AnsixTech liquid silicone baby pacifier injection molding process

FEATURES

- AnsixTech liquid silicone baby pacifier injection molding process

AnsixTech liquid silicone baby pacifiers are used in a wide range of applications. First, it is an important tool for baby feeding. The liquid silicone baby pacifier is very soft and elastic, and can adapt well to the baby’s oral structure, giving the baby a comfortable sucking feeling. It can be used to feed milk powder, juice, water, etc. to meet the baby’s various feeding needs. Secondly, liquid silicone baby pacifiers can also be used to comfort your baby. During the process of sucking the pacifier, the baby can gain a sense of security and soothing effect, helping the baby fall asleep or relieve uncomfortable emotions. In addition, liquid silicone baby pacifiers can also be used during the baby’s tooth growth period. During the teething period, babies will experience itchy gums. Chewing a liquid silicone baby pacifier can relieve the discomfort and promote the growth and development of teeth.

-

Mold Description

Product Materials:

ShinEtsu、Dow

Mold Material:

S136ESR

Number of Cavities:

1*6

Glue Feeding Method:

Hot runner

Cooling Method:

Water cooling

Molding Cycle

42.5s

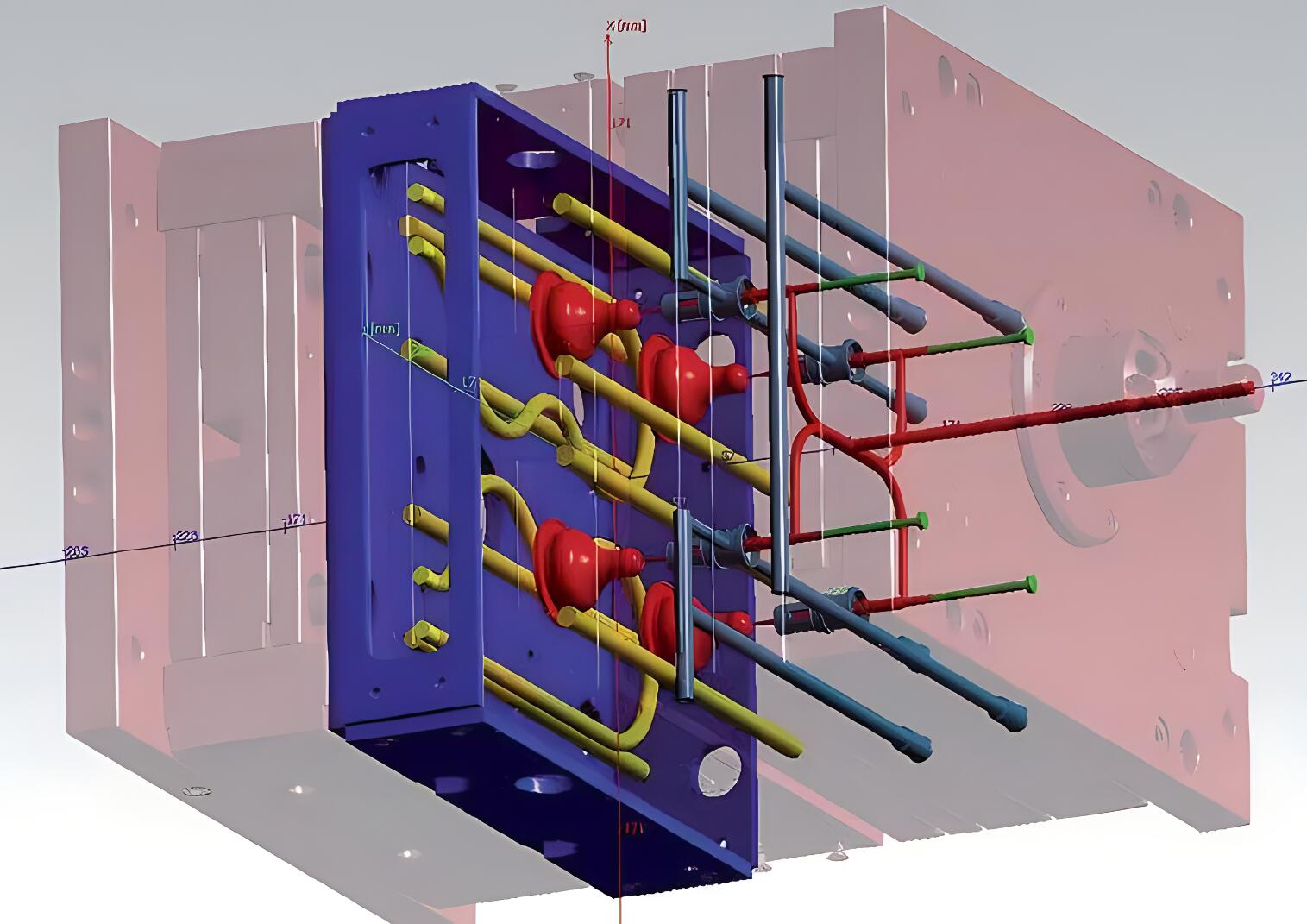

- liquid silicone baby pacifier Mold flow analysis and mold designThe mold flow analysis of liquid silicone baby pacifier molds and the design of liquid silicone molds are very important links in the manufacturing of baby pacifiers. The following will introduce the mold flow analysis of the liquid silicone baby pacifier mold and the design of the liquid silicone mold respectively.Mold flow analysis of liquid silicone baby pacifier mold:a. Collect relevant information about liquid silicone baby pacifiers, including size, shape, material, etc.b. Use mold flow analysis software to import the CAD model of the liquid silicone baby pacifier and set the injection molding process parameters, such as injection speed, temperature, pressure, etc.c. Conduct mold flow analysis to simulate the melt flow, filling, cooling and other processes during the injection molding process to