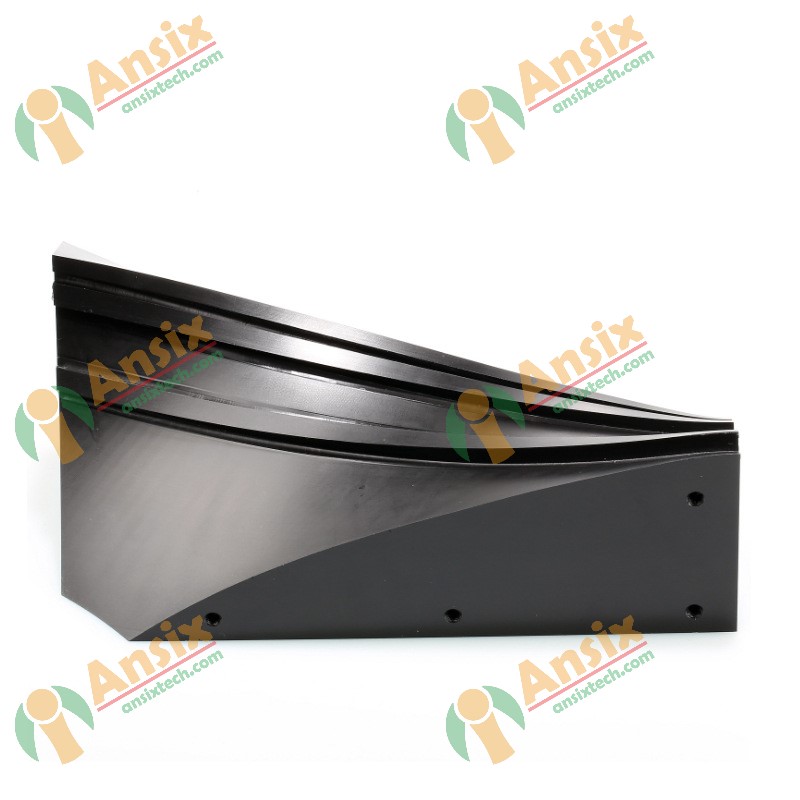

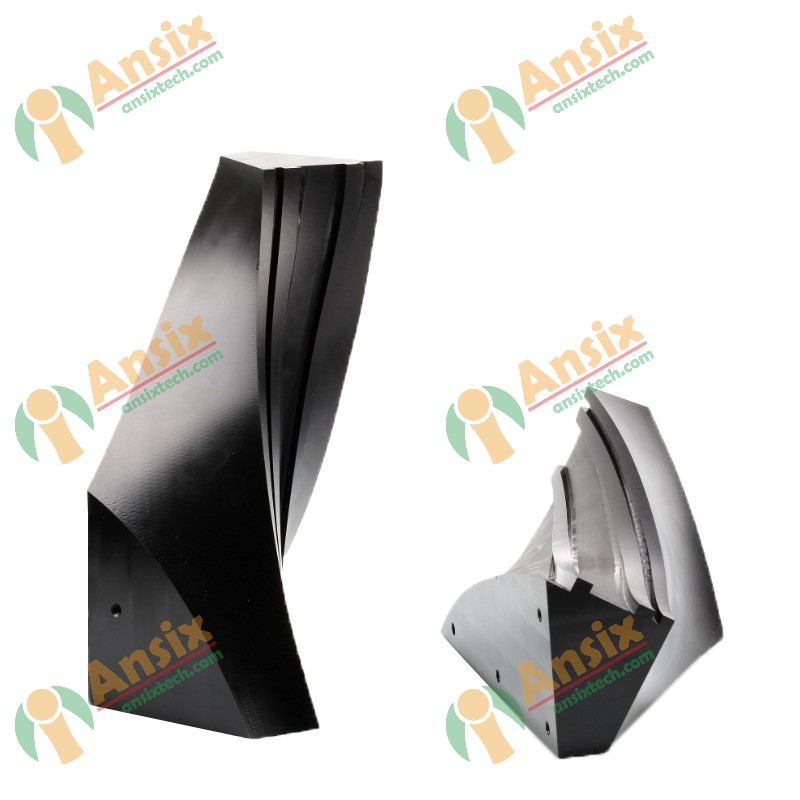

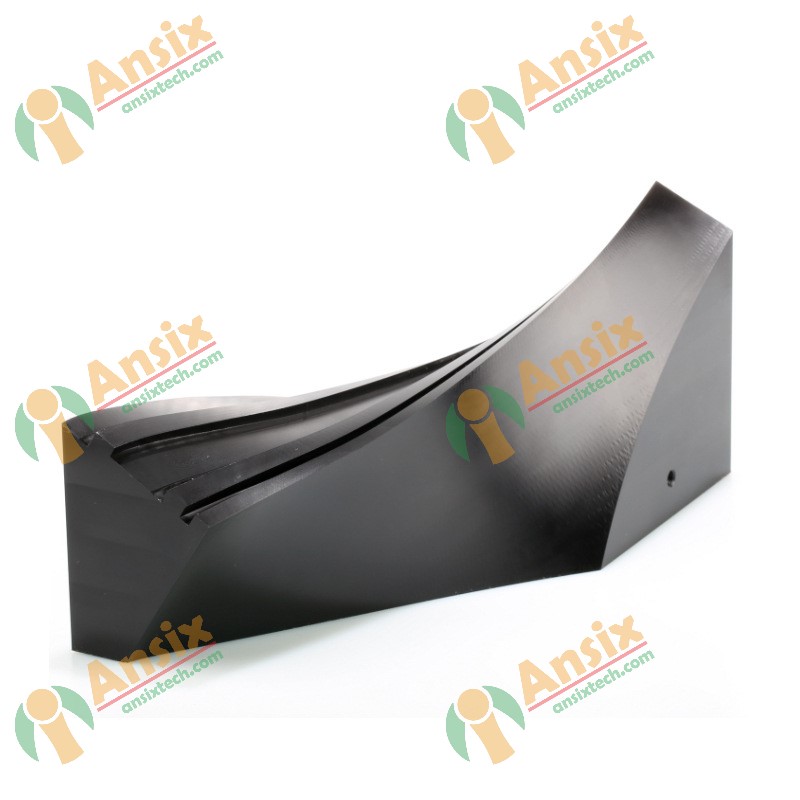

Natural peek parts CNC machining 5-axis CNC precision machining polyetheretherketone board anti-static peek rod CNC lathe

FEATURES

- Natural peek parts CNC machining 5-axis CNC precision machining polyetheretherketone board anti-static peek rod CNC lathe

The application technology of PEEK parts mainly depends on the specific application needs and processing requirements. According to different application scenarios, appropriate processing technology can be selected to manufacture PEEK parts to meet engineering requirements and performance needs., please send us a message (Email: info@ansixtech.com ) at any time and our team will reply to you within 12 hours.

