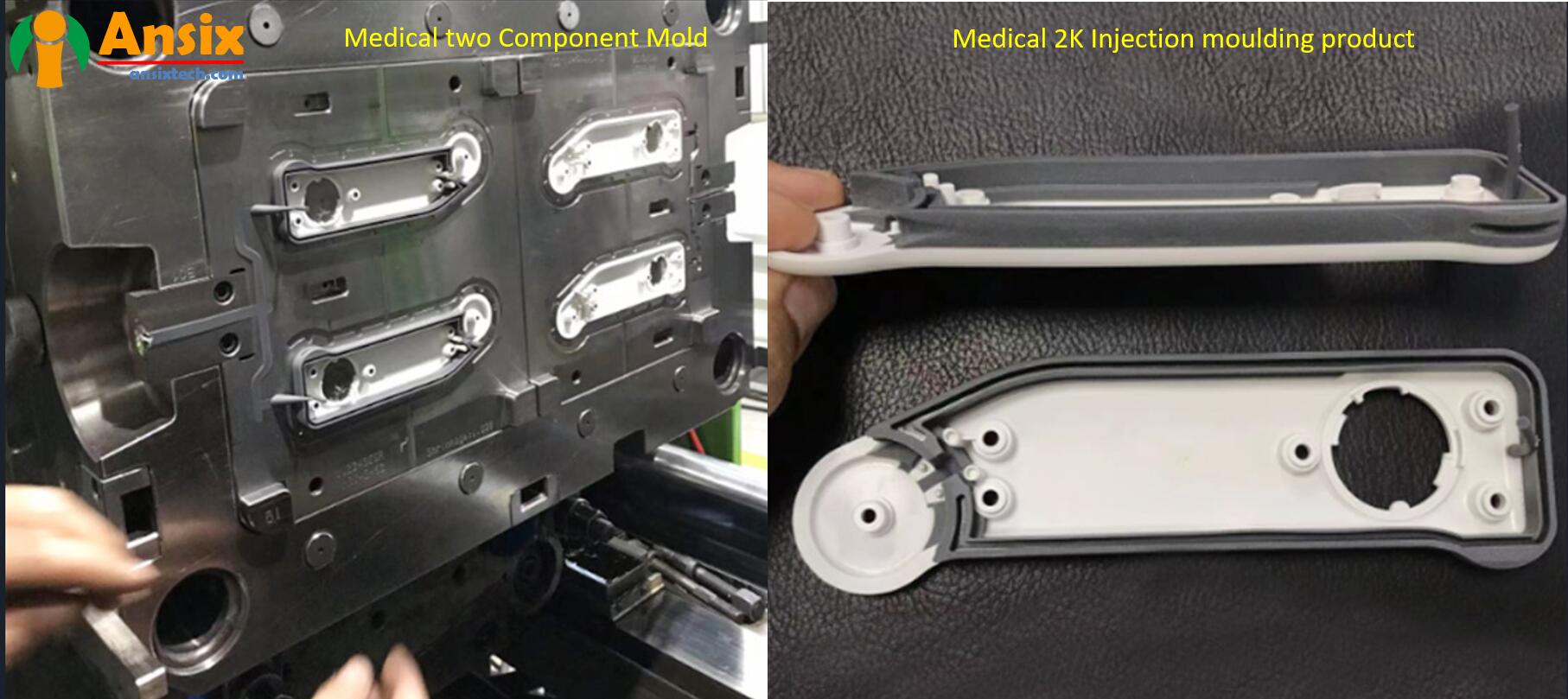

- Medical Device Manufacturing

-

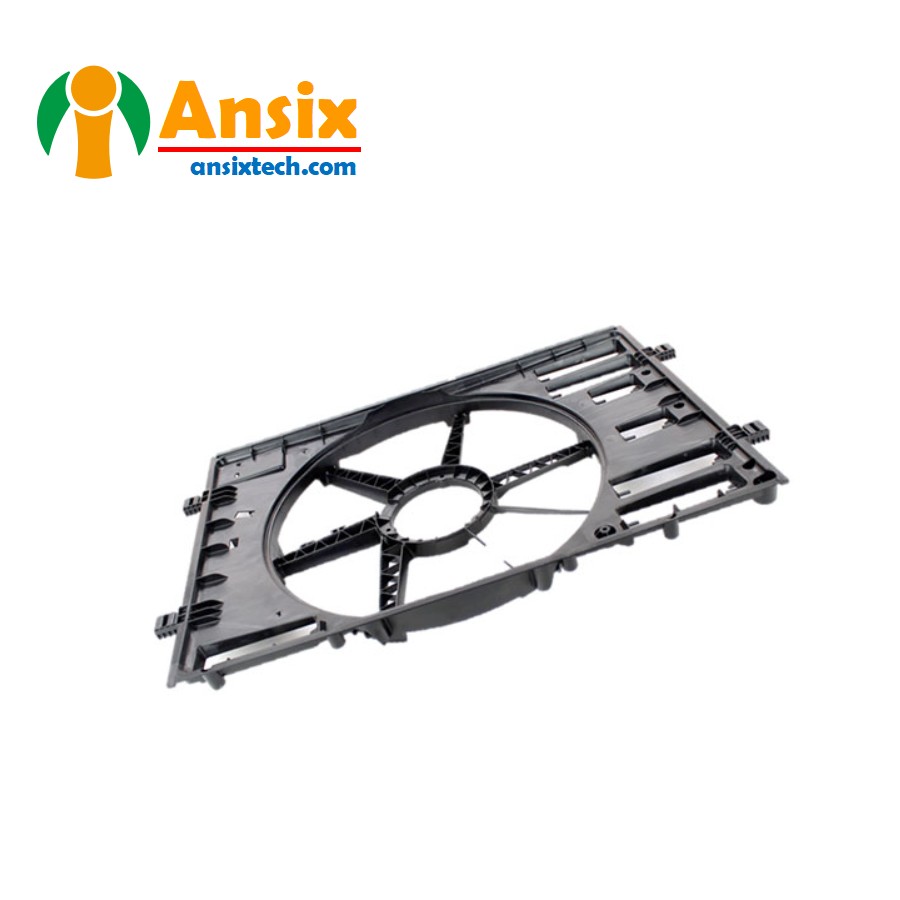

Precision Mold and Two Component

- Precision Plastic Injection Mould

- Thermoplastic molded components

- Precision Electrical Parts

- 2K Injection Mold for Electrical Switches