evaluate the filling performance, bubbles, short shots and other defects of the nipple, and optimize the injection molding process parameters.Design of liquid silicone mold:a. Determine the structure and size of the liquid silicone mold based on the mold flow analysis results. Taking into account the shape and requirements of the nipple, design an appropriate mold structure, including mold cavity, mold core, demoulding system, cooling system, etc.b. Determine the injection molding process, including injection sequence, injection point location, etc.c. Carry out detailed design of the mold, including the processing technology of the mold parts, assembly method, design of the demoulding mechanism, etc.d. Use CAD software for mold design and generate three-dimensional models and engineering drawings of the mold.During the mold flow analysis and liquid silicone mold design process, the following points need to be noted:Ensure the filling performance of the pacifier: Through mold flow analysis, the injection molding process parameters are optimized to ensure the filling performance of the pacifier is good and avoid defects.Design of cooling system: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.Design of the demoulding system: According to the shape and requirements of the pacifier, design an appropriate demoulding system to ensure that the pacifier can be demoulded smoothly and avoid damage and deformation.Injection molding sequence and injection point position: Determine the injection molding sequence and injection point position to ensure that the liquid silicone can fully fill the mold cavity and avoid voids and defects.In short, the mold flow analysis of liquid silicone baby pacifier mold and the design of liquid silicone mold need to conduct mold flow analysis, optimize the injection molding process parameters, design the appropriate mold structure and size, and determine the injection molding process flow and injection point location. Through reasonable design and control, high-quality liquid silicone baby pacifiers can be obtained.

- liquid silicone baby pacifier of the mold manufacturing process and product material selection

