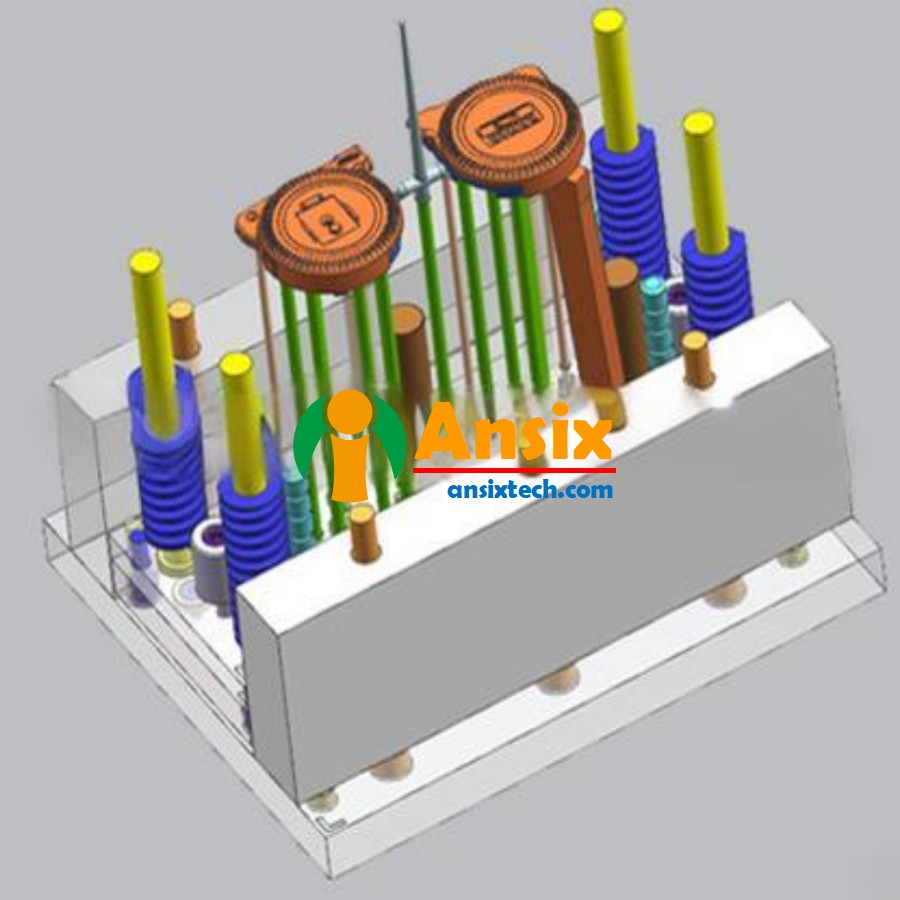

Tape measure houring double color injection molding

FEATURES

- Tape measure houring double color injection molding

The main steps of the two-color injection molding process include:Prepare plastic pellets: Prepare plastic pellets of two different colors separately.Design mold: According to the design requirements of the product, design a mold suitable for two-color injection molding, including two injection molding chambers and a turntable or rotating mechanism.Injection molding: Put two plastic particles of different colors into two hoppers of the injection molding machine, and then the plastic is melted by the injection molding machine and injected into the mold. During the injection molding process, the injection molding machine injects two colors of plastic alternately to create a two-color effect.Cooling and solidification: After the plastic injection is complete, the mold will continue to cool and solidify for a period of time.Take out the product: Finally, open the mold and take out the formed two-color tape measure shell.AnsixTech tape measure housing two-color mold process and two-color injection molding process are commonly used to manufacture two-color tape measure housing. Both processes enable different parts of the shell to have different colors, thereby increasing the aesthetics and personalization of the product. The specific choice of process depends on factors such as product design requirements, production costs, and production efficiency.. please send us a message(Email: info@ansixtech.com) at any time and our team will reply to you within 12 hours.

-

Mold Description

Product Materials:

ABS/PC

Soft rubber: TPR

Mold Material:

S136ESR

Number of Cavities:

4+4

Glue Feeding Method:

Hot runner

Cooling Method:

Water cooling

Molding Cycle

22.5s

- The two-color mold design for tape measure housing Mold flow analysis and mold designThe two-color mold design for tape measure housing:Determine the design requirements: Collect the design requirements for the tape measure housing, including size, shape, color, etc. Understand the requirements of two-color injection molding and determine the process flow of two-color injection molding.Mold structure design: Design an appropriate mold structure according to the design requirements. Including mold cavity, mold core, demoulding system, cooling system, etc. Taking into account the shape and requirements of the tape measure housing, a suitable mold structure is designed to achieve two-color injection molding.Injection molding sequence and color switching: Determine the process flow of two-color injection molding, including injection molding sequence and color switching method. According to the design requirements of the tape measure housing, determine the position and method of color switching to achieve a two-color effect.Detailed design of the mold: Carry out detailed design of the mold, including the processing technology of the mold parts, assembly methods, and the design of the demoulding mechanism, etc. Use CAD software for mold design and generate three-dimensional models and engineering drawings of the mold.Mold manufacturing: According to the mold design drawings, select appropriate processing technology and equipment to process and assemble mold parts. Ensure that the processing accuracy and size meet the requirements.Mold debugging and mold trial: After completing the mold manufacturing, mold debugging and mold trial are carried out. Adjust mold parameters and processes to ensure the effect and quality of two-color injection molding.Mass production: Carry out mass production according to production plan and schedule. As needed, multiple injection molding machines and molds can be used simultaneously to increase production efficiency and output.During the mold design process, you need to pay attention to the following points:Optimization of injection molding process parameters: According to the material and design requirements of the tape measure housing, optimize the injection molding process parameters to ensure the effect and quality of two-color injection molding.Design of cooling system: Reasonably design the cooling system to ensure good cooling effect during the injection molding process and improve production efficiency and product quality.Design of demoulding system: According to the shape and requirements of the tape measure shell, design a suitable demoulding system to ensure that the shell can be demoulded smoothly and avoid damage and deformation.Mold maintenance and upkeep: Regularly maintain and maintain the mold, including cleaning, lubrication, repair, etc., to extend the service life of the mold and ensure the stability of production.The design of the two-color mold for the tape measure shell requires determining the two-color injection molding process according to the design requirements, designing the appropriate mold structure and size, and conducting detailed design and manufacturing of the mold. Through reasonable design and control, a high-quality two-color injection molded tape measure housing can be obtained.

