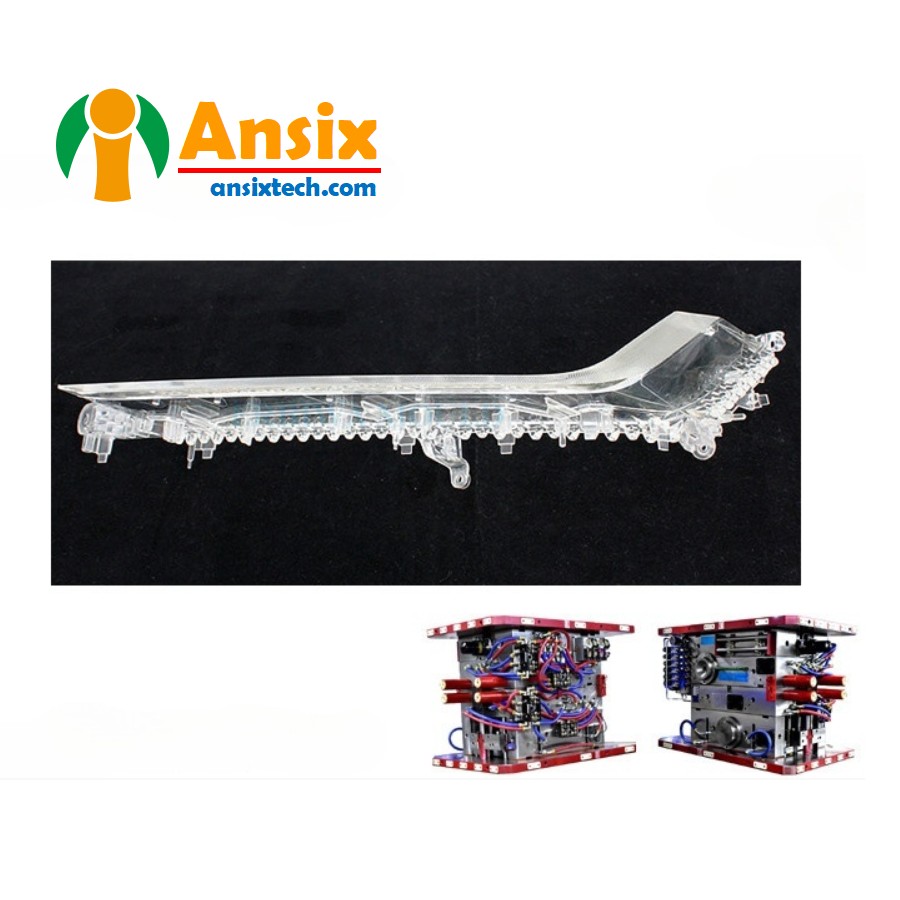

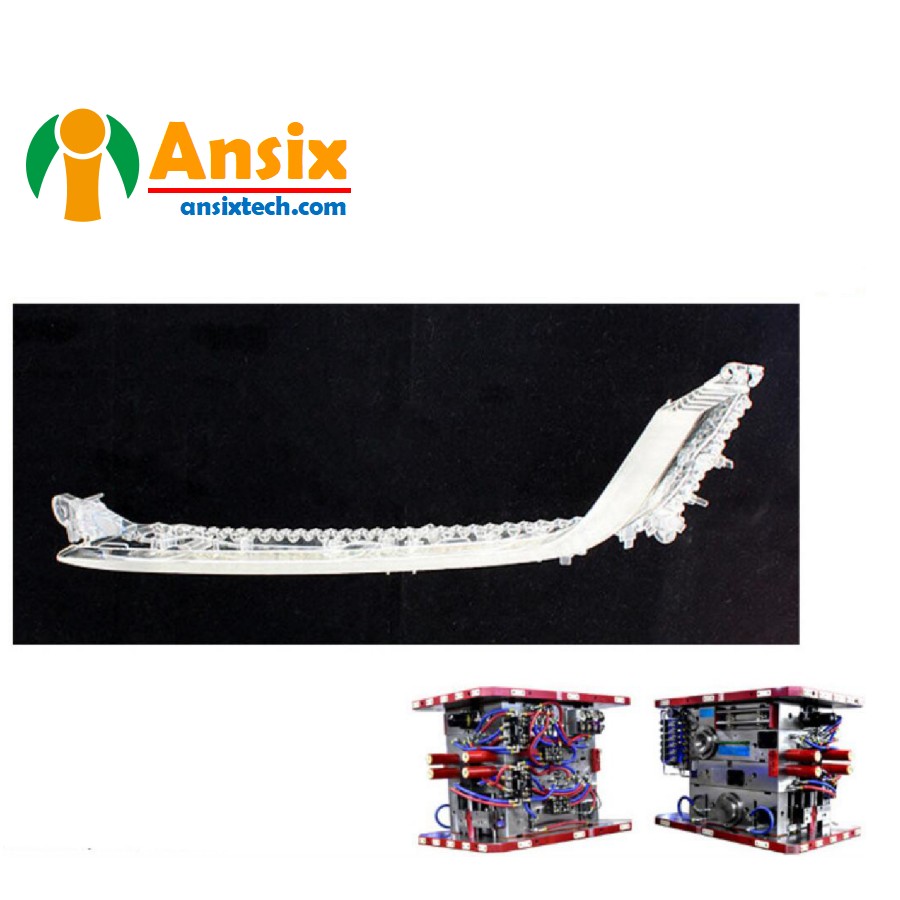

The difficulties and injection molding process of the injection mold for the transparent light guide light bar in front of the Mercedes-Benz car

FEATURES

-

Mold Description

Product Materials:

PC

Mold Material:

2344H

Number of Cavities:

1*2

Glue Feeding Method:

Hot runner

Cooling Method:

Oil cooling

Molding Cycle

58.5s

- The injection mold design and mold flow analysis of the transparent front light guide light bar for Mercedes-Benz cars is a complex and critical process link. Here are some of the key design and analysis aspects involved in a general case:Key points of mold designStructural Design: Light guide strips usually have complex curved surfaces and structures, and mold design needs to ensure that these complex shapes can be accurately formed.Material Selection: Choosing a suitable plastic material usually requires good transparency, weather resistance and high temperature resistance.Cooling system design: Design a reasonable cooling system to ensure that plastic materials can be cooled quickly during injection molding and reduce quality problems caused by uneven deformation and shrinkage.Gate design: Reasonable gate design can ensure uniform melt filling and reduce defects such as bubbles and short injection.Mold processing accuracy: Mold processing requires high precision to ensure the size and surface quality of the final product.Mold flow analysis detailsFilling Simulation: Simulate the filling process of melt in the mold cavity, and evaluate parameters such as filling time, filling pressure, and filling speed to predict possible defects such as poor filling, bubbles, and short injections.Cooling simulation: Considering the complex structure of the light guide light bar, cooling simulation is required to evaluate parameters such as cooling time, temperature distribution and shrinkage to ensure uniform cooling of the entire light guide light bar and reduce deformation and Quality problems caused by uneven shrinkage.Thermal Stress Analysis: Since light guide strips are usually large, thin-walled plastic parts, thermal stress needs to be analyzed and a reasonable structure and cooling system designed to reduce the impact of thermal stress on product quality. .Mold structure optimization: Based on the mold flow analysis results, the mold structure is optimized, including optimization of the cooling system, gate design, etc., to improve product molding quality and production efficiency.The above are the general key points of mold design and mold flow analysis. These processes and analyzes are crucial to ensuring the production quality and efficiency of transparent light guide strips for Mercedes-Benz cars.

