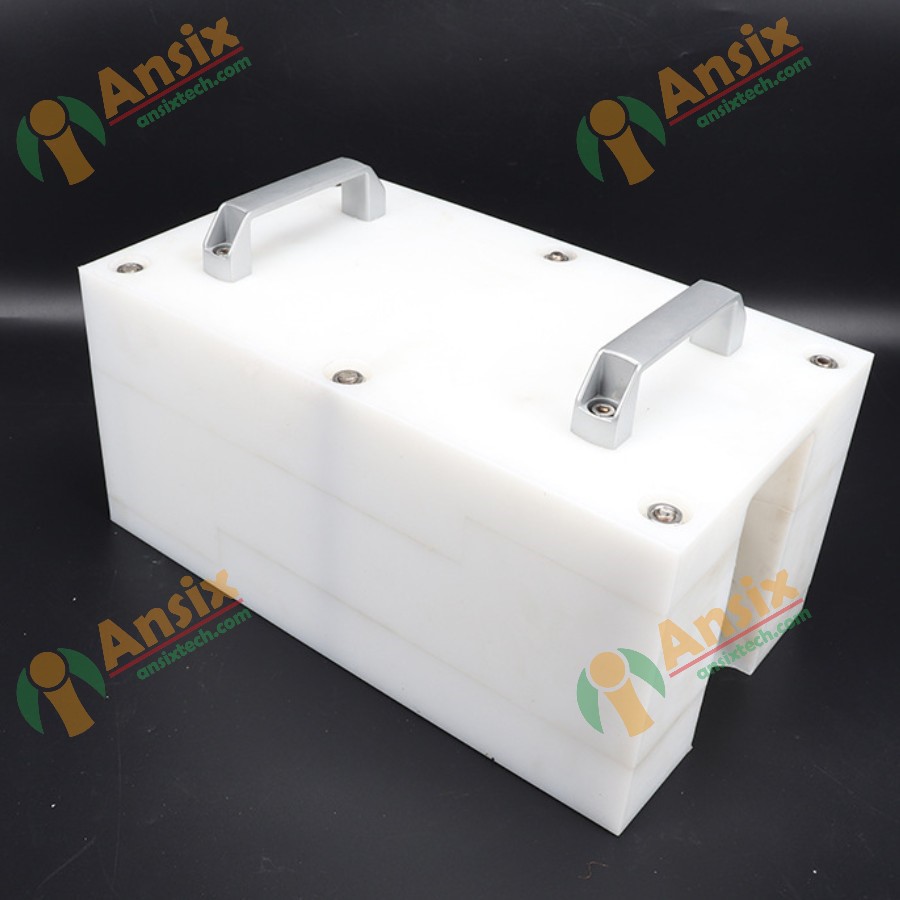

Self-lubricating customized preform bottle inverter 180 degree flip plastic can inverter new integrated UPE can inverter polymer material Bottle Flipper

FEATURES

- Self-lubricating customized preform bottle inverter 180 degree flip plastic can inverter new integrated UPE can inverter polymer material Bottle Flipper

UPE polymer materials have good performance and adaptability in the machining and application fields of bottle turners. Its wear resistance, corrosion resistance and high temperature resistance make it an ideal choice for bottle turner manufacturing, suitable for bottle turning operations in the food, pharmaceutical, cosmetics and other industries., please send us a message (Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