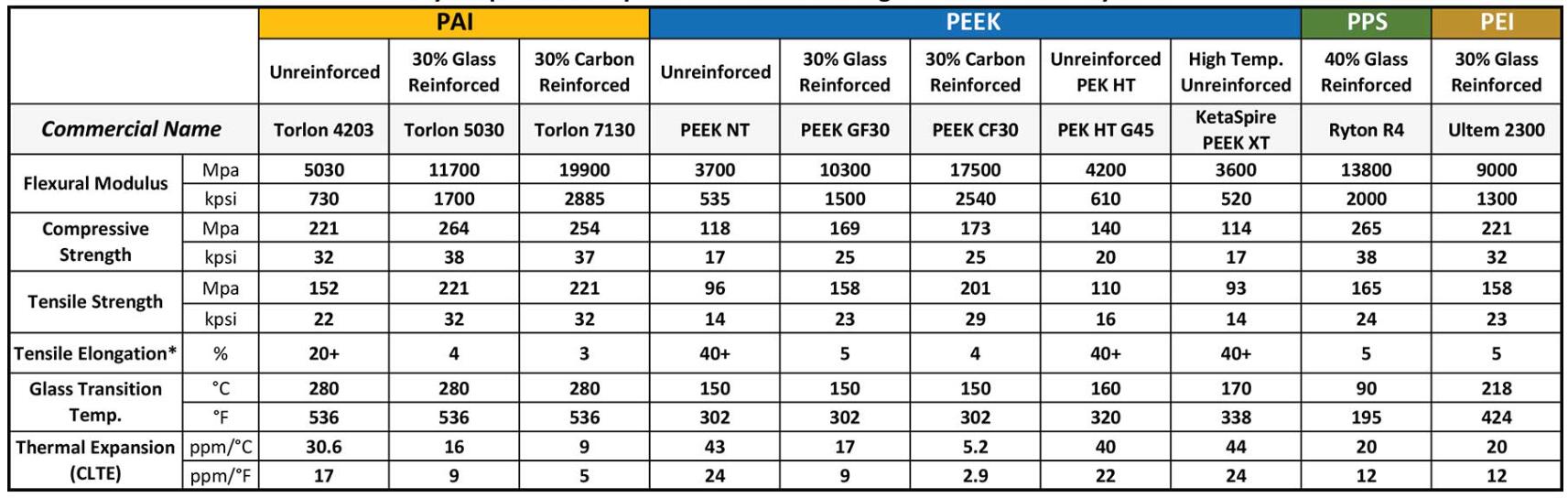

- PEEK Material Parameter Sheet

The chemical composition of PEEK (polyetheretherketone) is:-Polymer backbone: polyetheretherketoneChemical formula: (C19H12O3)nMolecular weight: approximately 60000-70000 g/molPEEK contains ether and ketone groups in its chemical structure, which gives it excellent high-temperature stability and chemical resistance. It is a colorless to light yellow solid with good mechanical properties and wear resistance. PEEK also has a low coefficient of friction and good electrical insulation properties.It should be noted that the specific composition of PEEK materials may vary between different manufacturers and products. Therefore, when using PEEK materials, it is best to refer to the specific ingredient list and technical data provided by the supplier.

