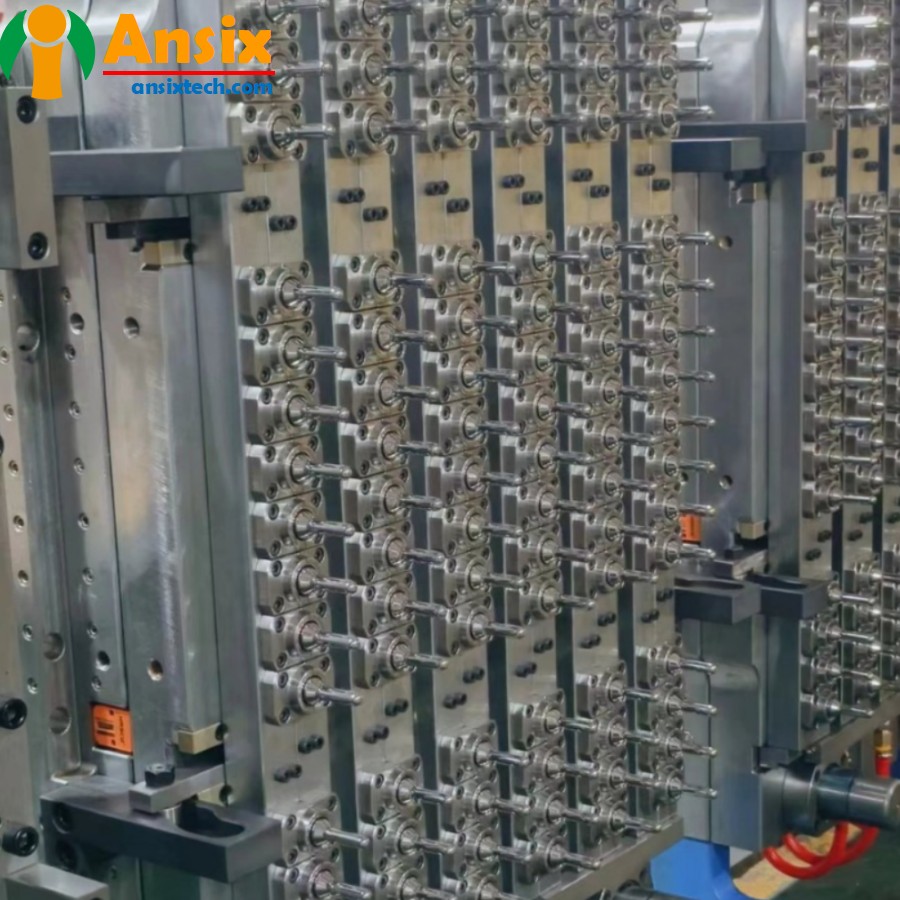

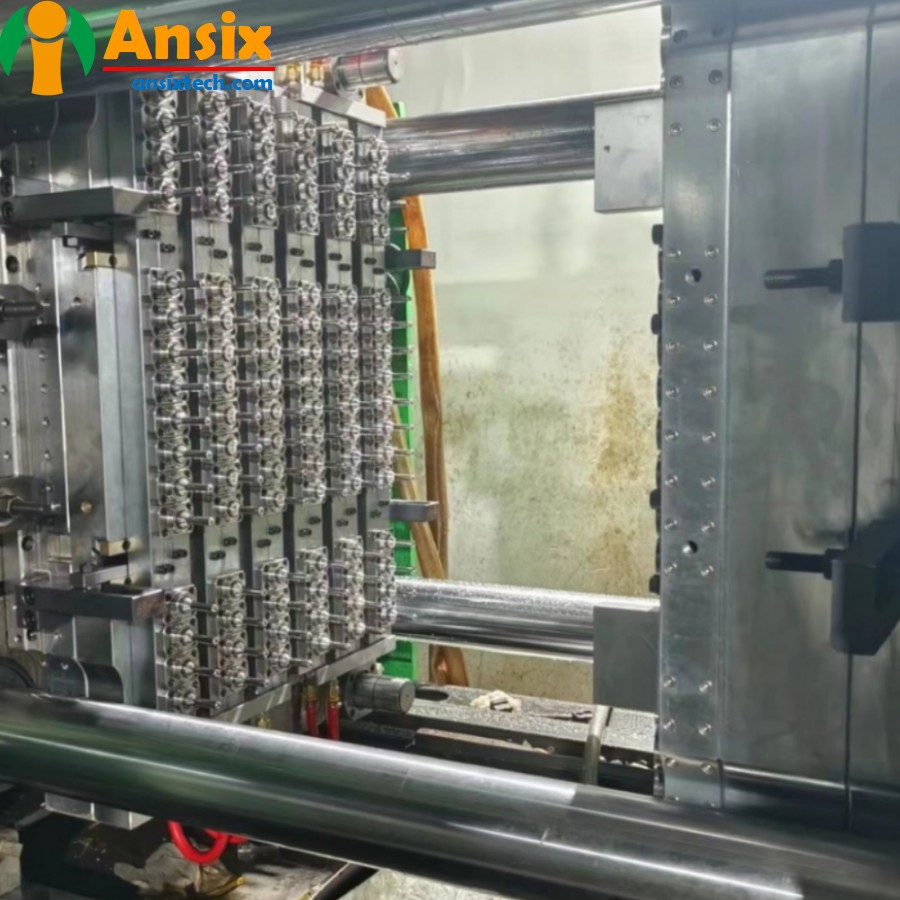

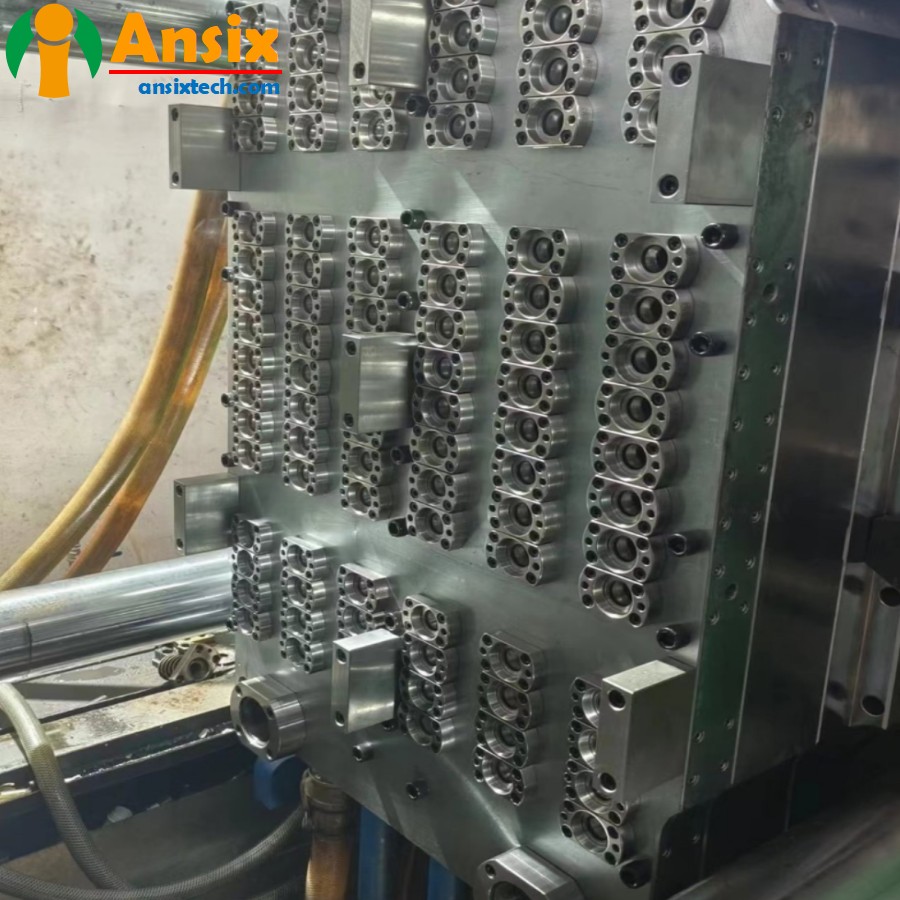

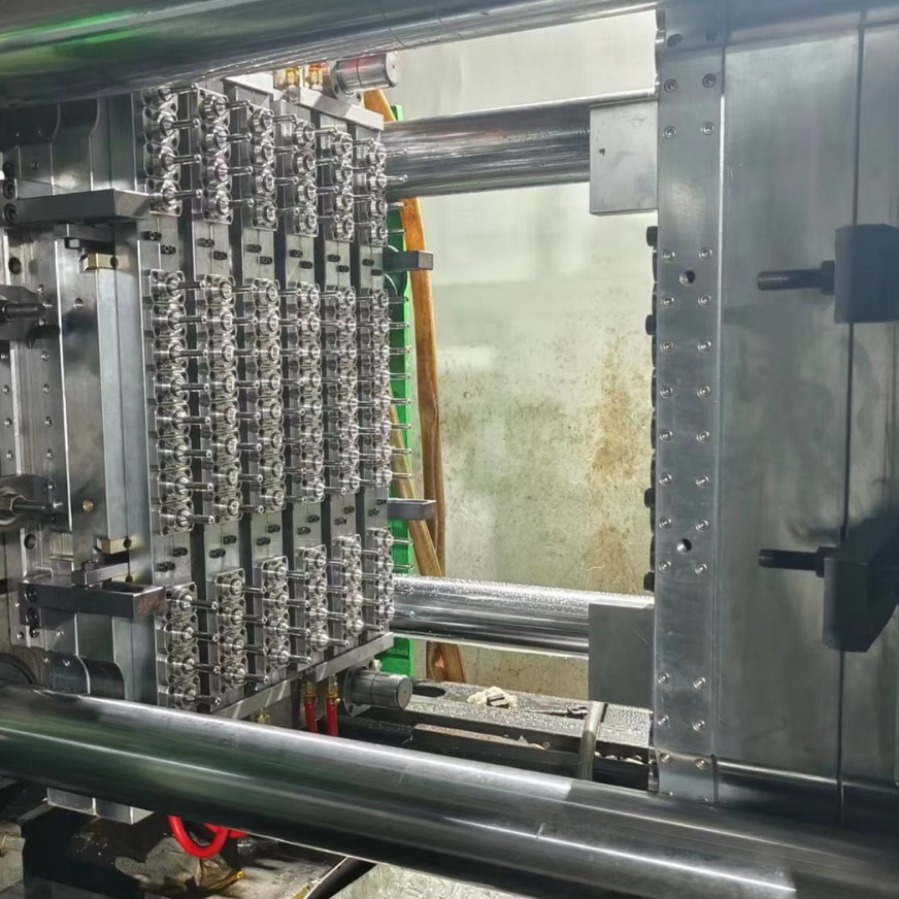

96 cavity bottle embryo mold needle valve air seal mold water bottle mineral water beverage bottle packaging bottle

FEATURES

-

Mold Description

Product Materials:

PET

Mold Material:

2344 S136 Cr12、Cr12MoV、Cr12Mo1V1

Number of Cavities:

96

Glue Feeding Method:

Hot runner

Cooling Method:

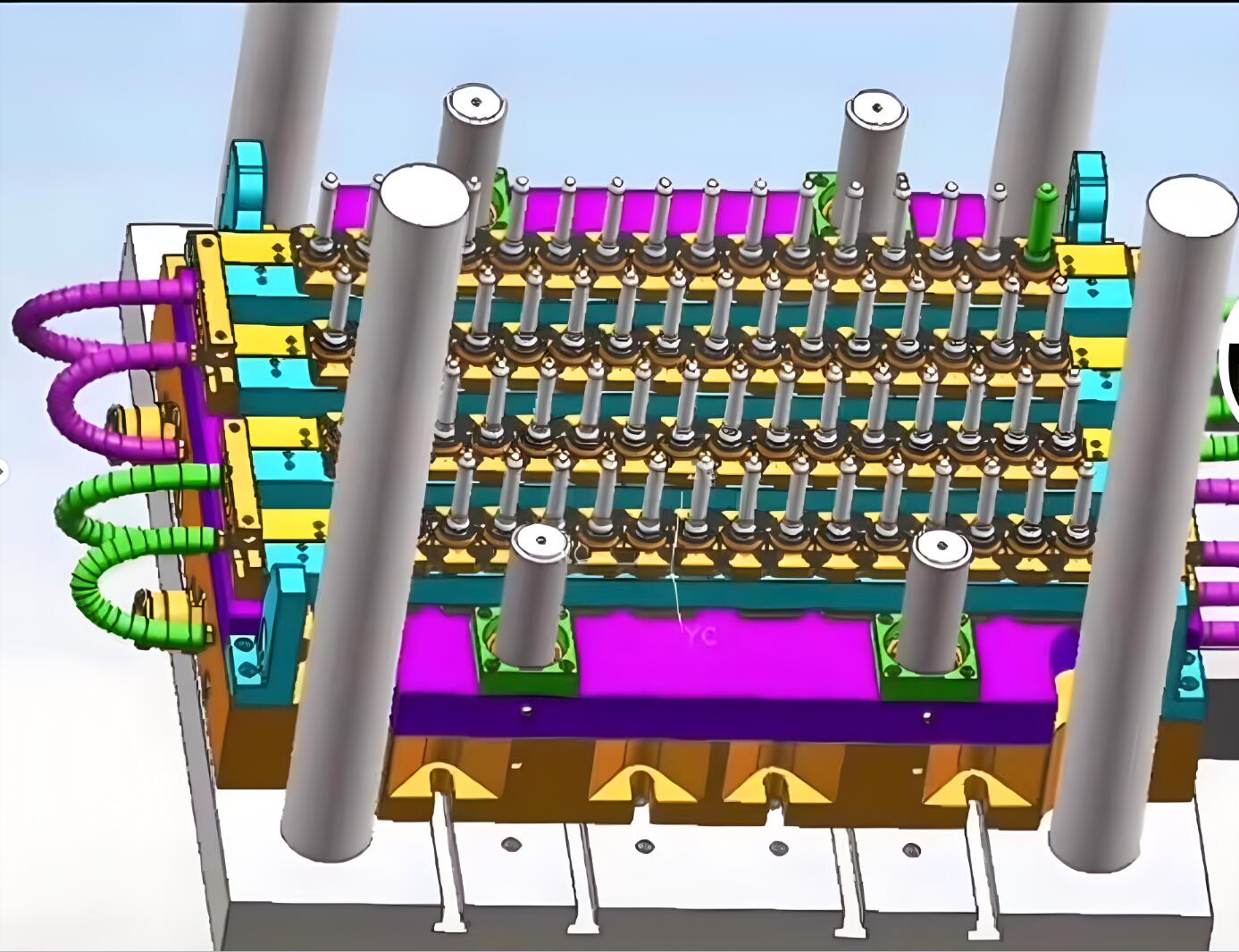

Water cooling

Molding Cycle

28.5s

- 96 cavity bottle embryo Mold flow analysis and mold designMold flow analysis and mold design of the 96-cavity bottle preform needle valve air seal mold are one of the key steps in manufacturing bottle preforms.Mold flow analysis:Mold flow analysis is an important step in the mold design process. Through mold flow analysis, the flow of plastic during the injection molding process can be simulated to help optimize mold design and avoid defects such as bubbles, short shots, and warpage. Mold flow analysis can be carried out using professional mold flow analysis software. According to the geometry of the mold and injection molding process parameters, the flow of plastic in the mold is simulated and corresponding analysis results and suggestions are given. Through mold flow analysis, the design of the mold can be optimized to improve product quality and production efficiency.Mold design:The design of the 96-cavity bottle preform needle valve air seal mold needs to consider the following factors:Shape and size of the preform: According to the shape and size of the preform, design the structure and cavity of the mold to ensure the accuracy and consistency of the preform.Needle valve air seal design: The needle valve air seal is a key component in the mold. It is necessary to design a suitable needle valve structure and air seal system to ensure air tightness and shot quality during the injection molding process.Cooling system design: Design a reasonable cooling system to improve cooling efficiency during the injection molding process and shorten the production cycle.Mold material selection: Choose appropriate mold materials, such as high-quality alloy steel or stainless steel, to ensure the hardness and wear resistance of the mold.In summary, the mold flow analysis and mold design of the 96-cavity bottle preform needle valve air seal mold are one of the key steps in manufacturing bottle preforms. Through reasonable mold flow analysis and mold design, bottle preforms with beautiful appearance and reliable quality can be produced. At the same time, attention needs to be paid to needle valve air seal design, cooling system design and mold material selection during the mold manufacturing process to ensure the quality and durability of the mold.