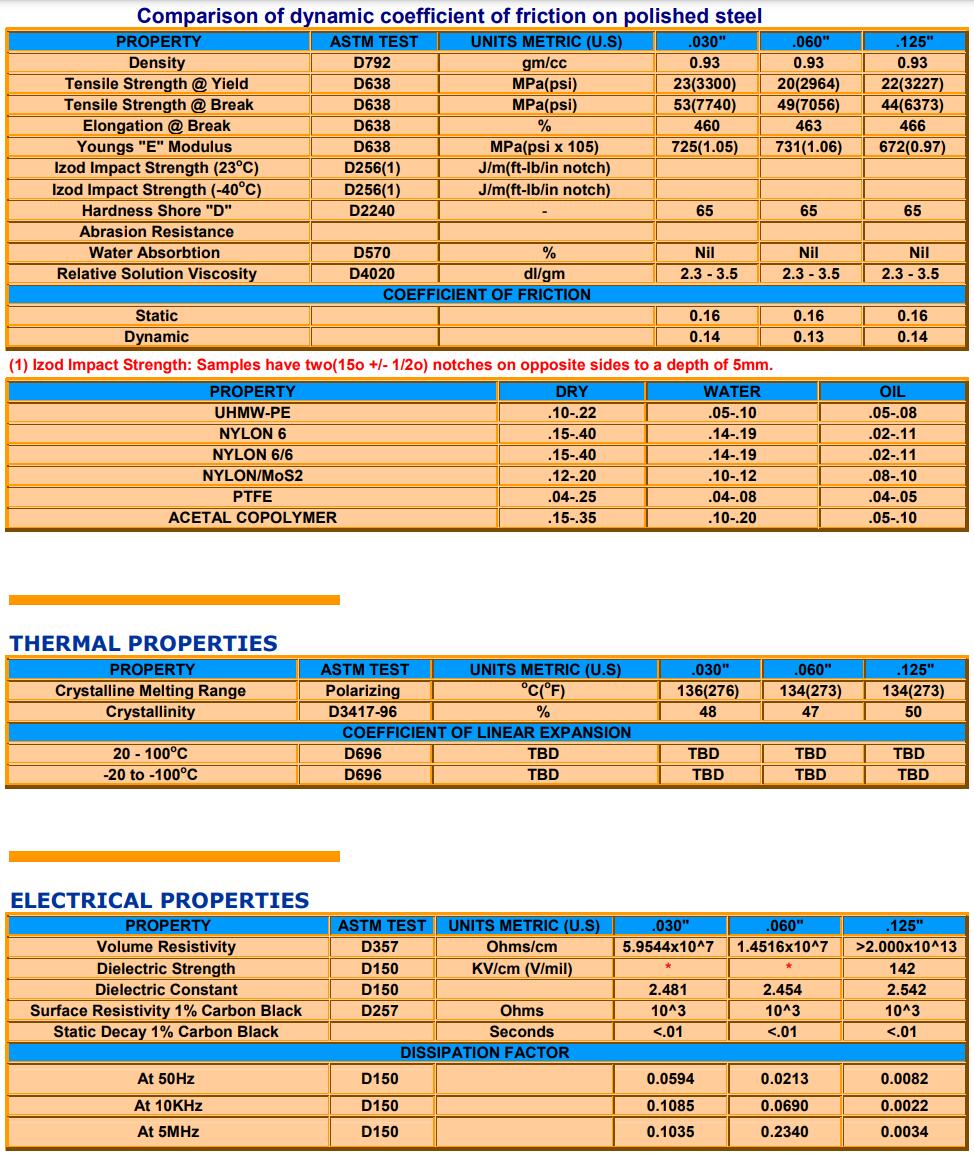

- UPE Material Parameter SheetUPE (Ultra-high Molecular Weight Polyethylene) is an ultra-high molecular weight polyethylene material whose composition mainly includes ethylene monomer.Ethylene is a colorless, odorless gas with the chemical formula C2H4. It is an alkene consisting of two carbon atoms and four hydrogen atoms. Ethylene is an important industrial raw material widely used in the synthesis of various plastics and chemicals.UPE materials are produced by polymerizing ethylene monomers. During the polymerization process, ethylene molecules are connected into long chain structures to form ultra-high molecular weight polyethylene. This long chain structure gives UPE excellent wear resistance, chemical resistance, low friction coefficient and high impact resistance.In addition to ethylene monomer, some auxiliaries and additives may be added during the preparation process of UPE materials to improve the characteristics and processing performance of the material. These additives may include antioxidants, stabilizers, lubricants, etc.The main component of UPE material is ethylene monomer, which is produced through polymerization. It is an ultra-high molecular weight polyethylene with excellent properties and a wide range of applications.

