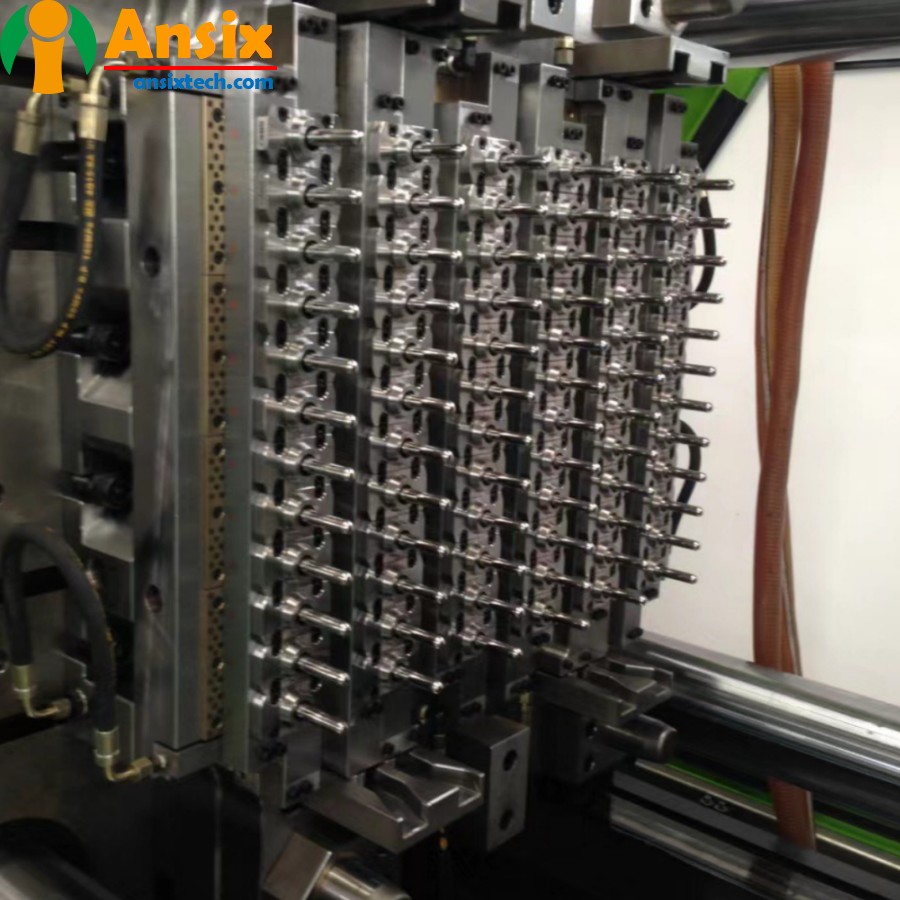

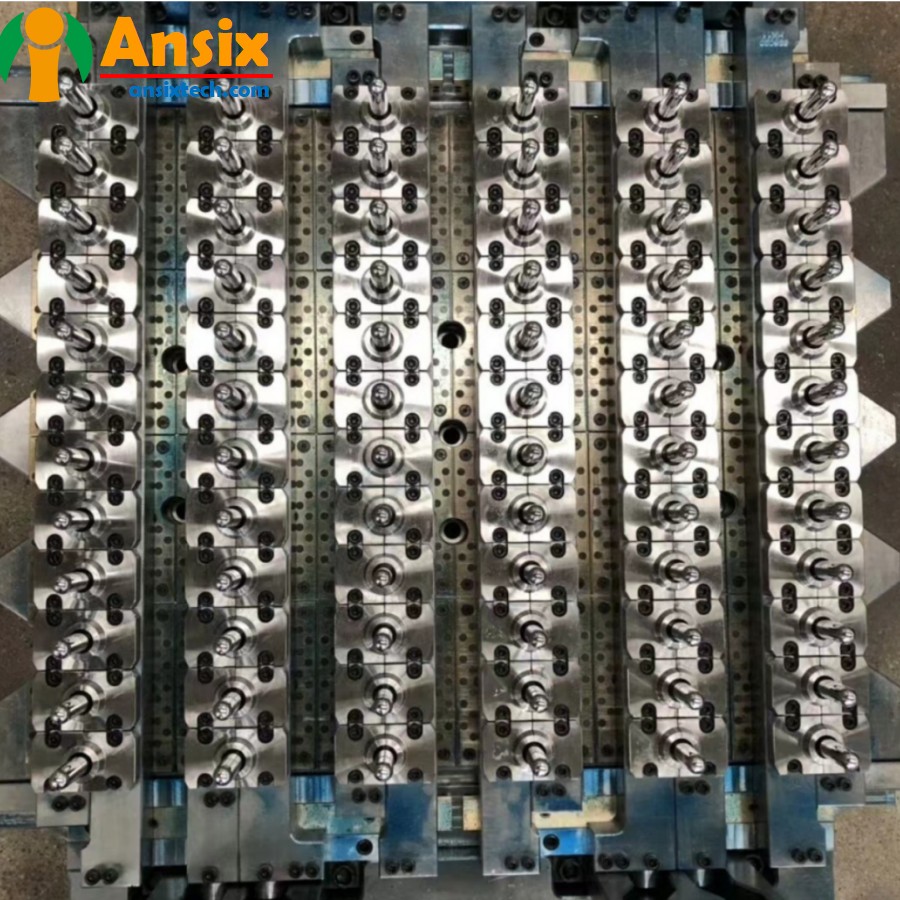

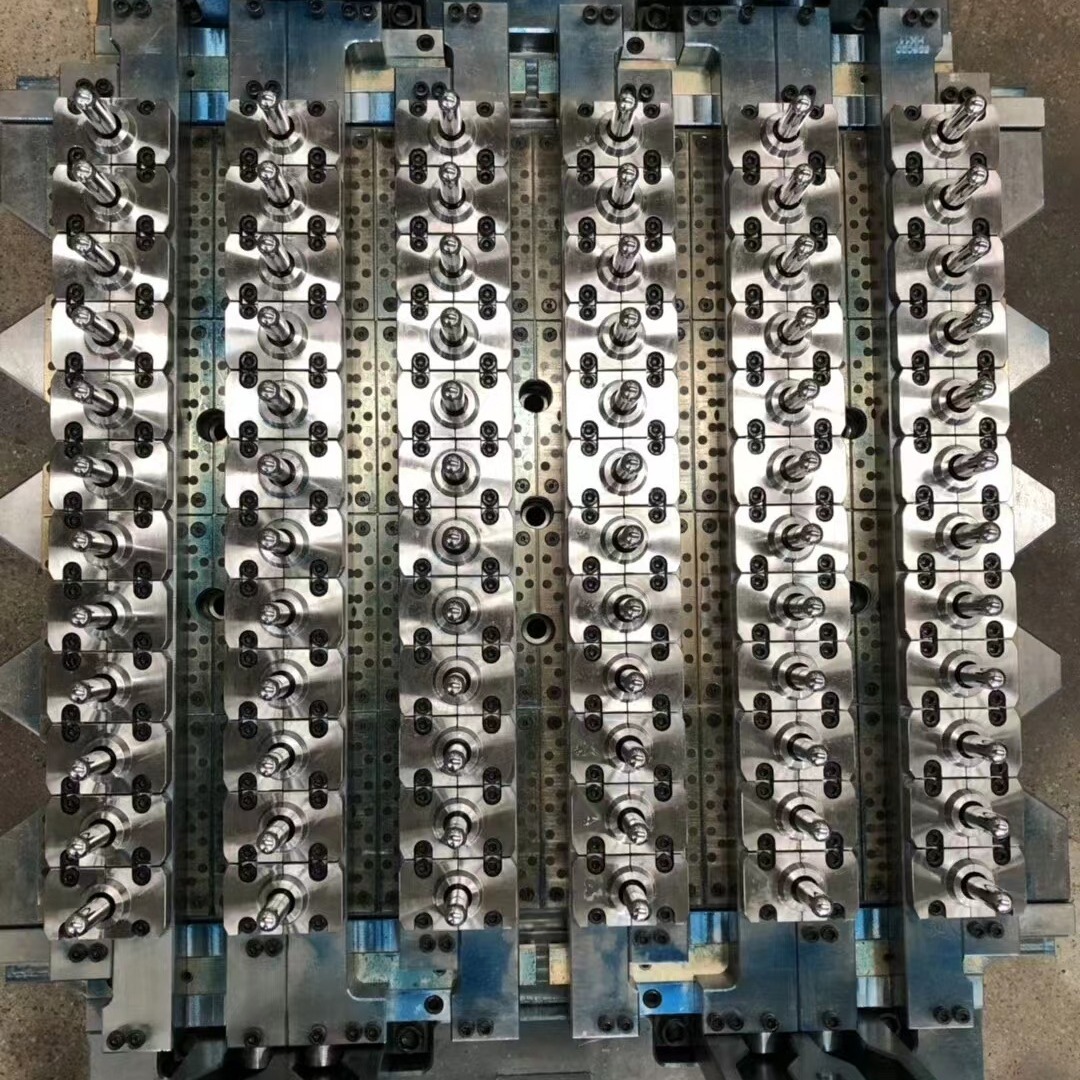

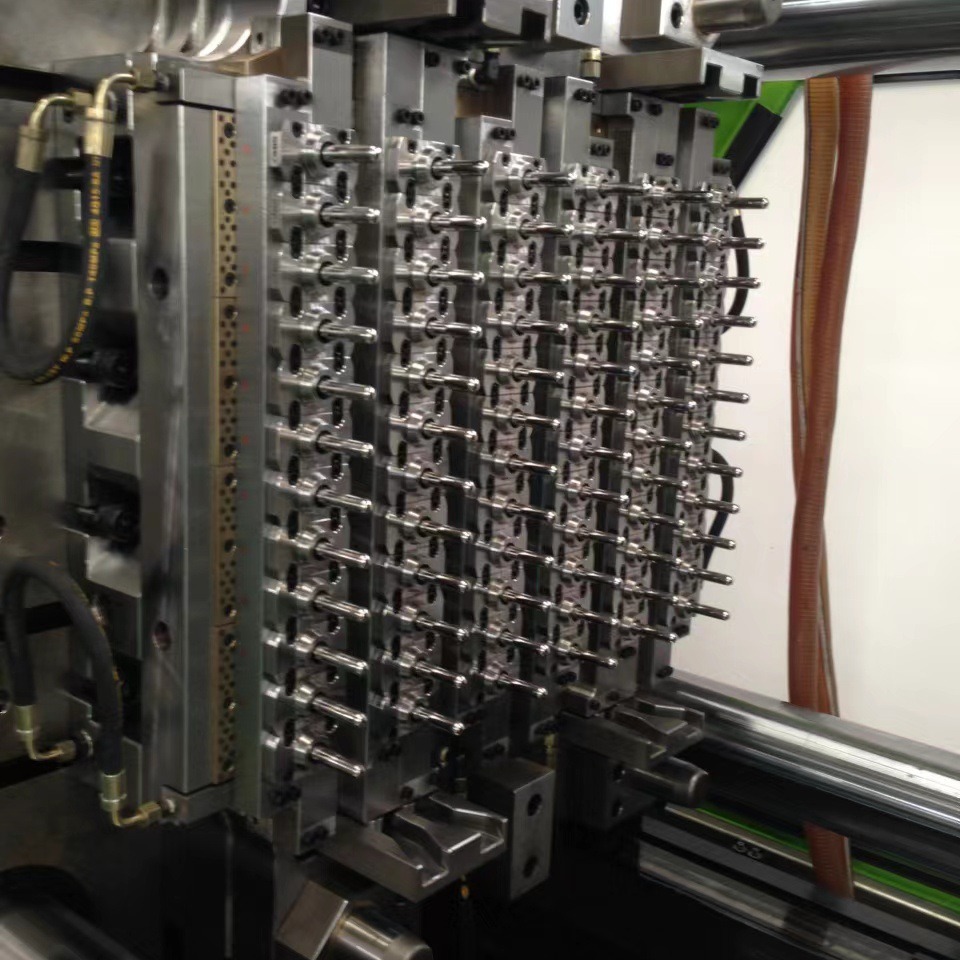

72cavity PET bottle preform mold tube preform mold beverage bottle food packaging standard caliber 30 caliber non-standard

FEATURES

-

Mold Description

Product Materials:

PET

Mold Material:

2344 S136 Cr12、Cr12MoV、Cr12Mo1V1

Number of Cavities:

72

Glue Feeding Method:

Hot runner

Cooling Method:

Water cooling

Molding Cycle

48.5s

-

72 cavity bottle embryo Mold flow analysis and mold designFor the mold flow analysis and mold design process of the 72-cavity bottle preform mold:Mold flow analysis:Collect relevant data required for mold design, including the size, shape, injection molding process parameters, etc. of the preform.Use professional mold flow analysis software to import the geometric model of the mold and set the injection molding process parameters.Conduct mold flow analysis to simulate the flow of plastic during the injection molding process, including filling, cooling and solidification.Analyze the mold flow results, check whether there are defects such as bubbles, short shots, warpage, etc., and make optimization and improvements based on the analysis results.Mold design process:Collect the design requirements and specifications of the bottle preforms, including size, shape, bottle mouth and thread requirements.Carry out mold structure design, including cavity design, cooling system design, needle valve air seal system design, etc.According to the mold structure design, design and manufacture mold parts, including mold core, mold cavity, needle valve, cooling system, etc.Carry out mold assembly and assemble mold parts to form a complete mold structure.Carry out mold debugging and optimization, including adjusting injection molding process parameters, optimizing the cooling system, debugging the needle valve air sealing system, etc.Carry out mold trial production and sample verification to check whether the size, appearance quality and performance of the preform meet the requirements.After completing the debugging and verification of the mold, proceed to mass production.In the mold design process, factors such as the size and shape of the preform, injection molding process parameters, mold structure design, cooling system design, needle valve air sealing system design, etc. need to be considered. Through reasonable mold flow analysis and mold design process, the mold design can be optimized and the quality and production efficiency of the preforms can be improved.

- 72 cavity bottle embryo the mold manufacturing process and product material selectionThe manufacturing and processing of the 72-cavity preform mold and the selection of preform materials involve mold manufacturing and the selection of preform materials.Mold manufacturing and processing:Mold material selection: Choose appropriate mold materials, such as high-quality alloy steel or stainless steel, to ensure the hardness, wear resistance and corrosion resistance of the mold.Mold processing: According to the mold design, CNC machining, EDM, wire cutting and other processes are performed to manufacture precision mold parts.Mold assembly: Assemble the mold parts to form a complete mold structure.Mold debugging: debug and optimize the mold to ensure the stability and production efficiency of the mold.Preform material selection:Polyethylene terephthalate (PET): PET material is a commonly used material for manufacturing bottle preforms. It has the advantages of high transparency, good heat resistance, good pressure resistance and good recyclability.Other plastic materials: Depending on specific needs, other plastic materials can also be selected, such as polypropylene (PP) or polyethylene (PE), but these materials may have limitations in transparency, heat resistance and pressure resistance compared to PET materials. There are some shortcomings in other aspects.During the mold manufacturing process, attention needs to be paid to the selection of mold materials and the control of the processing technology to ensure the quality and accuracy of the mold. In terms of bottle preform material selection, the commonly used material is PET, which has the advantages of high transparency, good heat resistance, good pressure resistance and good recyclability. Depending on specific needs, other plastic materials can also be selected, but it is necessary to consider whether their transparency, heat resistance, pressure resistance and other properties meet the requirements.The manufacturing and processing of 72-cavity bottle preform molds involves mold manufacturing and selection of bottle preform materials. Through reasonable mold manufacturing processing and preform material selection, high-quality preforms can be manufactured and meet product requirements.

- 72 cavity bottle embryo mold Mass production and Quality controlThe mass production of 72-cavity bottle preform mold injection molding involves aspects such as production efficiency improvement, automated tooling and fixture configuration, and process quality assurance.Improvement of production efficiency:In order to improve production efficiency, the following measures can be taken:Automated production line: Introduce automated equipment and production lines to achieve efficient operation of automated injection molding and production processes.Parallel production: Parallel production is adopted to carry out multiple processes at the same time to shorten the production cycle.Optimize injection molding process parameters: Improve injection molding efficiency and quality by optimizing injection molding process parameters, such as injection speed, temperature control, etc.Automated tooling and fixture configuration:By configuring automated tooling fixtures, production efficiency and product quality can be improved, and reliance on manual operations can be reduced. Automated tooling fixtures can achieve the following functions:Automatic loading and unloading: Automatic loading and unloading is realized through automated devices, reducing manual operation time.Automatic positioning and clamping: Automatic positioning and clamping of products are achieved through automated fixtures, improving production efficiency and product consistency.Automatic detection and elimination: Automatic detection and elimination of products are realized through automated devices to improve product quality and production efficiency.Process quality assurance:During mass production, process quality assurance is required to ensure product consistency and stability. Common quality assurance measures include:Quality control plan: Develop a quality control plan to clarify the quality requirements and control methods for each link.Inspection and testing: Conduct product inspection and testing, such as appearance inspection, dimensional measurement, functional testing, etc., to ensure that the product meets the requirements.Process monitoring: Monitor the production process, such as temperature control, injection pressure control, etc., to ensure product consistency and stability.In summary, the mass production of 72-cavity bottle preform mold injection molding involves aspects such as production efficiency improvement, automated tooling and fixture configuration, and process quality assurance. Through reasonable measures and management, injection molding efficiency can be improved, costs reduced, and product quality and stability ensured.