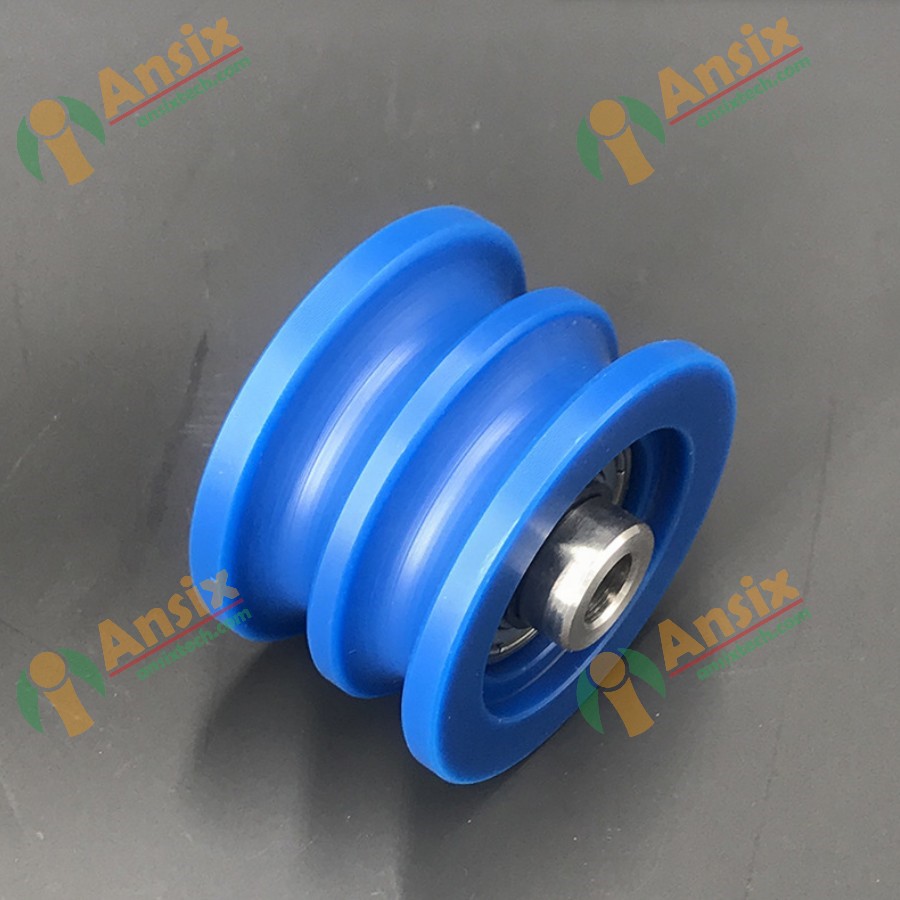

Self-lubricating universal pulley mechanical equipment MC pulley

FEATURES

- Self-lubricating universal pulley mechanical equipment MC pulley

Mechanical equipment pulleys are widely used in various fields. They can realize functions such as force transmission, friction reduction, speed adjustment, etc., and improve the efficiency and reliability of equipment.., please send us a message (Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