- Why Choose AnsixTech for Plastic Machining?Technical expertise: Ansix Tech has rich experience and a professional technical team in the field of bottle turners. They understand the design and manufacturing requirements for bottle turners and can provide customized solutions. Their technical expertise ensures bottle turner performance and quality.High-quality products: Ansix Tech is committed to providing high-quality bottle turner products. They use advanced manufacturing processes and strict quality control to ensure that their products meet international standards and customer requirements. Their products are rigorously tested and proven for reliable performance and durability.Customization capabilities: Ansix Tech is able to customize bottle turners according to customer needs and requirements. They can design and manufacture based on factors such as bottle size, shape and material to ensure that the bottle turner matches the customer’s production line and process flow. Their customization capabilities allow them to meet the specific needs of their customers.Service and Support: Ansix Tech provides comprehensive pre-sales and after-sales services. Their team can work with customers to understand their needs and provide professional advice and technical support. They also provide training and maintenance services to ensure customers can properly use and maintain their bottle turners.Reliability and Credibility: Ansix Tech enjoys a good reputation and credibility in the industry. Their products are widely used in various industries and are recognized and trusted by customers. Choose Ansix Tech as your bottle turner supplier to get reliable products and services.In summary, choosing Ansix Tech as a bottle turner supplier provides you with technical expertise, high-quality products, customization capabilities, service and support, reliability and credibility. These factors make Ansix Tech a trustworthy choice.