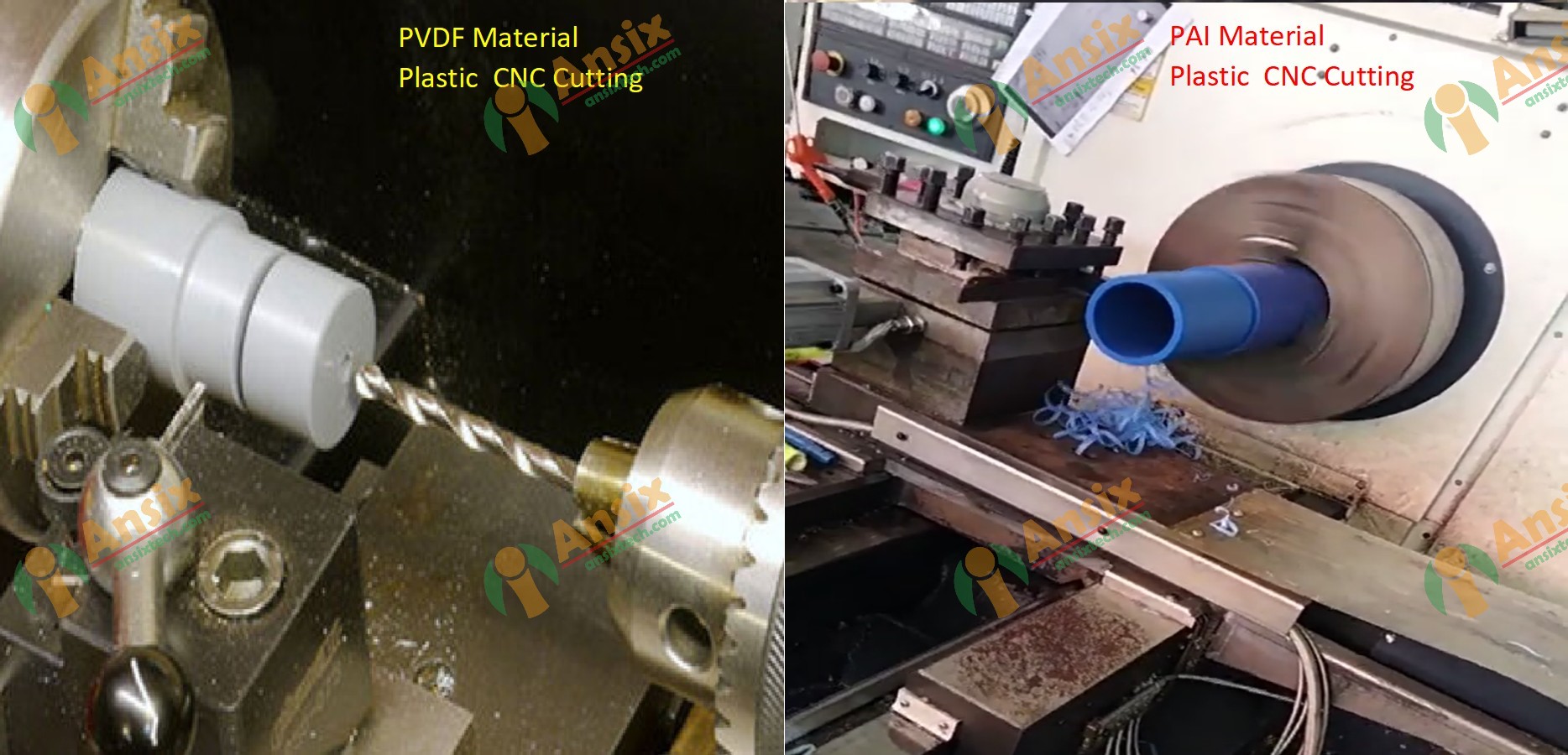

- PEEK Plastic CNC Turning

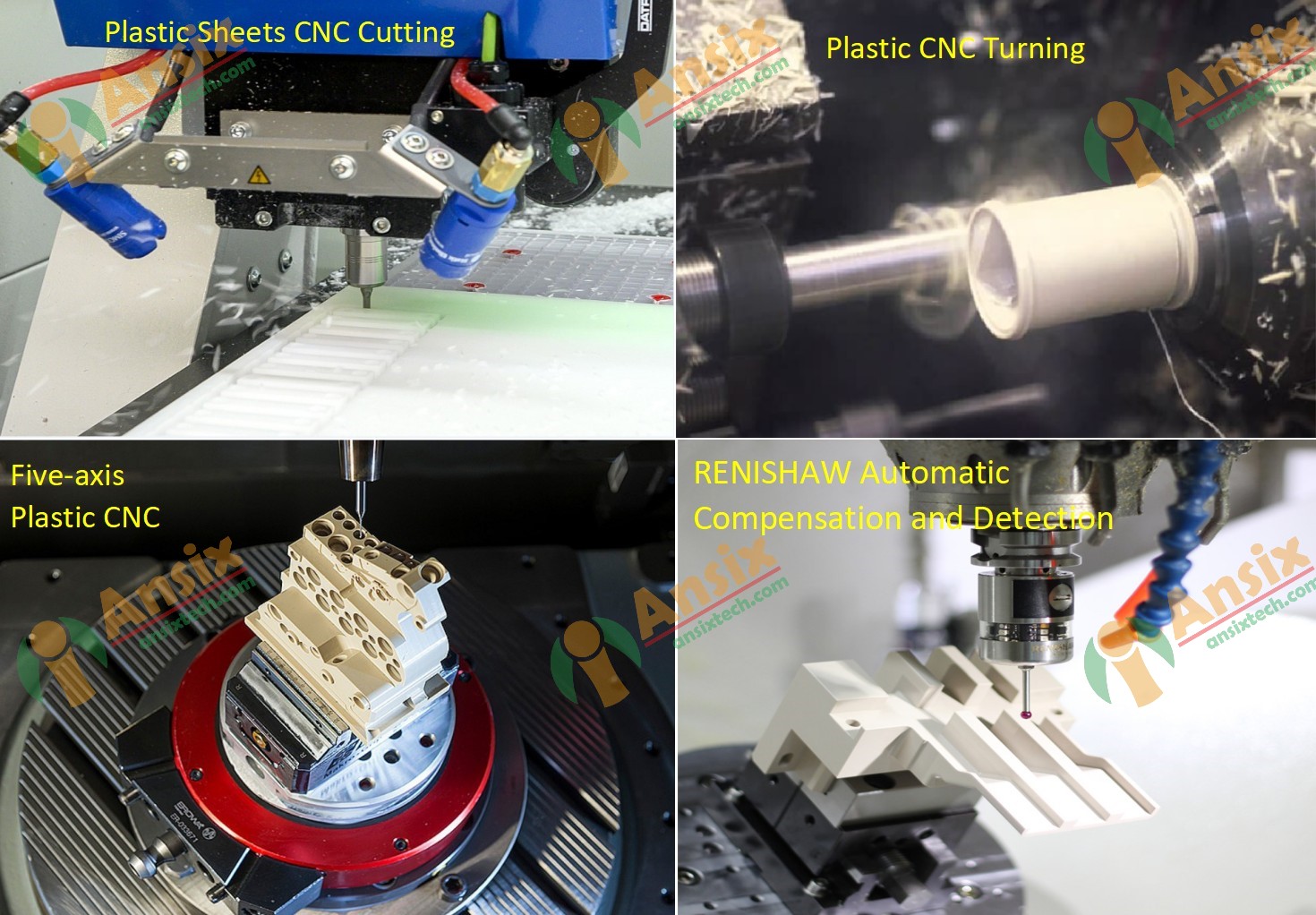

PEEK bar turning and milling refers to the process of turning and milling PEEK (polyetheretherketone) bar. PEEK is a high-performance engineering plastic with excellent heat resistance, chemical corrosion resistance and mechanical properties. It is widely used in aerospace, medical equipment, electronic equipment and other fields.In the process of turning and milling PEEK bars, we first need to carry out process planning and tool selection according to the requirements and drawings of the parts. The PEEK bar is then mounted on a lathe or milling machine, where it is cut and machined by rotating or moving tools.In turning processing, turning tools can be used to process the outer and inner diameters of PEEK rods. When turning, you need to pay attention to controlling the cutting speed, feed speed and cutting depth to avoid deformation or cracking of the PEEK bar caused by overheating and excessive cutting force.In milling operations, milling cutters can be used to process flat surfaces, grooves and holes on PEEK rods. When milling, you need to choose the appropriate tool type and cutting parameters to ensure the quality and accuracy of the machined surface.During the turning and milling process of PEEK bars, it is also necessary to pay attention to cutting lubrication and cooling to improve processing efficiency and extend tool life. At the same time, care should be taken to avoid the reaction between PEEK rods and cutting fluid to prevent the production of harmful substances.In short, PEEK bar turning and milling is a complex process that requires reasonable process planning and operating skills to ensure processing quality and efficiency.Plastic CNC turning is a method of processing plastic materials using a CNC lathe. A CNC lathe is an automated machine tool controlled by a computer that can perform precise turning operations according to a preset program.