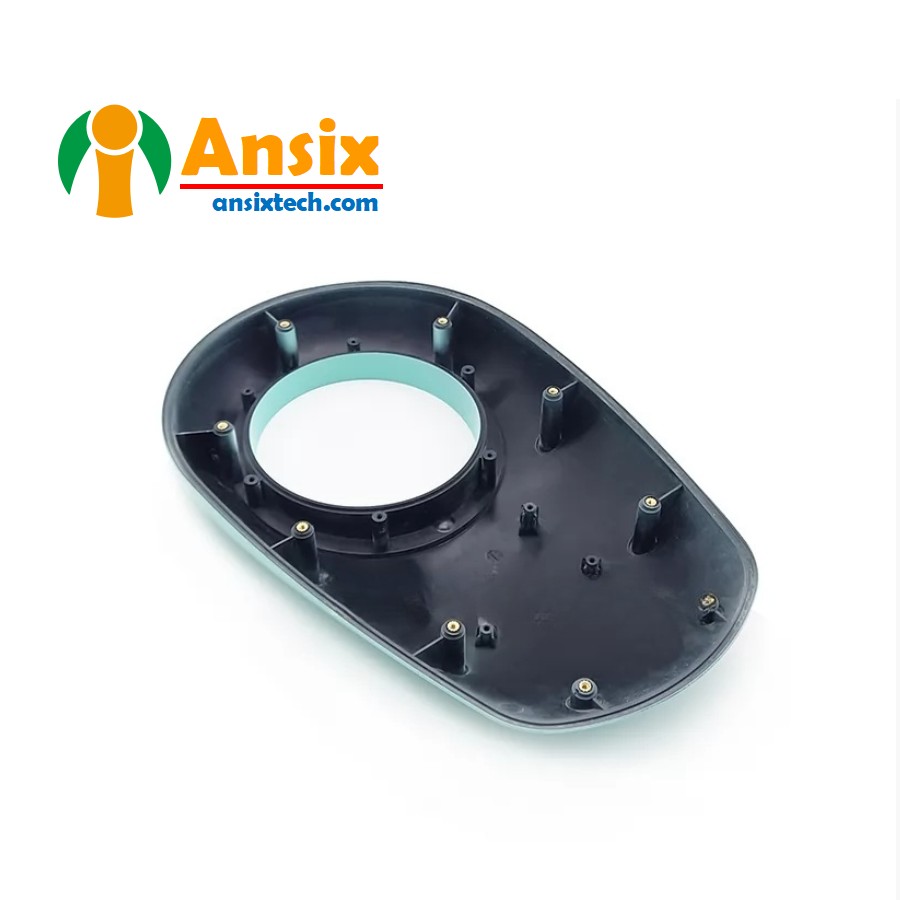

- Double Colour Injection Mold for Personal Care and Health Products

- Multi Material Injection Molding for Household Appliances

- Double Shot Injection Mold for Power Tools

- Two Colors Injection Mold for Automotive Parts

- Liquid Silicone Rubber(LSR)