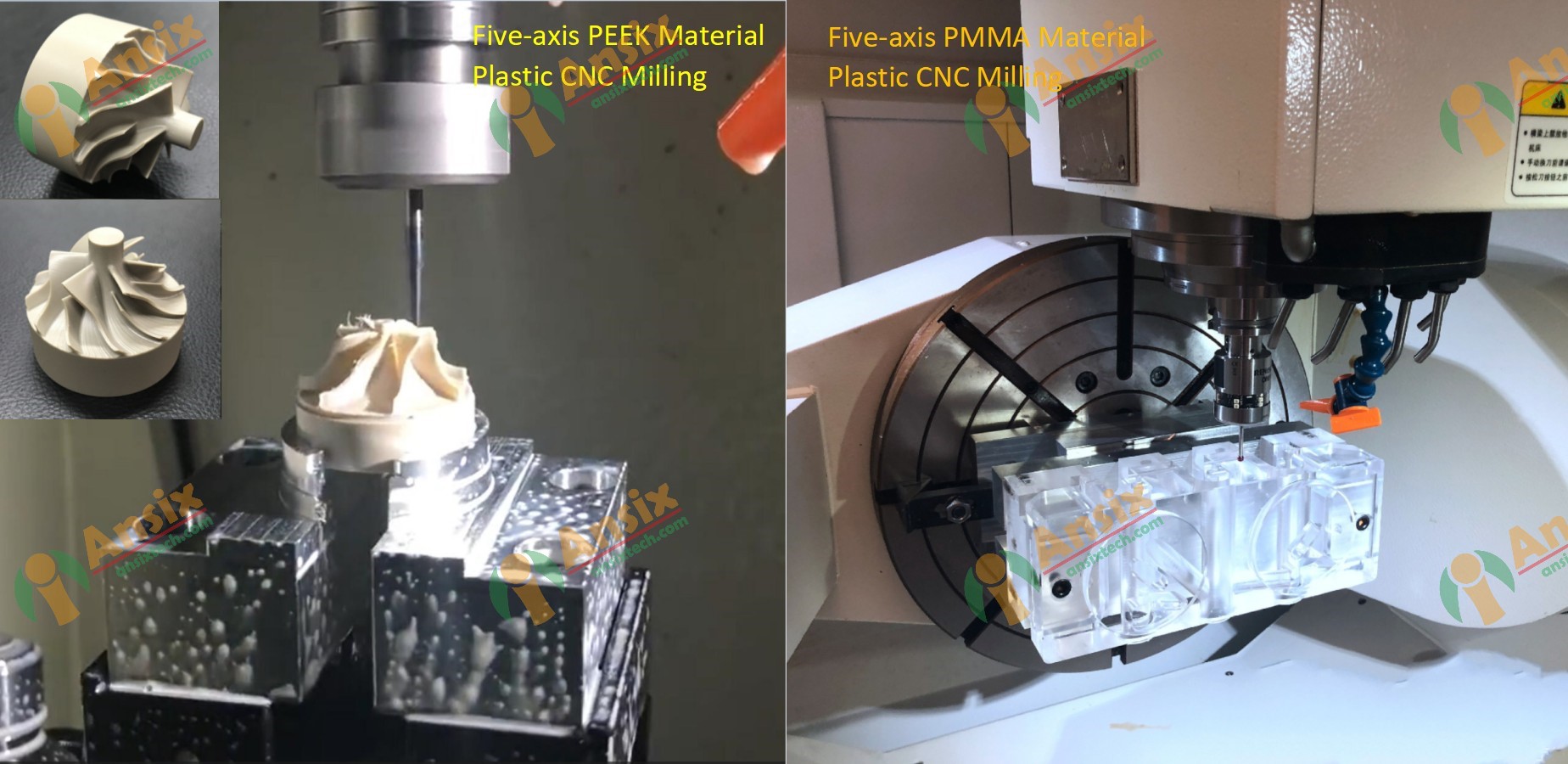

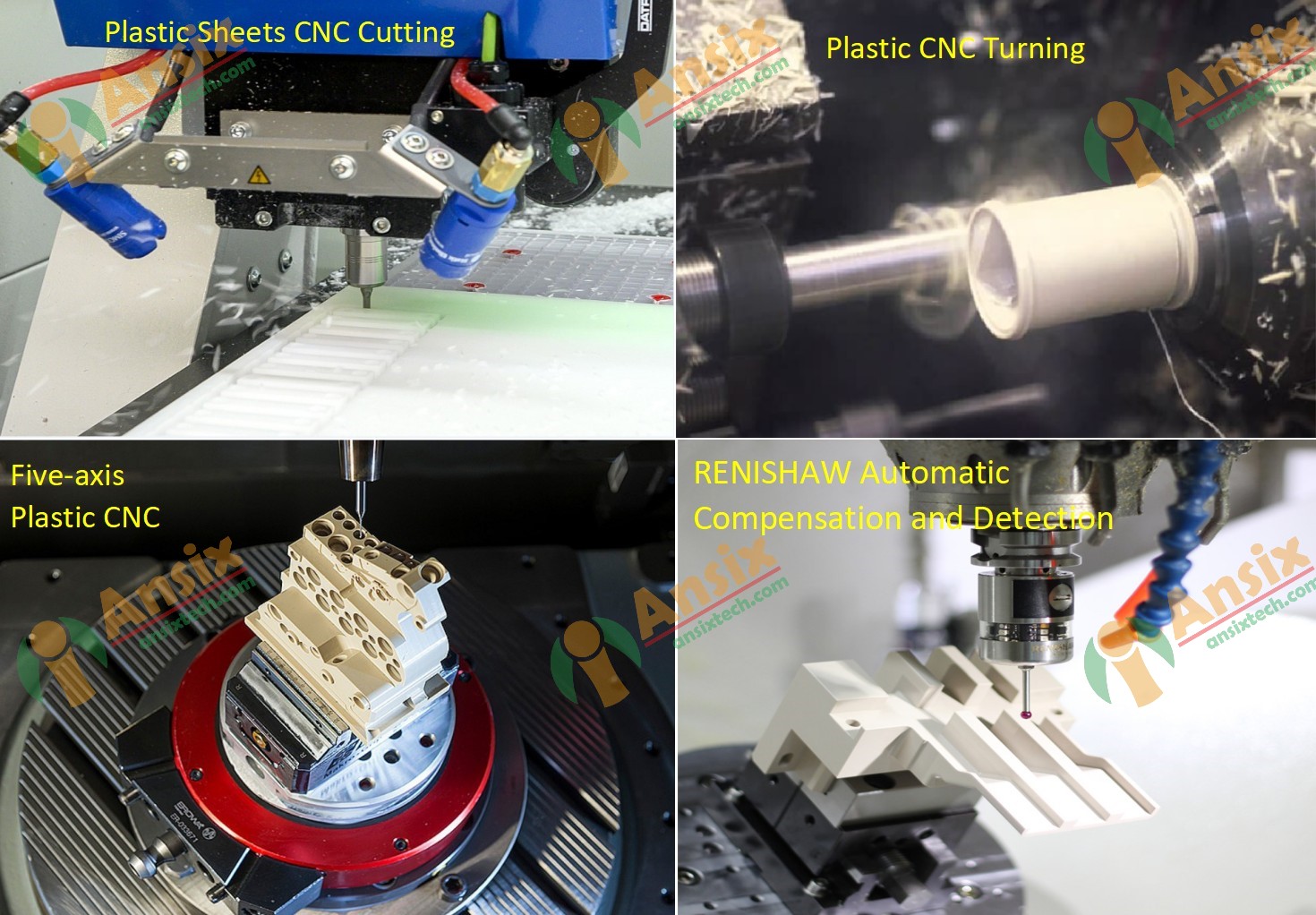

- Plastic CNC Milling

Having a large capacity of CNC Milling capabilities, AnsixTech Company can draw on many years’ experience to produce. high quality. Milled components from high specification industrial plastic materials.Plastic CNC milling is a method of processing plastic materials using a CNC milling machine. A CNC milling machine is an automated machine tool controlled by a computer that can perform precise milling operations according to a preset program.In the plastic CNC milling process, the plastic material first needs to be fixed on the workbench of the CNC milling machine. Then, through computer programming, parameters such as milling path, tool speed, feed speed, etc. are set. The CNC milling machine will automatically perform milling operations based on these parameters to cut the plastic material into the required shape and size.CNC milling of plastics offers the following advantages:High precision: CNC milling machines can achieve high-precision milling operations and can meet the high precision requirements for plastic parts.High efficiency: CNC milling machines can realize automated operations and improve production efficiency.Flexibility: Milling operations of different shapes and sizes can be realized through programming, which is suitable for the processing needs of various plastic parts.Good repeatability: The same milling operation can be achieved through programming, ensuring the consistency and repeatability of processing.However, there are some limitations to CNC milling of plastics:Tool selection: Different plastic materials require the selection of different tools to obtain the best milling effect.Thermal deformation: Plastic materials are prone to thermal deformation during high-speed cutting, which affects the processing quality.Small cutting force: Compared with metal materials, plastic materials have smaller cutting force and are prone to vibration and cutting instability.In general, plastic CNC milling is a high-precision and high-efficiency plastic processing method that can meet the demand for high precision of plastic parts.