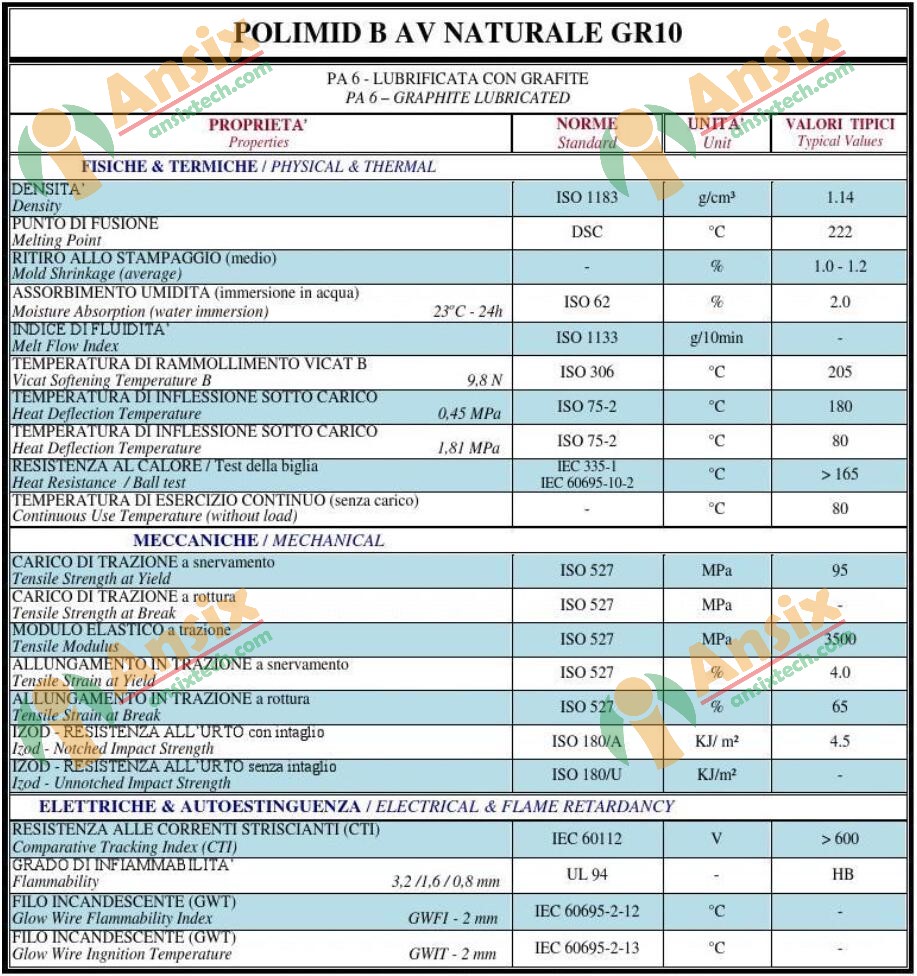

- PA66 Material Parameter SheetPA66 (polyamide 66) is a synthetic polymer whose main ingredients include caprolactam (Hexamethylene diamine) and adipic acid.Caprolactam is an organic compound with the chemical formula H2N(CH2)6NH2. It is a colorless liquid or solid with a strong amine odor. Caprolactam is one of the main monomers of PA66 and forms a polymer by reacting with adipic acid.Adipic acid is an organic compound with the chemical formula HOOC(CH2)4COOH. It is a colorless crystal that is soluble in water. Adipic acid, the other main monomer of PA66, reacts with caprolactam to form a polymer.During the polymerization process, caprolactam and adipic acid form polyamide chains through a condensation reaction to form PA66 polymer. PA66 has excellent mechanical properties, heat resistance, chemical corrosion resistance and wear resistance, and is widely used in automobiles, electronics, textiles, engineering plastics and other fields.In addition to caprolactam and adipic acid, some auxiliaries and additives may be added during the preparation process of PA66 to improve the characteristics and processing performance of the material. These additives may include antioxidants, stabilizers, lubricants, etc.The main components of PA66 are caprolactam and adipic acid, which form polyamide chains through condensation reaction. It is an excellent engineering plastic with a wide range of applications.