-

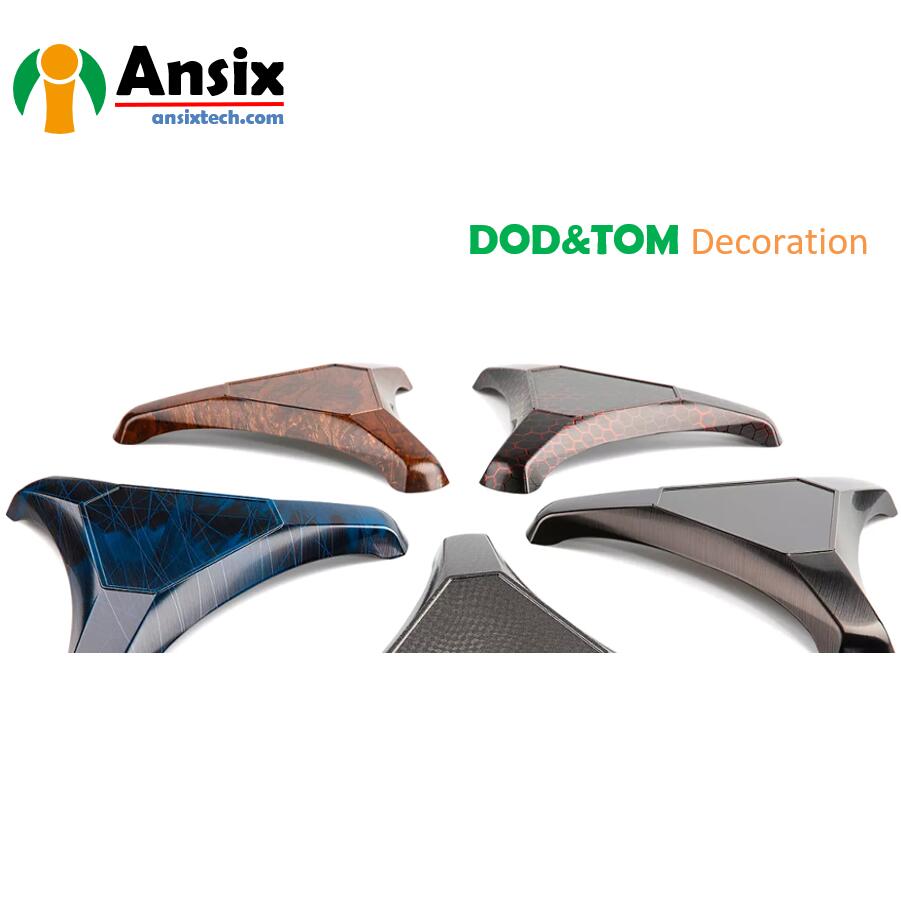

Insert Mould Decoration (INS/TOM/OMD) for Automotive Parts

- Injection Mold for New Energy Vehicle

- Automotive Parts Molding

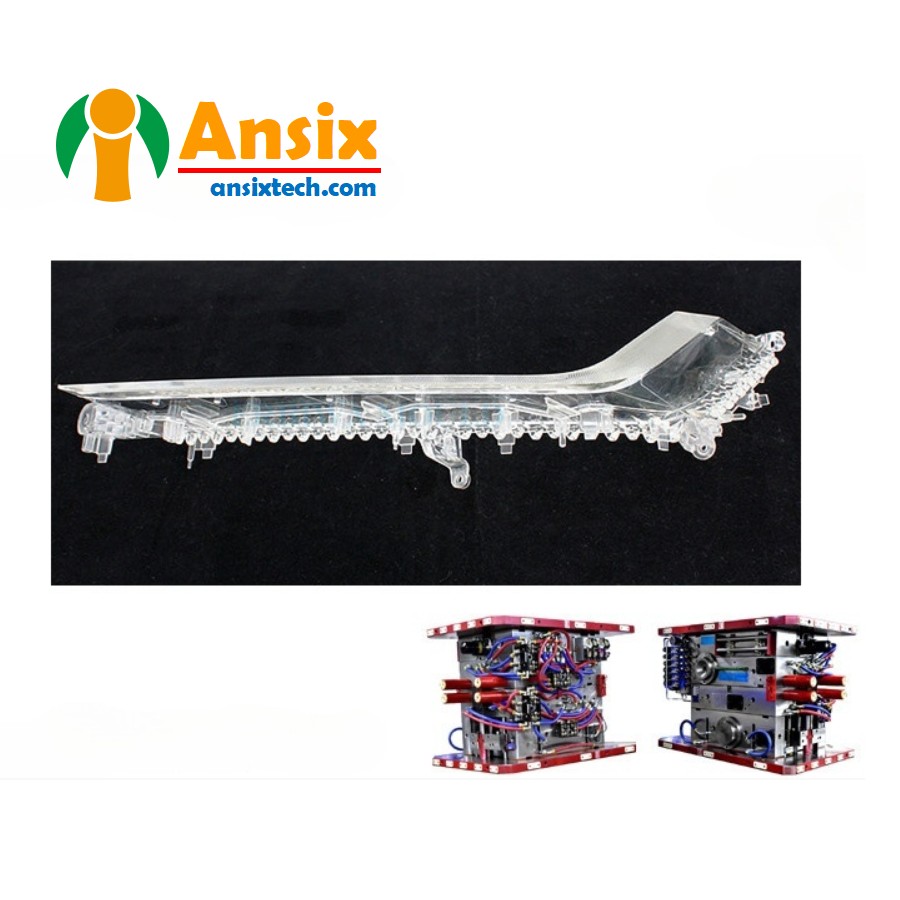

- Injection Mould for Car Lamps

- Pre-Deformation Mold

- Gas & Water Assisted Injection Mold

- Plastic Mold for Automotive Brake System

- Injection Mold for Auto Electrical Appliances

- Injection Mold for Automotive Interior Parts

- OMD&TOM Decoration

- IMD/INS/OMD/TOM Insert Mould Decoration

- Home Appliance and Electrical Mould&Injection

- Cosmetics packaging products and PET Preform Cap

- Plastic CNC Machining Parts

Custom Plastic Injection Molding Service in Ansix

FEATURES

-

Plastic Injection Molding

Plastic injection molding procedure utilizes plastic materials to make a custom mold after the raw substance is heated, melted, and cooled down. The customized plastic mold is used to manufacture bulk quantities of plastic parts.

-

Clean Room Injection Molding

With Class 8 clean room, Seasky can customize plastic injection molding for many industries with high molding environments. Plastic aerospace components and medical device components can be customized here.

-

Insert Molding

Insert molding integrates top-notch machines to construct creative, intricate parts via the procedure of molding or shaping plastic components around other inserts. Insert molding is ideal for manufacturing high-precision customized plastic molding parts for various industries.

-

Overmolding