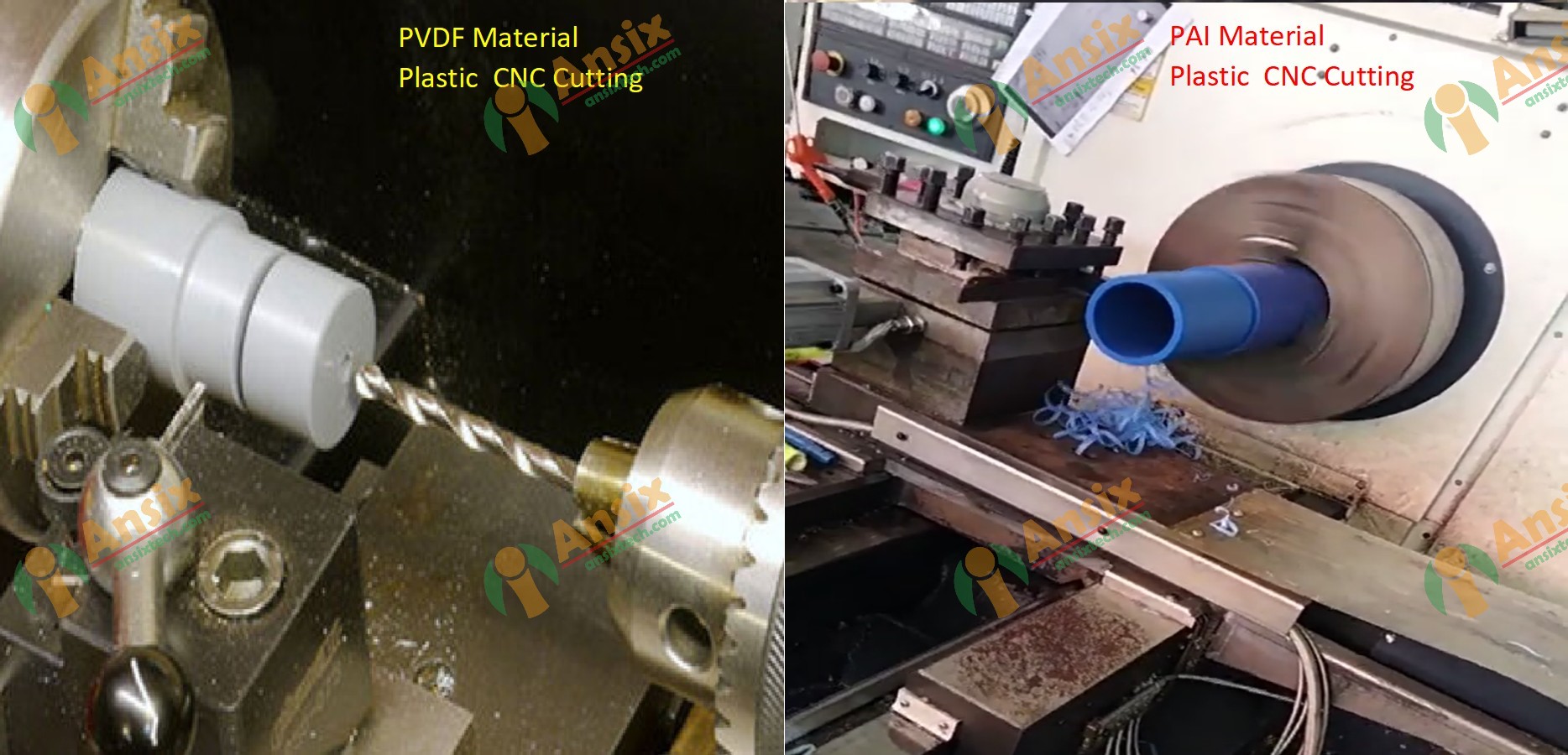

- Plastic CNC Turning

First and foremost, AnsixTech uses the latest in Plastic CNC Turning technology. Notably, the Company can produce large or small batch prototype Plastic Turned Parts from all the various types of Engineering Industrial Plastics available to today’s markets.Plastic CNC turning is a method of processing plastic materials using a CNC lathe. A CNC lathe is an automated machine tool controlled by a computer that can perform precise turning operations according to a preset program.In the plastic CNC turning process, the plastic material first needs to be fixed on the spindle of the CNC lathe. Then, through computer programming, parameters such as turning path, tool speed, feed speed, etc. are set. The CNC lathe automatically performs turning operations based on these parameters, cutting the plastic material into the desired shape and size.CNC turning of plastics offers the following advantages:High precision: CNC lathes can achieve high-precision turning operations and can meet the high precision requirements for plastic parts.High efficiency: CNC lathes can realize automated operations and improve production efficiency.Flexibility: Turning operations of different shapes and sizes can be realized through programming, which is suitable for the processing needs of various plastic parts.Good repeatability: The same turning operation can be achieved through programming, ensuring the consistency and repeatability of processing.However, there are some limitations to CNC turning plastics:Tool selection: Different plastic materials require the selection of different tools to obtain the best turning effect.Thermal deformation: Plastic materials are prone to thermal deformation during high-speed turning, which affects the processing quality.Small cutting force: Compared with metal materials, plastic materials have smaller cutting force and are prone to vibration and cutting instability. plastic CNC turning is a high-precision and high-efficiency plastic processing method that can meet the demand for high precision of plastic parts.