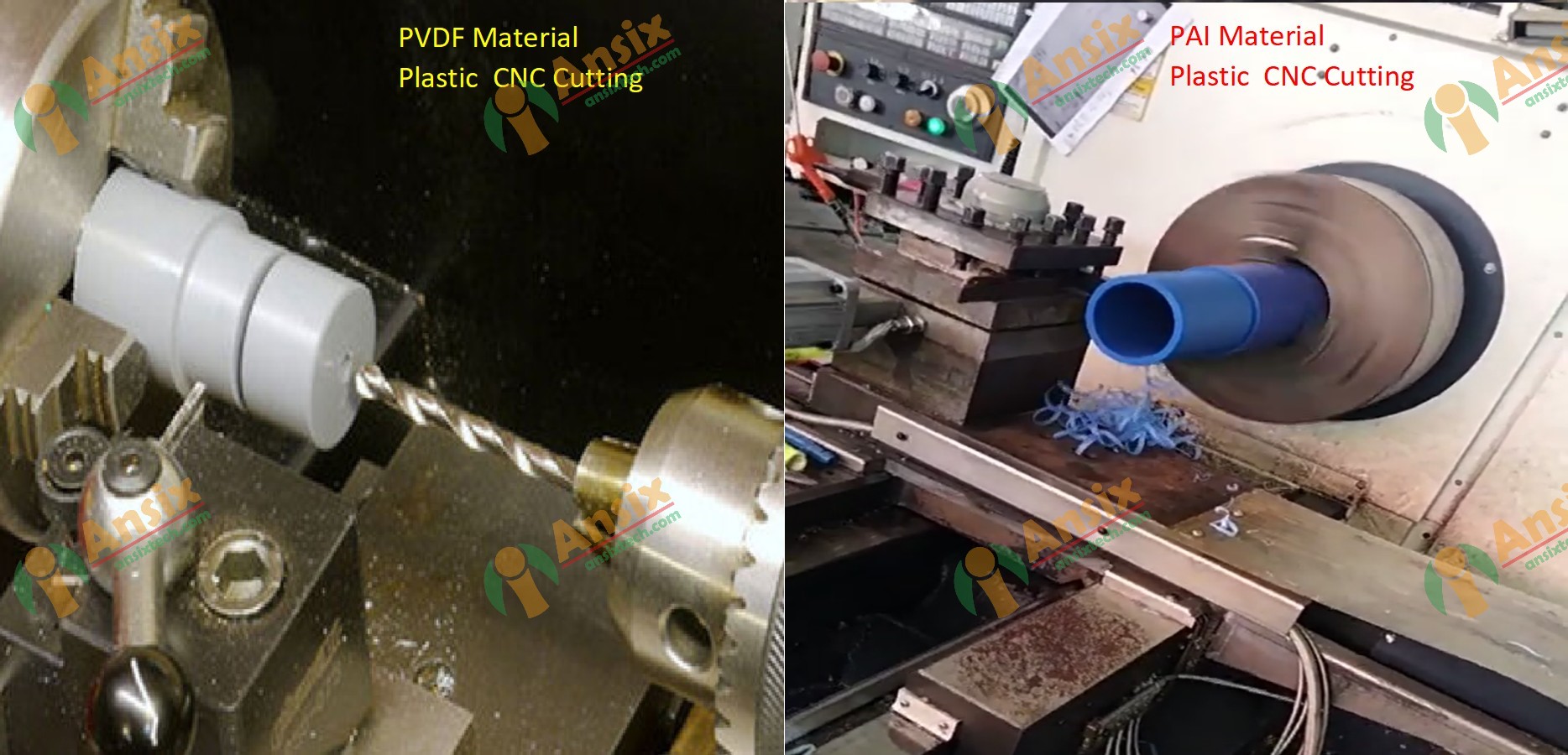

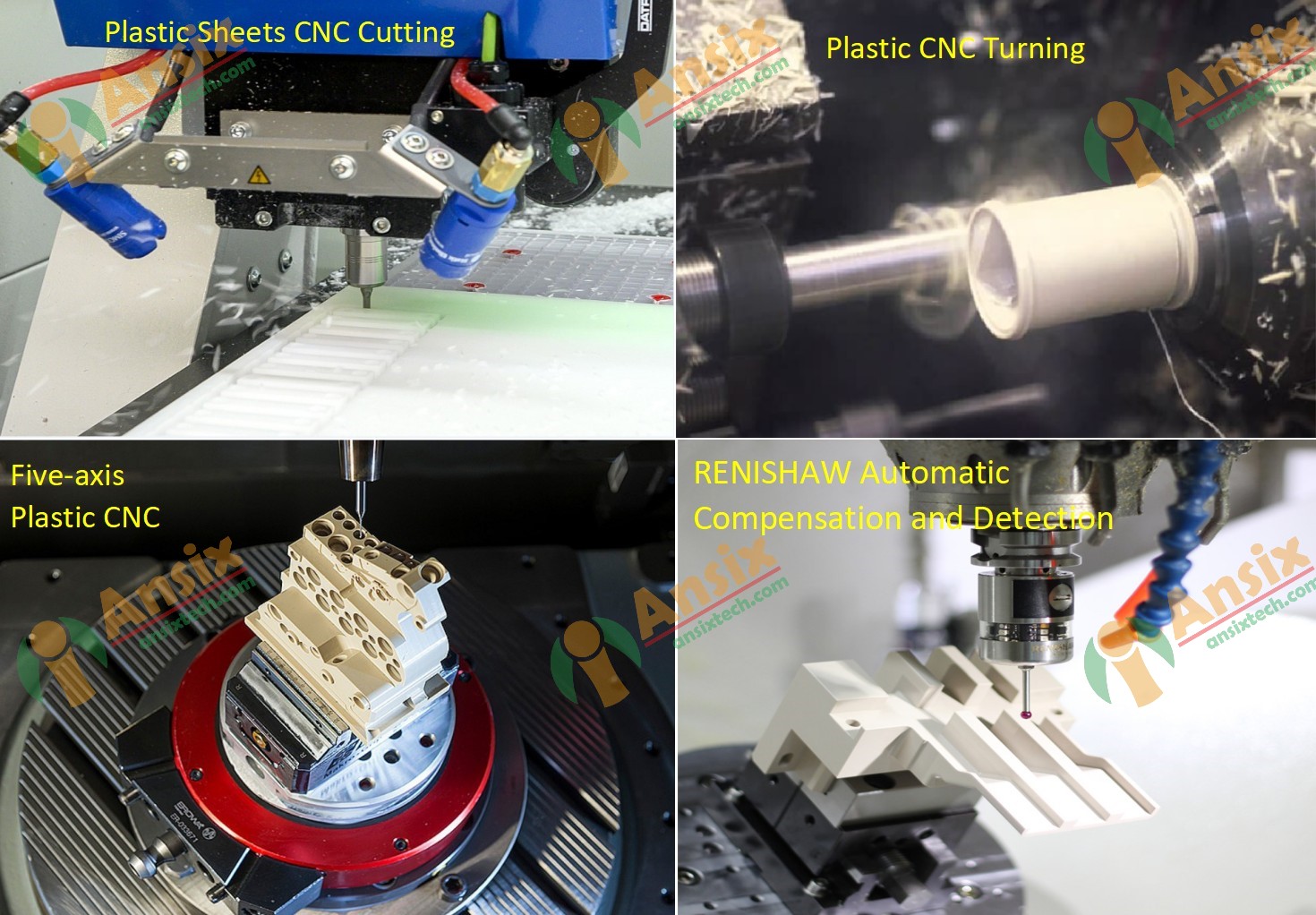

- Plastic CNC Turning for MC pulleysMachining PA66 pulleys refers to the process of using mechanical processing equipment to process PA66 materials and make pulleys. PA66 is an engineering plastic with excellent mechanical properties and wear resistance. It is widely used in pulleys, bearings, gears and other parts.In the process of machining PA66 pulleys, the following steps can be used:Design and planning: According to the requirements and drawings of the pulley, process planning and tool selection are carried out. Determine the size, shape, hole diameter and other parameters of the pulley.Material preparation: Prepare PA66 material to ensure the quality and compliance of the material. PA66 materials can be plates, rods or other shapes.Processing technology: According to the design requirements of the pulley, select appropriate mechanical processing equipment, such as lathes, milling machines, drilling machines, etc. Carry out turning, milling, drilling and other processing operations according to the shape and size of the pulley.Cutting parameters: According to the characteristics of PA66 material, reasonably set the cutting speed, feed speed and cutting depth. Pay attention to controlling the cutting temperature to avoid material deformation or burning due to overheating.Surface treatment: As needed, the surface of the pulley can be polished, grinded or sandblasted to improve surface quality and smoothness.Quality inspection: During the processing process, quality inspection is carried out to ensure that the size, shape and surface quality of the pulley meet the requirements. Measuring tools such as calipers, vernier calipers, etc. can be used for detection.Assembly and testing: If necessary, assemble the pulley with other parts and perform testing and debugging to ensure its normal operation and performance.In short, machining PA66 pulleys requires reasonable process planning, cutting parameter settings and quality inspection. With appropriate machining equipment and operating skills, PA66 pulleys that meet the requirements can be produced.