The overmolding procedure integrates two or more plastic materials in one final item. In this procedure, the base material is molded initially, and the extra plastic materials are molded around the first material to produce custom plastic injection molders.

-

Two Shot Molding

Two-shot molding is also known as double-shot, dual-shot, and 2k injection molding. In this custom injection molding procedure, two distinct plastic materials are combined in one machining cycle.

description

- Medical plastic injection molding procedure utilizes plastic materials to make a custom mold after the raw substance is heated, melted, and cooled down. The customized plastic mold is used to manufacture bulk quantities of plastic parts. AnsixTech is a leading medical device outsourcing manufacturer offering comprehensive solutions at every step of the product lifecycle. We provide precision component manufacturing, assembly, packaging, testing, sterilization management, and distribution.With reliable capabilities and adherence to FDA and ISO standards, AnsixTech is a unique full-service provider for everything from prototyping to high-volume production. Our products are manufactured in cleanroom environments across registered China and Vietnam sites. Optimize your product’s time to market with AnsixTech’s cost-effective and vertically integrated approach.

- Clean Room Injection MoldingWith Class 8 clean room, AnsixTech can customize plastic injection molding for many industries with high molding environments. Plastic medical parts components and medical device components can be customized here,Beauty equipment and medical beauty equipment shell kits,And we can also provide non-contact level and contact level medical component assembly services.