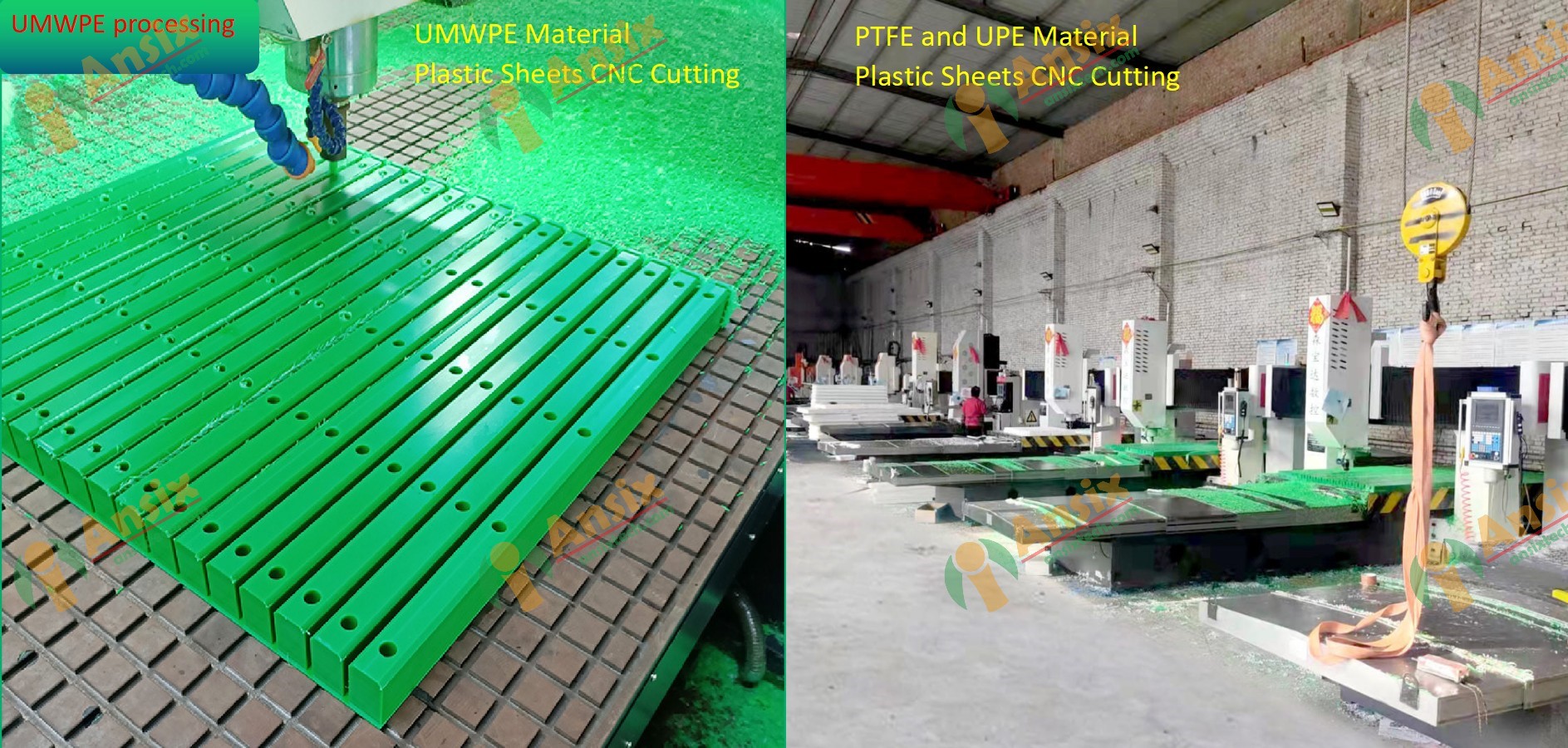

- PEEK Plastic Sheets CNC Cutting

CNC machining of PEEK sheets refers to the process of processing PEEK sheets using CNC machine tools. PEEK is a high-performance engineering plastic with excellent heat resistance, chemical corrosion resistance and mechanical properties. It is widely used in aerospace, medical equipment, electronic equipment and other fields.In the CNC machining process of PEEK sheets, you first need to carry out process planning and tool selection according to the requirements and drawings of the parts. Then, the PEEK sheet is fixed on the workbench of the CNC machine tool, and the PEEK sheet is cut and processed by controlling the motion axis of the machine tool and the motion trajectory of the tool.In CNC machining, different types of tools can be used, such as end mills, ball nose cutters, drills, etc., to perform flat processing, grooving, hole processing, etc. on PEEK sheets. Through the program control of CNC machine tools, the processing of complex shapes and precise dimensions can be achieved.During the CNC machining process of PEEK sheets, you need to pay attention to the following points:Tool selection: Select the appropriate tool type, tool material and tool geometry according to the processing requirements to ensure processing quality and efficiency.

- Customized PEEK Plastic CNC Machining Parts

To customize PEEK parts, you can follow these steps:Design and planning: First, determine the design and specification requirements of the required PEEK components based on your needs and application scenarios. This includes size, shape, functional requirements, etc. You can design it yourself or work with a professional designer or engineer.Material selection: Choose the PEEK material that suits your needs. PEEK has different grades and properties, such as heat resistance, chemical resistance, mechanical strength, etc. Choose the appropriate PEEK material based on your specific needs.Manufacturing process selection: Select an appropriate manufacturing process based on the design and requirements of the component. PEEK parts can be manufactured through a variety of processing methods, such as CNC machining, injection molding, thermoforming, etc. Select the most suitable manufacturing process based on the complexity, quantity and quality requirements of the part.Find suppliers: Find professional PEEK component suppliers or processing manufacturers. Reliable suppliers can be found through Internet searches, industry recommendations, or consulting professionals. Make sure the supplier has the experience and skills to meet your needs.Provide design files: Provide your design files to suppliers, including CAD drawings, 3D models or other related files. The supplier will manufacture and process according to your design files.Sample confirmation and adjustment: The supplier will manufacture samples according to your design files and send them to you for confirmation. If adjustments or modifications are needed, promptly communicate with suppliers and provide feedback.Mass production: After confirming the sample, you can discuss the details of mass production with the supplier, such as quantity, delivery time, price, etc. Ensure agreement with suppliers and signed contracts.Quality inspection and delivery: During the mass production process, suppliers should conduct quality inspection to ensure that PEEK parts meet your requirements and standards. Once production is complete, the supplier will deliver the parts to you according to the agreed delivery time.Customizing PEEK parts requires a series of steps such as design planning, material selection, manufacturing process selection, and finding the right supplier. Work with professional suppliers and ensure timely communication and confirmation to ensure you end up with PEEK parts that meet your needs. -

