How to ensure a precision mold with a part weight of 0.4 grams

2024-01-24 16:20:52

To ensure a precision mold with a part weight of 0.4 grams, the following methods can be used: Material selection: Choose raw materials with stable quality and uniform density to ensure the stability of the weight of the parts. Precision processing: Use high-precision processing equipment for precision processing to ensure that the size and weight of the parts meet the requirements. Customized mold design: Design and customize precision molds according to the specific requirements of the parts to ensure the consistency of the size and weight of the parts produced. Quality control: Establish a strict quality control process, including initial inspection, patrol inspection, and final inspection, and ensure that the weight of parts is stable within the range of 0.4 grams through strict testing methods. Automated production: Use automated production lines to reduce the impact of human factors on the weight of parts through precise control of production process parameters and automated assembly. Regular calibration and maintenance: Calibrate and maintain production equipment regularly to ensure the accuracy and stability of the equipment. Through the above method, it can effectively ensure that the weight of parts produced by precision molds is within the accuracy requirement of 0.4 grams.

If you want to know more about AnsixTech injection molding process, We have the most advanced manufacturing equipment in the world, and the mold accuracy can reach 0.002mm. We can provide you with the most effective quality assurance and the most competitive price.please call the official consultation hotline: 0086 13530645990 or enter the official website: https://www.ansixtech.com to learn more.

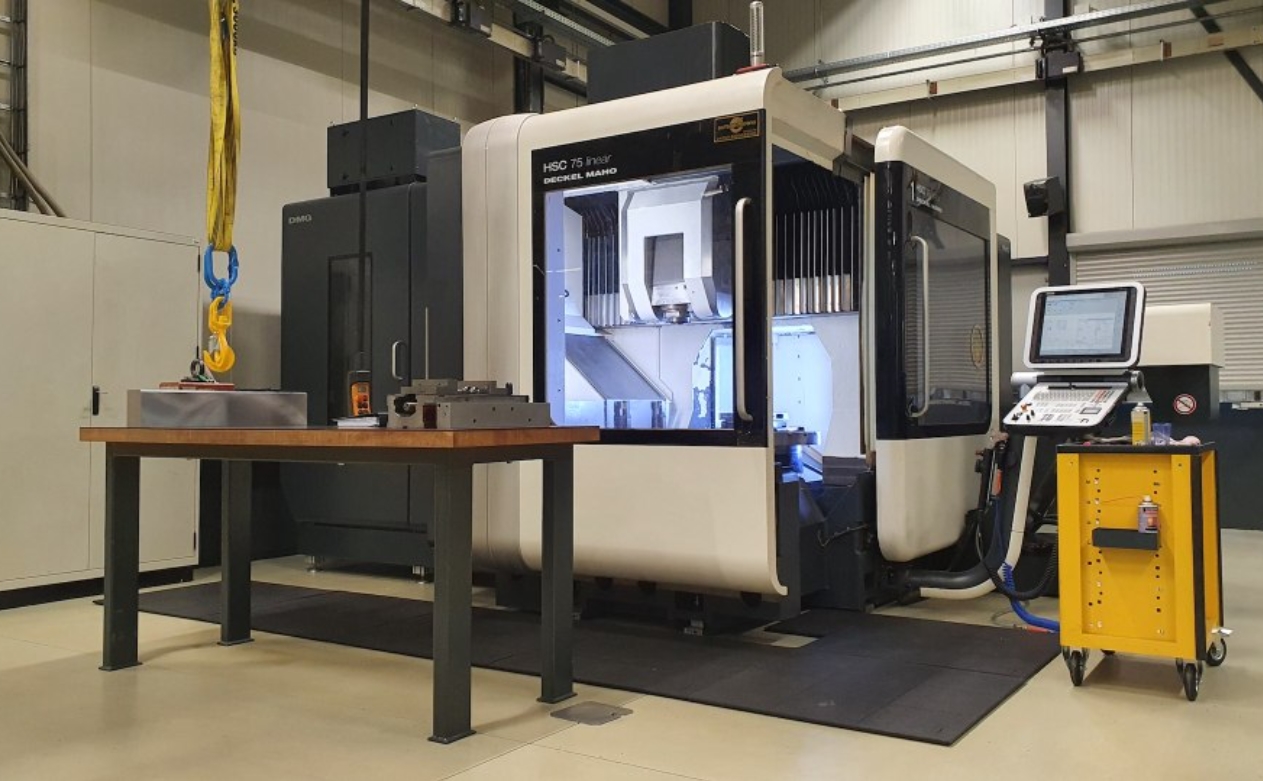

We use imported high-speed CNC to process the mold core.