- Hardware and Plastic Insert MoldingInsert molding integrates top-notch machines to construct creative, intricate parts via the procedure of molding or shaping plastic components around other inserts. Insert molding is ideal for manufacturing high-precision customized plastic molding parts for various industries. We also provide precision hardware processing for inserts. We have our own machining equipment and can provide supporting services for machining parts of titanium alloy, copper, steel, aluminum alloy, nickel, iron and other materials.

- Overmolding ProcessThe overmolding procedure integrates two or more plastic materials in one final item. In this procedure, the base material is molded initially, and the extra plastic materials are molded around the first material to produce custom plastic injection molders. Our base materials for overmolding are usually hard materials such as ABS, ABS/PC, PC, PP, PA, PPS, PEEK, PEI, PI, etc. We usually choose soft materials such as silicone, TPU, TPR, PVC, etc. There is also software overmolding software. Usually we use liquid two-color injection molding process to complete it. AnsixTech has more than 20 years of manufacturing experience in the injection molding industry and currently has 4 production bases, which can fully meet your needs in this injection molding industry. Various difficult technical problems have been broken through. If you have any technical problems, you can give us information at any time, and we will provide you with solutions and opinions within 24 hours.

- Medical two Component and 2K Injection moldingTwo-shot molding is also known as double-shot, dual-shot, and 2k injection molding. In this custom injection molding procedure, two distinct plastic materials are combined in one machining cycle. Two-color injection molding and 2K injection molding (bi-material injection molding) have many advantages. Here are some common advantages: Integrate multiple materials: Two-color injection molding and 2K injection molding can integrate more than two different materials or colors into one part, thereby reducing assembly steps and improving the appearance and functionality of the product. Reduce processes and costs: By completing the injection molding of two materials or colors in one step, assembly processes and costs are reduced. Improve product appearance and function: Make the product more beautiful in appearance, more diversified in function, and increase the added value of the product. Improve production efficiency: Some additional processing steps are reduced, improving production efficiency and product consistency. Generally speaking, two-color injection molding and 2K injection molding can increase the diversity of product designs, reduce production costs, and improve product appearance quality.

- Medical products benefits Of custom plastic injection moldingIn AnsixTech company,custom plastic molding is relatively beneficial, which is why companies rely on AnsixTech medical injection molding processes for manufacturing bulk quantities of custom plastic injection molds. We have a strong medical product design and development team that can provide you with more effective and faster technical services in a short time.

- Medical Plastic Parts Strength & StabilityThe customized injection molding process ensures that the final items are robust, resist temperature, withstand harsh conditions, and show impact resistance as only premium quality medical grade materials are used. Our design and development team has worked in the medical field for more than 20 years and has rich experience in material selection for medical products.We can select materials suitable for parts based on your product usage scenarios so that the product can meet durability, aging and different environmental conditions. Our medical parts are subjected to impact testing and aging testing before production. The testing standards are in accordance with customer requirements and ISO standards.

- High Efficiency & Enhanced Performance for AnsixTechThe custom injection mold technology is highly efficient, and our skilled designers only use advanced tools and reduce unnecessary expenses. We have the latest custom plastic injection molder machines that meet high-performance criteria. Choosing AnsixTech's high-precision mold manufacturing and advanced injection molding equipment can effectively improve the production efficiency and quality assurance of medical components. We have high-precision CNC of MAKINO , AgieCharmilles slow wire cutting, and EDM of Sodick . Precision injection molding machines include FANUC, Sumitomo, Toshiba, Arburg and Haitian etc.

