The mold manufacturing and processing process of PET bottle preforms for beverage bottles includes steps such as mold design, mold manufacturing and mold debugging.

Mold design:

Mold design is one of the key steps in manufacturing PET bottle preforms. During the design process, the following factors need to be considered:

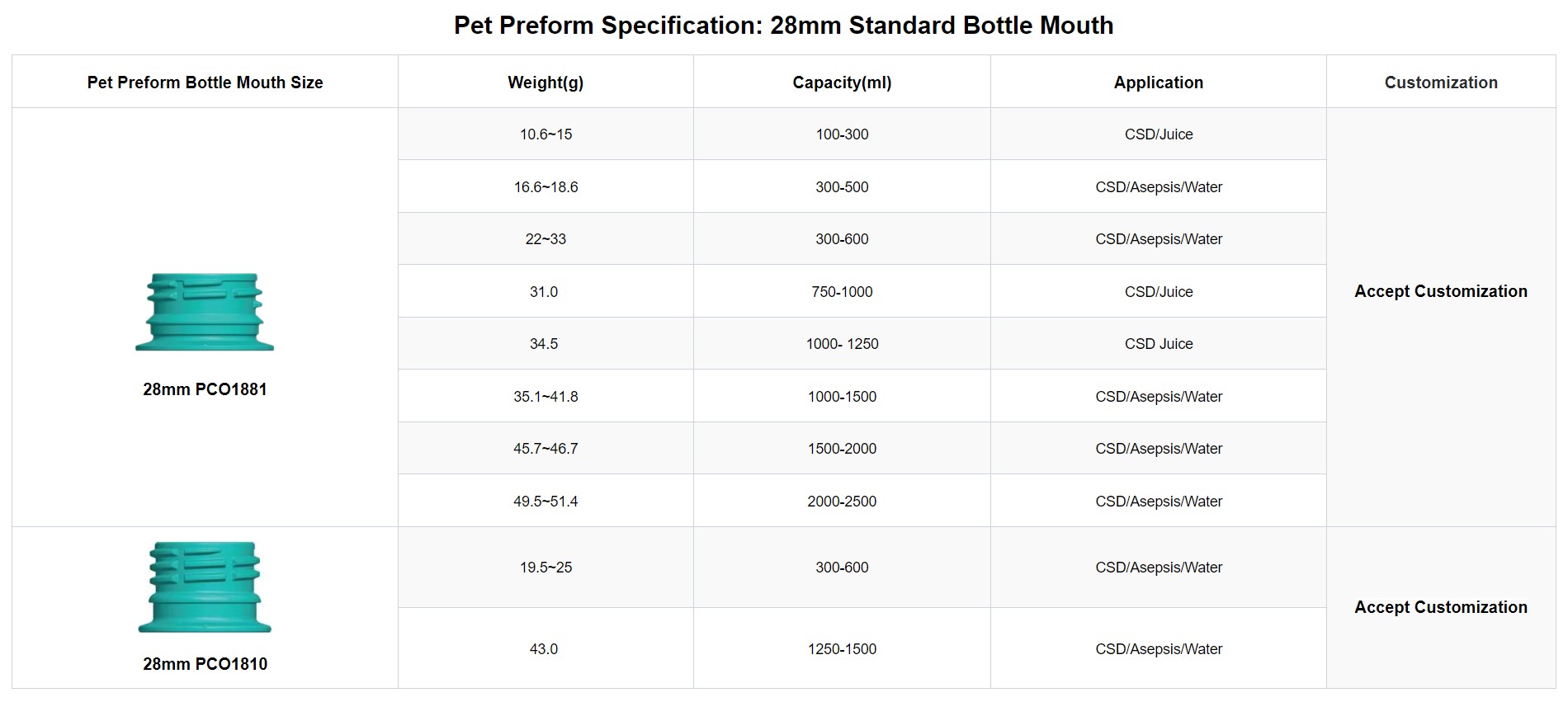

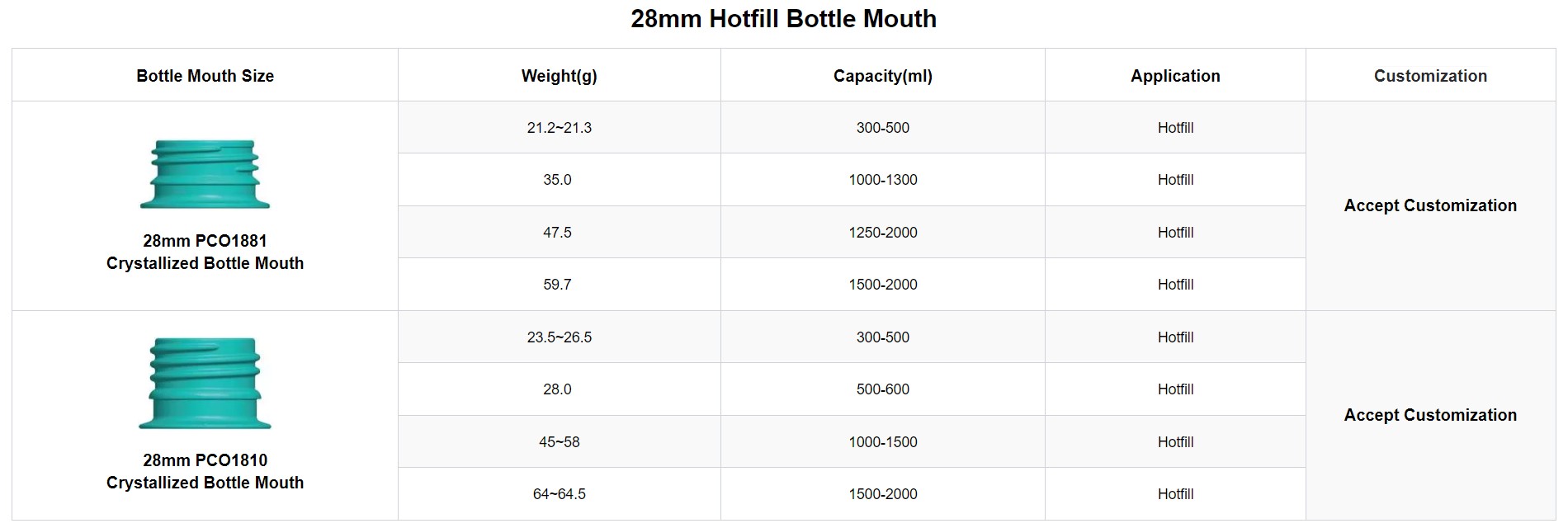

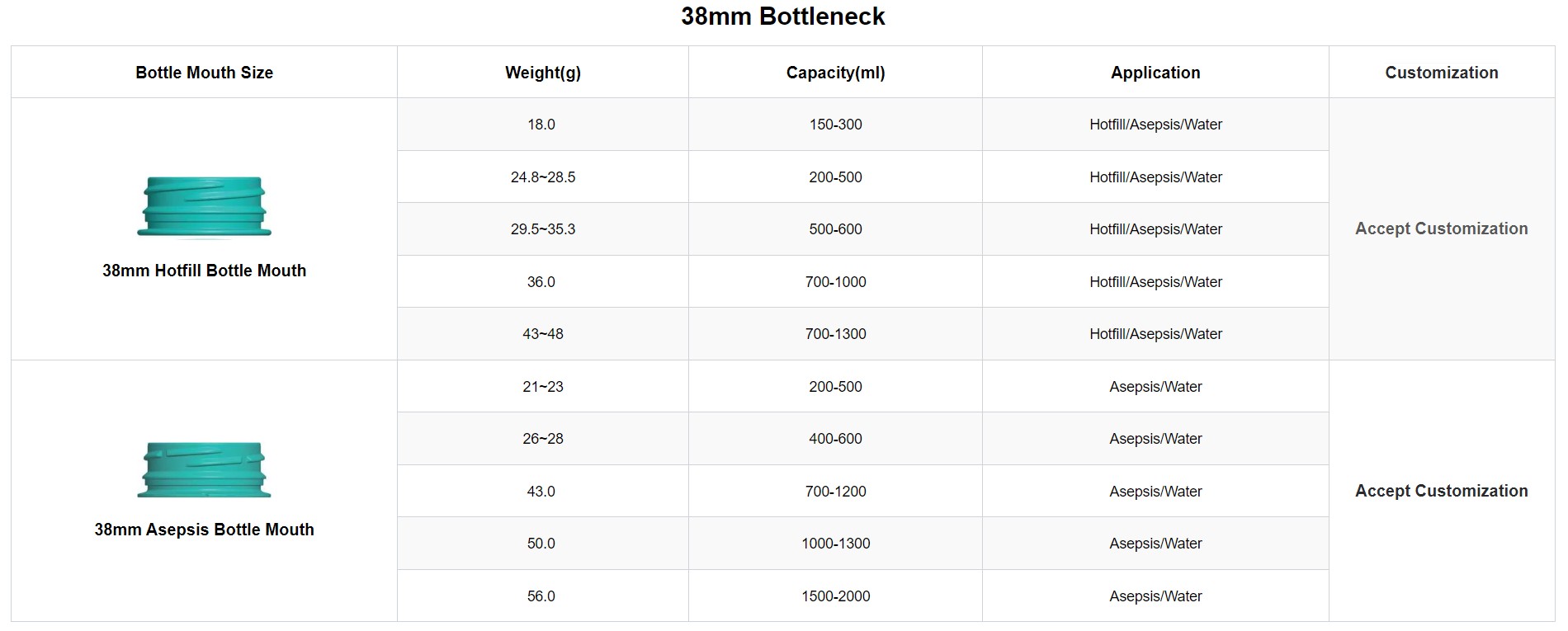

Shape and size of the preform: According to the shape and size of the preform, design the structure and cavity of the mold to ensure the accuracy and consistency of the preform.

Bottleneck and thread design: According to the bottleneck and thread requirements of the bottle preform, design appropriate mold parts to ensure the quality and size of the bottleneck and threads.

Cooling system design: Design a reasonable cooling system to improve cooling efficiency during the injection molding process and shorten the production cycle.

Mold material selection: Choose appropriate mold materials, such as high-quality alloy steel or stainless steel, to ensure the hardness and wear resistance of the mold.

Mold manufacturing:

According to the mold design, the mold manufacturing process includes the following steps:

Mold material procurement: According to the mold design requirements, select appropriate mold materials and proceed with material procurement.