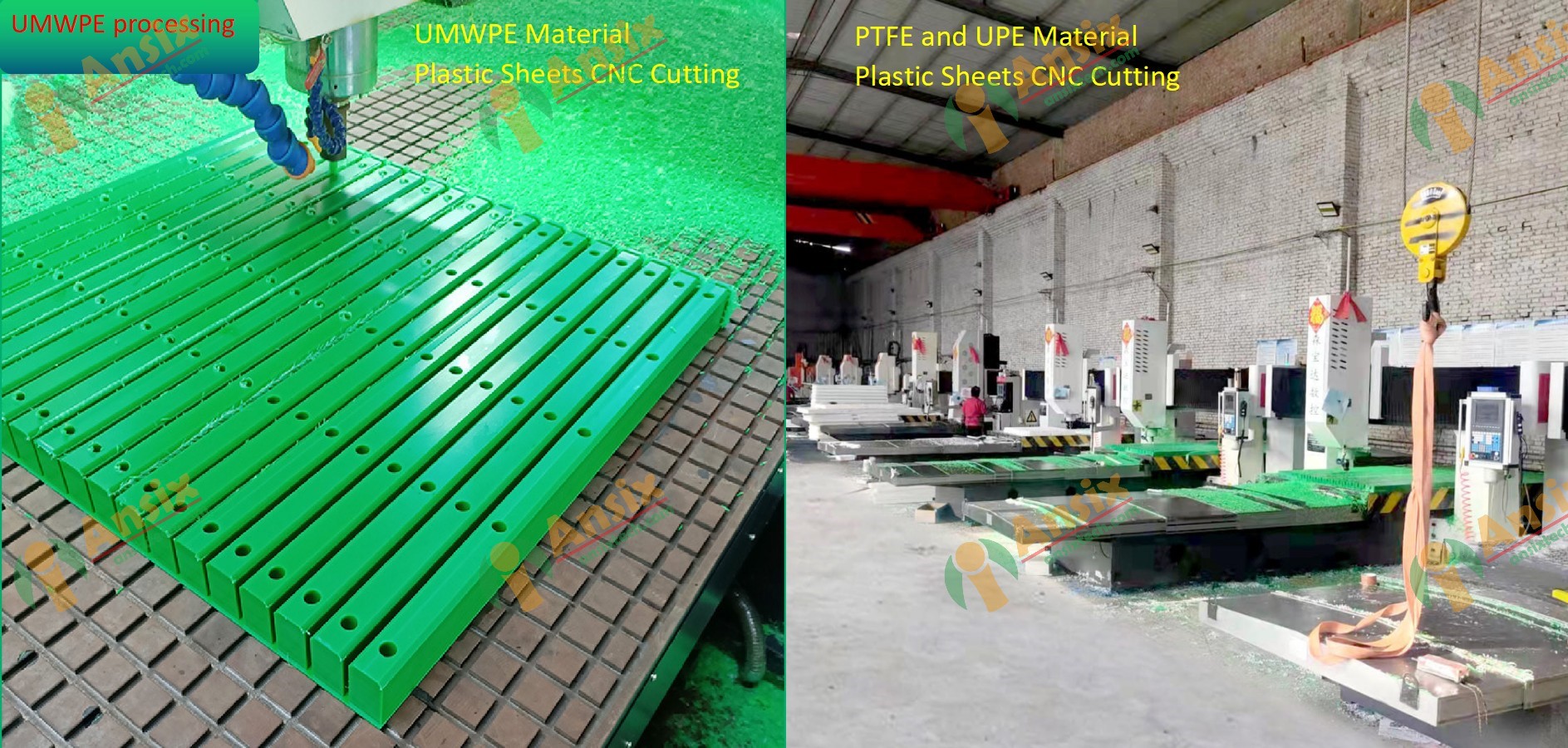

- Plastic Sheets CNC Cutting

Current clients recognise,AnsixTech is the place to come for large or small plastic component. Produced on one of a growing number of flatbeds CNC Routing Machines. All our table sizes are 3Mx2M.CNC cutting of plastic sheets is a processing method that uses CNC cutting machines to precisely cut plastic sheets. A CNC cutting machine is an automated device controlled by a computer that can perform precise cutting operations according to a preset program.In the CNC cutting process of plastic sheets, the plastic sheets need to be fixed on the workbench of the CNC cutting machine first. Then, through computer programming, parameters such as cutting path, cutting speed, and cutting depth are set. The CNC cutting machine automatically performs cutting operations based on these parameters to cut the plastic sheet into the required shape and size.CNC cutting of plastic sheets has the following advantages:High precision: CNC cutting machines can achieve high-precision cutting operations and can meet the high precision requirements for plastic sheets.High efficiency: CNC cutting machines can realize automated operations and improve production efficiency.Flexibility: Cutting operations of different shapes and sizes can be realized through programming, which is suitable for the processing needs of various plastic sheets.Good repeatability: The same cutting operation can be achieved through programming, ensuring the consistency and repeatability of processing.CNC cutting of plastic sheets is widely used in construction, advertising, packaging, Industrial equipment,furniture and other industries. It can be used to cut plastic sheets to make various products, such as billboards, display racks,industrial equipment windows, furniture panels, etc. CNC cutting of plastic sheets can not only improve production efficiency, but also ensure the accuracy and consistency of cutting, meeting the needs of different industries for plastic sheet processing.

- Customized Plastic UPE CNC Machining PartsThe process of ordering a bottle turner at AnsixTech is as follows:Demand communication: Communicate with AnsixTech’s sales team and explain your bottle turner needs in detail. Include bottle size, shape, material, and information about your production line and process flow.Technical assessment: AnsixTech’s technical team will evaluate your needs and provide professional suggestions and technical solutions. They will consider factors such as the bottle tumbler’s design, material selection, operation methods, etc. to ensure that the bottle tumbler can meet your requirements.Design and manufacturing: Based on your needs and technical assessment results, AnsixTech’s design team will start designing the bottle turner. They will use CAD software to design and consider the structure, function and safety of the bottle turner. Once the design is complete, the manufacturing team will begin building the bottle