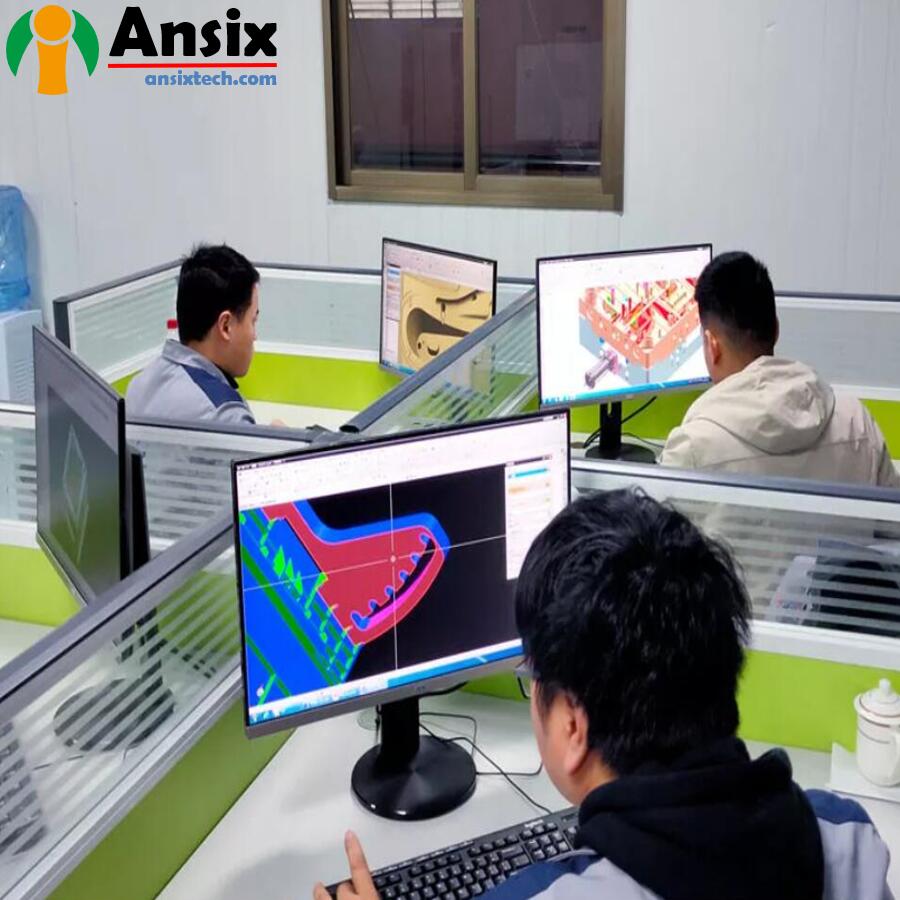

- Complex design and development capabilitiesCustom medical plastic injection molding machines have the capability to develop complex plastic parts without even missing minute details. With this technology, it is easy to make custom plastic injection mold parts in several shapes, designs and sizes with customized structure details. Our design and development team effectively uses CAD, CAE and CAM software to analyze product structure and mold flow analysis to analyze potential problems before mass production of our products and effectively avoid potential risks.

- Products Detailed FeaturesIt is possible to add intricate details to the custom plastic injection moldings and also improve the overall functionality and aesthetics to highlight your brand. The final products can have customized brand text, various surfaces, multiple color options, etc. We can also provide you with product value-added services, such as product appearance decoration and visual effect development. We have our own graphics and text processing engineers, and combined with our latest process technology (WTP/IML/IMD/INS/OMD/TOM decoration process), we can effectively increase the added value of our products.