- Plastic Sheets CNC Cutting

Customized plastic CNC machined parts refer to using CNC machine tools to process plastic materials according to customer needs and design requirements to create customized parts that meet customer requirements. Our customization process usually includes the following steps:Communication and design confirmation: Communicate with customers to understand their needs and design requirements. Confirm the shape, size, material, etc. of the part.CAD design: Carry out CAD design of parts according to the design requirements provided by the customer. This includes drawing a 3D model of the part and determining the machining path.Material selection and preparation: According to the design requirements, select suitable plastic materials and carry out material preparation, such as cutting, heat treatment, etc.CNC programming: Carry out CNC programming based on the part model and processing path designed by CAD. This includes setting parameters such as tool path, cutting speed, feed rate, etc.Processing operations: Operate CNC machine tools according to the requirements of CNC programming. Through automated processing processes, plastic materials are processed such as cutting, milling, and drilling according to design requirements.Inspection and adjustment: Conduct quality inspection on the processed parts to ensure that they meet the design requirements. Make adjustments and corrections if necessary.Surface treatment and assembly: Surface treatment of parts, such as grinding, polishing, spraying, etc., as needed. The parts are then assembled and tested to ensure they function properly.Custom plastic CNC machined parts require the use of professional CNC machine tools and related tools, as well as a team of experienced operators and engineers. Through custom processing, customer needs for plastic parts of specific shapes, sizes and functions can be met.Custom plastic CNC machined parts are widely used in various industries such as automotive manufacturing, electronics manufacturing, medical devices, etc. It can manufacture high-precision, high-quality customized parts to meet customers’ special needs. As technology continues to advance, the application of custom plastic CNC machined parts is also expanding, providing more solutions for various industries.

- Quality Assurance of Plastic CNC Machined Parts

Quality assurance of plastic CNC machined parts is an important aspect to ensure that the machined parts meet the design requirements and customer needs. Here are some common measures and methods used to ensure the quality of plastic CNC machined parts:Design confirmation and communication: Before starting processing, conduct full communication and design confirmation with the customer to ensure a clear understanding and consensus on the shape, size, material, etc. of the part.Material selection and preparation: Select appropriate plastic materials and perform material preparation, such as cutting, heat treatment, etc. Make sure the selected materials meet design requirements and have good physical and chemical properties.CNC programming and parameter setting: Carry out CNC programming and parameter setting according to the design requirements and processing characteristics. Ensure the rationality and accuracy of parameters such as tool path, cutting speed, and feed speed.Processing operation and monitoring: During the processing process, strict operation and monitoring are carried out. Operators should be familiar with the operating procedures and operating points of the machine tool to ensure the stability and accuracy of the processing process.Quality inspection and measurement: Carry out quality inspection and measurement of processed parts, using appropriate measuring tools and equipment, such as micrometers, three-dimensional coordinate measuring machines, etc. Ensure that the size, shape, surface quality, etc. of the parts meet the design requirements.Recording and tracing: Record and trace the processing process and quality inspection results to ensure the traceability of the processing process and the controllability of the quality.Continuous improvement and feedback: Continuous improvement and optimization based on quality inspection results and customer feedback. Handle quality issues in a timely manner to improve the stability of the processing process and the quality of parts.At the same time, reasonable selection of high-quality raw materials, use of advanced machine tools and processes, and training and improving the skill level of operators are also important factors in ensuring quality. Ultimately, through strict quality control and continuous improvement, high-quality plastic CNC machined parts can be provided to meet customer needs and requirements.

- AnsixTech’s Commitment to Cooperative Customers

Product or service quality commitment: Commitment to provide high-quality, reliable products or services to meet customer needs and expectations.Delivery and service commitment: Commitment to deliver products or provide services on time and provide timely after-sales support and customer service.Price and cost commitment: Promise to provide reasonable prices and cost-effectiveness to ensure that customers receive value-for-money products or services.Commitment to innovation and technology: Commitment to continuous innovation and introduction of new technologies to provide more advanced and competitive solutions.Commitment to sustainable development: Commitment to consider environmental, social and economic sustainability in business operations and promote sustainable development.