- Customized Plastic CNC Machining Parts

The process of customizing plastic pulleys at Ansix is as follows:Demand communication: Communicate with Ansix’s sales team and explain your plastic pulley needs in detail. Include the size, shape, material of the pulley, as well as relevant information such as your application scenario and requirements.Technical assessment: Ansix’s technical team will evaluate your needs and provide professional suggestions and technical solutions. They will consider the pulley’s design, material selection, load-carrying capacity and other factors to ensure the pulley will meet your requirements.Design and manufacturing: Based on your needs and technical assessment results, Ansix’s design team will begin designing the plastic pulley. They will use CAD software to design and consider the structure, function and safety of the pulley. Once the design is complete, the manufacturing team will begin fabricating the plastic pulleys.Material selection: Based on your needs and application scenarios, Ansix will select the appropriate plastic material for making pulleys. Common plastic materials include polyethylene (PE), polypropylene (PP), polyurethane (PU), etc. According to the requirements of the pulley, choose a plastic material with suitable strength, wear resistance and chemical resistance.Sample confirmation: After manufacturing is completed, Ansix will provide plastic pulley samples to you for confirmation. You can test and evaluate the sample to make sure it meets your needs and expectations. If adjustments or modifications are needed, promptly communicate with Ansix and provide feedback.Mass production: After confirming the sample, you can discuss the details of mass production with Ansix, such as quantity, delivery time, price, etc. Make sure to agree with Ansix and sign a contract.Quality inspection and delivery: During the mass production process, Ansix will conduct quality inspection to ensure that the plastic pulleys meet your requirements and standards. Once production is complete, Ansix will deliver the pulleys to you according to the agreed delivery time.After-sales service: Ansix provides after-sales service and support, including training, maintenance and technical support. If you encounter problems or need help using the pulleys, you can contact Ansix at any time.The process of customizing plastic pulleys includes demand communication, technical evaluation, design and manufacturing, material selection, sample confirmation, mass production, quality inspection and delivery, and after-sales service. Working with Ansix, you get professional technical support and high-quality plastic pulley products. -

- Quality Assurance of Plastic CNC Machined Pulley

Strict process control: Develop detailed process flow and operating specifications to ensure that each processing step is carried out in accordance with regulations. Including tool selection, cutting parameters, processing sequence, etc. Ensure that process controls comply with the design requirements and material properties of the pulley.High-quality raw materials: Choose high-quality raw materials, such as high-quality metal materials or engineering plastics. Ensure that raw materials meet relevant standards and requirements and have good mechanical properties and wear resistance.Accurate measurement and inspection: During the pulley machining process, accurate measurement and inspection are carried out. Use high-precision measuring tools, such as three-dimensional coordinate measuring machines, projectors, etc., to check the processing size, shape and surface quality. Make sure the size and shape of the pulley match the design requirements.Quality control system: Establish a complete quality control system, including formulating standard operating procedures (SOP), setting up inspection points and quality inspection processes, etc. Each processing step is inspected and recorded to ensure that every link meets quality requirements.Operator training and technical support: Provide necessary training and technical support to operators. Ensure that operators have good processing skills and operating experience and can correctly operate processing equipment and tools to avoid quality problems caused by operational errors.Equipment maintenance and upkeep: Perform regular maintenance and upkeep on processing equipment to ensure normal operation and accuracy of the equipment. Regularly check and replace consumables such as cutting tools and lubricants to maintain processing quality and efficiency.Continuous improvement: Continuous quality improvement and optimization. By analyzing and evaluating the problems and defects in the processing process, we can take corresponding improvement measures to improve the quality and efficiency of pulley machining.Partner selection: Choose to cooperate with an experienced and reputable pulley machining supplier to ensure that it has advanced equipment and a professional technical team to provide high-quality pulley machining services.Ensuring the quality of pulley machining requires strict process control, high-quality raw materials, precise measurement and testing, quality control systems, operator training and technical support, equipment maintenance and upkeep, and continuous improvement. Through these measures, you can ensure that the quality of pulley machining meets the requirements.