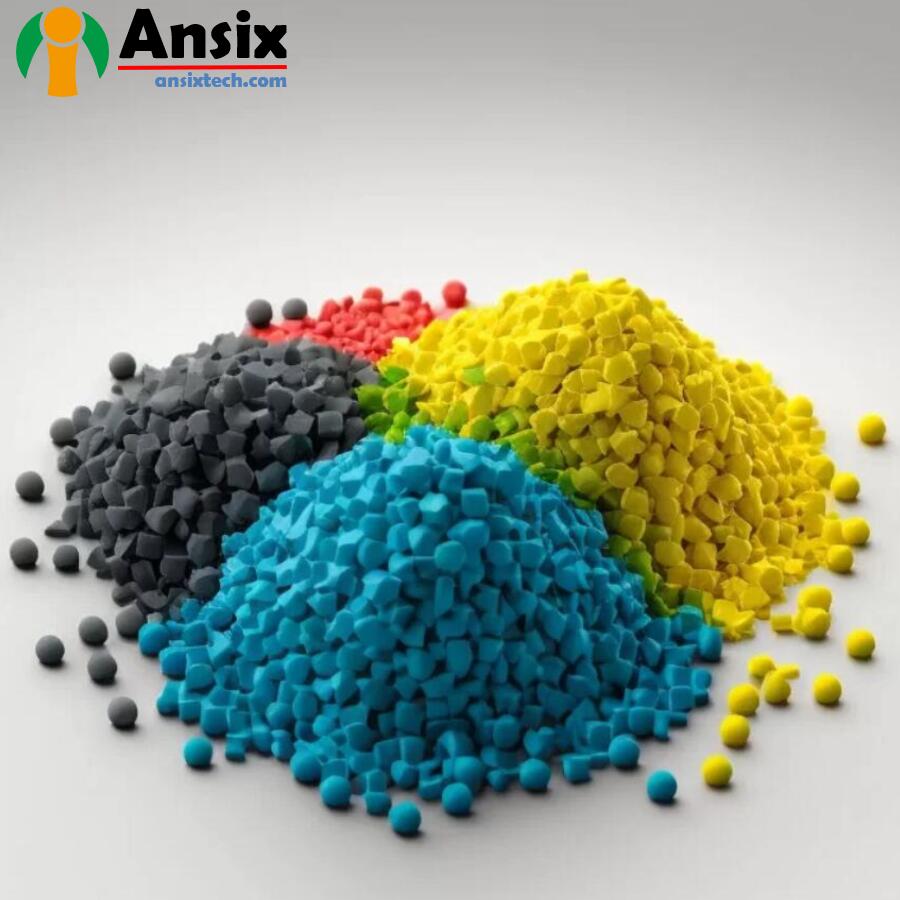

- Materials Various in the medical fieldFor manufacturing custom plastic injection molds, there are various medical-grade material choices like Silicone, Acrylonitrile Butadiene Styrene (ABS), Polypropylene, PEEK, High Impact Polystyrene (HIPS), Polyethylene, Nylon, ABS/PC,PC,PPSU,PCTG,PBT,PPS,PEI,PFA,PET,PMMA PFA etc. Various materials in the medical field

- Environmentally Friendliness and ROHS, REACH, FDA and ISO13485Customized plastic molding parts are likely to remain in good working condition for a long time because of their quality and resilience. there will be little to no wastage custom injection molding process. In addition, we provide corresponding materials according to customer requirements and meet the standards required by customers. Most of our medical product materials comply with the corresponding standards of ROHS, REACH, FDA and ISO13485.

Custom Plastic Injection Molding Process

AnsixTech Medical is a global full-service contract manufacturer of Class II and Class III medical devices and specialty components, ranging from implantable stents and tubing sets to pediatric and orthopedic-care products. We serve customers through every stage of the product life cycle, including design and development, component manufacturing, final assembly, and packaging. Founded in 1998 with headquarters in Dongguan city, and manufacturing locations in Dongguan city,Yongzhou city Hunan China and Vietnam.

AnsixTech Medical is a high-class Chinese plastic molding company that offers a one-stop injection mold service. In the custom injection molding process cycle, there are four different stages, which are clamping, injection, cooling, and ejection. Firstly, a plastic substance is heated till it turns into a viscous melt, which is then pushed into the closed mold design machine. When the plastic substance in the mold is cooled down, it turns into a solid-shaped product that is taken out from the opened mold machine.

AnsixTech offers end-to-end turn-key solutions backed by full regulatory compliance with FDA registration and ISO 13485 compliant operations. We are a market leader in providing solutions for mission-critical precision components, medical equipment, and finished FDA-Class II and Class III medical devices. Our customers count on us to deliver their most challenging applications. Our team of experts can help in the design and manufacturing of disposable devices and a wide-range of specialty components.Through acquisitions and investments, we have been able to vertically integrated each step in the manufacturing process, from prototype to production technologies. This enables us to provide high quality services across the supply chain, strategically marrying high volume and high value capabilities. At AnsixTech, we offer completely customized solutions to manufacture your medical devices and components.

We leave the choices to you, bringing our team of experts and engineers into any stage of the process to build the right combination of services to meet your needs. Backed by more than 25 years of medical device experience, AnsixTech prides itself in manufacturing high-quality devices that will positively impact lives.

- New Product Design And Engineering for AnsixTechWe have expert designers who cooperate with clients to offer new plastic mold designs. Use Solidworks and PRO/E for product modeling and structural design. Use Moldflow for mold flow analysis and NX software for splitting.With skilled engineering skills, we ensure that no design defects arise during the custom plastic molding. Avoid potential risks during product production.

- Custom Mold ToolingTo produce high-quality and robust custom plastic injection molder products, we offer a custom mold tooling service. Our experts design and use the latest technology and highly advanced machines for simple production. High-precision products require high-precision molds to complete. Our mold manufacturing precision tolerance can reach 0.002mm. Product precision tolerance can be controlled at 0.02mm

- Injection Molding ProductsThe advanced machines are used to manufacture the custom plastic injection moldings that are required to meet the client's requirements. We only use premium raw materials for producing mold products in the ISO-certified cleanroom factory.The varying plastic types used in custom injection molding allow for various melting points required for different applications.

In addition to having very high electrical and heat-resistant properties;

PEEK Polyetheretherketone is a special engineering plastic with excellent properties such as high temperature resistance, self-lubrication, easy processing and high mechanical strength. It can be manufactured and processed into various mechanical parts, such as automobile gears, oil screens, and shift starters. ; Aircraft engine parts, automatic washing machine wheels, medical equipment parts, etc.