The advantages of high-speed CNC machining include: Efficient production: Fast cutting and processing speed can greatly improve production efficiency and shorten the production cycle. Improved accuracy: High-speed CNC machining equipment often achieves greater accuracy and surface quality, ensuring high-quality parts are manufactured. Save energy: High-speed machining can usually complete processing in a shorter time, reduce energy consumption, and reduce production costs. Reduced process steps: Due to the fast processing speed, it is usually possible to reduce the processing steps and improve production efficiency. Wide applicability: High-speed CNC machining is generally suitable for processing a variety of materials, including metals, plastics, etc. In short, high-speed CNC machining can improve production efficiency, accuracy and applicability, and is an indispensable part of modern manufacturing.

Imported high-precision slow wire cutting for wire cutting

Makino is a famous CNC machine tool manufacturer. Their slow wire processing machines are known for their high precision and stability. Slow wire machining is a high-precision machining method that is often used to produce parts with extremely high precision requirements. Slow-moving wire processing machine tools manufactured by Makino usually have sophisticated control systems, high-quality screws and nuts, and stable structural designs to help ensure processing accuracy and stability. In addition, Makino also provides high-end processing technology and processing technology to ensure that slow wire processing can meet the requirements of high-precision processing. Generally speaking, Makino's slow wire processing machine tools can usually provide excellent processing accuracy and are suitable for industries and applications that require high-precision processing.

Using the most advanced imported EDM processing

MAKINO's EDM (Electro Discharge Machining) machine tool is a high-precision machine tool used for metal processing that uses electrical pulses to process metal materials into complex shapes. EDM machine tools are widely used in fields such as mold manufacturing, aerospace, and automotive industries because they can process extremely difficult materials such as titanium alloys and carbide. MAKINO's EDM machine tools usually have advanced control systems, high-frequency electric pulse generators, and high-precision worktables and electrodes. These features enable it to provide outstanding performance in terms of machining accuracy, efficiency and surface quality. In general, MAKINO's EDM machine tool is an advanced processing equipment suitable for industries and application fields that require high processing accuracy.

Produced with injection molding machines imported from Germany

Our company has dozens of Arburg injection molding machines, with an injection molding accuracy of up to 0.1 grams.ARBURG injection molding machine (ARBURG) is a professional injection molding equipment with many advantages, including: Advanced technology: Arburg injection molding machines adopt advanced injection molding technology to ensure product quality and production efficiency. Flexibility: This machine is suitable for injection molding of various sizes and materials, with a high degree of flexibility and versatility. Precision: Arburg injection molding machines have high-precision control systems to ensure precise dimensions and high-quality surface treatment of products. Automation: Some Arburg injection molding machines are equipped with automation systems that increase production efficiency and reduce human errors. Reliability: Due to high manufacturing quality and stable performance, Arburg injection molding machines generally have a long service life and reliability. To sum up, Arburg injection molding machines have excellent performance and advantages in the injection molding industry and are suitable for various production needs and application scenarios.

Measure each component to ensure proper dimensions

The mold measurement refers to the process of measuring, analyzing and verifying the dimensions, geometry and surface properties of molds. Mold measurement typically involves using a variety of tools and equipment to accurately measure various parts of the mold to ensure that it meets design requirements and can produce parts or products that meet specifications. Common mold measurement tools and equipment include: Caliper, vernier caliper: used to measure linear dimensions such as length, width, and depth of the mold. Coordinate measuring machine (CMM): used to accurately measure and analyze the three-dimensional size, shape and position of molds. Surface roughness measuring instrument: used to measure the roughness and texture characteristics of the mold surface to ensure that the product surface quality meets the requirements. Optical projector: used for precise measurement and comparison of contours and appearance of mold parts. X-ray and CT scanning equipment: used for non-destructive testing and measurement of mold internal structures and structures. By using these tools and equipment, molds can be effectively and comprehensively measured and analyzed to ensure the accuracy and consistency of mold manufacturing, thereby ensuring the production of high-quality parts and products.

If you want to know more about AnsixTech injection molding process, We have the most advanced manufacturing equipment in the world, and the mold accuracy can reach 0.002mm. We can provide you with the most effective quality assurance and the most competitive price.please call the official consultation hotline: 0086 13530645990 or enter the official website: https://www.ansixtech.com to learn more.