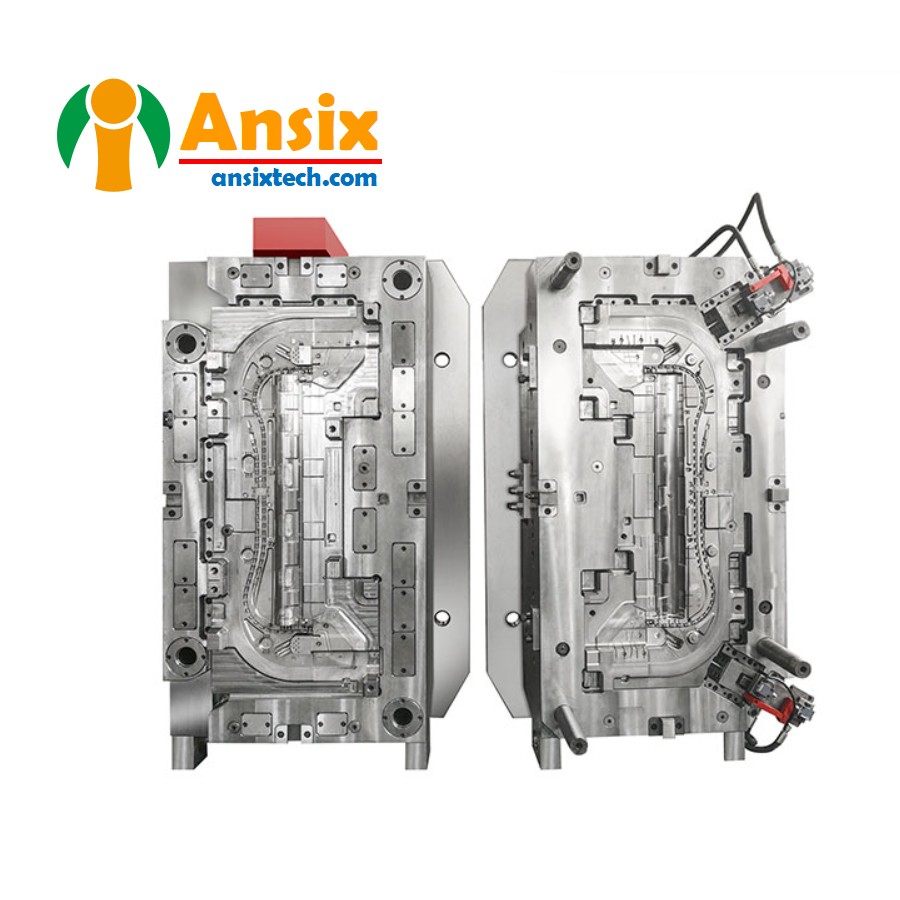

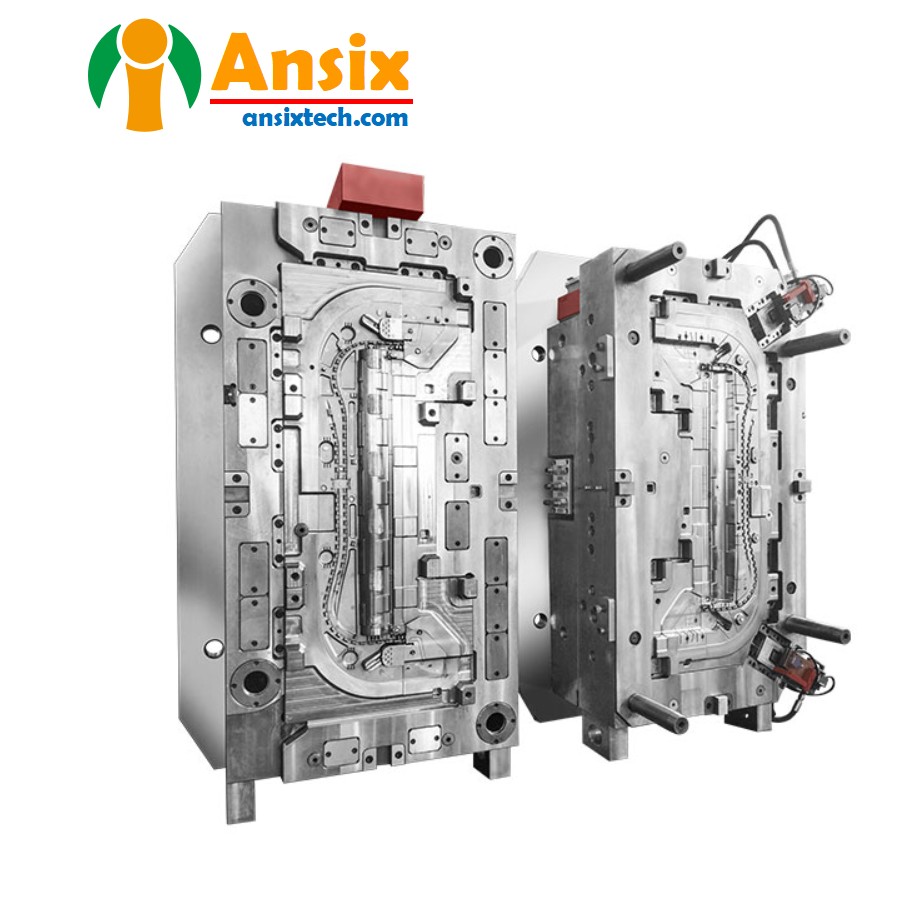

Automotive Window Frame Mould

FEATURES

- In general, injection molds and injection molding processes for manufacturing automotive window frames face some difficulties, such as complex shapes and structures, material selection and processing, etc. However, through reasonable mold design and manufacturing, as well as precise control of injection molding parameters and cooling systems, these difficulties can be overcome and high-quality automotive window frame injection moldin....Please send us a message(Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