RENATUS® PET is also a glass-reinforced material with excellent molding properties.

•The load deformation temperature is 220-242°C, which is the highest among general engineering plastics.

•Even if it is exposed to high temperature for a long time, it can still excellently maintain its various physical properties such as mechanical properties. Product grades certified to the UL standard Relative Temperature Index (RTI) 155°C are also available.

•For products or fields that require flame retardancy, we have V-0 level products certified by UL94 flammability standards.

•Because the water absorption rate is low, there is almost no change in electrical properties due to water absorption after molding.

Acrylonitrile Butadiene Styrene (ABS): A common thermoplastic used for products that do not require chemical, electrical, or UV resistance. ABS is a flexible and lightweight material with good impact strength and durability. Many everyday objects use ABS custom injection molded parts, such as children’s toys, components in household appliances, and automotive parts.

Low-Density and High-Density Polyethylene (LDPE and HDPE): As one of the most versatile thermoplastics, LDPE and HDPE have high tensile strength, impact resistance, and moisture resistance. HDPE is a material used in a range of consumer and industrial products, while LDPE is a softer version popular in consumer and industrial production.

Polycarbonate (PC): As a transparent, lightweight material, PC is a durable alternative to glass. With high durability and extreme impact resistance, many demanding applications use PC, including bulletproof glass.

Polyamide (Nylon): Nylon offers excellent electrical properties, strength, and resistance to heat wear, and chemicals. Applications in the medical and automotive industries often use nylon for custom plastic injection molded parts.

High Impact Polystyrene (HIPS): As a versatile, impact-resistant, and economical plastic, HIPS consists of crystal styrene and rubber. With non-toxic properties, HIPS is ideal for food-grade components.

Polypropylene (PP): With excellent chemical and stress resistance and high impact strength, PP is a robust plastic with a high melting point. PP is often used as a food-grade polymer in the food and beverage industry.

- The mold surface finish optionsWe offer various surface finish options for custom plastic injection molder parts. Some of the common finishing choices are PM-F0, PM-F1, PM-F2, SPI-C1, PM-T1, PM-T2, SPI-B1, SPI-A2, etc. In addition, we also offer Industry standard Mold-Tech finish choices. We use mold mirror EDM treatment, mold surface polishing mirror, mold surface electroplating mirror treatment, mold surface PVD treatment, etc.

Part Labeling and Finished Device & Sub-Assembly

The in-mold labeling machines are utilized to develop an eye-catching look with illustrations or labels on customized injection molding products. In addition, Finished Device & Sub-Assembly,

We’re your full-service partner for complex subassemblies and finished medical devices, leveraging our broad spectrum of products and capabilities. we have massive labeling and assembly lines and ensure quick packaging.

why choose us

-

ISO13485 Certified Plastic Injection Molding factory

AnsixTech Medical is an ISO13485-certified custom plastic injection molding company with an ISO 13485:2016 factory and ISO 8 clean room molding for safe and dust-free manufacturing. Meets FDA-510K medical registration standards.

-

25+ year Medical Industry Experience

We have 25+ years of industrial experience coming to the designing and manufacturing of custom plastic injection molding parts, and we supply them to several domestic and international regions. Provide customers with high-quality product guarantee.

-

Use Medical Grade Material

We only utilize medical-grade premium raw substancessuch as ABS, Polyethylene, PEEK, HIPS, Silicone, Polycarbonate,PA,PES and many more for producing custom plastic injection molds. And ensure that our materials meet customer requirements and FDA and ISO13485 standards.

-

Precise mold and Injection Molding Machines

At AnsixTech Medical, We are equipped with high-precision mold making equipment and high-precision injection molding machines. The mold precision tolerance reaches 0.002mm. The product precision tolerance reaches 0.02mm.

-

Quality Assurance

To ensure reliable manufacturing of customized injection molding components, our quality engineer use high-technology machines and measuring instrument solutions that meet the custom client’s needs. Ensure that each of our product size structures meet customer standards.

-

Try Our Problem-solving Injection Molding Services Now

AnsixTech Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.ISO 13485 Certified factoryISO 8 CleanroomRobust Expertise for Medical Injection MoldingAdvanced mold manufacturing capabilities and plastic injection molding equipmentQuick Response within 12 hoursIf you have any questions about products in the medical field, please send us a message at any time and our team will reply to you within 12 hours.

description2