turner.Sample confirmation: After manufacturing is completed, AnsixTech will provide bottle turner samples to you for confirmation. You can test and evaluate the sample to make sure it meets your needs and expectations. If adjustments or modifications are needed, promptly communicate with AnsixTech and provide feedback.Mass production: After confirming the sample, you can discuss the details of mass production with AnsixTech, such as quantity, delivery time, price, etc. Make sure you have an agreement with AnsixTech and a signed contract.Quality inspection and delivery: During the mass production process, AnsixTech will conduct quality inspection to ensure that the bottle turner meets your requirements and standards. Once production is complete, AnsixTech will deliver the bottle turner to you according to the agreed delivery time.After-sales service: AnsixTech provides after-sales service and support, including training, maintenance and technical support. If you encounter problems or need help while using the bottle turner, you can contact AnsixTech at any time.The process of customizing a bottle turner includes demand communication, technical evaluation, design and manufacturing, sample confirmation, mass production, quality inspection and delivery, and after-sales service. Working with AnsixTech, you get professional technical support and high-quality bottle turner products.

-

- Quality Assurance of Plastic UPE bottle turners

The key to controlling the quality of machined bottle turners produced by Ansix Tech lies in strict quality management and production process control. Specific control measures may include: Set strict process parameters and specifications: Determine appropriate processing parameters, including cutting speed, feed speed, cutting depth, etc., to ensure the accuracy and surface quality of product processing. Use high-precision processing equipment: Ensure that machine tools, tools and other equipment on the production line have precise processing capabilities to ensure the accuracy of product size and shape. Introduce advanced quality inspection equipment: Use automated quality inspection equipment, such as three-dimensional coordinate measuring machines, optical inspection systems, etc., to conduct precise measurement and surface quality assessment of products. Implement a strict quality control process: Establish a comprehensive quality control process, including strict screening of raw materials, intermediate inspection during the production process, final inspection of finished products, etc., to ensure that products meet standards. Train and manage employees: Train and manage production personnel to ensure that they are familiar with the production process and quality requirements to fully perform their roles and ensure the consistency and stability of production. Through these measures, Ansix Tech can effectively control the quality of machined bottle turners, meet customer needs and ensure that products meet standards.