- The injection mold manufacturing and processing of the transparent light guide light bar in front of the Mercedes-Benz car and the material selection of the light guide light bar are very important. Here are some of the key process and material selection aspects typically involved:Mold manufacturing and processingMold Design: According to the shape and size of the light guide bar, design the mold structure, including mold cavity, cooling system, gate, etc.Mold processing: Use CNC machining, EDM, wire cutting and other processes to precision process mold parts.Mold Assembly: Assemble the mold parts, including installing the cooling system, gate system, etc.Mold debugging: Debug the assembled mold to ensure the accuracy and stability of the mold.Trial mold production: Carry out trial mold production, adjust and optimize the mold to ensure the molding quality and production efficiency of the product.Light guide strip material selectionTransparency: The light guide strip needs to have good transparency to ensure the transmittance and uniformity of the light.Weather Resistance: The material needs to have good weather resistance and be able to resist ultraviolet rays and high temperatures to ensure the stability of the product in outdoor environments.High temperature resistance: Since the light guide bar is located at the front of the car, it needs to have good high temperature resistance to ensure the stability of the product in high temperature environments.Molding Performance: Materials need to have good molding properties to ensure the quality and efficiency of mold processing and product molding.Common material choices include PC (polycarbonate) and PMMA (polymethylmethacrylate). These materials have good transparency, weather resistance and high temperature resistance, and are suitable for the manufacture of car front transparent light guide strips. In addition, other special materials can be selected according to the requirements of specific products, such as materials with flame retardant properties.The advantage of these materials is that they have good transparency, weather resistance and high temperature resistance, which can meet the requirements of automobile front transparent light guide strips during use. They also have good processing properties and are suitable for mold manufacturing.