- The mold manufacturing process and product material selection of the two-color mold design for tape measure housingFor the manufacturing, processing and mold selection of the two-color mold for the tape measure shell, as well as the selection of the two-color injection molding material for the shell, ABS/PC encapsulated TPR:Mold manufacturing and processing:a. According to the design requirements of the two-color mold, select the appropriate processing technology and equipment, such as CNC machining center, EDM machine, etc.b. Process mold parts, including mold cavity, mold core, demoulding system, cooling system, etc. Ensure that the processing accuracy and size meet the requirements.c. Assemble the mold parts to ensure accurate fit and adjustment of the parts and ensure the stability and reliability of the mold.Mold selection:a. Select a suitable two-color mold according to the design requirements of the tape measure shell and the process requirements of two-color injection molding. Considering the shape and requirements of the shell, choose a mold with two-color injection molding capabilities.b. Consider the quality and stability of the mold, choose a reliable mold manufacturer or supplier, and ensure that the quality and performance of the mold meet the requirements.Shell two-color injection molding material selection:a. Consider the design requirements and usage environment of the shell and select a suitable two-color injection molding material. In this case, you can choose ABS/PC encapsulated TPR material, which combines the strength and stiffness of ABS/PC plastic with the flexibility and wear resistance of TPR elastomer.b. Cooperate with reliable material suppliers to ensure the quality and stable supply of materials.During the mold manufacturing process and mold selection process, you need to pay attention to the following points:Processing accuracy and size control: Ensure that the processing accuracy and size of mold parts meet the requirements to ensure the quality and stability of injection molding.Surface treatment: According to the requirements of the shell, perform appropriate surface treatment, such as grinding, polishing, etc., to improve the surface quality and smoothness of the shell.Heat treatment of materials: According to the requirements of the mold material, appropriate heat treatment, such as quenching, tempering, etc., is performed to improve the hardness and wear resistance of the material.Mold maintenance and upkeep: Regularly maintain and maintain the mold, including cleaning, lubrication, repair, etc., to extend the service life of the mold and ensure the stability of production.For the manufacturing, processing and mold selection of the two-color mold for the tape measure shell, it is necessary to select the appropriate processing technology and equipment to ensure processing accuracy and dimensional control. In terms of mold selection, consider the design requirements of the shell and the process requirements of two-color injection molding to select a suitable two-color mold. In terms of the selection of two-color injection molding materials for the shell, select a suitable two-color injection molding material, such as ABS/PC encapsulated TPR material, according to the design requirements and use environment of the shell. Through reasonable manufacturing processing and mold selection, high-quality two-color injection molded tape measure housings can be achieved.

- The two-color mold design for tape measure housing Mass production and Quality controlThe mass production of two-color mold injection molding for tape measure housing has the following efficiency and quality:Efficiency:a. High output: Through reasonable production planning and scheduling, using multiple injection molding machines and molds, high-output production can be achieved and production efficiency can be improved.b. Automated production: The use of automated equipment, such as robotic systems, can improve production efficiency and reduce labor costs.c. Injection molding process optimization: By optimizing injection molding process parameters, such as injection speed, temperature, pressure, etc., the filling performance and production efficiency of injection molding can be improved.Quality:a. Mold quality: Choose a high-quality mold manufacturer or supplier to ensure the quality and stability of the mold to ensure the quality of injection molding.b. Injection molding process control: By strictly controlling injection molding process parameters, such as temperature, pressure, etc., the quality and consistency of injection molding can be ensured.c. Quality inspection: Conduct quality inspection on the injection molded tape measure shell, including appearance quality, dimensional accuracy, color consistency, etc., to ensure that the product meets the requirements.During the mass production process of two-color mold injection molding for tape measure shells, the following points need to be noted:Optimization of injection molding process parameters: By optimizing injection molding process parameters, ensure the balance between filling performance and production efficiency of injection molding, as well as product quality and stability.Mold maintenance and upkeep: Regularly maintain and maintain the mold, including cleaning, lubrication, repair, etc., to extend the service life of the mold and ensure the stability of production.Quality control and continuous improvement: Establish a quality control system, continuously monitor and improve the production process, discover and solve problems in a timely manner, and improve product quality and consistency.The efficiency and quality of mass production of two-color mold injection molding for tape measure shells can be achieved by optimizing injection molding process parameters, selecting high-quality mold manufacturers, strictly controlling the injection molding process, and conducting quality inspections. Through reasonable production planning and scheduling, the use of automated equipment, and continuous improvement and quality control, production efficiency and product quality can be improved to meet the needs of mass production.