- 96 cavity bottle embryo of the mold manufacturing process and product material selection

The manufacturing and processing of the 96-cavity bottle preform needle valve air seal mold has some advantages and difficulties. The following will introduce these two aspects respectively and discuss the selection of preform materials.

Advantages:

High productivity: The 96-cavity mold can inject 96 bottle preforms at the same time, greatly improving production efficiency and capacity.

Consistency and stability: Through precise mold design and manufacturing, the consistency and stability of the size and appearance quality of the 96 preforms can be guaranteed.

Cost-effectiveness: The 96-cavity mold can achieve mass production, reducing the mold cost of each preform and improving cost-effectiveness.

Difficulties:

Mold design and manufacturing: The design and manufacturing of a 96-cavity mold is relatively complex. Factors such as the layout of the 96 cavities, the design of the needle valve air seal system, and the optimization of the cooling system need to be considered. The requirements for mold design and manufacturing are relatively high.

Mold debugging and maintenance: The debugging and maintenance of the 96-cavity mold is relatively complex and requires precise debugging and regular maintenance to ensure the stability and production efficiency of the mold.

Preform material selection:

The choice of preform material is critical to the quality and performance of the preform. Common preform material choices include:

Polyethylene terephthalate (PET): PET material is a commonly used material for manufacturing bottle preforms. It has the advantages of high transparency, good heat resistance, good pressure resistance and good recyclability.

Other plastic materials: Depending on specific needs, other plastic materials can also be selected, such as polypropylene (PP) or polyethylene (PE), but these materials may have limitations in transparency, heat resistance and pressure resistance compared to PET materials. There are some shortcomings in other aspects.

In summary, the manufacturing and processing of 96-cavity bottle preform needle valve air seal molds has the advantages of high productivity, consistency and stability, but it also faces difficulties in mold design and manufacturing, mold debugging and maintenance. In terms of bottle preform material selection, the commonly used material is PET, which has the advantages of high transparency, good heat resistance, good pressure resistance and good recyclability.

- 96 cavity bottle embryo Mass production and Quality controlMass production and quality control are the keys to ensuring product quality and production efficiency.Production planning and scheduling: Develop detailed production plans, including production time, quantity, delivery date, etc. According to the production plan, reasonably arrange production tasks and resources to ensure that production tasks are completed on time.Injection molding process control: Establish strict injection molding process control, including the control of injection temperature, injection pressure, injection speed and other parameters. Through real-time monitoring and adjustment of process parameters, the dimensional accuracy and appearance quality of the product are ensured.Raw material control: Strictly control the quality and source of raw materials. Work with reliable suppliers to ensure raw materials meet product requirements and standards. Conduct inspection and testing of raw materials to ensure stable quality of raw materials.Production process control: Use statistical process control (SPC) methods to monitor and analyze the production process in real time. By collecting and analyzing data, abnormalities and variations in the production process are discovered and corrected in a timely manner to ensure the stability and consistency of product quality.Inspection and testing: Inspection and testing are carried out during the production process, including raw material inspection, process inspection and finished product inspection. Use appropriate testing equipment and methods to test the size, appearance and function of the product to ensure that the product meets the requirements.Capacity planning and scheduling: Capacity planning and scheduling are carried out according to customer needs and delivery time. Arrange production plans reasonably to ensure production tasks are completed on time.After-sales service and customer feedback: Establish a sound after-sales service and customer feedback mechanism to handle customer problems and needs in a timely manner. Through customer feedback, understand product usage and quality issues, and make timely improvements and corrections.Continuous improvement: Improve production efficiency and product quality through continuous improvement and optimization of the production process. Adopt advanced technology and processes, introduce automation and intelligent equipment, and improve the stability and consistency of production.At the same time, the production process is continuously improved and optimized to improve production efficiency and product quality. Ensure on-time delivery to customers and provide satisfactory after-sales service and support.