The manufacturing process of liquid silicone baby pacifier molds and the selection of liquid silicone injection molding materials involve the following aspects:Mold manufacturing and processing process:a. According to the design requirements of the liquid silicone baby pacifier, formulate the mold manufacturing and processing process, including mold design, mold processing, mold assembly and other links.b. According to the mold design, select appropriate processing technology and equipment, such as CNC machining center, EDM machine, etc.c. Process mold parts, including mold cavity, mold core, demoulding system, cooling system, etc. Ensure that the processing accuracy and size meet the requirements.d. Assemble the mold parts to ensure accurate fit and adjustment of the parts and ensure the stability and reliability of the mold.Liquid silicone injection molding material selection:a. Select the appropriate liquid silicone injection molding material according to the requirements of the liquid silicone baby pacifier. Commonly used liquid silicone materials include food-grade silicone, medical silicone, etc.b. According to the use environment and requirements of the product, select liquid silicone materials with good mechanical properties, high temperature resistance, chemical resistance and wear resistance.c. Considering the safety and hygiene of baby pacifiers, choose liquid silicone materials that meet relevant standards and certification requirements.During the mold manufacturing process and liquid silicone injection molding material selection process, you need to pay attention to the following points:Processing accuracy and size control: Ensure that the processing accuracy and size of mold parts meet the requirements to ensure the quality and stability of injection molding.Surface treatment of the mold: According to the requirements of the liquid silicone baby pacifier, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the pacifier.Control of injection molding process parameters: According to the characteristics of liquid silicone, rationally design and control the injection molding process parameters to ensure that the fluidity and solidification time of the silicone meet the requirements.Material selection and certification: Select liquid silicone materials that meet relevant standards and certification requirements to ensure product safety and hygiene.Injection molding material: Select the appropriate injection molding material according to the requirements of the plastic product and the application environment. Common plastic materials include ABS,PP,PC,ABS/PC,PBT,PMMA,SAN,PA,PA66,PA6,POM,PET,PE,PVT,TPE,TPR,SILICONE,PEEK,PEI,PS,PES,PI,PPSU,PETG,PCTG,PFA,NBR,PTFE,PAEK,PAA,PEAA etc. According to the characteristics and requirements of the product, select materials with appropriate hardness, wear resistance, chemical resistance and other properties.Mold material selection:The selection of mold materials should take into account the shape, size and requirements of the plastic product, as well as the service life and production volume of the mold. Common mold materials include tool steel, stainless steel,738、2738H 、718、718H、NAK80、2083、2316、2344、2083H、2316H、S136、S136H、S136-D、HPM38、M300、S-STAR、M333、S196 etc., which have high hardness and wear resistance.In short, the manufacturing process of liquid silicone baby pacifier molds and the selection of liquid silicone injection molding materials require the selection of appropriate processing techniques and equipment to ensure processing accuracy and dimensional control. In terms of liquid silicone injection molding material selection, liquid silicone materials with good mechanical properties, high temperature resistance, chemical resistance and wear resistance are selected according to the product requirements and use environment. Through reasonable manufacturing processing and injection molding process control, high-quality liquid silicone baby pacifiers can be achieved.

- Liquid silicone baby pacifier Mass production and Quality controlMass production of liquid silicone baby pacifier mold injection molding involves considerations of tooling, production efficiency, cost and quality:Workwear:Tooling fixture design: According to the shape and requirements of the liquid silicone baby pacifier, design a suitable fixture to fix the mold and pacifier to ensure stability and consistency during the injection molding process.Manufacturing and debugging of tooling fixtures: Manufacturing tooling fixtures, debugging and optimizing them to ensure the stability and reliability of the tooling fixtures.Production efficiency:Automated production: Use automated injection molding machines and robot systems to achieve automated production, improve production efficiency and reduce labor costs.Multi-cavity molds and multi-machine production: Use multi-cavity molds and multiple injection molding machines for simultaneous production to increase output and production efficiency.Production plan and schedule optimization: Develop reasonable production plans and schedules, and rationally arrange production tasks and resources to improve production efficiency and reduce production downtime.Cost control:Material cost control: Select appropriate liquid silicone injection molding materials, and conduct procurement and inventory management according to actual needs to control material costs.Equipment and energy cost control: Use equipment rationally, optimize energy consumption, and reduce equipment maintenance and energy costs.Labor cost control: Reduce manual operations and reduce labor costs through automated production and optimized production processes.Quality assurance:Establishment of quality control system: Establish a complete quality control system, including quality inspection, process control and defective product processing, to ensure that products meet quality standards.Inspection and testing: Inspection and testing of liquid silicone baby pacifiers, including appearance quality, dimensional accuracy, physical properties, etc., to ensure product quality and consistency.Continuous improvement: Regularly evaluate and analyze the production process, find opportunities for improvement, optimize production processes and processes, and improve product quality and production efficiency.In the mass production process of liquid silicone baby pacifier mold injection molding, factors such as tooling, production efficiency, cost and quality need to be comprehensively considered. Through reasonable tooling design, automated production, cost control and quality assurance, high-efficiency, low-cost, and high-quality mass production of liquid silicone baby pacifiers can be achieved.