-

Mold Description

Product Materials:

PBT+GF25

Mold Material:

2344

Number of Cavities:

1*1

Glue Feeding Method:

Hot runner

Cooling Method:

Oil cooling

Molding Cycle

49.5s

- The design and mold flow analysis of automobile window frame molds are key process links. The following are some key design and analysis aspects generally involved:Key points of mold designStructural Design: The window frame mold needs to take into account the shape, size and structure of the window frame to ensure that these complex shapes can be accurately formed.Material Selection: Choose a suitable mold material, usually tool steel with high hardness, high strength and wear resistance, to ensure the service life and stability of the mold.Cooling system design: Design a reasonable cooling system to ensure that plastic materials can be cooled quickly during injection molding and reduce quality problems caused by uneven deformation and shrinkage.Gate design: Reasonable gate design can ensure uniform melt filling and reduce defects such as bubbles and short injection.Mold processing accuracy: Mold processing requires high precision to ensure the size and surface quality of the final product.Mold flow analysis detailsFilling Simulation: Simulate the filling process of melt in the mold cavity, and evaluate parameters such as filling time, filling pressure, and filling speed to predict possible defects such as poor filling, bubbles, and short injections.Cooling Simulation: Conduct cooling simulation to evaluate parameters such as cooling time, temperature distribution and shrinkage to ensure uniform cooling of the entire window frame and reduce quality problems caused by uneven deformation and shrinkage.Thermal Stress Analysis: Analyze thermal stress and design a reasonable structure and cooling system to reduce the impact of thermal stress on product quality.Mold structure optimization: Based on the mold flow analysis results, the mold structure is optimized, including optimization of the cooling system, gate design, etc., to improve product molding quality and production efficiency.The above are the general key points of mold design and mold flow analysis. These processes and analyzes are critical to ensuring the production quality and efficiency of automotive window frames.

- The advantages of automotive window frame mold manufacturing include:High-precision processing: Mold manufacturing and processing usually uses high-precision processing techniques such as CNC machining and EDM to ensure the dimensional accuracy and surface quality of the window frame mold.Efficient production: Mold manufacturing and processing can achieve mass production, improve production efficiency, and reduce production costs.Customizable design: Mold manufacturing and processing can carry out customized design according to the shape, size and structural requirements of the window frame to meet the needs of different models.Long life and stability: Molds made of materials such as tool steel with high hardness, high strength and wear resistance have a long service life and stable processing performance.Precision cooling system design: A reasonable cooling system can be designed during mold manufacturing and processing to ensure that plastic materials can be cooled quickly during injection molding and reduce quality problems caused by uneven deformation and shrinkage.Advantages of automotive window frame material selection include:Lightweight and high strength: Window frame materials are usually made of materials with high strength and rigidity, such as aluminum alloy or high-strength steel, which can provide sufficient support and protection.Corrosion resistance: Window frame materials need to have good corrosion resistance and be able to resist erosion from the external environment and extend their service life.Good surface treatment properties: Window frame materials need to have good surface treatment properties and can be sprayed, anodized and other surface treatments to improve appearance quality and weather resistance.Plasticity: Window frame materials need to have good plasticity to facilitate molding and processing to meet the design needs of different models.Environmental protection: Window frame materials need to meet environmental protection requirements and have good recyclability and reusability.The advantages of mold manufacturing and window frame material selection can ensure the production quality and performance of automobile window frames and meet the needs of automobile manufacturing.

- Mass production and Quality control for automated tooling preparationAutomated tooling preparation, process quality control, secondary processing and transportation for mass production of automotive window frame injection molding require comprehensive consideration of production efficiency, product quality and production cost. Here are some possible measures:Automated tooling preparationAutomatic feeding system: Introduce an automatic feeding system to realize automatic supply of raw materials, reduce manual operations, and improve production efficiency.Automated mold changing system: Use an automated mold changing system to reduce mold changing time and improve production line utilization.Automated gate cutting: Use automated gate cutting equipment to realize automatic cutting and processing of gates and improve production efficiency.Process quality controlOnline quality monitoring: Introduce online quality monitoring equipment to monitor product size, appearance, etc. in real time, and detect and handle abnormalities in a timely manner.Automated testing equipment: Use automated testing equipment to automatically detect the size and appearance of the product to ensure stable product quality.Quality Record Traceability: Establish a complete quality record traceability system to record and trace quality data during the production process to ensure product quality is controllable.Secondary processingAutomated assembly line: Establish an automated assembly line to realize automated assembly of window frames and improve production efficiency.Automated spraying equipment: Use automated spraying equipment to automatically spray the window frames to improve surface quality and production efficiency.transportationAutomated logistics system: Introduce an automated logistics system to realize automated transportation and warehousing of products and improve logistics efficiency.Packaging Automation: Use automated packaging equipment to automatically package products to improve packaging efficiency and product protection.Through the above measures, the efficiency and product quality of mass production of automobile window frame injection molding can be improved, ensuring that products can meet market demand and improving the competitiveness of enterprises.