements of the RO membrane shell, select wear-resistant and corrosion-resistant mold materials to increase the service life of the mold.Mold flow analysis:Use mold flow analysis software to import the CAD model of the RO membrane shell and set the injection molding process parameters.Conduct mold flow analysis to simulate melt flow, filling, cooling and other processes during the injection molding process to evaluate filling performance, bubbles, short shots and other defects, and optimize injection molding process parameters.Through reasonable design and mold flow analysis, a high-quality 10-inch household water purifier RO membrane shell PP casing mold can be obtained. Please note that mold design and mold flow analysis require professional knowledge and experience, and it is recommended to cooperate with a professional mold design and mold flow analysis team to ensure the accuracy and feasibility of design and analysis.

- 10 Inch Household Water Purifier Injection Mould for RO membrane shell of the mold manufacturing process and product material selectionThe manufacturing and processing of the PP casing mold for the 10-inch household water purifier RO membrane shell and the selection and application of the casing PP material:1. Complex structure: Water purifier filter element casings usually have complex structures, including internal threads, connections, filter element support structures, etc. The design and processing of the mold need to take these complex structural characteristics into consideration.2. High dimensional accuracy requirements: The dimensional accuracy of the water purifier filter core casing is high, especially the dimensional accuracy of the internal threads and connections. Mold processing needs to ensure the dimensional accuracy and consistency of the product.3. Material selection: The water purifier filter element casing usually needs to be made of high-temperature-resistant, pressure-resistant, and corrosion-resistant plastic materials to ensure the service life and stability of the product.4. Injection molding process control: The injection molding process of the water purifier filter core casing needs to be strictly controlled, including injection pressure, speed, temperature and other process parameters to ensure the molding quality of the product.When choosing the material of the water purifier filter core casing, you usually need to consider the following factors:1. High temperature resistance: The water purifier filter core casing needs to have certain high temperature resistance to ensure stability in high temperature environments.2. Pressure resistance: The water purifier filter element casing needs to have certain pressure resistance to ensure that the product will not deform or break during use.3. Corrosion resistance: The water purifier filter core casing needs to have certain corrosion resistance to ensure that the product will not be corroded when it comes into contact with water.4. Injection molding processing performance: The material needs to have good injection molding processing performance to ensure the molding quality and production efficiency of the product.Common materials used for water purifier filter cartridge casings include:1. Polypropylene (PP): PP material has good high temperature resistance, corrosion resistance and injection molding performance, and is suitable for the manufacture of water purifier filter core casings.2. Polyethersulfone (PES): PES material has excellent high temperature resistance and pressure resistance, and is suitable for making high temperature and high pressure water purifier filter core casings.3. Polytetrafluoroethylene (PTFE): PTFE material has excellent corrosion resistance and high temperature resistance, and is suitable for making water purifier filter core casings that are highly chemically corrosive.When selecting materials, comprehensive considerations need to be based on the specific requirements of the product and the use environment.Selection of casing PP material:Select the appropriate material according to the requirements of the 10-inch household water purifier RO membrane housing casing. Commonly used materials include polypropylene (PP).PP material has good chemical resistance, high temperature resistance and mechanical properties. It is suitable for the manufacture of RO membrane shell casing for water purifiers and can meet the requirements of chemical resistance and high temperature environment.During the manufacturing and processing of PP casing molds for water purifier RO membrane shells and the selection and application of casing PP materials, the following points need to be noted:Surface treatment of the mold: According to the requirements of the water purifier RO membrane shell casing, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the casing.Control of injection molding process parameters: According to the characteristics of the casing PP material, the injection molding process parameters are reasonably designed and controlled to ensure that the filling performance and curing effect of the material meet the requirements.The manufacturing and processing of PP casing molds for 10-inch household water purifier RO membrane shells and the selection and application of casing PP materials require the selection of appropriate processing techniques and equipment, and the selection of materials with good chemical resistance, high temperature resistance and mechanical properties. Through reasonable processing and control of injection molding process parameters, high-quality RO membrane shell PP casing can be achieved.

- 10 Inch Household Water Purifier Injection Mould for RO membrane shell Mass production and Quality controlThe mass production and secondary processing ultrasonic welding of 10-inch household water purifier RO membrane shell PP casing:Mass production of RO membrane shell PP casing:Prepare the injection molding machine, mold and suitable PP material.Carry out injection molding production according to mold design, and ensure filling performance and product quality by optimizing injection molding process parameters.Prepare the fixture:According to the shape and requirements of the RO membrane housing PP casing, design and manufacture suitable tooling fixtures for fixing and positioning the casing during ultrasonic welding process.The fixture should have good rigidity and stability to ensure the position and alignment of the casing.Carry out ultrasonic welding secondary processing:Place the RO membrane housing PP sleeve in the tooling fixture, ensuring correct position and alignment.Start the ultrasonic welding equipment to generate heat energy through ultrasonic vibration, heating the contact surfaces of the casing and pressing them together.Process quality control:Establish a complete quality control system, including quality inspection, process control and defective product processing, to ensure that products meet quality standards.Conduct inspections and tests on product appearance quality, dimensional accuracy, physical properties, etc. to ensure product quality and consistency.Monitor injection molding process parameters and ultrasonic welding parameters, and make timely adjustments and optimizations to ensure the stability and consistency of the production process.Through mass production of RO membrane shell PP casing and secondary processing ultrasonic welding, efficient production and high-quality products can be achieved. The use of tooling fixtures can improve production efficiency and welding quality. The implementation of process quality control ensures product quality and consistency. Throughout the production process, quality control and inspection are required to ensure product quality and consistency.