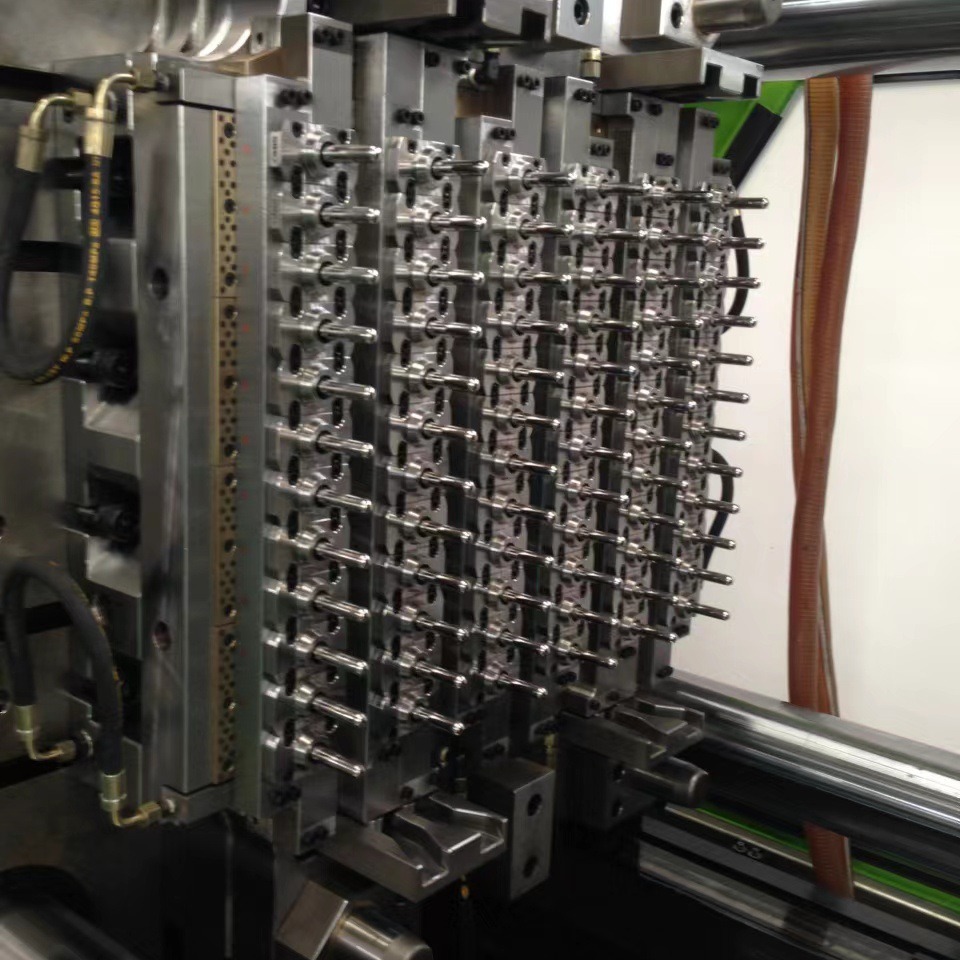

Mold processing: According to the mold design, CNC machining, EDM, wire cutting and other processes are performed to manufacture precision mold parts.

Mold assembly: Assemble the mold parts to form a complete mold structure.

Mold debugging: debug and optimize the mold to ensure the stability and production efficiency of the mold.

Difficulties in mold manufacturing and mold cost advantages:

The difficulties in mold manufacturing are mainly reflected in the following aspects:

Complex structural design: The mold design of PET bottle preforms for beverage bottles needs to consider the shape, size, bottle mouth and threads of the preform, which places higher requirements on the structural design of the mold.

High-precision processing requirements: The manufacturing of PET bottle preforms requires high-precision mold processing to ensure the size and appearance quality of the bottle preforms.

Wear resistance and durability requirements: The injection molding process of PET bottle preforms places high requirements on the wear resistance and durability of the mold.

The cost advantages of mold manufacturing are mainly reflected in the following aspects:

High productivity: The mold manufacturing of PET bottle preforms can achieve high-capacity injection molding production and improve production efficiency.

Long life: High-quality mold materials and manufacturing processes can give the mold a long service life and reduce mold replacement and maintenance costs.

Reusable: Molds can be reused, reducing the cost of each production.

Preform material selection:

PET bottle preforms are usually made of polyethylene terephthalate (PET), which is a transparent, heat-resistant and pressure-resistant plastic material. PET material has the following advantages:

Transparency: PET material has good transparency, which can show the color and quality of the drink.

Heat resistance: PET material has good heat resistance and can withstand the high temperature filling process.

Pressure resistance: PET material has good pressure resistance and can withstand the high-pressure filling process.

Recyclability: PET material has good recyclability and meets environmental protection requirements.

To sum up, the mold manufacturing and processing process of PET bottle preforms for beverage bottles includes steps such as mold design, mold manufacturing and mold debugging. The difficulties in mold manufacturing are mainly reflected in complex structural design, high-precision processing requirements and wear resistance requirements. Mold manufacturing has the cost advantages of high productivity, long life and reuse. The material selection advantages of PET bottle preforms include high transparency, good heat resistance, good pressure resistance and good recyclability.